TECHNICAL EXAMINATION OF RENAISSANCE MEDALS THE USE OF LAUE BACK REFLECTION X-RAY DIFFRACTION TO IDENTIFY ELECTROFORMED REPRODUCTIONSGlenn Wharton

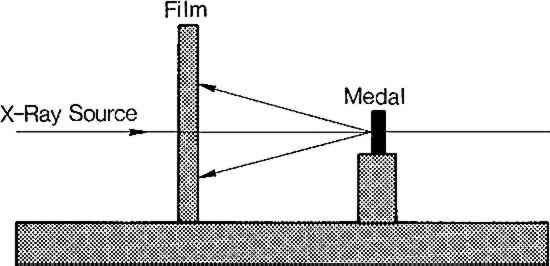

4 THE USE OF LAUE BACK REFLECTION X-RAY DIFFRACTION TO IDENTIFY ELECTROFORMED REPRODUCTIONSTHE LAUE METHOD of X-ray diffraction is commonly used to determine orientation within a single crystal.13 Normally a beam of “white” radiation is directed into the crystal which diffracts the X-rays onto a recording film. The pattern of spots which appear on the photograph indicates the crystallographic orientation of the specimen. Laue photographs can also provide information on the grain size and the actual composition of polycrystalline metal, although they are less commonly used for this purpose.14 In this study, a flat-plate camera was used with a collimated beam of monochromatic X-rays (nickel filtered copper Kα, 1.54�) in the back reflection mode.15 As depicted in Figure 5, the incident beam of X-rays passes through the center of the film to the medal surface, where it is diffracted back onto the film. The medals were placed three centimeters from the film, which was contained in a Land Diffraction Cassette. The exposure was a standard fifteen minutes at thirty-five kilovolts and fifteen milliamps. Other details of the experiment have been included as a footnote.16

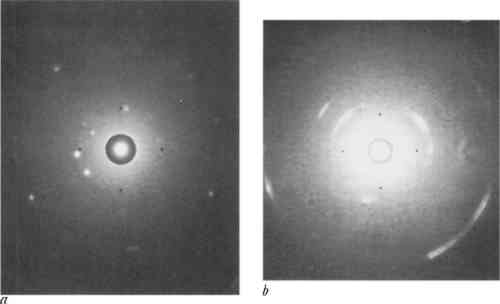

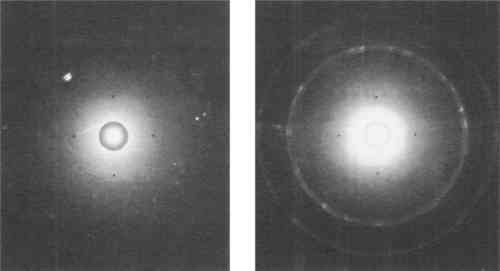

The number of spots which appear on the film corresponds to the number of grains which have diffracted X-rays. The number of grains which take part in this diffraction depends on their size, the diameter of the incident beam of X-rays, and its actual depth of penetration.17 This depth is often no more than about twenty-five micrometers, which in some cases represents only the surface layer of grains.18 As indicated in Figure 6, with a decrease in grain size, there is a corresponding decrease in size and increase in number of spots on the Laue photograph. When the grain size is relatively coarse, as in cast and struck medals, X-rays are diffracted in only a few directions, and the Laue photograph consists of several large spots. Grains in struck medals which have been deformed by blows from the die produce elongated Laue spots, as seen in Figure 6b. A fine grained electrotype will produce a photograph with many more and much smaller spots. These minute spots may be too small to be distinguished on the photograph. In this case they merge to form continuous “Debye ring” patterns (Fig. 6), which will be discussed in the final section.

During the course of this research it became evident that the grains in an electrotype are often smaller on the front surface than on the back surface. This phenomenon

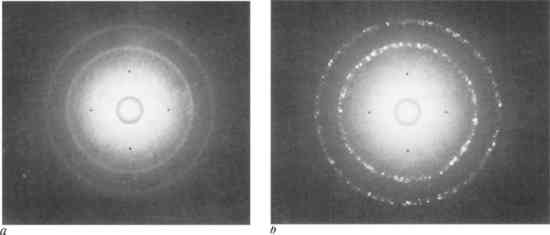

This variation in grain size will correspondingly produce different numbers of spots on Laue photographs. Figure 8a represents a typical Laue photograph from a copper electrotype, with a solid ring formation. However, the reverse of the same electrotype, where the grains were larger, yielded a somewhat spottier ring formation (Fig. 8b). Because of this difference in grain size, it is best to test the medals on the obverse whenever possible.

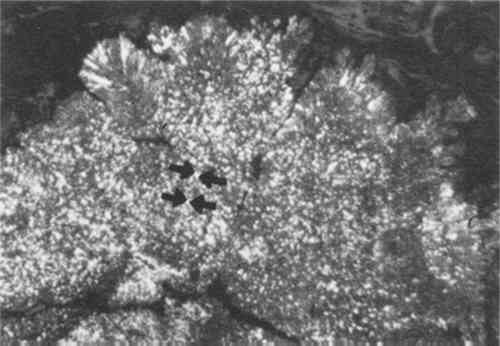

To better understand the effects that surface treatment has on Laue photographs, a variety of tests were performed on electroformed copper, and cast copper, silver and bronze medals. They were pickled, annealed, polished, sanded with six-hundred grit carborundum paper, and filed. Laue photographs were taken before and after these processes. The photographs from copper and bronze medals were only altered by filing. This harsh treatment distorted the grain boundaries, and a blurred but solid ring pattern was produced (Figs. 9a and 9b). The Laue photographs from the silver medals exhibited differences even after light sanding, since silver is a softer metal (Figs. 9c and 9d).

This study also showed that heat normally used in chemical patination or in soldering will not change the appearance of the Laue photographs. This is to be expected since the grain size of unstrained metal is not altered until the higher temperatures of secondary recrystallization of each metal is reached.19 Lightly polishing the surface will not affect the test results either. Yet if the medal has been chased, filed or in the case of silver, even lightly sanded, the patterns on the Laue photographs will be altered. Thus it is necessary to take readings from areas which have not been cold worked. It was also found that chemical patination affected the Laue photographs. To examine a medal beneath a patinated surface, it was necessary to remove the patina from an area about two millimeters in diameter. This is of course unfortunate, since the patina on most museum quality medals must remain intact. Often the patina is worn in areas of high relief however, which may expose enough of the metal surface to obtain a Laue photograph. |