THE EFFECTS OF LIGHT EXPOSURE AND HEAT-AGING ON SELECTED QUILTING PRODUCTS CONTAINING ADHESIVESJanet Evenson, & Patricia Cox Crews

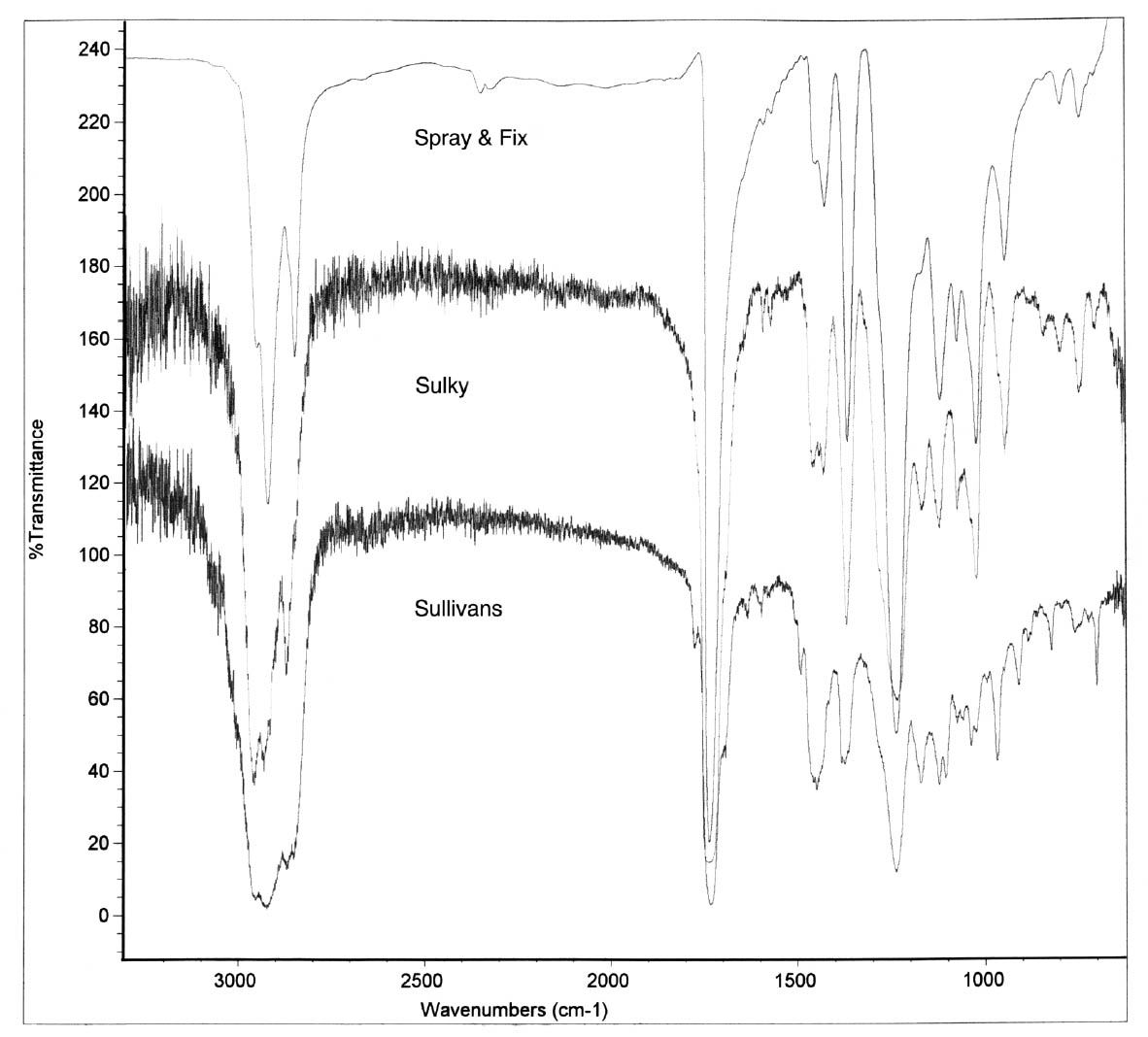

2 MATERIALS AND EXPERIMENTAL METHODS2.1 MATERIALSQuilt-basting sprays have been available for some time and are used to temporarily bond the top and backing layers to the batting in lieu of pin or hand basting. The adhesives in these sprays are dissolved in a solvent; when the solvent evaporates, it leaves behind the solid adhesive that bonds fabric to batting with pressure. The chemical constitution of these quiltbasting sprays is proprietary. Most brands proclaim their adhesives to be colorless, nontoxic, nonstaining, and acid free, and to have little or no odor. Sulky brand claims “bonding will disappear in 2–5 days.” Sullivans' labeling information asserts its adhesive spray “has a non-permanent bond which is repositionable,” and upon washing it will be “completely removed.” The Spray and Fix label claims that it is “colorless, stainless” and “acid free.” While the adhesive bond may dissipate over time, the adhesive compound will not disappear. In addition, the adhesives may be water-soluble as claimed during the first few months after application, but it is unlikely that they will remain water-soluble indefinitely. Therefore, unless the quilt is laundered soon after completion, it seems likely that the adhesive spray will eventually cause discoloration of the fabrics. Fusible webs have been available for more than 30 years and are used for appliqu� techniques as well as for “basting” fabric to batting. The adhesives in fusible webs activate when heat is applied, thereby bonding fabric to batting. Stitch Witchery, developed and trademarked in 1969, is a polyamide polymer, which patent records describe as a “thermally activatable adhesive in net form” (Stitch Witchery 1969). Pellon's Wonder-Under is another polyamide polymer commercially available since 1986 (Wonder-Under 1987). Polyamide polymers are known to be particularly susceptible to photo-oxidation from ultraviolet light and heat (Smith 1983). HeatnBond, available since 1989, is a mixture of polyvinyl alcohol (PVOH) polymers, resin, and a tackifier, according to the company (Scott 2002). PVOH in its pure form has been used for conservation treatments for many years. However, it is known to stiffen over time (Timar-Balazsy and Eastop 1998). Fusible battings, coated with a heat-activated resin, “baste” the fabric to the batting when ironed in place and are another option for eliminating traditional basting. Fusible battings have been around since 2001 (Repp and Yogerst 2001). As with the quilt-basting sprays, the adhesive resins used in fusible battings are proprietary. 2.2 EXPERIMENTAL METHODSThe resistance of temporary-bond adhesive sprays, fusible webs, and fusible battings to light and heat was evaluated in this study. Fabric assemblies were constructed using the three categories of adhesive-containing products and cotton muslin (Testfabrics Style 400M) as the top layer, and cotton batting (Hobbs Heirloom bleached) as the bottom layer. The two layers were bonded together with each of the adhesive sprays or fusible webs. Fusible batting fabric assemblies differed from the others in that, because adhesive is applied to both surfaces