PAPER SPLITTING: HISTORY AND MODERN TECHNOLOGYIRENE BR�CKLE, & JANA DAMBROGIO

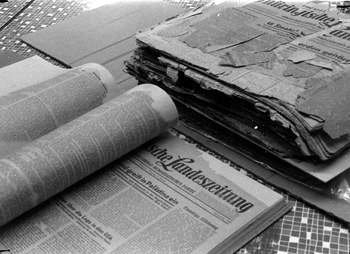

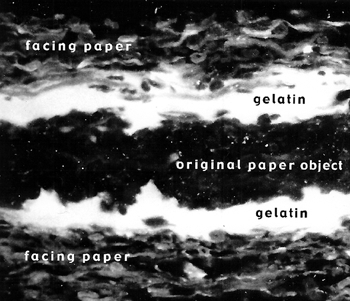

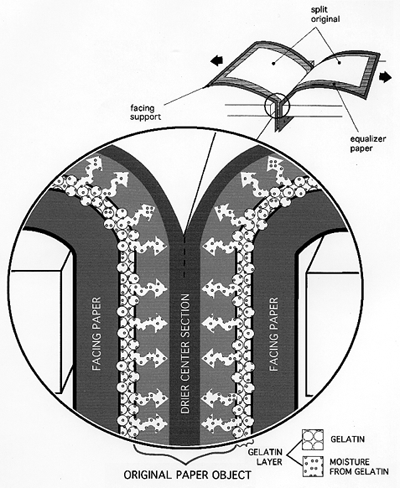

ABSTRACT—ABSTRACT—In the 19th century, restorers used paper splitting to separate recto and verso of double-sided prints or drawings. Today, the treatment is employed for strengthening weakened paper. Two German conservation centers are chiefly responsible for the development of the process to its current level of sophistication: over the course of more than 30 years, G�nter M�ller at the Thuringian University and State Library at Jena perfected manual paper splitting; over the same time period, Wolfgang W�chter, now at the Zentrum f�r Bucherhaltung in Leipzig, developed the paper-splitting machine. We outline the history of paper splitting and describe the contemporary processes from firsthand observations and interviews with the conservators at Jena and Leipzig. Technical evaluations of contemporary paper splitting are summarized, and some observations on objects that were split for the authors are documented (a 19th-century newspaper page, a 17th-century document written in iron gall ink, 17th-century book leaves). A short guide to the identification of papers that may have historically undergone splitting is provided. A bibliography can be found under “Web-accessible Projects” at www.buffalostate.edu/~artcon/. TITRE—D�doublage du papier: histoire et technologie moderne. R�SUM�—Au 19�me si�cle, les restaurateurs utilisaient le d�doublage du papier pour s�parer le recto et le verso de pages imprim�es ou dessin�es des deux c�t�s. Aujourd'hui, cette technique est utilis�e pour renforcer le papier affaibli. Deux centres allemands de restauration sont essentiellement responsables du d�veloppement du proc�d� � son niveau actuel de sophistication. Sur une p�riode de plus de trente ans, G�nter M�ller � l'universit� de Thuringe et � la biblioth�que d'�tat � I�na a perfectionn� le d�doublage manuel du papier; tandis que, paral�llement, Wolfgang W�chter, qui travaille aujourd'hui au Zentrum f�r Bucherhaltung (Centre pour le maintien des livres) de Leipzig, a d�velopp� la machine � d�doubler le papier. Nous tra�ons les grandes lignes de l'histoire du d�doublage du papier et d�crivons les proc�d�s contemporains � partir d'observations directes et d'entrevues avec les restaurateurs d'I�na et de Leipzig. Le sommaire d'une �valuation technique du d�doublage contemporain du papier est pr�sent� et quelques observations sur les objets qui ont �t� d�doubl�s pour les auteurs sont document�es (une page de journal datant du 19�me si�cle, un document du 17�me si�cle �crit � l'encre pyrogallique, les pages d'un livre du 17�me si�cle). Un court guide est fourni sur l'identification des papiers qui ont possiblement subi le d�doublage dans le pass�. Une bibliographie peut �tre consult�e � l'adresse www.buffalostate.edu/~artcon/, sous la rubrique “Web-accessible Projects”. TITULO—Exfoliaci�n de papel: historia y tecnolog�a moderna. RESUMEN—En el siglo XIX, los restauradores utilizaban la exfoliaci�n para separar el recto y verso de las estampas o dibujos de dos caras. Actualmente, el tratamiento se emplea para reforzar el papel debilitado. Dos centros de conservaci�n alemanes son los principales responsables del desarrollo del proceso a su actual nivel de sofisticaci�n: durante m�s de 30 a�os, G�nter M�ller de la Universidad Thuringiana y Biblioteca Estatal en Jena, perfeccion� la exfoliaci�n manual del papel. Durante el mismo per�odo, Wolfgang W�chter, actualmente en el Zentrum f�r Bucherhaltung de Leipzig, cre� la m�quina para exfoliaci�n de papel. Hacemos un resumen de la historia de la exfoliaci�n de papel y describimos los procesos contempor�neos a partir de observaciones directas y entrevistas con los conservadores de Jena y Leipzig. Resumimos evaluaciones t�cnicas de la exfoliaci�n de papel contempor�nea. Adem�s, se documentan algunas observaciones sobre objetos que fueron exfoliados para las autoras (una p�gina de un peri�dico del siglo XIX, un documento del siglo XVII escrito en tinta ferrog�lica, hojas de un libro del siglo XIX). Se incluye una gu�a corta para la identificaci�n de papeles que hist�ricamente pudieran haber pasado por un proceso de exfoliaci�n. En la direcci�n www.buffalostate.edu/~artcon/, bajo “Web-accessible Projects”, se puede obtener una bibliograf�a acerca del tema. 1 1. WHAT IS PAPER SPLITTING?Contemporary paper splitting is an invasive treatment process designed to strengthen paper artifacts so deteriorated that their physical use is severely restricted. The brittle paper sheet is split in half through its thickness, and a strong, stable, thin paper is inserted in the center before the original paper halves are reunited. The treated paper regains its functionality (M�ller 1989; Gast 1993; W�chter et al. 1996, 1997). Today paper splitting is considered a library and archives mass preservation tool that presents an alternative to other methods of preserving weakened paper artifacts, including encapsulation in polyester film, surface sizing, lining with thin tissues, leaf-casting, and lamination. Candidates for this treatment are materials damaged by water or mold attack; documents severely embrittled by corrosive media, especially iron gall ink; and 19th- and 20th-century papers deteriorated due to acidic ingredients, foremost alum used in paper sizing and lignin present in wood pulp (fig.1). Prior to splitting, original papers may undergo preparatory treatments such as pest eradication through anoxic fumigation; disinfection through gamma radiation; washing in alkalized water; and leaf-casting (W�chter 1999b). Following these treatments, both sides of the dry or lightly dampened original are temporarily faced with absorbent paper or polyester support sheets that are adhered with a viscous gelatin solution (fig. 2). While the laminate is subjected to slight pressure, the gelatin is allowed to bond firmly with the three papers. During pressing, water contained in the gelatin layers penetrates deeply through both sides of the original, moistening the interior. The laminate is removed from the press, and the facing supports are pulled apart, each side ideally carrying one-half of the split original (fig. 3). The split halves are coated on the inside with an adhesive; a thin cellulose-fiber paper core is inserted; and the halves are reunited. The core adhesive may consist of methyl cellulose and a small amount of acrylic resin emulsion, or it may be a starch paste. Alkaline buffers may be added to the core tissue and core adhesive, and the latter may also receive antifungal agents. The facing papers are removed via aqueous treatment, which may involve a protease enzyme bath and several subsequent rinsing baths at elevated temperatures. Stabilized materials can be microfilmed or preservation-photocopied and can be reintegrated with their collections (see figs. 1, 16).

