EVALUATION OF CLEANING METHODS FOR THE EXTERIOR BRICK AT THE BROOKLYN HISTORICAL SOCIETY

CLAUDIA KAVENAGH, & GEORGE WHEELER

2 EXISTING CONDITIONS AND MATERIALS CHARACTERIZATION

2.1 BRICK

The primary facades of the Brooklyn Historical Society are constructed of orange-red machine-pressed brick with smooth surfaces. Overall, the facades are in good condition except for areas that have been subjected to a great deal of water infiltration. The brick from the Brooklyn Historical Society may have been inadequately fired. Brick fired at high temperatures is red; the brick at the Brooklyn Historical Society is orange. Unlike adequately fired brick, the Brooklyn Historical Society brick is easily scratched and is highly absorptive (see absorption testing below) (Robinson 1982). Funds were not available to confirm this theory, nor was such a study necessary to achieve the project goal of the selection of a cleaning process for the brick.

2.2 MORTAR

Many of the mortar joints on the building are either failing or are completely missing (fig. 2). Mortar joint size varies but typically is narrow, in the range of 1/8 in. (3 mm) wide. The pointing mortar is typically gray and very fine in texture. The setting or bedding mortar is light tan and with a fine but visible texture. Both the gray and the tan mortars were analyzed by x-ray diffraction (XRD) and x-ray fluorescence (XRF). X-ray diffraction demonstrated that the gray pointing mortar contained gypsum and calcite; x-ray fluorescence indicated an average of 92% (atomic %) calcium and 8% sulfur for 20 measurements. No other elements were detected. Assuming all the sulfur in the mortar derived from gypsum, these percentages would correspond to approximately 13 parts lime and 1 part plaster of paris by volume in the original pointing mixture (the form of calcium sulfate added when the mortar was prepared is not known). If calcium carbonate were also used as aggregate, then the amount of lime in the original pointing mixture would be correspondingly reduced. XRD determined that the bedding mortar contained calcite, gypsum, and quartz; XRF found 65% calcium, 18% sulfur, and 15% silicon. Therefore, the original mixture for the bedding mortar contained a fine quartz aggregate, lime, and some form of calcium sulfate. Finding gypsum in each of these mixtures indicates that the mortars were gauged (Ashurst and Dimes 1990). “Gauging the mortar” was typically done to speed the setting time and increase the strength of the mortar. A literature search and field experience suggest that its use on a building exterior is not common; gauging of lime plasters was more typical. It is not clear why the exterior mortar was gauged with gypsum (Hodgson 1916; Boynton 1980; Maxwell 1995).