of the batting, the fusible batting was sandwiched between two layers of cotton fabric. Two sets of controls were prepared without adhesive products. One set (control C) contained a top layer of cotton muslin stitched to cotton batting (Hobbs Heirloom bleached). This control was used for the adhesive sprays and the fusible webs. The other set contained a layer of nonfusible batting sandwiched between two layers of cotton muslin and stitched together to provide a control for the fusible battings. Control-C2 contained cotton batting (Hobbs Heirloom bleached), and control-P2 contained polyester batting (Stearns Mountain Mist). Three replicate sets of materials were prepared and evaluated. 2.3 ADHESIVES ANALYSISThe University of Nebraska's Department of Chemistry Research Instrumentation Facility was enlisted to identify the chemical classification of the adhesives used in the products being tested. Fourier transform infrared (FTIR) spectroscopy was employed to determine the chemical classification of the adhesive sprays. A Nicolet Avatar 360 instrument with a Spectra-Tech horizontal attenuated total reflectance (HATR) accessory was used for the analysis. Specimens were prepared by spraying each commercial adhesive product directly onto a zinc selenide ATR plate and allowing the adhesive

Archival-quality PVAC is one of the most light resistant of the solvent-based adhesives. In addition, it does not appreciably cross-link or degrade in air and in some formulations remains soluble in an alcohol-water mixture after more than 30 to 40 years (Horie 1987). It has been used in conservation treatments since the 1930s (Himmelstein and Appelbaum 1977; Smith 1983; Horie 1987). Nevertheless, it has a number of negative properties; it is “inflammable, toxic, foul-smelling and expensive since you … throw over half the bulk away by evaporation” (Smith 1983, 49). In addition, PVAC becomes brittle as it ages, owing primarily to loss of solvent (Smith 1983). Composition of the thermoplastic polymers constituting the fusible webs was corroborated using fiber solubility tests rather than infrared or nuclear magnetic resonance (NMR). American Society for Identification of the adhesives used in the fusible battings proved more challenging because they were applied in such a thin layer. FTIR spectroscopy (Nicolet Avatar 360 instrument) and proton nuclear magnetic resonance using a Bruker Avance 500 MHz instrument were employed in an attempt to determine the chemical classification of the adhesives used in the fusible battings. The results were inconclusive. Given the wide range of thermosetting resins available and constraints on resources, it was not possible to conclusively identify the chemical class of the adhesives. The adhesive compound incorporated in the June Tailor batting looked visually different from the adhesives used in the Hobbs Heirloom and Mountain Mist fusible battings. The June Tailor adhesive appeared as fine, golden-colored strands throughout the batting. By contrast, the adhesives applied to the Hobbs and Mountain Mist fusible battings were white and were applied in a thin, fairly uniform layer across the surface. We speculate that acrylic resins may have been used in the Mountain Mist and Hobbs battings. Acrylic polymers are increasingly being selected for a variety