ADHESIVE QUALITIES OF CONSOLIDANTS FOR DETERIORATED WOODTOMOYASU SAKUNO, & ARNO P. SCHNIEWIND

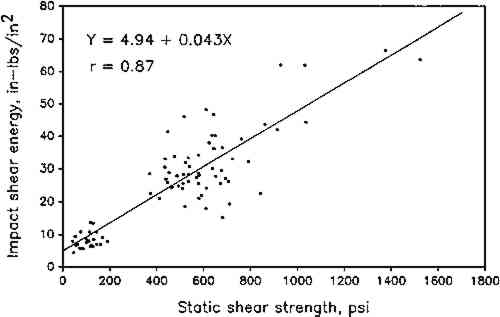

4 DISCUSSION4.1 THE ADHESIVE QUALITIES OF THE CONSOLIDANTSTHE BONDING properties or adhesive qualities of the consolidants can perhaps be evaluated best by comparing them with adhesives ordinarily used for wood. For this comparison a PVA emulsion adhesive was selected and used as the reference standard in this study. There was a significant difference between the bond strength of the consolidants and the PVA emulsion adhesive. This result can be attributed to two factors, both of which relate to the fact that the PVA emulsion adhesive was specifically formulated as an adhesive whereas the consolidant solutions were formulated with other objectives. In particular, consolidant solutions must have low viscosity to obtain optimum penetration, a quality considered undesirable for adhesives. Excessive penetration of an adhesive into In the case of series 2, B72 and AYAT exhibited very poor bonding qualities with the nonpolar solvent, whereas B98 with a mixture of polar and nonpolar solvent had equal impact bond strength and only somewhat reduced static bond shear strength as compared to series 1. Wang and Schniewind (1985) found similarly that B72 and B98 gave generally better strength improvement when used as consolidants in pure polar as compared to nonpolar solvents either pure or in mixture. It is possible that the relatively short time of one week between bonding and testing contributed to the differences in solvent performance, since toluene is known to be retained more tenaciously than other solvents, particularly by Acryloid B72 (Horie 1987). However, it is not believed that this quality can explain more than a fraction of the difference, especially considering that essentially the same results were obtained with both Acryloid B72 and AYAT. Several studies of the effectiveness of consolidants for deteriorated wood in terms of their strengthening capability have ranked Butvar B98 first, followed in order by Acryloid B72 and AYAT (Grattan 1980; Schniewind and Kronkright 1984; Wang and Schniewind 1985). In the present study B98 also performed best in adhesion as measured by impact test, while all three resins had about equal adhesive qualities as measured in static shear test, provided that polar solvents were used. In terms of adhesive qualities, it therefore appears that the most important choice to be made is that of solvent; the choice of resin is secondary. The results of bond tests and strength tests of consolidated wood will not necessarily be the same, since effective strengthening depends not only on adhesion but also on the cohesive strength of the resin. The latter differs substantially among the three resins studied here, with B98 showing the greatest cohesive strength (Schniewind and Kronkright 1984). 4.2 THE EFFECT OF ADHEREND PROPERTIES ON BONDING STRENGTHThe energy absorbed in impact shear by sound Douglas-fir wood was found to range from 48 to 76 in-lb/in2, and for sound wood bonded with PVA emulsion adhesive from 58 to 72 in-lb/in2. The maximum static shear strength parallel to the grain of coast type Douglas-fir is 1130 psi when dry at a mean specific gravity of 0.45 (based on green weight and volume) (Forest Products Laboratory 1987). By comparison, the deteriorated Douglas-fir piles used in this study had specific gravity values ranging from 0.33 to 0.45 (table 2) for the outermost 1-in layer. At the surface where bonding was effected, the specific gravity was most likely even lower than the reported values, since the deterioration progresses from the outside inward. The particular density of each pile is a function of both natural variability and mass loss because of deterioration. Sakuno and Goto (1969) found that the density of wood significantly affects both the static block shear strength and absorbed energy in impact shear. In this study the same trends were obtained for the PVA emulsion adhesive and also when results were averaged over all seven treatments. Since at least part of the observed specific gravity variation is due to deterioration, the condition of the wood will have an important effect on the bond strength that can be achieved. The greater the mass loss due to deterioration, the lower the bond strength will tend to be. However, when used as consolidants, the resins studied are more effective 4.3 CORRELATION BETWEEN ENERGY ABSORBED IN IMPACT SHEAR AND STATIC SHEAR STRENGTHSakuno and Goto (1973) found that there was a highly significant correlation between energy absorbed in impact shear and static shear strength of wood bonded with various types of adhesives. All of static shear strength and impact shear energy data of series 1 and 2, averaged over three (or two where applicable) replications, were plotted against each other, as shown in figure 6. A high correlation coefficient of 0.87 was obtained. This result implies that whichever test is conducted, the value of the other can be estimated from the regression equation.

|