EFFICIENT NEW METHODS FOR EMBEDDING PAINT AND VARNISH SAMPLES FOR MICROSCOPYMELVIN J. WACHOWIAK

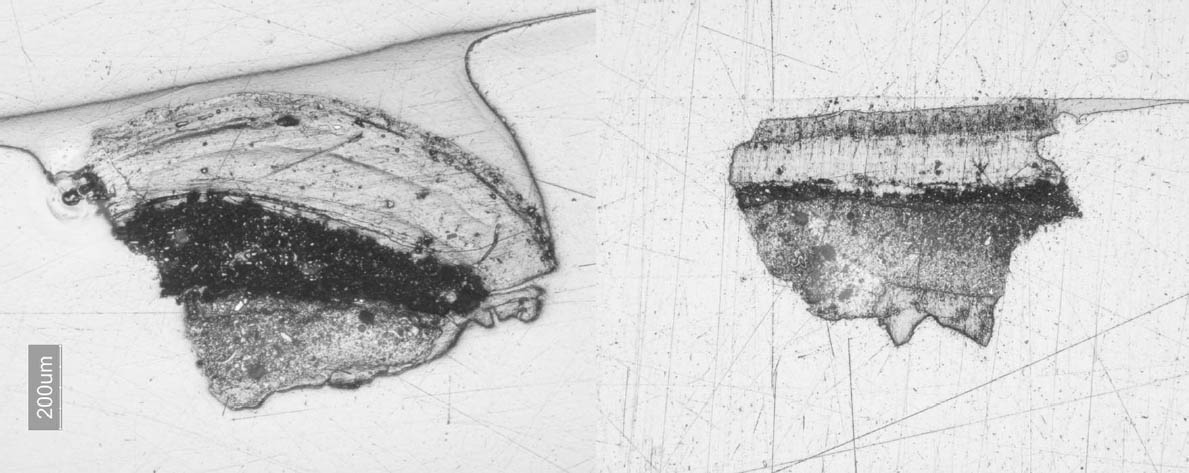

1 INTRODUCTIONBeginning more than 150 years ago with natural resins such as Canada balsam, scientists have refined procedures for microscopical preparation of various materials. Paint and other coating materials have been embedded for at least a century, in the beginning with natural resins and waxes (Laurie 1914). The shortcomings of these natural plastic media were partially overcome with mid-20th-century use of Successful embedding of paint and varnish samples can be defined as implementing appropriate and efficient means to preserve and reveal the microstructure of the area of interest sampled. Selecting the appropriate combination of materials and techniques for unknown samples requires experience on the part of the analyst. This situation is different from an industrial or academic perspective, in which materials are often well known beforehand. At the outset of conservation studies, the physical and chemical properties of the materials in the cross section are often unknown. The embedding process and preparation procedures should therefore be well defined and reproducible and work in practice for most materials. Bousfield (1992) is an excellent source of guidance on this point. In common practice, optical microscopy may be followed by electron microscopy. All preparation outlined below is to the standard of electron microscopy: the microstructure is preserved at high magnification, and the sample is all in the same optical plane. Using the methods and materials described below, samples can be prepared to this standard at the rate of two minutes per sample (fig. 1). The analyst must determine the relative value, but the cost of new materials is low compared to the time saved. For example, the first holders for four samples were produced for under $100. Many benefits derived from the development of the high-volume procedure were applied to a simple system for hand preparation of small numbers of samples, described in appendix 1 (fig. 2).

For the balance of this article, it will be assumed that (as is most often the case with coatings) the nature of the sample dictates embedding. Samples are often very small, porous, and friable, and their outer edges need to be retained for microscopical observation. A sample or area of interest can certainly be investigated without embedding. For instance, a cross

Mounting materials, methods, and preparation techniques should not limit analysis of paints and varnishes. The choice should be guided by the need to exploit the optical microscopy contrast techniques available. Singly or in combination, bright-field, dark-field (with and without cover glass), fluorescence, and transmitted light can be very revealing in our studies. In fact, methods and materials should only enhance our analysis and increase our efficiency, if possible. Some industrial epoxy resins not specifically formulated for microtomy or even polishing seem well suited to our task. The epoxy resin Tra-Bond 2113, made by Tra-Con, meets the selection criteria for conservation studies and criteria of Waentig (1993) and Derrick et al. (1994) (although not tested for microtomy). It is available in efficient, premeasured packaging that promotes reliability and reproducibility. The preparation techniques described below allow for systematic production of samples that can be easily monitored during the process and can be used in all optical contrast techniques. |