of applications in the coatings industry because of their improved flexibility compared to polyvinyl acetate emulsions (Lombardi and Gasper 2001). Selected acrylic resins are used in thermosetting adhesives and are known to be extremely resistant to degradation by heat and light (Horie 1987; Lombardi and Gasper 2001). In addition, the newer low-temperature curing types of acrylic adhesives can be designed to have activation temperatures anywhere between room temperature and 90�C (Lombardi and Gasper 2001). 2.4 LIGHT EXPOSURE AND HEATAGINGTo determine whether quilting materials containing adhesives would yellow, weaken, or stiffen over time, specimens cut from the fabric assemblies were exposed to heat or light. Light exposure tests were conducted according to American Association of Textile Chemists and Colorists Procedures (AATCC 2001a). An Atlas Ci65A Xenon Weather-o-meter with soda lime filter was used to simulate sunlight through window glass. Specimens were exposed to either 40 or 80 AATCC fading units (AFUs) of light because selected household textiles (e.g., draperies) are expected to withstand 40 AFUs of accelerated xenon light exposure, according to voluntary industry guidelines. Textiles capable of withstanding 80 AFUs of light without fading exceed most voluntary performance specifications. Heat-aging was conducted according to a protocol described by AATCC (2001b). Specimens were aged in a VWR forced-air oven, model 1350M, at 275 + 4�F (135 + 2�C) using water to create steam. The specimens were exposed to either 6 or 36 hours of heat-aging because conservation scientists have equated 7 hours of aging at 140�C to a life span of approximately 20 years, and 36 hours of aging at 140�C to a 100-year minimum life span (Feller 1994), the expected life span for an heirloom. This AATCC test method was selected as it is a proven protocol for accelerated heat-aging of textiles, and the conditions used in this study were similar to those described by Feller (1994) in aging tests for conservation materials. 2.5 EVALUATION OF COLOR CHANGE, BREAKING STRENGTH, AND STIFFNESSFollowing light exposure or heat-aging, changes in color, strength, and stiffness were measured. Color change was evaluated using a HunterLab UltraScan XE diffuse/8� spectrophotometer according to AATCC (2001c) specifications. An illuminant D65/10� observer was used to calculate the colorimetric values. Total color change (� E) was calculated using the CIE 1976 L*a*b* equation. Three measurements were performed per specimen. Because there were three replicate specimens, the mean color difference Warp-breaking strength was measured using an MTS Qtest/10 materials testing system according to ASTM (2001b) standards. The 2.5-cm. cut strip option was followed. Flexural rigidity of the fabric assemblies following light exposure or heat-aging was determined according to the ASTM (2001c) standard cantilever test using a Drape-Flex Stiffness Tester. Color difference, percent change in breaking strength, and changes in flexural rigidity were assessed by analysis of variance (ANOVA) procedures. When ANOVA procedures showed that an independent variable had a significant effect, Tukey's post hoc mean comparison tests were performed to ascertain where statistically significant differences in means were located. |