ABRASIVENESS OF CERTAIN BACKING FABRICS FOR SUPPORTING HISTORIC TEXTILESLoERNA PALMER SIMPSON

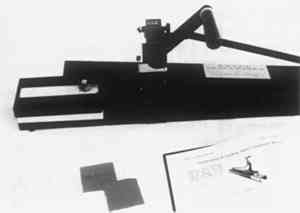

3 EXPERIMENTAL PROCEDURE3.1 EQUIPMENT AND PROCEDURETHE MODE of abrasiveness selected for study was the rubbing of fabric against fabric, while the measurement value selected was the number of loosened fiber particles transferred during rubbing. The crockmeter, a commonly used textile testing instrument, was adapted for this purpose. Buras and Harris (1983) had similarly adapted the crockmeter to produce linting of surgical fabrics. They had measured the weight of the transferred fibers on a sensitive analytical balance and made photomicrographs of representative transferred fibers with a scanning electron microscope. This researcher felt that such expensive equipment would limit the development of a simple, inexpensive test method that a conservator might use in a conservation laboratory. Therefore, it was decided to develop a simpler test procedure by counting the number of fibers transferred to the backing fabric specimens, using a readily available linen tester/pick glass. The crockmeter was selected as a modestly priced, readily available, and simple-to-use textile testing instrument. The crockmeter's primary purpose is to evaluate colorfastness to crocking, i.e., the rubbing off of dyes from a fabric surface onto another surface. In the colorfastness to crocking test, AATCC Test Method 8 (AATCC 1988), the dyed or printed fabric is mounted on a lower platform, and rubbed 10 cycles with a white fabric mounted on a peg in the upper rubbing arm. The degree of color that rubs off onto the white fabric is then rated against a color transference scale. For this abrasiveness test the crockmeter peg was covered in a brightly colored, napped 100% cotton fabric obtained from Springs Industry, and the backing fabric specimen was placed on the lower platform (fig. 1). The rubbing action of the peg (10 cycles back and forth) allowed fibers from the upper colored flannel fabric surface (simulating the historic textile) to be transferred onto the white backing fabric mounted on the lower platform. The standard design of the crockmeter incorporated the following features: with a complete turn of the crank, a flat 5/8 in diameter peg moved back and forth in a straight line along a 4.125 � 0.125 in track on the specimen surface with a downward force of 900 g (32 oz) on the peg.

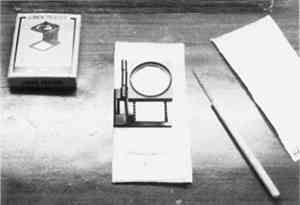

Although this method of fiber transfer was more accelerated than actual museum conditions would be, it was selected as an appropriate, fast test by which the abrasive action of the lower fabric surface might be studied. A 5 power linen tester with a 1 in square area was positioned over a centered template for viewing the transferred fibers, and a pick needle was used to assist in counting while scanning the representative 1 sq in

3.2 BACKING FABRICSFour backing fabrics from Testfabrics, Inc.—representative of backing fabrics used by textile conservators—were selected for initial investigation. The unbleached 100% cotton fabrics (table 1) included muslin, duck, sailcloth, and warp sateen. Fabrics with similar fiber content but different fabric weights and fabric constructions were deliberately selected in order to determine if the test method would show a measurable range of values. TABLE 1 Backing Fabrics Selected for Study The backing fabrics were pretreated by laundering, then specimens were cut and conditioned under standard testing conditions of 70�F and 65% RH before being evaluated by the abrasiveness test method. A description of these procedures follows. 3.3 PRETREATMENT OF BACKING FABRICSPretreatment of the backing fabrics was performed, based upon recommendations in the ASTM draft 53.702, “Standard Practice for Pretreatment of Backing Fabrics Used in Textile Conservation” (ASTM 1988). The fabrics were washed, rinsed, and dried three times, using a phosphate detergent that did not contain bleaches, enzymes, carbonate builder, or fluorescent whitening agents (AHAM Standard Detergent or AATCC Standard Detergent 124-W.O.B). This special detergent was selected in order to avoid adding substances to the fabric that might not be thoroughly rinsed out and might later damage and weaken fiber structures by reactions such as oxidation. The wash-rinse-dry cycles were completed in order to remove residual amounts of sizing and impurities remaining in the backing fabrics as well as to reduce relaxation shrinkage that might occur. Tortora (1987, 389) states that “the wetting of a fabric causes the tension that has been applied during the manufacture of the fabric to be relaxed, so that fabrics generally shrink after the first and up to the fifth laundering.” 3.4 SIZE AND NUMBER OF FABRIC SPECIMENSTwenty specimens, 2 �–by–6 in, were cut from each backing fabric, with 10 specimens for the face evaluation and 10 for the back evaluation. These fabric specimens were cut with the longer dimension (6 in) in the warpwise direction rather than on the true bias as had been done in a preliminary Both the face and back sides of the backing fabrics were tested. The muslin, duck, and sailcloth did not visually appear to be different from top to bottom side, so a face and a back side were designated arbitrarily. However, the nature of the warp sateen weave provided a warp float face side and distinctly different back side. 3.5 STATISTICAL ANALYSISThe first research question to answer was whether differences existed between the arbitrary face and back sides for each of the four backing fabrics. The t-test for independence was calculated, with significance set at .05 (SAS 1985). When differences did not exist, data from the two sides were pooled for further analysis. The one-way analysis of variance by ranks (SAS 1985) was used to measure the effect of fabric type on the number of fibers removed; if significant, the effects of fabric weight and fabric construction on number of fibers removed were also determined. Where significance was shown, the Ryan-Einot-Gabriel-Welsch multiple range test (REGWQ) (SAS 1985) was used to determine which fabrics differed significantly from the others. Significance levels were set at .05 for both tests. |