2.3 SOILING

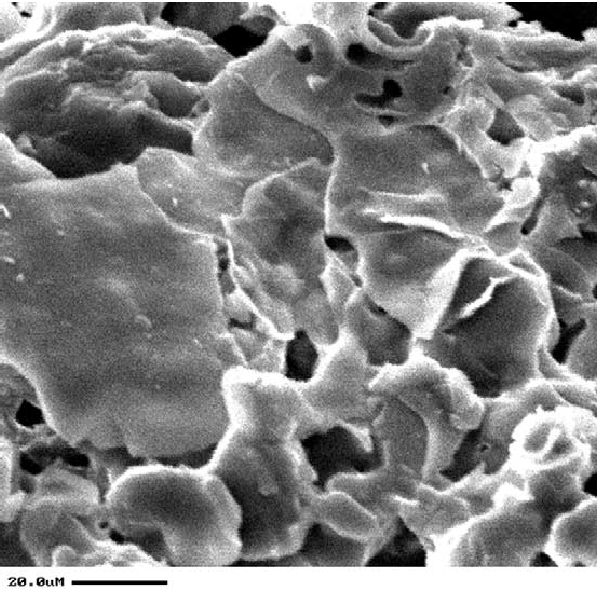

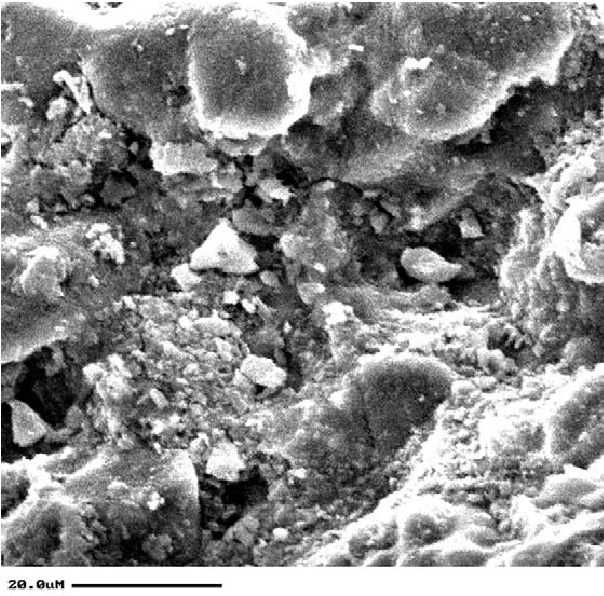

The soiling on the brick consists of a thin but tenacious layer and follows a fairly regular pattern. Overall, there is light to moderate soiling on the majority of surfaces, with heavier buildup at the corners of the building. The soiling pattern on a typical individual brick face is roughly elliptical and occurs approximately 6–12 mm in from the brick edges. Closer examination reveals that there are white deposits and roughened surfaces associated with these soiling rings (fig. 3, see page 71). Samples of soiling were removed for analysis by scanning electron microscopy–energy dispersive spectroscopy (SEM-EDS). Scanning electron images of soiled and unsoiled brick are seen in figures 4 and 5. SEM-EDS found elements typical of flyash (silicon, aluminum, iron) as well as gypsum (calcium and sulfur) (Matero and Bede 1992). The presence of gypsum was also confirmed by Fourier transform infrared reflectometry (FTIR) and XRD.