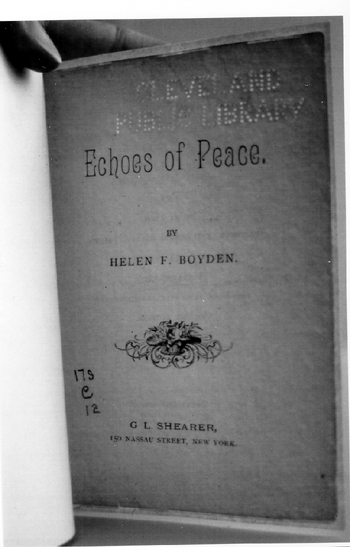

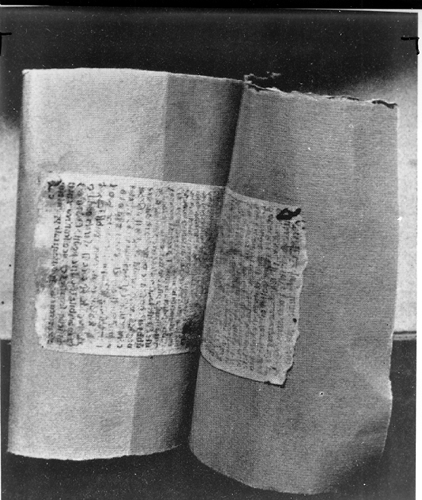

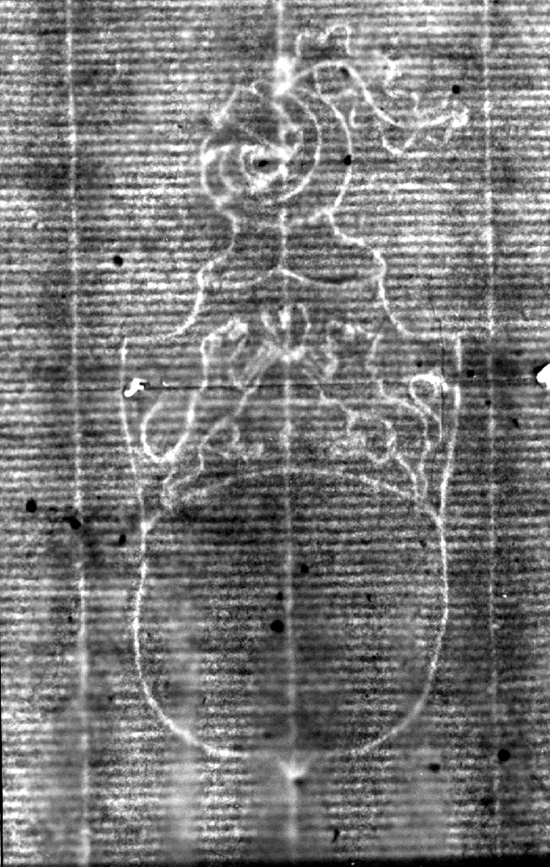

2 2. THE HISTORY OF PAPER SPLITTING“Here we are talking about that which could be referred to as the ‘opera magna’ in the field of restoration … paper splitting … the division into two parts in the thickness of any piece of paper” (Morgana [1932] 1994, 83). 2.1 2.1 BEGINNINGSNeither the inventor nor the invention date of paper splitting is known. Celebrated as a novelty, the treatment appeared seemingly quite suddenly in Europe during the first half of the 19th century. A certain W. Baldwin, an English restorer, is said to have split paper in 1848. The famous French restorer Alfred Bonnardot, who unfortunately did not witness Baldwin's process firsthand, believed it to be the earliest feat of paper splitting. It must have rapidly become public knowledge, however, when Baldwin succeeded in splitting English bank notes. So the process would not end up in the hands of dishonest individuals, the Bank of England generously offered him monetary compensation if he would divulge his method to bank officials instead of publicizing it (Bonnardot 1858, 332). According to Bonnardot, Baldwin was an employee at P. Colnaghi, a London print dealership that still exists today. There is, however, no confirmation of his tenure there because none of Colnaghi's business records predating 1870 survive (Colnaghi Art Gallery 1999). A possible reason for their disappearance is suggested by the English book conservator Bernard Middleton. Many company records, he says, “were destroyed by bombs in the Second World War, and others were deliberately discarded at that time because stored paper was a [fire] hazard” (Middleton 1999). Middleton believes that Baldwin was probably not self-employed because his name does not appear in the lists of 19th-century English bookbinders. Apparently, Baldwin was not the only one to proudly offer this miracle treatment. A short notice in a mid-19th-century leaflet testifies to the increasing popularity that paper splitting enjoyed in England: “PAPER SPLITTING. W. Kennington, bookbinder, undertakes to show any person the process of splitting paper, however thin, for the sum of ten shillings, subject to the condition that the person to whom the secret is made known will not reveal it to any one else. Specimens may be seen on application to Mr. S. Gibbs, Stationer 5, Union Street” (Middleton 1999). Bonnardot also mentions a Parisian intaglio printer and restorer, A. Pierron, who placed several examples of split engravings at the Universal Exposition of 1855 (Bonnardot 1858). The first detailed description of paper splitting was written by none other than Josef Meder, director of the Graphic Art Collection Albertina in Vienna from 1909 to 1923. As a print connoisseur and curator, he was interested in restoration matters and occasionally treated prints and drawings himself. In 1877 and probably around 1881, while he still was curator, he jotted down private notes on paper splitting (Helm 1979). Bonnardot's and Meder's accounts are important because they constitute the most detailed sources on paper splitting dating before the First World War. As late as the 1930s, Mario Morgana sought out Bonnardot, looking in vain for newer published information. This search inspired him to write this romantic recapitulation of the origin of paper splitting: “In 1848, a crafty restorer, a Londoner named Mr. Baldwin, succeeded in splitting prints. When the news reached Alfred Bonnardot, it must have disturbed his dreams because he had thought about a similar procedure that would have made possible certain special restorations that could not have been possible any other way” (Morgana [1932] 1994, 83). No doubt paper splitting was a process shrouded in mystery, even guarded with secrecy by those few who knew how to accomplish the task. 2.2 2.2 WHY WERE PAPERS SPLIT ORIGINALLY?Paper splitting originated among art collectors and restorers who recognized it as a method designed to separate the recto and verso of double-sided prints, drawings, and manuscripts for their easier enjoyment (fig. 4). Although it may appear to the contemporary reader that this treatment was motivated by the potential monetary gain that results from making two artifacts out of one, 19th- and early-20th-century restorers and collectors seem to have been more concerned with optimizing the aesthetics of viewing artworks they owned. Bonnardot reported that a Paris collector, M. Hennin, owned a rare engraving showing a portrait of Henry IV that had large letters printed on its verso. These were apparent on the recto and “detrimental to the effect of the burin” (Bonnardot 1858, 332). The print was split in London by Baldwin and returned in two pieces “without even the least abrasion” (Bonnardot 1858, 332). Meder presumably split artworks on paper belonging to the Albertina (Schack and Fackelmann 1987, 7 n. 7). The German restorer Max Schweidler recommended splitting double-sided drawings for their easier viewing (Schweidler 1950).

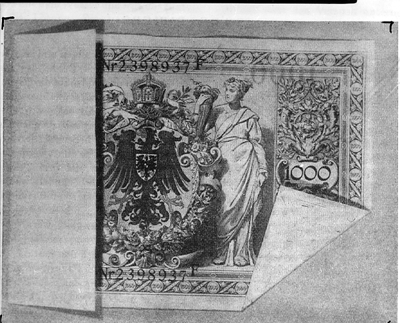

Meder also considered paper splitting for matters other than restoration. Somewhat cryptically, he commented on the splitting of certain printed images: “If they are illustrations on printing paper, these often very thin [split] sheets now can be adhered to white papers to be used as pictures, or they can be used as colored decal pictures” (Helm 1979, 213). This decorative use of split prints was not a mere aberration. Schweidler explained that prints could be split to be made into lampshades if their paper was not translucent enough to allow the light to pass without being split. We may assume that pictures used for lampshades were not considered valuable or important, and that the more serious business of paper splitting concerned the treatment of artwork. These excursions show, however, that an intimate connection still existed then between restoration and craft traditions. Indeed, paper splitting may well have originated with bookbinders, for they would have had a chance to observe in their practice that certain papers easily split (Sievers 1966). This realization could have easily led them to the development of a new treatment. Even the 1983 bookbinding manual of the German binder Fritz Wiese still mentions that the practitioner might occasionally be obliged to split “pictures” printed on both sides on request of a client (1983, 359). Schweidler was also aware of the surprise effect and publicity value of splitting bank notes (fig. 5) (Schweidler 1950).

