EVALUATION OF CLEANING METHODS FOR THE EXTERIOR BRICK AT THE BROOKLYN HISTORICAL SOCIETYCLAUDIA KAVENAGH, & GEORGE WHEELER

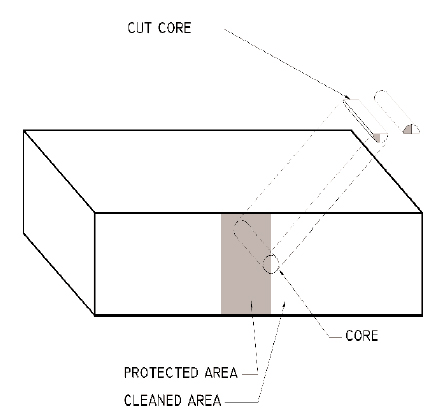

4 ASSESSMENT OF CLEANING METHODSOnly two products resulted in the removal of significant amounts of soiling: Bac2Nu, an ammonium bifluoride–based cleaner, and Restoration Cleaner, a hydrofluoric acid–based cleaner. After drying, a light white haze was observed on portions of the surface of the brick cleaned with Bac2Nu; it is likely that the chemical cleaner attacked the silica component of the brick and redeposited some of it onto the surface of the brick (Matero and Bede 1992, 37). The brick cleaned with Restoration Cleaner more closely matched the color of the brick face that had not been exposed to the weather and had no white haze. Further evaluations were performed to determine the effect of the cleaning methods on the brick. 4.1 EXAMINATION OF CROSS SECTIONSTo evaluate the effects of the cleaning materials and methods on the surface of the brick, the center third of each of three bricks was coated so that these areas would not be affected by cleaning2 (Mossotti et al. 2002) (fig. 8). The exposed surfaces of the three bricks were then cleaned using the following three methods: Brick One Restoration Cleaner, diluted 1:5 in water and mixed with Carbopol 940. Dwell time of 5 minutes. Two applications.

Brick Two Bac2Nu, mixed with Carbopol 940. Dwell time of 10 minutes. Two applications.