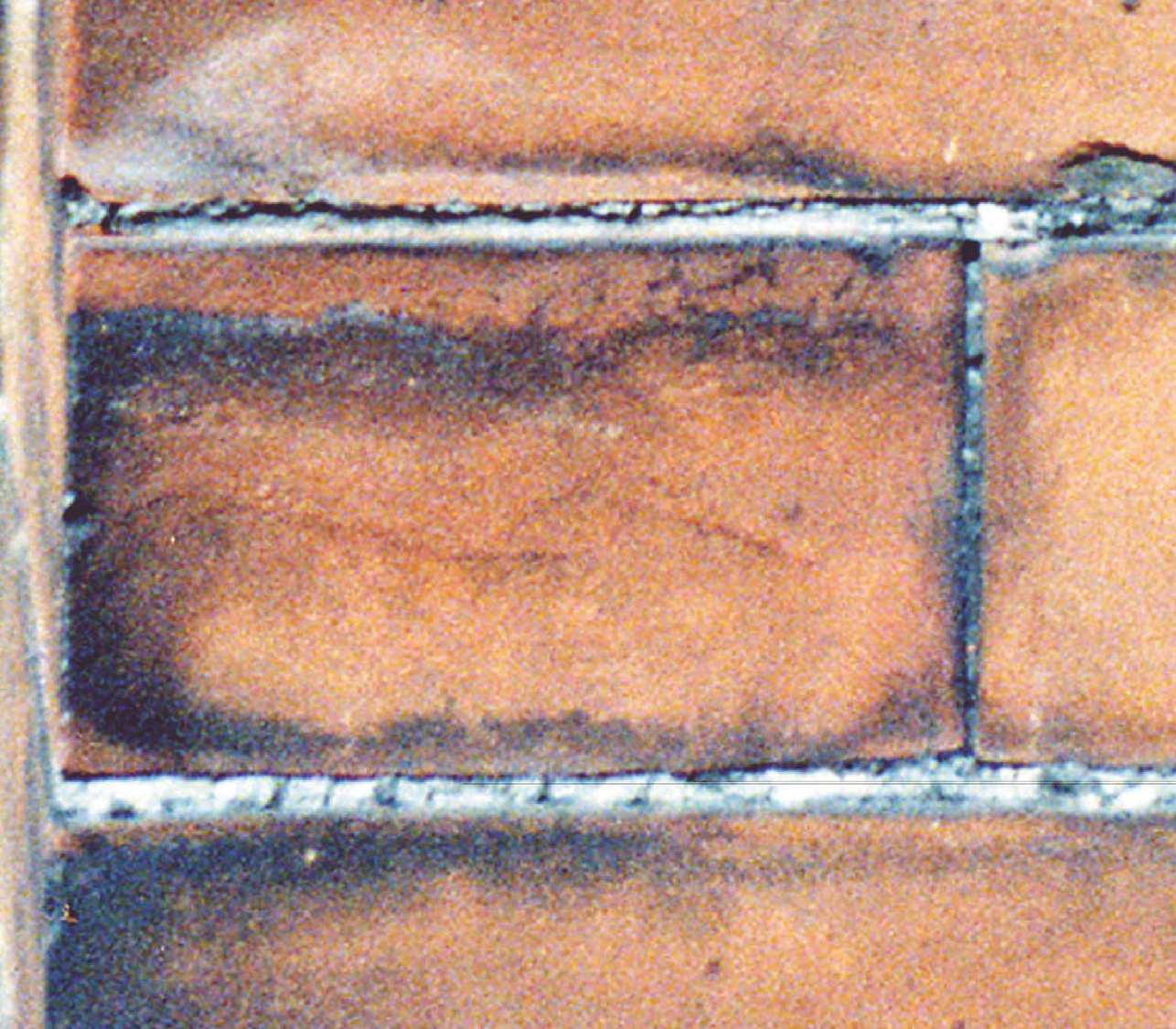

Fig. 2.