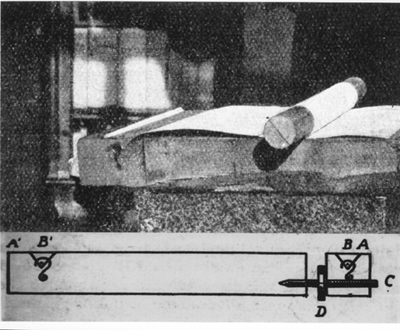

Schweidler further commented on splitting: “One will be forced to separate a paper if engravings or lithographs were printed on the reverse and should be lined. The application of paste would make the printing on the reverse show through to the front and would make it look unattractive” (Schweidler 1950, 75). However, “repair papers used purely for restoration should never be split because the side of the paper that receives the glue application will always acquire a certain density” (Schweidler 1950, 75). Schweidler is best known for a special mending technique that is often referred to as “invisible repair.” Rarely practiced today, it was much admired for its subtle finish. Papers used for these repairs were extensively thinned along their edges to match the chamfered losses of an artwork. Residues of a glue layer applied to such an insert paper during the splitting process would have made it difficult to shape the paper edges. Schweidler further wrote that papers that were to be split should be homogeneous in composition and free of lumps and metal inclusions. During splitting, these would become separated and leave small holes in the paper. In the days of Schweidler, splitting double-sided artworks was still considered a necessary treatment and part of a reputable restoration practice. Even recently there have been signs of a residual interest—although little publicized and less easily accepted—in the separation of double-sided artworks. In the 1980s, two Austrian conservators split several privately owned double-sided drawings by 20th-century artists, including one by Oskar Kokoschka (1886–1980), lining each half with Japanese paper. The conservators argued that their procedure in this case was acceptable because they had adequately documented the original state of the drawings (Schack and Fackelmann 1987). Conservators today refuse to perform such treatments, considering them an unethical interference with the integrity of the artwork. This case is not mentioned here to generate obvious reactions but rather to show that we are part of a heterogeneous international community, evolving at different rates, and even recently following in good faith standards different from those by which we abide today. 2.3 2.3 SPLITTING PAPER BY HANDThroughout the history of paper splitting, the fundamental principles and relatively rigid parameters of the treatment have remained unchanged. It is instructive to see, however, that some restorers and conservators were able to—and sometimes had to—develop their own treatment variations. As far as these are recorded, they allow us to appreciate the creativity and skill of our professional forebears. In Essai sur l'art de restaurer: Les estampes et les livres (1858), Bonnardot said he regretted he had no firsthand knowledge of paper splitting. Having heard, however, of splitting treatments performed by the English restorer W. Baldwin and the French restorer and printmaker A. Pierron, he assured his readers that “the possibility of such a procedure is not an illusion” (Bonnardot 1858, 330). He consoled his eager audience: “I will share with the lovers of this art some observations that perhaps will enlighten them; because, from a reasonable hypothesis to the practical conclusions the step is sometimes very short” (Bonnardot 1858, 330). Bonnardot was able to intuit the basic principles that underlie the idea of paper splitting, and he even hypothesized about two different paper-splitting methods. He guided his audience step-by-step: “Let us begin with this consideration: when a force is applied to a solid body with the purpose of splitting it, it is always the part that is less strong, that is softer, or that is not stabilized, that will yield first. Now, in a piece of paper, one may consider the two outside surfaces … the firmest layers, and the intermediate layer, in its entirety, the weakest” (Bonnardot 1858, 134). To save only the recto of a print, Bonnardot suggested adhering the print facedown to a marble slab and scraping off undesired paper layers on the verso. One should smooth away the roughened surface with a piece of sharkskin and then soak off the thinned paper sheet by immersing the marble in a water bath. If, however, it was desired to save both sides of a print, one side of the original should be adhered to a rigid, flat support using animal glue. Bonnardot was perceptive with regard to the quality of this adhesive: “It would have to be perfectly pure, without impurities, of homogeneous viscosity, and should not penetrate into the interior of the paper, but attach only to its surface” (Bonnardot 1858, 135). A varnish or resin could also be used as adhesive. The adhered paper should be allowed to dry. On the verso, one should then evenly apply another viscous layer of glue to adhere a piece of cloth or a smooth piece of parchment larger in dimensions than the original. After this support dried, one of its edges should be peeled off along its entire width, working slowly and with uniform force. Half of the paper would remain on the rigid support, the other half would attach to the cloth or parchment. Once the separation was accomplished, the split paper halves could be released from their respective supports in a hot water bath or alcohol, depending on the adhesive present. Bonnardot's interest in technology was not unusual for his era, but it still may impress us today for being well ahead of contemporaneous developments in the restoration field. He suggested yet another method for paper splitting that was based on his knowledge of machines used in the leather and parchment industry to split sheepskins (Bonnardot 1858). A paper sheet would first be fully adhered on both sides between two thin wood panels. After drying, the edges of the panels would each be clamped to opposite sides of a vise with wide jaws and would be pulled apart along one entire edge just far enough to begin the splitting of the paper. The split, Bonnardot presumed, would occur in the center of the sheet not penetrated by the glue. Along the already split edge, the wood panels would be adhered between two revolving cylinders. Turning the cylinders, one could then pull the two panels apart to effect a separation in the center of the paper. If it is true that Bonnardot indeed never witnessed paper splitting, he is to be credited with an imaginative mind and an anticipation of even the most recent accomplishments in paper-splitting technology. In his unpublished notes from 1877 and 1881, Josef Meder detailed a paper-splitting treatment designed to separate two-sided prints or drawings (Helm 1979). Judging by the procedural improvement recorded in the later text, we may assume Meder had considerable practical experience with paper splitting and monitored his results. In his 1877 notes, Meder recommended that one apply a thin coat of fine glue to two firm, smooth support paper sheets and allow them to dry. To remove the gelatin sizing of the paper to be split, it was immersed—depending on its thickness—for up to 12 hours in a 10% solution of hydrochloric acid, followed by 15 minutes in a lukewarm potassium hydroxide solution. Residual chemicals were then rinsed out in a succession of warm water baths. The paper was hung to evaporate excess water and then was placed between the two sheets of glue-coated support paper. It was lightly pressed to remove air bubbles and kept in a press for 12–24 hours. After being removed from the press, the support papers were trimmed to the dimensions of the original paper laminated between them. This step would prevent tears from occurring during splitting: “The surfaces of the paper to be split adhere to the glued paper, whereas the de-sized paper in the center will easily split into two planes, depending on the quality and make of its fiber matrix. One of the planes is usually thinner and carries the wire pattern and watermark, the other is usually a slightly dense fiber felt with an even, often amazingly beautiful texture” (Helm 1979, 221). To remove each paper half from its respective support, a piece of oil or wax paper was placed on the split side and the assembly was immersed in a warm water bath. After a few minutes, the support papers released and floated to the water surface. The split original could be removed from the bath with aid of the oil paper. A new piece of oil paper was placed on the front of the split original, and the assembly was immersed again. The washing was repeated until the glue was removed from the paper surface. The recipes in the 1881 manuscript, however, allow us to infer that Meder may have been a bit apprehensive regarding the intense chemical treatments he had recommended in the 1877 manuscript for the removal of sizing from the paper to be split. Instead, he now suggested that the paper be soaked in warm water for several hours, then immersed for 1–2 hours, instead of 12 hours, in hydrochloric acid, and finally rinsed in hot water until completely free of acids. After this procedure, the paper was allowed to rest on a blotting paper. The recipe for the adhesive to be spread on the support papers called for 4 parts water, 1 part glue, 3 parts sugar, and 3/4 parts gum arabic. The addition of sugar and gum arabic improved the flexibility of the adhesive. Meder also recommended that the paper to be split be adhered to support papers that were first dampened to prevent curling and ensure even adhesion. The English bookbinder Douglas Cockerell addressed the subject of paper splitting in his repair manual, Bookbinding and the Care of Books (1902). His scant description of the procedure differs from that of Meder in several points. Instead of preparing two support papers with animal glue, he preferred to brush the paper to be split on both sides with a thick starch paste. Then, a fine linen or cotton fabric (jaconet) was placed on each side of the pasted paper. The laminate was pressed briefly so that the fabric adhered well overall, and it was allowed to dry before the fabric sheets were pulled apart, each carrying half of the split paper. Mario Morgana, in Restauro dei Libri Antichi (1932), was perhaps the first restorer to recommend splitting as a way of strengthening deteriorated paper, specifically tattered book frontispieces. Not satisfied with the results of manual splitting, he gave detailed specifications on an apparatus that, so he suggested, would make it easier to maintain the necessary force to pull the support sheets apart. First, two sheets of parchment were coated with animal glue and dried. The paper to be split was soaked in water to remove the sizing. Excess water was allowed to drain, and the sheet was placed between the gelatin-coated parchment sheets. The laminate was then passed over with a roller to ensure uniform adhesion before drying it under high pressure. After the faced paper had dried, it was inserted in Morgana's device (fig. 6). The splitting was initiated by hand. The bottom parchment sheet was clamped at head and tail between two bars (B/, B). A screw control (D) was used to increase the space between the larger block (A/) and smaller block (A) until the clamped laminate was stretched taut. One edge of the top parchment was threaded through a slit in a cylinder. While pressure was kept on the surface of the instrument, the cylinder was rotated around its own axis from B/ to B so that the parchment on top rolled up on the cylinder (see fig. 6). One-half of the paper was thus rolled up with the upper parchment sheet while the other remained on the lower, clamped parchment sheet (Morgana [1932] 1994).