Brick Three

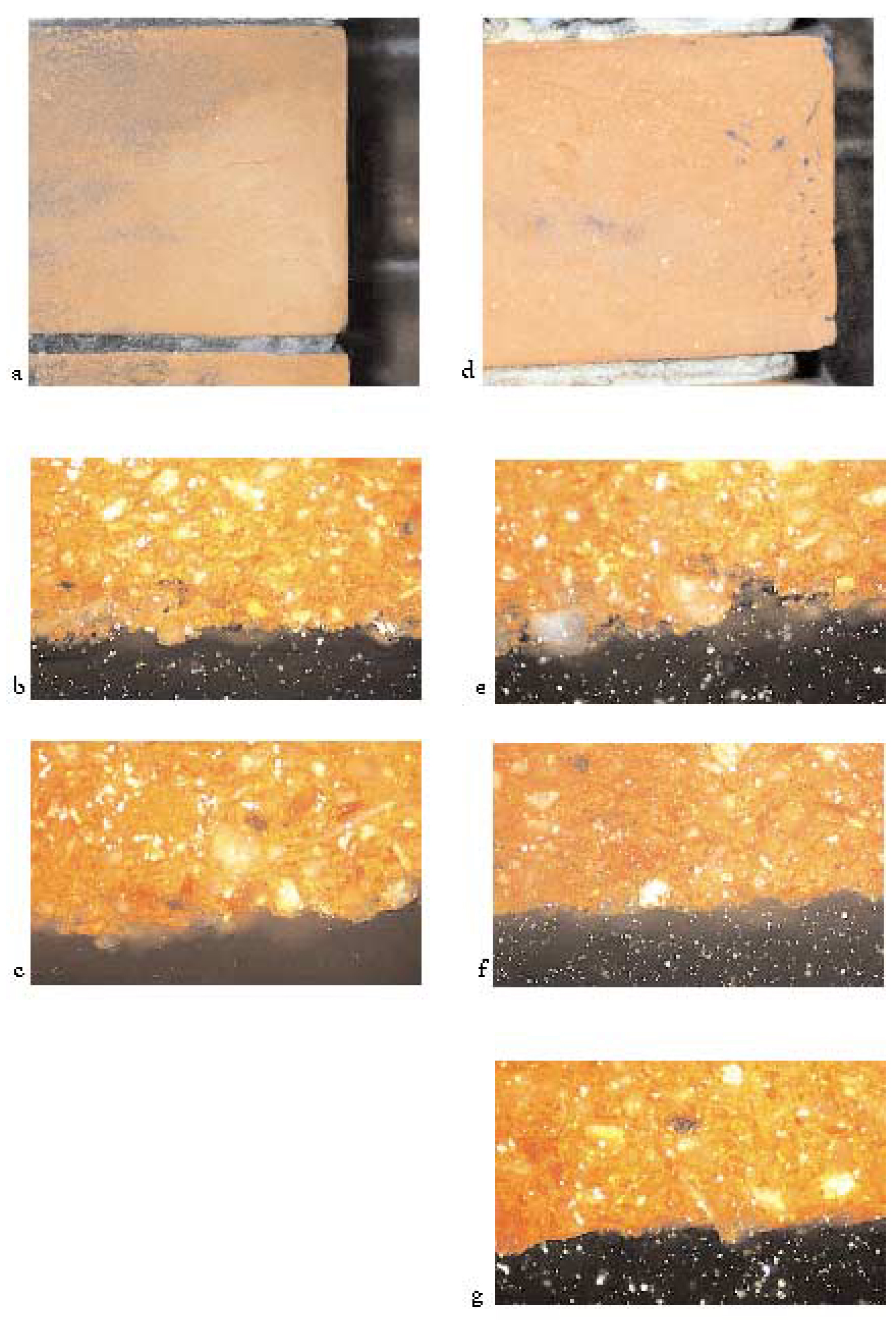

At the completion of the cleaning tests, the bricks were removed from the wall, and a series of 3/4 in. diameter cores were extracted. Each core was centered over the dividing line between the cleaned area and the protected area, so that one-half of each core was cleaned and one-half of each core was uncleaned. Each core was then split lengthwise so that the surface of the brick could be viewed in cross section, thus allowing for a direct comparison of cleaned and uncleaned surfaces (fig. 9). In addition, a core was removed from the back face of one brick to represent an unweathered, unsoiled, and uncleaned surface of the brick. Samples were viewed in reflected light at 25x magnification, using a Zeiss Axioplan II microscope. As can be seen in figure 10 (see page 73), the back of the brick (g) has a somewhat uneven and slightly rough surface with few openings or crevices observed. The uncleaned surface of each brick face that had been exposed to the weather was much

