FINDING SUBSTITUTE SURFACTANTS FOR SYNPERONIC NJOHN A. FIELDS, ANDREW WINGHAM, FRANCES HARTOG, & VINCENT DANIELS

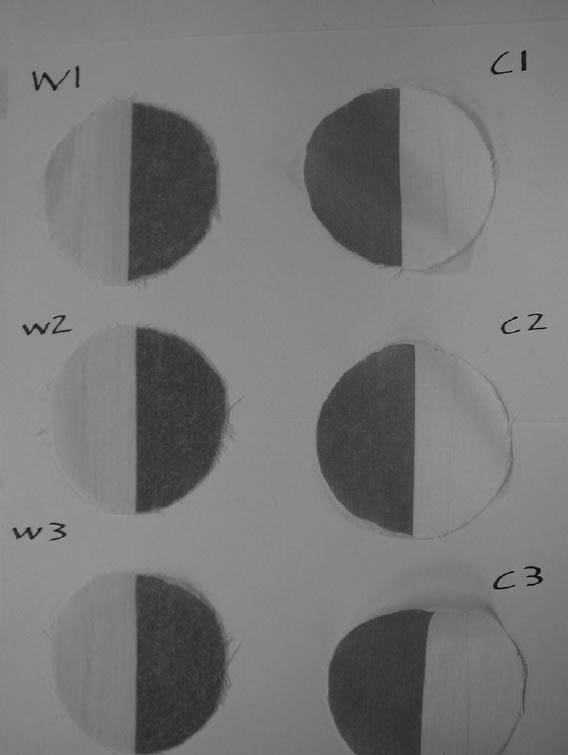

5 PHASE 1: EVALUATION OF THE SURFACTANTSThis first set of experiments aimed to provide a subset of approximately six surfactants for further testing. The selection criteria were based chiefly on efficiency of cleaning, taking into account the conductivity and pH of the washing solutions as indications of rinsing efficiency. To determine the cleaning efficiency, the color change was measured after experimental washes were performed on standard soiled wool and cotton fabrics. Many standard soiled fabrics are commercially available; those used for these experiments were manufactured by Testfabrics. The soiling had an initial composition of keltex 1.3%, corn starch 2.2%, water 72.4%, mineral oil 14%, oleic acid 0.4%, butanol 0.3%, morpholine 0.4%, vegetable fat 1.7%, solvesso 4.5%, ethyl cellulose 0.7%, and carbon black 0.7%. The fabric comes in a strip half printed with the standard soil (fig. 4). Rolls of both wool (style 530) and cotton (style 405) textile were obtained. These fabrics were kept in a refrigerator when not in use to prevent mold growth. A textile conservator devised a standardized manual cleaning technique so that it reflected the standard cleaning regime that would apply to a textile (table 2). The use of a mechanical shaker was investigated instead of using manual sponging of the object. By lengthening the washing time, the mechanical cleaning regime produced approximately the same color-change results as the manual hand washing (table 3). The mechanical regime was used in the first round of tests, and the manual method in the second round.

Discs of test fabric (80 mm diameter) were cut from the wool and cotton fabrics so that half of the disc was clean and the other half soiled (see fig. 4). Using a Minolta CR-300 Chroma Meter, which was calibrated using the standard tile provided by the manufacturer, the color of the surface was measured five times at three points on each half of the fabric using a Melinex template to locate the measuring areas. Measurements of the slightly translucent textiles were obtained in the CIE1976 L*a*b system with the textile resting on a white glazed tile. The textile discs were then placed faceup in a 250 cm3conical flask with a screw-top stopper, and 100 cm3of the test solution was added. The washing followed the regime described in table 2.

As the solutions were emptied from the flasks, 50 cm3 was saved for pH and conductivity measurements. The fabric discs were placed on a Melinex sheet to dry overnight before the color was remeasured as described above. |