Also in the 1930s, another Italian, F. Leti, came up with the idea of using celluloid—then a new commercial product—as facing support (W�chter [1982] 1987a). The paper to be split was placed between two celluloid sheets, and all three were immersed in an acetone bath until the solvent had completely volatized. Apparently, this process fused the celluloid to the paper so it could be split. The split halves were again immersed in acetone to help release the celluloid. This procedure was suitable only for undamaged papers without losses that could be evenly attached to the celluloid. To the German restorer Max Schweidler, paper splitting was not magic but just a “simple hand skill” (1950, 73). Schweidler was the first restorer to suggest dampening the artifact before facing it. He washed the facing papers and the artifact in cold water to allow the papers to expand and relax, drained them, and placed them on absorbent cardboards to remove further moisture. A pure, heated animal skin glue was applied to one side of the damp artifact (Schweidler 1950). A facing paper, slightly larger than the artifact, was placed on top. The second facing paper was attached in the same manner on the other side. Because all three papers were damp, wrinkles and bubbles could be easily brushed out. The laminate was weighted between absorbent boards under increasing pressure until it was dry. The overlapping facing paper margins were cut off along three sides of the original, and the splitting could begin at one of the exposed corners. The split halves were placed in a cold water bath to release them from their support papers. Once they were separated, the split papers were soaked in hot water to remove residual glue. Schweidler split damaged double-sided artworks permanently because he thought they required repairs that were best administered by lining. He also split undamaged double-sided artworks for the separate use of their split halves, but he did not mention whether he treated the newly exposed raw paper on the reverse by applying a surface size or by burnishing it. Up to and even beyond Schweidler's time, glue and starch paste were the common adhesives used in paper splitting. Since the 1960s, however, some conservators have replaced the starch paste core adhesive with mixtures of methyl cellulose and polyvinyl acetate (PVA) dispersions (H�ge 1981). Polyvinyl acetates ensured good adhesion of the paper layers, while methyl cellulose was intended to ensure that treated papers could be separated again in the future, a claim that, conservators realized, was of more theoretical than practical concern (Schack and Fackelmann 1987). Fungicides and alkalizing agents have been added to these mixtures (H�ge 1981). 2.4 2.4 PAPER SPLITTING BY HAND IN THE UNITED STATESBeginning in the 1940s, a few American conservators explored paper splitting for the treatment of individual artifacts. Willman Spawn, honorary curator at Bryn Mawr College, recently recounted his experiences with paper splitting during the 1950s. As the book conservator for the American Philosophical Society in Philadelphia, he was one of the first conservators known to the authors to employ this treatment in the United States (Spawn 1999). Spawn became interested in the process after he read Schweidler's manual and followed its instructions, the only exception being that he used rice starch paste instead of animal glue to adhere the facing papers. Like Schweidler, he split two-sided drawings into two separate works if desired by private clients, but he also used the treatment to strengthen severely damaged book endpapers in the society's collection. He felt that this technique offered an invisible repair that could strengthen the original paper internally. Because newsprint was the easiest type of paper to split, he often chose the Sunday funnies during the demonstrations he would provide when he lectured at various universities, conservation graduate programs, and libraries across the country (Spawn 1999). Paper splitting was performed during the 1940s and 1950s at the Extra Bindery at the R. R. Donnelley & Sons Company in Chicago. The bindery specialized in fine and replica binding and conservation. In one of the bindery's pamphlets, paper splitting was promoted as a method of separating drawings or printed images without damaging either side of the paper, as a treatment to strengthen weakened paper, and as a method to reduce the thickness of blank paper that was to be used for repair (Lakeside Press n.d.). In one case, to fill losses in a printed broadside, pulp inserts were made and the missing text was replicated in an elaborate procedure that involved the production of a facsimile print of the broadside on a paper that matched the texture of the original sheet. The facsimile was split to reduce its thickness. Then, letters and individual words of the split facsimile were cut out and pasted on the pulp fills of the repaired broadside (Wiest and Crusius 1979). In the present day, Frank Mowery, head of conservation at the Folger Shakespeare Library in Washington, D.C., practices manual paper splitting. He first attempted the treatment following W�chter's description in his book Buchrestaurierung, which was first published in 1982. In 1986, Mowery hosted W�chter during his first U.S. visit when he spoke about the splitting machine to the Washington Conservation Guild. Later, Mowery perfected his methods, learning from G�nter M�ller, chief conservator at the Thuringian University and State Library in Jena, Germany. Interested in determining accurately the critical moment when splitting of the faced original paper should best occur, Mowery has availed himself of a paper moisture meter (Sovereign Dual Probe Moisture Master). He allows the laminate to rest until the instrument indicates that only around 14% moisture is retained on its surface, and then splits it. The interior of the recently split original usually still measures 80–90% moisture content. Mowery split 19th-century papers from the Folger's collection that were weak and brittle due to previous restoration treatments, especially those that had been bleached without proper subsequent rinsing. He also split several incunabula and part of a 17th-century manuscript with severe iron gall ink corrosion. He favors paper splitting in such problem situations because it produces aesthetically pleasing results, provides good structural stability, and can be reversed. Working together with book conservator Bill Minter, Mowery has recently conceived of a paper-splitting device that is based on the Beloit sheet splitter, a machine used in the printing industry to sever paper into several layers for a determination of ink penetration. Adapting such a device for conservation would potentially eliminate the need for facing papers because the paper to be split would be frozen on both sides to metal surfaces (Mowery 1999). 3 3. PAPER SPLITTING IN MASS PRESERVATION3.1 3.1 BEGINNINGSIt is no accident that paper splitting evolved into a mass preservation treatment after World War II when many European libraries and archives were faced with significantly increased preservation tasks brought about by wartime destruction and neglect. As early as the 1960s, the Czech conservator Josef Vyskocil considered paper splitting as a mass preservation measure that he applied, for example, in the treatment of fire-damaged papers (M�ller 1970; W�chter [1982] 1987a). The Czech conservator L. Sedlecky advanced the unusual idea of using a viscous polyamide solution as facing support (W�chter [1982] 1987a). Designed to simplify the splitting process, Sedlecky's treatment never became popular, but it is still referenced in the 1967 conservation treatment survey by German book conservator H. Eckhardt (Eckhardt 1967). Silk gauze, also known as chiffon, and jaconet, a fine cotton or linen fabric, were recommended by Vyskocil, Sedleczky, and Eckhardt as core materials for strengthening paper; Eckhardt also suggested nylon fabric. It was also discovered that paste used as a core adhesive could be made insoluble in water by the addition of alum or formaldehyde (Sievers 1966). However, since the 1960s, more stable alternative materials have become the standard. 3.2 3.2 PAPER SPLITTING AT THE THURINGIAN UNIVERSITY AND STATE LIBRARY, JENAG�nter M�ller, chief conservator of the Thuringian University and State Library at Jena, Germany, began experimenting with manual paper splitting in the early 1960s (fig. 7). He is responsible for the preservation of rare printed books and manuscripts, among them a great number of historically important specimens damaged during World War II. In some books, M�ller even now still finds shrapnel fragments (M�ller 2000); many books also suffer from extensive mold and water damage. Many of the library's unique manuscripts exhibit severe losses in the ink lines caused by advanced iron gall ink corrosion; others carry notations in various types of inks, a further challenge for the conservator (M�ller 1991). Industrial pollution and sulfur emitted by the library's coal heating system, which was used between 1918 and 1988, contributed extensively to the deterioration of the library holdings. Many fragile materials requested by library users are first passed to M�ller's conservation laboratory before they can be forwarded to readers. Thousands of rare books have already been conserved by M�ller through paper splitting, and hundreds of thousands of brittle manuscripts are still waiting to be strengthened by this process (M�ller 1999b).

His pressing need for a mass treatment that would strengthen brittle paper led M�ller to many years of intensive investigation, which, until 1989, was curtailed by the lack of contact with the West. When M�ller began his work in the 1960s, two paper-strengthening methods were commonly practiced, silking and the more recent lamination of brittle paper with cellulose acetate film. Lamination, in particular, was considered a perfect solution for supporting brittle paper. However, the supplies and equipment needed for these treatments were difficult for him to obtain as they were available only from Western distributors (M�ller 1999b). After examining sample lamination treatments he had received from the American scientist William Barrow, M�ller felt he needed a mass treatment process that was less expensive, did not alter the appearance of the original, and involved only readily available materials. He explored leaf-casting developed by Yugoslavian conservators and soon was directed to articles by Sievers and Vyskocil, which described their trials with paper splitting (Sievers 1966; M�ller 1999b). Realizing the potential of this treatment, M�ller began experimenting with published procedures and, in his early articles, discussed their shortcomings (M�ller 1970). Over the course of 30 years he increased the refinement and efficiency of paper splitting, which until recently was still regarded as too labor-intensive to allow the timely treatment of vast library holdings (M�ller 1991). Today, M�ller is able to split 400 sheets per day using his “Jenaer Papierspaltverfahren” (Jena Paper Splitting Procedure) that was patented in 1964 and again 1991 and since then has evolved still further. Books are disbound, and artifacts may be disinfected, surface-cleaned, washed, and leaf-cast in advance. Water-sensitive materials do not receive any aqueous treatment before splitting. M�ller has observed that the gelatin facing adhesive, applied to iron gall ink documents that constitute a major part of his work, consistently prevents the ink from bleeding during the splitting process. The preparatory work is followed by a paper-splitting cycle that usually takes 10 days. The night before splitting begins, a 40% (w/v) solution of pharmaceutical-grade gelatin (170 bloom strength) is prepared with the addition of glycerin (M�ller 1999b). This recipe is adjusted depending on the nature and condition of the artifacts. The first part of the procedure takes place in a small room that is conditioned to 70�F and 70% RH. The liquefied gelatin is warmed to 140�F and funneled onto rollers that are located in a heated gluing machine of the type employed in bookbinderies (part of the machine can be seen in figure 9, which illustrates a later stage of the process). The controlled room climate ensures that the facing support papers receive an even gelatin coating when they are passed through the gluing machine. A sheet of glued facing paper is laid on a table, and the dry or lightly dampened paper to be split is swiftly adhered to it before the gelatin solidifies. The paper relaxes and expands evenly before the laminate is pressed to establish a firm bond between the two papers.

An absorbent paper, a so-called equalizer sheet as large as the facing support paper, is placed on top of the original already attached to the center of the facing paper. The equalizer sheet prevents a glue-to-glue bond between the margins of the two facing papers that would complicate the splitting process. It also allows the entire laminate to react uniformly to moisture and prevents uneven drying, cockling, and tearing of the original during splitting. No portion of the equalizer sheet remains permanently with the original. Originals suffering paper losses receive a matching fill paper or leaf-cast pulp fill instead of the equalizer paper. Either of these fill materials functions in the same way as the equalizer sheet, except that portions of them remain permanently attached to the original where losses exist. Since the early 1990s, a leaf-caster has been available in the laboratory to fill losses in artifacts that can be subjected to aqueous treatment. If fills cannot be made by leaf-casting because a water-sensitive ink is present on the artifact, M�ller resorts to a special insert technique he developed over many years. It is perhaps best called a “double-splitting” method since it requires two splitting actions that follow each other in quick succession. First, the faced laminate is split; then an insert paper is placed between the split paper halves while the gelatin is still tacky; the split halves are then pressed a second time to adhere the filler paper to the facing papers in areas where the original suffered losses; the laminate is opened up again; this causes the filler paper to split where it adheres to the gelatin; excess insert paper is easily trimmed around the losses; finally, the two split halves are brushed with core adhesive and permanently united (M�ller 1970; H�ge 1981). An artifact not suffering losses is sandwiched between the first facing paper and the equalizer sheet. It is then placed between plastic-covered cardboard pages of a large press book (such books are seen in figure 11, which illustrates a later stage of the process). The plastic covering is critical to the procedure because it prevents the moisture contained in the paper laminate from escaping. Several press books of the same dimensions are filled with faced originals. Each of the press books is placed in a press for five minutes to ensure good bonding between the papers, and then all books are stacked on top of each other to rest until the next treatment step. After pressing, the equalizer sheet is scored with a sharp knife along the perimeter of the original, and the portion that covered the original is lifted off. A second facing support paper is coated with gelatin and adhered to the open side of the original. This procedure creates a uniform laminate consisting throughout of three layers of paper (see fig. 3, upper right). All faced originals are returned to the press books and stacked for a few hours. Frank Mowery varies M�ller's procedure in that he first lays an equalizer sheet larger in size than the original on the table. He places the original paper on top and then adheres the first facing sheet to both papers (Mowery 1999).