Deteriorated and missing mortar in brick joints

|

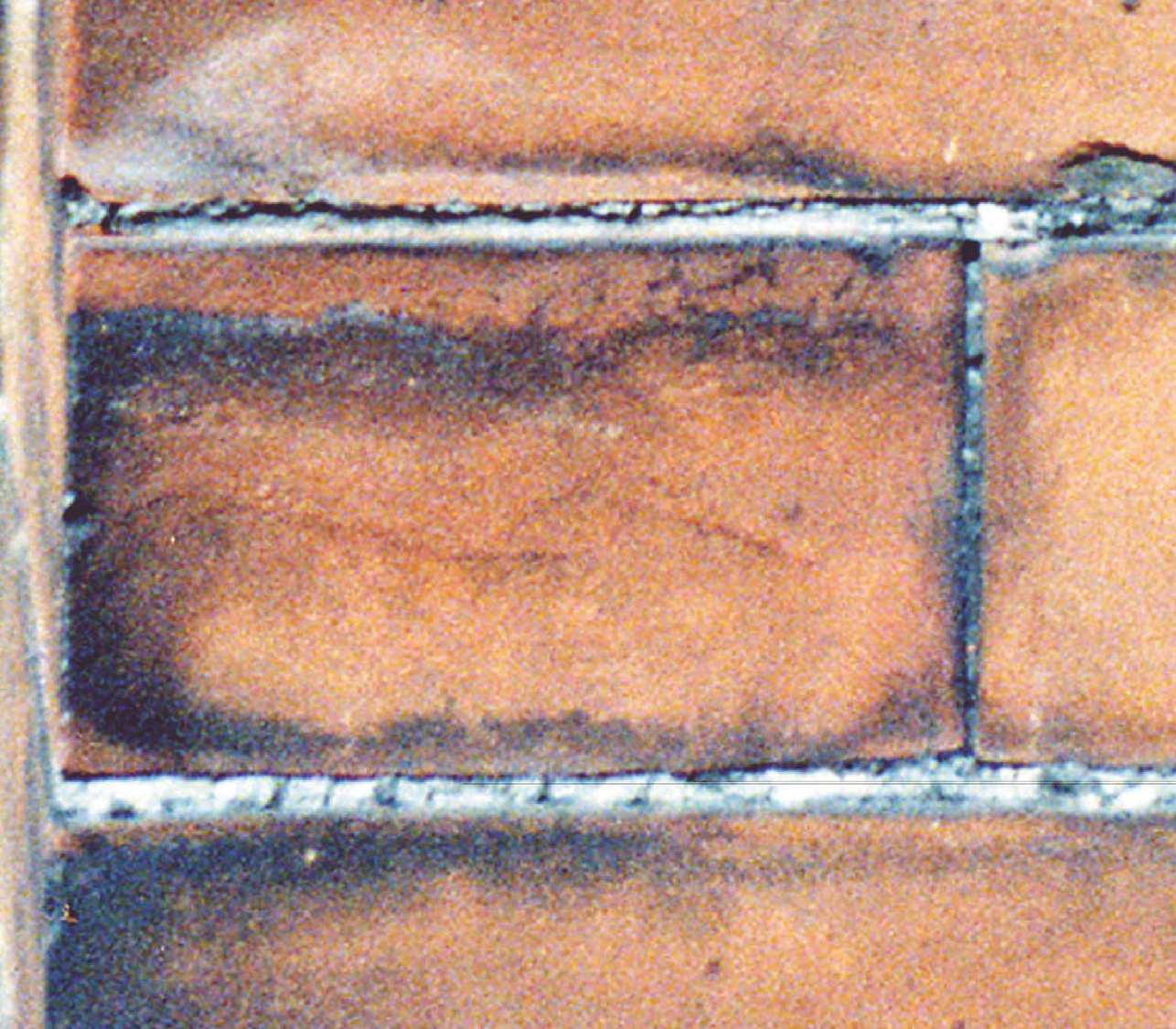

Fig. 3.

Typical soiling “ring” on brick face. Note white deposits in soiling near top edge of brick.

|

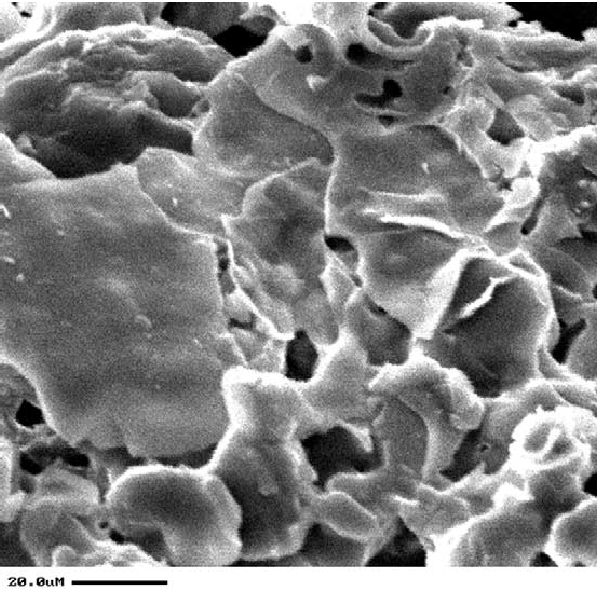

Fig. 4.

Scanning electron micrograph of freshly broken surface of brick

|

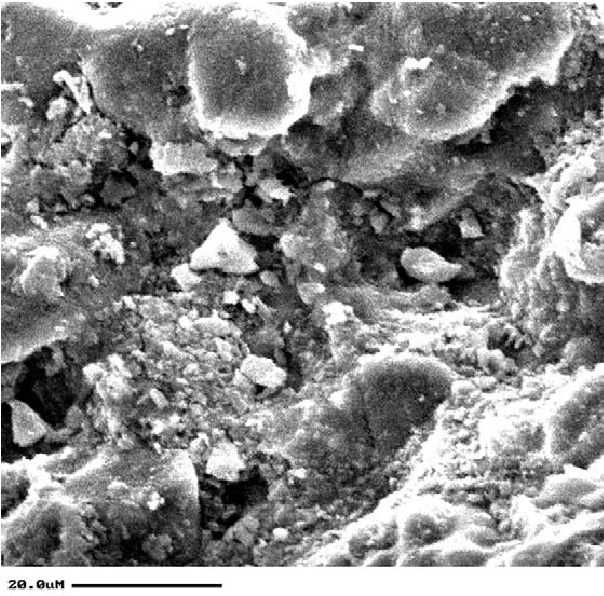

Fig. 5.

Scanning electron micrograph of soiled surface of brick

|

|