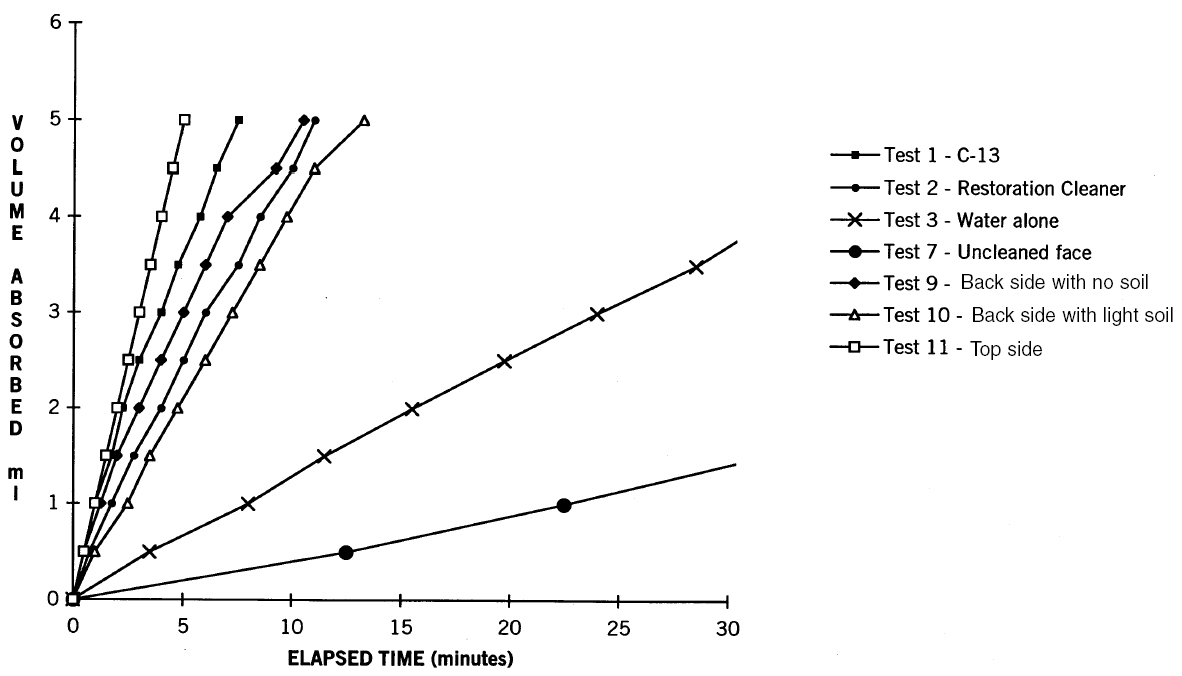

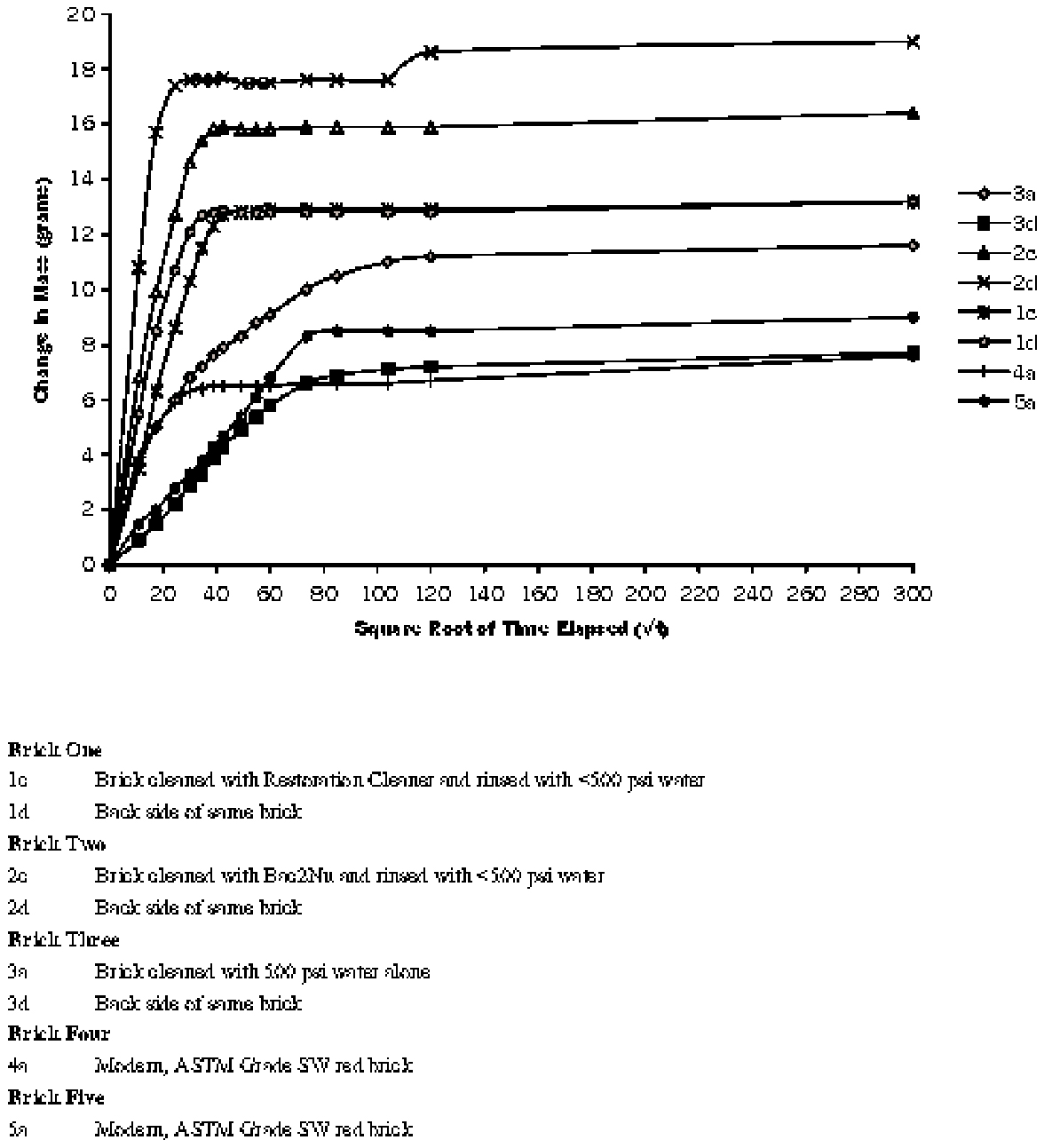

4.2 ABSORPTION TESTINGTests were performed on the brick to determine changes in this property brought about by different cleaning methods. Face brick were removed from the wall to perform the tests. The brick had little to no mortar adhering to the inner surfaces. Mortar remnants were soft and were easily removed from the surfaces. 4.2.1 RILEM Test Method No. II. 4R�union Internationale des Laboratoires d'Essais et de Recherche sur les Mat�riaux et les Constructions (RILEM) Test Method No. II. 4 (Gale 1989) (commonly referred to as the pipe method) was performed on soiled, weathered faces of brick, on the top side of bricks, on the back side of bricks (to simulate as closely as possible the condition of the brick when it was initially installed in the wall), and on representative cleaned surfaces. The RILEM test is a comparative method that measures the rate at which water is absorbed through the surface of a masonry element. A high-quality modern-face brick, graded SW (severe weathering) by ASTM standard C62 (ASTM 1996) to withstand harsh winters, will absorb little to no water over an extended period of time. On one uncleaned brick surface, 5 ml of water was absorbed in 26 minutes and 30 seconds, and on another test brick, the test was halted after one hour and 46 minutes when only 4 ml of water had been absorbed. In comparison, tests on the back side of 4.2.2 ASTM C67To further evaluate the effect of the cleaning methods on the absorption properties of the brick, the American Society for Testing and Materials (ASTM 1996) C67 Initial Rate of Absorption test was performed.3 The tests were performed on samples removed from the cleaned brick, from the back side of the same brick, and from the two different modern bricks. The rate of uptake of water for the brick cleaned with water alone was similar to but somewhat higher than for the back side of the same brick and similar to the two ASTM-standard bricks. Most important, uptake rates for chemically cleaned brick closely resembled those for the unweathered back sides of the same brick (fig. 12).