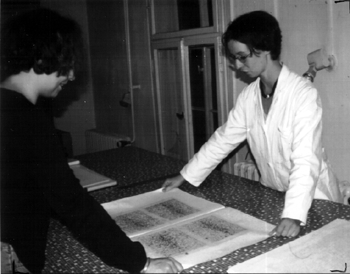

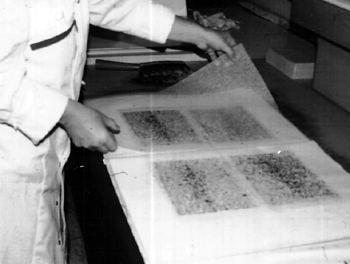

The success of every splitting process depends much on the consistency of the gelatin solution, which serves two important purposes. It attaches the facing paper to the original and supports it during splitting, and it also delivers moisture to the faced, dry, or lightly dampened original. It is important that the gelatin solution be viscous enough to remain on the surface of the original paper while the moisture it contains penetrates into the interior. A thick, dense paper can be sufficiently moistened only with a low-viscosity gelatin solution, but that same solution will penetrate and transparentize a thin, porous paper (Mowery 1999; M�ller 1999b; W�chter 1999b). Only if these parameters are observed will the paper moisten evenly and split in its center. To accomplish the splitting, the faced original is placed in a slit between two tables. The paper halves are pulled in opposite directions, beginning at a corner, until they are completely separated (fig. 8). Along one side, the facing papers are allowed to remain attached to each other, forming a hinge between the two split paper halves that serves as a registration guide when the halves are reunited after the insertion of the core tissue (M�ller 1999b).

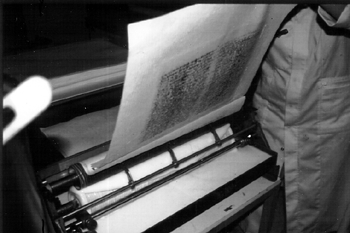

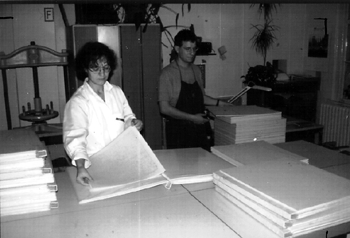

The viscosity of the core adhesive is adjusted depending on the paper thickness, a thin paper requiring a more viscous adhesive than a thick one (M�ller 1999b; W�chter 1999b). A cellulose ether adhesive mixture is prepared in M�ller's laboratory using a high-speed industrial blender. The standard core adhesive recipe published in 1989 included the following ingredients (M�ller 1989): 200 ml acrylic resin; 4,000 ml distilled water; 200 ml ethanol; 75 g carboxymethyl cellulose; 75 g methyl cellulose; 20 g calcium carbonate. The acrylic resin is emulsified in the blender before the rest of the ingredients are added. The adhesive is stirred for approximately 3 hours and then is rested for 12 hours to allow the cellulose ether to swell. In past years, the core adhesive was applied to the two hinged split paper halves by brush. Today, the paper halves are coated by feeding them manually through the gluing machine (fig. 9). A thin abaca fiber paper (3.8g/m2), made by a German paper manufacturer from fibers imported from the Philippines, is placed on one of the coated halves (fig. 10). Good contact is ensured, and then the other split half is eased down on top (M�ller 1999b). Items reunited in this fashion are pressed between cardboards (fig. 11). The pressure is kept low to prevent the core adhesive from penetrating, and thereby transparentizing, the originals. After a few hours, all laminates are removed from the boards and placed on drying racks overnight. Finally, the facing papers are removed in water baths.

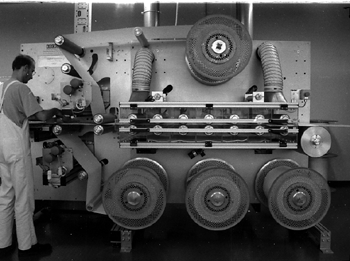

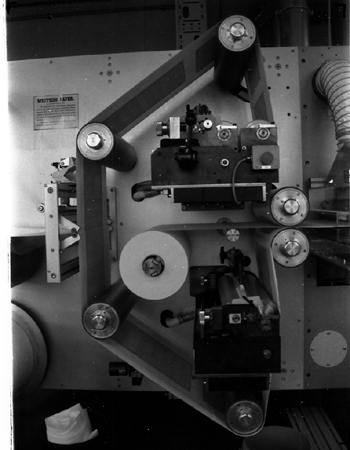

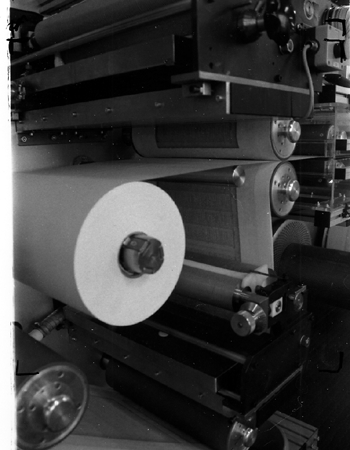

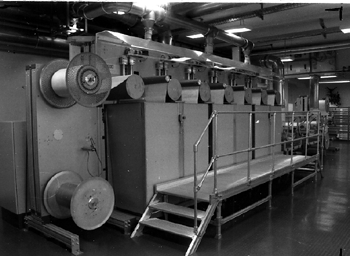

M�ller developed an efficient wet treatment system consisting of steel cassettes that hold 70 polyester fabric pockets, each of which can accommodate one paper laminate. The cassettes are lowered into washing tanks filled with deionized water (140�F), where they remain for 15 minutes. A small amount of a protein-digesting enzyme can be added to the washing solution. The facing papers release quickly during the short bath, and the cassettes are transferred to a final hot water bath (185�F) for 5 minutes (M�ller 1999b). The core adhesive remains unaffected, while the gelatin is reduced on the surface of the originals. Recently, however, M�ller has begun to eliminate the enzyme baths in the treatment of iron gall ink documents in order to leave a thin gelatin film on their surface as a form of resizing. After the final bath, the originals are removed from the pouches and separated from the reusable facing supports. It takes M�ller three to four weeks to disbind, treat, and rebind 5–10 damaged books; many more, however, are in treatment at any given time. M�ller points out that at Jena and elsewhere, university and research libraries are faced with increasing requests by users who wish to see original materials that today are retrievable through electronic library catalogs and via the Internet. Paper splitting, he says, can secure and stabilize badly deteriorated paper, realign tears, and, combined with leaf-casting, fill losses and preserve original deckle edges and other paper features as well as various types of writing media. The procedure stabilizes paper mechanically and biochemically, and it stabilizes corroded ferrous inks (M�ller 1999b; M�ller 2000). 3.3 3.3 PAPER SPLITTING AT THE ZENTRUM F�R BUCHERHALTUNG AT LEIPZIGDr. Wolfgang W�chter's lifelong commitment to the development of efficient mass conservation treatments began in 1964 when the Restoration Department was first established at the Deutsche B�cherei in Leipzig, Germany. Dedicated to preserving materials in their original format, “the policy governing the workshop development has always been to translate research findings into the practice of preservation and restoration and to improve the cost-benefit ratio for these operations” (W�chter 1987b, 129). After Germany's reunification in 1989, the Deutsche B�cherei Leipzig, the Deutsche Bibliothek Frankfurt am Main, and the Deutsches Musikarchiv Berlin merged under the name Die Deutsche Bibliothek. The library's primary responsibility is the collection and bibliographic indexing of all German-language publications since 1913, including the work of German-speaking emigrants from 1933 to 1945. W�chter (1995) points out that, each year, 4.66% of an average library's holdings becomes unusable. W�chter was closely acquainted with M�ller's work in nearby Jena, where he had studied at the university. Having been introduced to paper splitting at Jena, W�chter began experimenting with the mechanization of the process in the 1960s. By the early 1990s, he had fully developed a machine that would streamline and economize paper splitting for mass preservation. In 1992, the West German firm Becker Preservotec was contracted to further perfect W�chter's design. With the support of Becker Preservotec, the Conservation Department of the Deutsche B�cherei was privatized in 1997 and the Zentrum f�r Bucherhaltung (ZFB) was formed to serve clients in Germany and abroad. The first complete model of the paper-splitting machine has been operational since 1997. In 1999, the machine already had the capacity of splitting up to 5,000 paper sheets per day (W�chter 1999b). Rare materials including manuscripts are split by hand at the ZFB, while other materials such as newspapers are split by machine. Preparatory treatments usually include disbinding, collation, washing, alkalization, and disinfecting of damaged papers. Formerly, papers also routinely underwent bleaching with oxidizing bleaches such as potassium permanganate. The treatment has been almost completely abandoned today because conservators have become aware of the importance of preserving the original tonality of historic paper and of the risk of weakening it during bleaching. Only a short bath in a 0.05% sodium borohydride solution is sometimes administered to lighten paper and stabilize the cellulose. When required, degraded papers may undergo leaf-casting on a machine developed by the Danish book conservator Per Laursen that W�chter plans to integrate with the splitting machine to streamline his mechanized paper-strengthening process. Pure alpha cellulose pulp purchased from paper manufacturers is used in leaf-casting (W�chter 1999b). The mechanized process of paper splitting is continuous from the facing of the paper sheets to removal of the facings after completion of the splitting process. The machine is composed of three separate parts that are aligned in a formation comparable to a Fourdrinier machine (the first two parts of the machine are described in W�chter et al. 1996; the third, newest part is described in W�chter et al. 1997). In the first part of the machine, dry or lightly dampened original sheets with a maximum width of 48 cm are laid manually on a moving belt that is 50 cm wide and carries a continuous sheet of facing paper freshly coated with gelatin adhesive (fig. 12). Once attached to the facing paper, the sheets are transported a short distance to receive the second facing paper that is also coated with gelatin. A strip of filler paper (similar in function to M�ller's equalizer sheet) frames the originals, preventing a glue-to-glue bond along the very edges of the facing papers that would lead to uneven splitting. The facing adhesive is made of 7,000 ml water, 2,500 g food-grade gelatin (220–50 bloom strength), and 150 ml glycerin (W�chter 1997). For a thinner paper, a more viscous gelatin is used to prevent the penetration of the gelatin into the paper interior (W�chter 1999b). The two continuous facing paper sheets firmly adhere to the originals, while the sandwich passes between a set of rubber rollers adjusted to exert a certain amount of pressure (see fig. 12). The rollers operate under a dome that allows control of the ambient temperature and humidity. This environment ensures that the facing adhesive has time to set before the laminate travels a short distance to the second part of the machine. There, the facing papers are pulled in two opposite directions, causing the original sheets to be split into two even halves (fig. 13). Two opposite sets of rollers guide both halves to their point of reunification. The tension of the rollers is adjustable so that the split sheets traveling at a speed of about 1–2 m per minute can be kept properly aligned during machine operation. A staff member remains stationed at this part of the machine to monitor its operation. If the rolls of facing paper need to be changed or other adjustments made, newsprint is fed into the machine until placement of the originals can resume.

