ABRASIVENESS OF CERTAIN BACKING FABRICS FOR SUPPORTING HISTORIC TEXTILESLoERNA PALMER SIMPSON

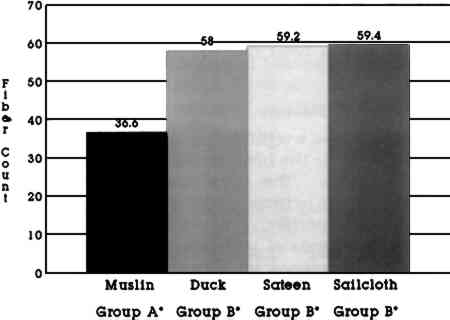

4 RESULTS AND DISCUSSION4.1 DIFFERENCES IN FACE AND BACK SIDES OF FABRICSTHERE WERE no significant differences in the number of fibers removed by the abrasive test for the face and back sides for the muslin, duck, and sailcloth fabrics, so the two sides were pooled for further statistical analyses. As anticipated, there were differences in the face and back sides for the warp sateen fabric. Therefore, the face side of the sateen fabric, which had the warp satin floats, was included individually in the analysis. The back side of the warp sateen fabric was eliminated from further analysis, since it was felt that this fabric would be chosen specifically to utilize the warp satin face. 4.2 EFFECT OF FABRICSignificant differences were evident for the four fabrics tested (fig. 3). The muslin fabric removed fewer fibers (36.6 fibers) than did the duck, warp sateen, and sailcloth fabrics (58.0, 59.2, and 59.4 fibers, respectively). The latter three fabrics were not significantly different from each other when analyzed by the REGWQ multiple range test.

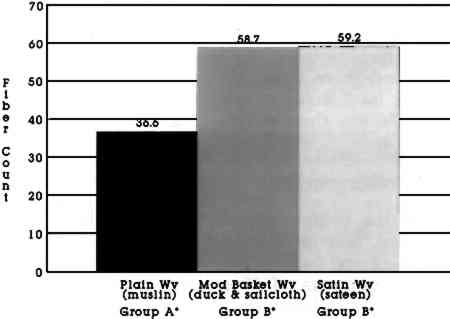

Because differences were noted for the muslin fabric when compared with the duck, warp sateen, and sailcloth fabrics, further analyses of the fabric construction characteristics were completed. Fabric weave and weight differences were investigated. 4.3 EFFECT OF WEAVE CATEGORY AND YARN INTERLACEMENTThere was one plain-weave construction, the muslin fabric. In the warp sateen fabric, each warp yarn floated over 4 filling yarns in a warp satin-weave structure. Both the duck and sailcloth fabrics were a modified basket weave, with paired warp yarns interlacing over and under each filling yarn. As shown in figure 4, the plain-weave fabric removed the fewest fibers when tested for abrasiveness (36.6 fibers), while the modified basket-weave fabric group removed significantly more fibers (58.7 fibers), as did the satin-weave fabric structure (59.2 fibers). The modified basket-weave and satin-weave categories were not significantly different from each other but were different from the plain weave. It was originally theorized that the satin weave, having the fewest interlacements of warp with filling yarns, would have the lowest abrasiveness rating, while the plain weave with the maximum number of interlacements would have the highest rating. Instead, the opposite was true. For these four fabrics, other factors appeared to be more influential on abrasiveness

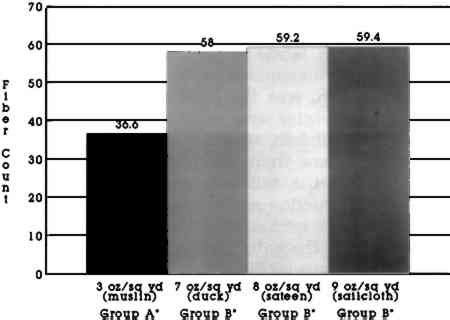

4.4 EFFECT OF FABRIC WEIGHTThe lightest weight fabric was 3 oz/sq yd (muslin), while the heaviest fabric was 9 oz/sq yd (sailcloth). The duck and warp sateen fabrics fell in between, at 7 oz/sq yd and 8 oz/sq yd, respectively. When analyzed by the one-way analysis of variance, there were significant differences in abrasiveness between the lightest-weight fabric and the other three heavier fabrics. However, the three fabrics weighing 7, 8, and 9 oz/sq yd were not significantly different from each other (fig. 5). The 7 oz/sq yd fabric was more than twice the weight of the lightweight fabric and did remove significantly more fibers in the abrasiveness test. However, the 9 oz fabric weighed three times that of the light-weight fabric (at 3 oz/sq yd) yet did not remove any more fibers than did the 7 and 8 oz/sq yd fabrics.

|