4.3 MOBILIZATION OF GYPSUMTo determine the amount and distribution of gypsum present in the brick before cleaning procedures were carried out and to ascertain whether or not the cleaning process mobilized gypsum, full-size bricks were removed from several locations on the building, including one that had been cleaned using Restoration Cleaner. Cores were removed from the bricks and sliced into sections. Each slice was weighed, then immersed in a measured amount of distilled water to produce a constant weight/weight ratio of brick to water. Conductivity measurements to determine salt content were made using an Accumet 50 pH/conductivity meter. Cores removed from the cleaned brick had significantly higher concentrations of salts at the surface (figs. 13–15) Microchemical tests also confirmed that these salts contained calcium and sulfate ions.

To determine if salts could be identified and subsequently removed by in situ poulticing, small-scale poultice tests were carried out on-site. For comparison purposes, poultices were applied at three locations each for soiled brick, brick cleaned with Restoration Cleaner, and brick that had been repointed and then cleaned with Restoration Cleaner. At each of the nine test locations, sterile cotton batting was submerged in distilled water and then placed firmly over an area approximating the size of one brick. The batting was covered with polyethylene sheeting, which was taped at the edges to retard evaporation. The batting was removed after 24 hours and brought to the laboratory, where conductivity measurements were made as described above. At soiled brick locations, conductivity readings ranged from 37 μs/cm to 61 μs/cm. At cleaned (but not repointed) brick locations, readings ranged from a high of 32 μs/cm to a low of 6 μs/cm. Significantly, at locations that had been repointed and then cleaned, readings ranged from only 10 μs/cm to 6 μs/cm (table 2). |