Shortly before they are reunited, the split halves are coated with a core adhesive. A core tissue delivered from a continuous roll is inserted between the two split halves at their point of reunification (fig. 14). The core adhesive consists mainly of methyl cellulose and carboxymethyl cellulose with the addition of less than 1% acrylic resin and sufficient calcium carbonate to leave a 3% alkaline reserve in the core of the treated paper. A recipe W�chter published in 1997 contained 4,000 ml distilled water; 200 ml acrylic resin (optional); 200 ml ethanol; 75 g carboxymethyl cellulose; 75 g methyl cellulose; 20 g calcium carbonate/magnesium carbonate; 30 g galactomannan (polysaccharide added optionally); 1 g Captan (fungicide added optionally [1,2,3,6 tetrahydro-N-trichloromethyl thiophtalimide]) (W�chter 1997, 111; W�chter 1999b).

The core adhesive formulation is adjusted depending on the paper thickness and quality. The acrylic resin adhesive is added to reinforce particularly fragile materials. Galactomann, a polysaccharide gum from the guar plant and carob tree, has a chemical structure closely related to cellulose and many hydroxyl groups suitable for hydrogen bonds that ensure good bonding between the core tissue and the split original. Captan is the fungicide of choice at the ZFB because it is, according to W�chter, chemically stable and effective over long time periods without adverse side effects. The core tissue is an unsized cotton fiber paper (12 g/m2) that contains 5% calcium carbonate (W�chter 1999b). This laminate passes through a set of rollers that allows the core adhesive to set, ensuring proper adhesion. The laminate is then transported to the third part of the machine for the final washing cycle, where it is guided in and out of a series of six narrow water tanks available (fig. 15). The tanks contain hot water that can be conditioned to various temperatures. Operators can change conditions for each tank separately and adjust the duration of each washing cycle by moving the rollers that guide the sheets inside the tanks up or down. Usually, only three washing cycles are needed to reduce the gelatin and release the originals from the reusable facing supports. In the first tank, a cellulase-free protease (Corolase 7089, a liquid bacteria protease from Bacillus subtilis) aids the release of the facing papers and the reduction of gelatin on the surface of the sheets. The enzyme operates best at a pH of 6.0–8.5 and a temperature of 131�F. In the second tank, the enzyme is deactivated at a temperature between 149�F and 158�F, and in the third tank, residual gelatin and deactivated enzymes are rinsed out. The paper sheets, now connected only by the continuous core tissue, are guided through a drying section. At the end, they are automatically cut into separate sheets using a laser sensor-operated blade. In 1999, the cost per folio was approximately $4 (W�chter 1999b).

The possibilities of mechanized paper splitting were recently explored by the Cleveland Public Library, a current U.S. client of the ZFB. The library's Preservation Office wanted to restore the original format of three decorative 19th-century publisher's bindings and one early Ohio publication. The splitting and leaf-casting restored the flexibility of the pages and reestablished the spine fold that was previously cut to make preservation photocopies of the books. The text blocks were bound at the ZFB, incorporating the original bindings for all three volumes (fig. 16) (Olszewski 1999). 3.4 3.4 ARE THERE ANY MISHAPS IN PAPER SPLITTING?Beset by seemingly imponderable variables, paper splitting holds more risks than benefits for the novice practitioner. Experimenting with splitting newsprint samples, the authors encountered some of the many pitfalls that await the inexperienced paper splitter. Some of them were also noted by paper conservator Monika Gast (1993), who candidly wrote about her early splitting attempts after attending a workshop conducted by G�nter M�ller. Several common failures may occur during the splitting process: the facing support may not adhere if the viscosity of the gelatin is not calculated correctly; uneven splitting may occur if the gelatin is applied inconsistently or gels too quickly (this may happen when applying the gelatin by brush, and if the temperature and humidity in the work area are too cool and dry); the original paper may transparentize if the faced laminate is too strongly pressed, causing the gelatin facing adhesive to penetrate into the original paper; pressing too strongly may also cause the original paper to separate from the core tissue in the last stages of treatment when the gelatin penetrated into the paper interior is dissolved with the aid of enzymes; a weak or unevenly applied core adhesive may also cause internal separation of the paper layers after treatment. It is with good reason that experts who have split paper for many years warn that one must practice on at least 1,000 mock-ups before considering this treatment on an artifact. Even in the hands of experienced practitioners, paper splitting is not completely without risks. Most of them are apparent and can be calculated in advance while one makes the decision to have an artifact split: the paper may lose some of its original texture (see fig. 30); although virtually all of the ca. 100 treated papers examined by the authors showed excellent alignment of the paper halves, small misalignments may occasionally occur (see fig. 20); small losses of the paper or media may occur (see fig. 26); small paper areas may not split if a damaged artifact was not properly aligned before splitting (see fig. 32).

