REPAIR OF A SIDE CHAIR WITH PERFORATED PLYWOOD SEATWalter Angst

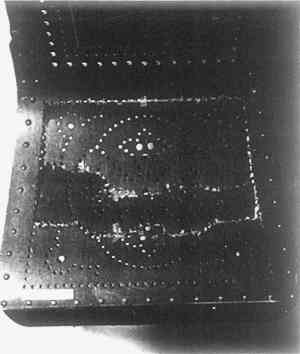

1 EXAMINATIONTHE 410 MM HIGH Renaissance revival side chair has slender turned legs, six stretchers, and a back and seat of 3-plywood1 bent to follow the direction of the curved seat rails. Besides being glued to the rails, the seat is also fastened with a row of nails at its edge and two clusters of seven nails at the steepest curve, where the seat bends into the back. Two nails of the cluster on the proper left side are replacements (of a larger size), and one nail on the opposite side is missing. Both seat and back are perforated with holes of varying sizes. The back is also decorated with a (stable) painted floral design. The sides of the back legs, the fronts of the front legs, and the cresting are ornamented with incised gilded lines. As viewed from the top, the seat appears to be broken along the outermost row of holes in the back, along both sides, and across its width; one irregularly shaped oblong, about 55–95 mm in width, is actually separated. The back-part of the seat, ca. 320 � 200 mm, is still partially attached but has caved in along a jagged central fracture line, forming two separate pieces. Obviously, the seat has been pushed downwards with great force (Fig. 1). The two pieces of plywood are now arranged in two separate planes and need to be aligned before they can be rejoined. The plies have separated and some 25 areas of the top layer, varying from 10 � 5 mm to 20 � 15 mm, are splintered-out and are missing. Two roughly triangular areas, 20 � 6 mm and 40 � 25 mm, respectively, are completely broken through and missing. The outermost rows of holes in front and back are only cracked.

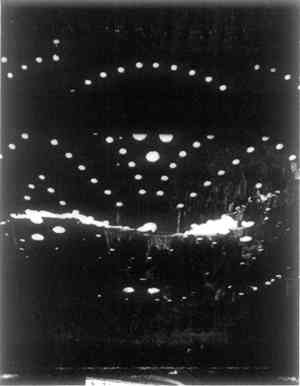

As seen from underneath, (Fig. 2) it appears that the seat has been previously repaired. Originally attached to its underside with moldings and brads, but now torn loose, is a second piece of perforated plywood which extends the width of the seat inside the rails, and reaches ca 200 mm in the other dimension. This sheet of plywood is now bulging in a tented curve. Of the moldings, only a few broken parts remain. By noting differences in color of the stain on this piece, on the back side of the back, on the underside of the seat, and on the inside of the rails, it is concluded that this added section of plywood never extended over the entire seat. It could have been an

With the Curator's permission, this reinforcing piece was removed so that the condition of the broken seat could be investigated. Examination of the two surfaces under 16 dia. magnification revealed the following: The underside of the actual seat is rough, water stained, having many patches and runs of what appears to be hide glue, and is variously discolored with wood stain. Some of its missing segments are stuck to the corresponding surface of the removed reinforcement piece. The surface of the underside of the actual seat, where it has not been covered by the reinforcing piece, is markedly lighter, with a quite different texture, as if it had been scratched in a regular cross-hatching pattern, possibly in preparation for applying adhesive to that surface. The inside of the reinforcement piece is smooth, finely coated with what seems to be hide glue, dirty, and darkened towards its back edge. This edge might have been stained and varnished, or it might have been simply a glue joint. A dark reddish discoloration spreads around each hole, probably seepage of stain from above. Stuck to the side of the reinforcement piece are three large pieces and innumerable tiny fragments torn from the underside of the seat's surface. Around each hole are accumulations of white and black fibers and dust particles. Two further facts support the assumption that this piece had been added to the chair as a repair. It was found that the periphery of virtually every single hole in it was broken out in varying degrees at the (finished) bottom side, indicating that these The repair of this seat posed a serious problem. Since the nature of the irregular fractures is such that the various layered pieces deeply interlock in different planes and different directions and have to be carefully flexed into place, any adhesive applied before a part is joined will not only prevent visual guidance of the operation, but actually interfere with the delicate fitting. It was therefore proposed that the breaks be joined without adhesive, and the glue injected afterwards with a hypodermic needle. This required that the adhesive be (in order of importance):

In an attempt to satisfy the criteria listed above, the literature was searched (see Bibliography, Appendix A). It was found that of all the adhesives suitable for this job, those PVA emulsions4 enumerated in Table I seemed most promising. They were preferred over:

TABLE I RATING OF ADHESIVES FOR BONDING WOOD, ACCORDING TO THE SIX CRITERIA STIPULATED FOR THE REPAIR OF THE “PERFORATED CHAIR” (see Text) Only those adhesives were considered which are intended for bonding wood (ndoor application). Four PVA emulsions marked with an asterisk (not mentioned by Shields) are known to CAL, but only one: Elmer's Glue-All—appears to have been used for bonding wood. It must be emphasized that these are strictly theoretical considerations: the joints on the objects, for all practical purposes, will be irreversible. Given their meandering indentions overlapping in both planes and in three plies, they cannot be pulled apart without breaking the seat once they have been properly glued—no matter what kind of (redissoluble) adhesive is used. To see just how much Titebond might shrink upon drying, a film of adhesive about 0.5 mm thick was spread on a metal ruler. This glue area, measuring 52 � 11 mm, was found to have dried within 30 minutes to an island of 18 � 3 mm, but leaving a thinner film uniformly covering all of the original area. Within the first 10 minutes, this drying was about 2 mm from all sides. Drying continued at about the same rate, but irregularly, until within 40 minutes the whole area was uniformly coated with the dried glue, which, measured with a micrometer, registered a thickness of 0.127 mm after 2 hours. It was felt that this degree of shrinkage could be compensated by appropriate amounts of glue being added during the course of the injection. It was not felt that the yellow color of Titebond, which might intensify with age, would interfere with the brown color of the finished plywood. It is often difficult to determine which factors that affect a glue bond and its aging are the most important, as they become intermingled in practical use. In this case, it appeared that the nature of the fractures, an interlocking, extremely variable system of indentations, was determinant. Therefore, the following test was made. A piece of plywood 120 � 70 mm and 3 mm thick was broken in half, and the irregularly-indented fracture fitted together, leaving a 1 mm-wide gap to simulate The glue set within 15 minutes, but the glue line, which had been filled even with the surface, shrank to a depth of ca 1 mm. Half the length of the break line was therefore injected a second time. Since the glue receded again, a third application was made along about one-third of the total glue line, remaining as an overfill. This dried initially to an approximate evenness with the surface. The bond thus achieved was amazingly strong, even though only a third of the glue line had been filled. It withstood a bending stress comparable to that applied earlier to break the wood. After 1� hr, this third application of glue produced a line that was only slightly recessed. Titebond, to which fumed silica10 (2 g M5 fumed silica to 3 g Titebond) had been mixed, was then smeared with a spatula into the part of the joint that had been injected only once. Examination under 16 and 40 diam. magnification showed that this approach gave the best result: the glue line was still roughly even with the surface after 18 hours. Part of a piece of purportedly 5-year-old stone-hard Titebond adhesive was wetted with four drops of deionized water, and after a half hour, the glue could easily be scraped off with a fingernail. Upon total evaporation of the water, the adhesive became hard again. The curator decided to have the gaps of missing plywood filled in and perforated, and various broken-out areas touched up with color. She agreed to have a support under the seat if needed, but not to reuse the piece removed, which was returned to her. |