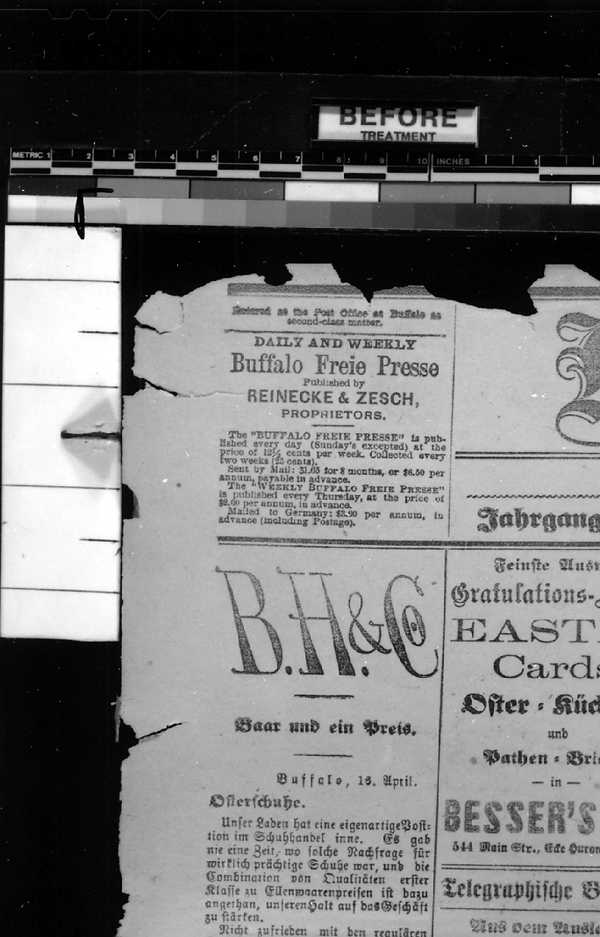

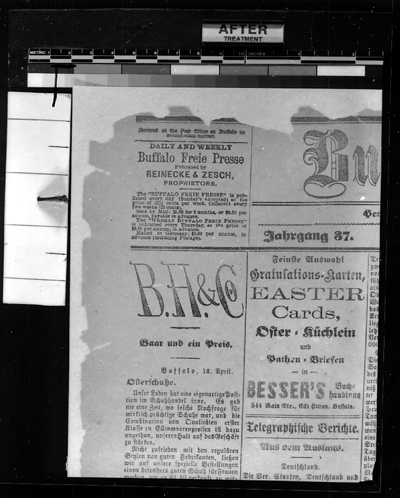

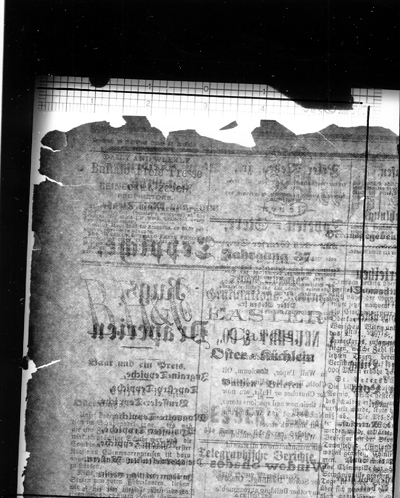

Current paper splitting by machine is a precise process that allows the efficient treatment of large quantities of materials. Rare and precious artifacts, however, are split by hand if it is decided that splitting is indeed the best method of preservation. The hand-splitting process allows greater control over individual artifacts because each one is treated separately. 4 4. EVALUATIONS OF PAPER SPLITTINGTo date, three analytical studies have been published about paper splitting as a method of strengthening paper (Liers et al. 1996; Vilmont et al. 1996a, 1996b; Bansa and Ishii 1997). Paper splitting has been compared with lamination, resizing, leaf-casting, and Parylene impregnation. Physical strength has usually been the most important parameter investigated, but other factors such as appearance and reversibility of the strengthening process have also been considered. Two scientific research projects are still in progress (Galinsky 2000; Kolbe and Banik 2000). 4.1 4.1 PHYSICAL CHARACTERISTICSCommissioned by the Bibliotheque Nationale in Paris, the Centre du Papier at the University of Grenoble conducted a study on paper lamination and splitting. The laminate was formed using a polyamide or acrylic adhesive to adhere a paper tissue or polyamide fiber material to one side of the original. Paper splitting was carried out manually under the supervision of W�chter at the Deutsche B�cherei (Vilmont et al. 1996a, 1996b). Three types of core papers were tested: Japanese kozo, and both bleached and unbleached cotton fiber tissues. Two types of modern paper were strengthened by one or the other of these two methods. They were tested before and after artificial aging for their mechanical and optical qualities and the reversibility of the treatments. When compared to their nonstrengthened, artificially aged counterparts, the strengthened papers showed the following results: paper treated by splitting showed less average thickness increase (55%) than laminated paper (146%); the average tensile strength increase (machine direction) of split paper (125%) surpassed that of laminated paper (74%); the average bursting strength increase was virtually equal for split paper (147%) and laminated paper (143%); only the average folding endurance increase (machine direction) was markedly better for laminated paper (370,927%) when compared to split paper (4,304%). Overall, Vilmont et al. (1996a, 1996b) favored splitting over lamination. Another study showed that splitting increases the pH of paper by around 3.5 units, and the tensile strength (TS) of resized paper is lower than that of paper strengthened by splitting, especially with regard to degraded, weak paper (Liers et al. 1996). Helmut Bansa and Ritsuko Ishii (1997) tested six different papers, including degraded historic samples. They used three core adhesives for manual splitting carried out at the Bavarian State Library and compared splitting with leaf-casting, lamination, and Parylene impregnation. The samples were strengthened either before or after artificial aging. The TS of all of the pre-aged, strengthened papers increased markedly when compared to nonstrengthened, aged controls (=100%): split papers with a methyl cellulose core adhesive had the highest average TS increase (329%); papers that received paste as core adhesive showed a TS increase of 172%; papers that received an acrylic emulsion as core adhesive showed a TS increase of 152%; leaf-casting (154% TS increase) and lamination (170% TS increase) compared favorably with splitting; Parylene was less satisfactory (111% TS increase) and had distinctly negative effects on some papers. 4.2 4.2 APPEARANCEVilmont et al. (1996a, 1996b) found that during artificial aging, papers strengthened by splitting suffered a greater loss of whiteness than papers sealed with a laminate; this phenomenon was not explained. Lamination, however, altered the appearance of the documents and made them less easily legible than the split documents. Vilmont et al. (1996a, 1996b) favored paper splitting over lamination for its more pleasing appearance overall. Bansa and Ishii (1997) observed that none of the four tested treatments—leaf-casting, splitting, lamination, and Parylene coating—were uniformly accepted by a group of evaluators as the one most aesthetically pleasing conservation method; leaf-casting was slightly favored. 4.3 4.3 REVERSIBILITY OF SPLITTINGTo date, only the French team has investigated in detail whether the paper strengthened by splitting later can be separated from its core paper (Vilmont et al. 1996a, 1996b). It found that splitting could be far more easily reversed than any of the lamination processes tested. Soaking the strengthened paper for ca. 10 minutes in water released the two split paper halves from the core paper. The papers laminated with polyamide adhesives required several hours of soaking in organic solvent baths. H�ge (1981) reversed splitting treatments by immersing the strengthened paper in a solution of 75% ethanol and 25% water. Gast (1993) and Mowery (1999) also observed that paper strengthened by splitting could be separated again. W�chter maintains that the process can be repeated by refacing the paper, opening the existing split, and replacing the existing core sheet with a new one (W�chter 1999b). It will be interesting to see emergency treatment directives for strengthened paper that has suffered extensive water exposure. Salvage and treatment of water-damaged papers that were strengthened by splitting will require special considerations. 4.4 4.4 STRENGTHENING DETERIORATED IRON GALL INK MANUSCRIPTSOne of the most difficult questions discussed in paper-splitting concerns the preservation of deteriorated iron gall ink manuscripts. In a recent survey of treatments performed at the Institut f�r Erhaltung von Archiv- und Bibliotheksgut in Ludwigsburg, conservation scientist Anna Haberditzl (1999) considered paper splitting to be an effective salvage treatment for papers suffering from the effects of severe iron gall ink corrosion. Manuscripts that had been stabilized through splitting a few years earlier still exhibited neutral to alkaline pH values, were free of detrimental ferrous ions within the ink lines, and under UV radiation exhibited no fluorescent halos around ink lines, the presence of which can indicate the onset of cellulose degradation. In their recent investigation, Gesa Kolbe and Gerhard Banik agreed that paper-splitting can “chemically inhibit iron gall ink corrosion” (Kolbe and Banik 2000). However, severely deteriorated iron gall ink manuscripts often do not split uniformly and incur substrate losses during the removal of the gelatin-coated facing papers. In the area of the ink application, the embrittled paper remains attached to the facing papers instead of adhering to the core paper. Therefore, paper-splitting “has to be considered a risky procedure … in the treatment of iron gall ink corrosion” (Kolbe and Banik 2000). Robert Fuchs et al. (2000) also observed that while blank areas of 18th-century manuscript pages split in the center, deteriorated ink lines did not undergo splitting and ended up in their entirety on one side of the core tissue. There has been some speculation regarding the reputed benefit of the gelatin layer brought into contact with the surface of the iron gall ink during splitting. The gelatin is believed to immobilize metallic ions in the ink, an effect that partially fixes the ink and prevents it from bleeding during final washing when the facing supports are released and acids in the paper are rinsed out (M�ller 1999b; W�chter 1999b). Kolbe and Banik (1999) investigated the chemical interaction of gelatin with iron gall ink and proved that under certain conditions, the gelatin is able to bind free ferrous ions in the area of ink application, thereby inhibiting their detrimental catalytic activity. These reactions are dependent on a variety of factors including the pH conditions, the reaction time, and the protein-metal ion ratio. It is just this otherwise beneficial interaction between gelatin and deteriorated iron gall inks that complicates the removal of the facing papers and causes losses along the ink lines during paper-splitting. 4.5 4.5 ENZYMATIC REMOVAL OF FACING PAPERSIn the treatment of objects that are not water-sensitive, the paper-splitting process concludes with extensive rinsing cycles that allow the deactivation and subsequent removal of the industrial enzymes that are used to release the facing papers. In the treatment of water-sensitive objects such as iron gall ink manuscripts, however, the aqueous procedures are less extensive to avoid alterations in the appearance of the media. Whether in this case degraded gelatin residues or deactivated enzymes remain on the paper surface has not yet been clarified. A systematic analysis of the paper-splitting process is currently being conducted by Eva Galinsky (2000) at the Institut f�r Erhaltung von Archiv- und Bibliotheksgut in Ludwigsburg with funding from the Deutsche Forschungsgemeinschaft. In cooperation with the Physiological-Chemical Institute of the University at T�bingen, Galinsky seeks to introduce immobilized enzymes that can be permanently anchored on reusable facing papers. This procedure will establish better control of the enzymes during treatment and will improve their cost-effectiveness. 5 5. OBSERVATIONS ON SAMPLE TREATMENTSThe authors had paper artifacts split at the Leipzig and Jena workshops to evaluate them for their appearance and for the possibility of recording watermarks through radiography after treatment. Also, the paper thickness was measured with Stanet Micrometer Calipers. Depending on the size of the artifact, between four and eight measurements were taken for each folio before and after treatment under ambient room climate conditions (45% RH, 70�F). 5.1 5.1 19TH-CENTURY NEWSPAPER PAGEA severely embrittled section of a newspaper page from 1898, printed on wood pulp paper, first underwent leaf-casting at ZFB and then was split by machine (figs. 17–20). The treatment was conducted as described in section 3.3. The leaf-cast paper margin and the original paper were split together, and both received the cotton fiber core tissue (12g/m2) adhered with a core adhesive consisting of methyl cellulose, carboxymethyl cellulose, calcium carbonate, less than 1% acrylic resin, and the fungicide Captan. The facing papers were released in a warm water bath with the aid of Corolase, a protease enzyme, and the paper underwent a final rinsing bath. The leaf-cast margin offers protection to the page edges during handling and makes it possible to bind stacks of loose pages by fastening them together along the back edge without touching the original paper (see figs. 17, 18). The strengthened paper is lighter in color and has a subtle drape that is reminiscent of what we may assume were the paper's original handling qualities. In transmitted light, one can see that the paper has retained much of its translucency and still shows the irregular pulp distribution pattern characteristic of its manufacture (see figs. 19, 20). The upper right corner shows an area of slight misalignment.

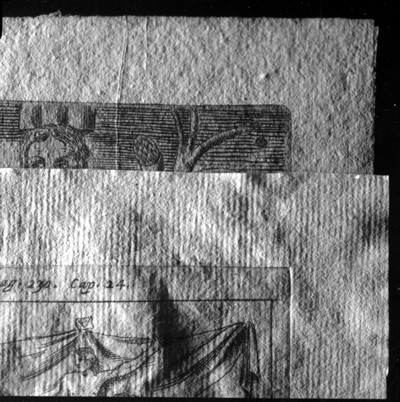

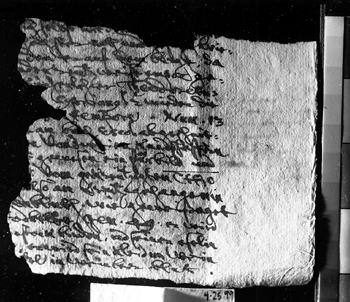

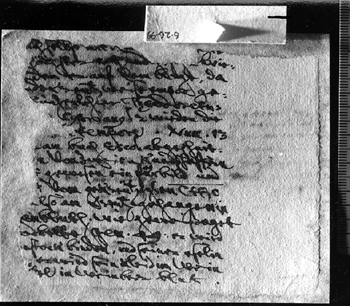

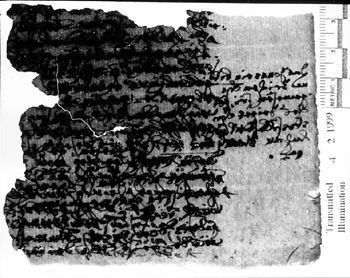

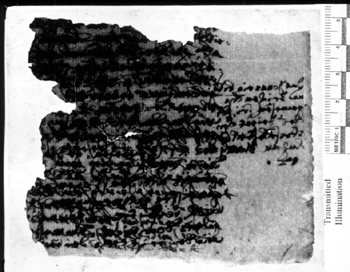

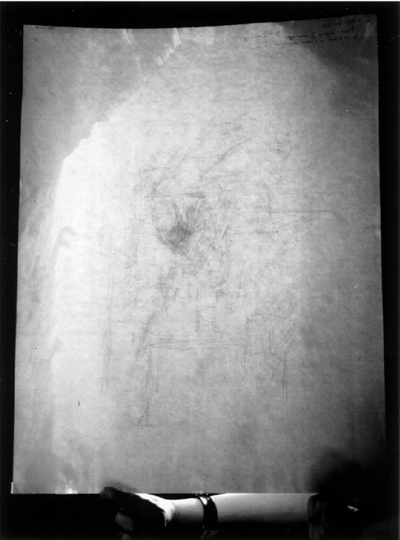

5.2 5.2 17TH-CENTURY DOCUMENT WRITTEN IN IRON GALL INKA fragment of a severely damaged iron gall ink manuscript dating from around 1680 was split by hand at Jena (figs. 21–26). The paper was so brittle that it could barely be handled. Individual sections were in constant danger of breaking off, and indeed a small fragment of the untreated piece broke loose during travel although the manuscript was carefully packaged. The manuscript underwent splitting without aqueous pretreatment as described in section 3.2. Losses in the manuscript were filled during the splitting treatment following the special double-spitting procedure developed by M�ller (see section 3.2). The facing papers were attached with a 30% (w/v) food-grade gelatin solution (240 bloom strength); an abaca fiber core paper was adhered with an adhesive consisting of methyl cellulose, acrylic resin emulsion and calcium carbonate as a buffering agent (the exact composition of the adhesive is now proprietary to Jena University); the facing papers were removed in a warm water bath with the aid of Corolase, a protease enzyme; and the paper underwent a final rinsing bath.

The treatment successfully reunited the fragments. The appearance of the iron gall ink is well preserved after treatment, and the texture of the paper is still evident as seen in raking light illumination (see figs. 21, 22). Transmitted light illumination shows the excellent registration of the split halves after treatment. Also, the width of a long fracture in the paper was reduced during splitting—a treatment that would hardly have been possible using conventional repair methods due to the fragility of the paper (see figs. 23, 24). The paper now can be turned over without an auxiliary support. The paper thickness increased by 1.7 mil (0.043 mm). A number of pinhole losses of around 0.5 mm diameter occurred within the ink lines across the paper during treatment. One of these can be seen inside the loop of the letter “h” in fig. 26 (compare to fig. 25).

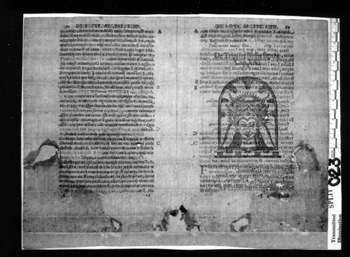

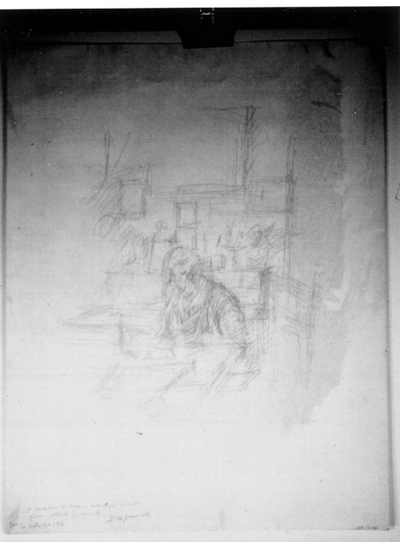

5.3 5.3 17TH-CENTURY BOOK LEAVESA 17th-century book (Johann Baptist Casalio Romano, De profanis et sacris veteribus ritibus, Rome, 1644) was so severely damaged by mold that the pages could hardly be turned without incurring losses. The book was disbound, and the leaves were washed by the authors in deionized water baths conditioned with calcium hydroxide to pH 7.5 and 8. The leaves were split by hand at the ZFB using the materials described in section 3.3 (figs. 27–34): they were faced using a 30% (w/v) gelatin solution (220 bloom strength) and received a cotton fiber tissue (12g/m2) adhered with a core adhesive consisting of methyl cellulose, carboxymethyl cellulose, calcium carbonate, less than 1% acrylic resin, and the fungicide Captan. The facing papers were released in a warm water bath with the aid of Corolase, a protease enzyme, and the paper underwent a final rinsing bath.

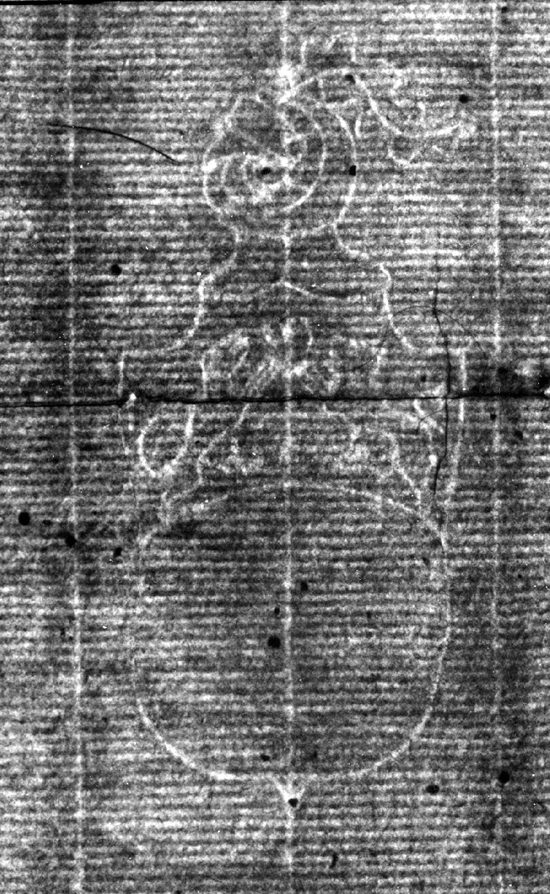

Five leaves had photographs and thickness measurements taken. Watermarks were documented with beta-radiography by the authors. The paper showed an average thickness increase of 1 mil (0.025 mm). The thickness of the 300-page book block increased by ca. 5/16 in. (0.8 cm) or 17%. The mold-damaged areas regained their original flexibility without feeling stiff (see fig. 27). The appearance of the paper in transmitted light remains unaltered, except where Japanese paper tissues were added to secure particularly weak areas during the splitting process (see figs. 28, 29). The surface texture of the paper was diminished during the process—a loss that one must anticipate and that will be acceptable for certain types of paper artifacts; as expected, the plate marks of the intaglio prints were flattened (see fig. 30). Some of the intaglio-printed pages were not split but repaired individually by the authors to demonstrate that the separate treatment of selected sheets within a given book is also a treatment option. The printed design on the recto and verso of one leaf shows the same alignment after treatment (see fig. 31). Small flaws in the splitting process can occur (see fig. 32). Beta-radiographs of watermarks taken before and after treatment under the same exposure and development conditions show that watermarks can still be documented after papers have been strengthened by splitting, provided they are perfectly aligned (see figs. 33, 34).

6 6. DETECTING PREVIOUS SPLITTING TREATMENTSWhether a sheet of paper was split in the past may not always be immediately apparent—especially if it was split to separate recto and verso, if the treatment was done flawlessly, if information on the original characteristics of the paper is not available, or if an untreated artifact of similar makeup is not available for comparison. Even in cases where splitting was done clumsily and signs of past manipulation are noticeable, the paper's appearance might still lead to puzzling questions, as the following example illustrates. A drawing by Alberto Giacometti (1901–1966) on Rives BFK paper arrived at the laboratory of Swiss conservator Florence Darbre Gubbins. It was lined with a Western paper and showed an odd band of discoloration on the front (fig. 35) (Darbre Gubbins 1999). In transmitted light, the paper revealed severe uneven skinning, the thinnest area of which corresponded to the area of discoloration on the front (fig. 36). The surface of the drawing showed residual adhesive accretions and a slight, unnatural cloth pattern. From these phenomena, Darbre Gubbins concluded that the paper had been crudely split in order to separate it from another design on the verso—a likelihood given that Giacometti is known to have worked on both sides of a sheet of paper. Darbre Gubbins removed the mounting by peeling part of the backing paper off while the print was lightly dampened, then wetting the paper and peeling off the remaining backing paper while the wet print rested on top of a black glass plate. She evened out the skinned paper areas by applying a large complex pulp fill to the sheet verso, using a dropper while working on a suction table and checking the fill over a light box. The aqueous treatment was also successful in removing the discoloration and improving the paper surface texture.

The splitting of this drawing—which has had the good fortune of now being expertly conserved—brings to mind Morgana's cautionary thoughts about paper splitting: “The procedure seems to be very easy to do, but in reality some problems might occur from carelessness” (Morgana [1932] 1994, 89). The treatment of the Giacometti drawing is, thanks to its careful description by Florence Darbre Gubbins, an instructive case study. It might inspire a closer reading of the older literature on paper splitting with attention to those procedural details that might cause changes in the appearance of treated papers. They may not always be immediately explainable and may not even be very obvious: The original surface of paper that was split may show:

Paper that was split in order to permanently separate recto and verso may show:

Paper that was split to strengthen it by insertion of a core paper may show: