THE RATIONALE FOR MICROABRASIVE CLEANING: A CASE STUDY FOR HISTORIC GRANITE FROM THE PENNSYLVANIA CAPITOLJ. CHRISTOPHER FREY, & TIMOTHY NOBLE

6 EXECUTION AND DISCUSSION OF EXPERIMENTAL PROGRAMIn light of the negative consequences of natural weathering and previous cleaning treatments, it was deemed appropriate to undertake an experimental testing program to evaluate the potential utility of several widely accepted cleaning techniques. Along with the primary goal of cleaning the building to improve its appearance (an intervention that had been recommended in a previous preliminary study), addressing certain performance characteristics of the stone, which had been obviously compromised by previous treatments, was deemed equally important. Entering the experimental program, it was recognized that full restoration of all original properties of the stone was neither practical nor possible. For instance, completely removing the alteration layer across 400,000 sq. ft. of building surface would have required aggressive mechanical methods and would have resulted in the undesirable loss of significant quantities of historic material (3–5 mm from the surface of each stone on the building). Such an approach neither would have been ethical nor could it have been achieved without considerable expense and potential damage. Treatments that would have altered the chemical composition of the stone were similarly deemed inappropriate. While it would not have been possible to completely remediate micro-cracking caused by tooling, removing surface contamination that could continue to negatively impact the stone offered a means to reduce the likelihood of additional subsurface alteration and subsequent damage. The treatment options that follow were selected by virtue of the facts that they had been used successfully on previous projects where similar cleaning scopes were required and that they possessed the potential to address all critical existing conditions, including soiling, surface alteration (including clouded and crazed quartz), and iron staining. While the list represents a broad range of treatment options, the scope of testing within this study is not intended to represent a comprehensive range of all available conservation treatments, which might include various alkaline cleaners, nonionic detergents, poultice

6.1 SELECTION AND ASSESSMENT OF POTENTIAL CLEANING TREATMENTS (FIRST TIER)Potential cleaning treatments were subjected to a two-tiered analytical program that was intended to: (1) provide basic performance data for a wide range of typical cleaning treatments and (2) establish more substantial performance data for the treatment that appeared to best meet the following criteria in accordance with widely held conservation standards (Tabasso 1988; Winkler 1994):

The first tier of treatment assessment included the execution of in situ mock-ups for a range of procedures and products. These mock-ups were evaluated visually with a 30x field microscope and, where required, subjected to assessment with a Minolta Chroma Meter CR-221. First-tier assessments (table 1) were completed for:

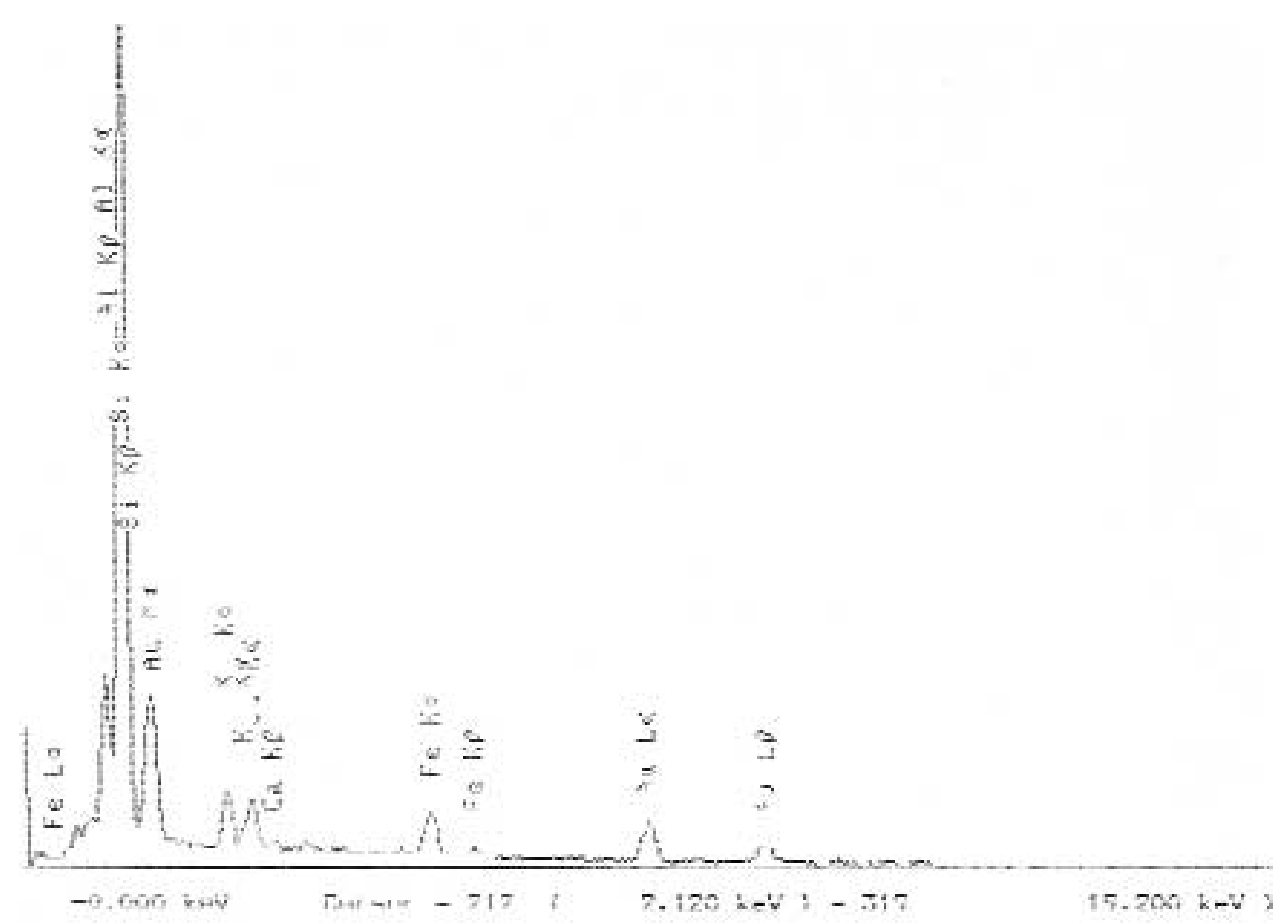

6.1.1 Pressure WashingAs tested, pressure washing with fan-tip nozzles spraying potable water was evaluated at three pressure variables: 300–500 psi, 600–800 psi, and 1200 psi (measured at the nozzle tip) at a distance of 12–24 in. (30–60 cm) from the surface. Variables that affect the success of this treatment include application pressure, nozzle type, angle of application, angle of spray at the nozzle, dwell time, and distance of application. These variables were examined during in situ tests. Low-pressure (300–500 psi) water washing removed very little soil and had no visual effect on clogged pores or crazed-clouded minerals within the zone of alteration, and thus was deemed unacceptable. Higher pressure (600–800 psi) effectively removed more soil but caused some surface roughening and resulted in an uneven appearance. Even higher pressure (1200 psi) resulted in additional surface roughening and the loss of tooling patterns. While low-pressure washing did not significantly affect tooling patterns, some erosion was noted at high pressure. Employing only clean, potable water, these procedures were deemed to entail no significant health or property risks. Furthermore, since chronic moisture was found to be problematic in many areas of the building, it was deemed inadvisable to pursue a treatment that might introduce significant quantities of moisture into the building's walls. Considering its failure to meet several critical performance criteria, pressure washing was immediately removed from consideration. 6.1.2 Acidic CleanersTwo cleaning compounds whose predominant reagent is hydrofluoric acid (SureKlean Heavy Duty Restoration Cleaner and SureKlean Restoration Cleaner) were identified as treatments with the potential to address all surface conditions. Each was brush-applied in dilute concentrations (1:3, 1:4, and 1:6 in water) at various dwell times before being rinsed and neutralized. These cleaners function by dissolving soil on the surface of the stone, but they also dissolve silicate portions of the stone itself. Variables that affect the impact of such cleaners include method of application (brush or spray), concentration, and dwell time. Understandably, higher concentrations of reactive compounds increase the effects that those compounds will have; similarly, increased effects can be expected the longer a compound is provided the opportunity to react with a treated surface. Lower concentrations (1:6 and 1:4) generally removed soil, but higher concentrations (1:3) and longer dwell times were required to remove altered material from surface pores. The higher concentrations and increased dwell times that were necessary to address all surface conditions increased the potential for damage. Test panels indicated that higher concentrations and increased dwell times resulted in both the dissolution of silicate-rich quartz veins and further erosion of tooling patterns, the end result being a roughly textured, streaky appearance. In addition, the potential risk to health and property associated with the use of strong acids was of concern, especially in light of the fact that cleaning would occur on a fully occupied building that has hundreds of windows and is closely surrounded by pedestrian walkways and parking areas. The manufacturer identifies the cleaners as corrosive products that are harmful to wood and glass and states that substantial protection of such materials is required when they are used (SureKlean Restoration Cleaner and Heavy Duty Restoration Cleaner product data sheets, 2002. Available at www.prosoco.com). Also noted was the possibility that strong acidic applications could leave behind residual reactive chemicals that might contribute to the development of future problematic conditions unless completely neutralized. It is important to recognize that the criteria that led to the removal of these products from consideration are project-specific (due in part to the previous damage to the stone) and also relate to the success of other treatment options that more closely matched the project's overall goals. 6.1.3 JOS/Quintek Microabrasive SystemAs part of the study, the authors investigated the effects of the JOS/Quintek System. Equipment is now provided under the Quintek Rotec Vortex The JOS/Quintek System uses a low-pressure blasting apparatus that combines different types of fine, nonreactive microabrasive media with a minimal amount of water in what the manufacturer refers to as a swirling “vortex” motion (fig. 6). Compressed air forces fine media through hoses into a nozzle, where it is combined with water into a stream before being applied to a selected surface. Cleaning is followed by a gentle, low-pressure water rinse (typically similar to the amount of pressure that would emanate from a garden hose) to remove residual media from the cleaned surface. Variables that impact the intensity of treatment include the type of media selected, the pressure at which it is applied, the distance of the application from the surface, and the amount of media that is mixed into the application stream. JOS/Quintek requires that the manufacturer certify all applicators. This testing program evaluated several media types, which differed by composition, particulate size, and particulate angularity. M1035 is a fine, nonreactive milled glass. M1040 is compositionally identical to M1035 but slightly finer. Dolomitic media is composed primarily of ground calcium–magnesium carbonate and is more angular than the M1035 (table 2). M1035 media, applied 35 psi, 12–24 in. (30–60 cm) from the surface, effectively removed both soil from the surface and deteriorated material from clogged pores at the surface of the zone of alteration.

Applied at slightly higher pressures (50 psi), M1035 media was slightly more aggressive, causing minor erosion of tooling patterns and a slight increase in surface relief. Applied at pressures of 35 psi and 50 psi, M1040, dolomite media and stone powder were slightly less effective at soil removal and did not result in the noticeable color correction associated with the removal of severely deteriorated bleached material. Since the overall performance-criteria values were more desirable for the M1035 at 35 psi than for these treatments, these did not merit significant additional consideration. 6.1.4 Fa�ade GommageAs tested, the Fa�ade Gommage system projects a very fine, nonreactive microabrasive glass slag powder in a direct, low-pressure stream onto the surface. The process employs a compressed-air and vacuum system that distributes the media and then removes them from the surface. Fa�ade Gommage is a proprietary system that can be applied only by professionals of the parent company. Fa�ade Gommage performed moderately well,

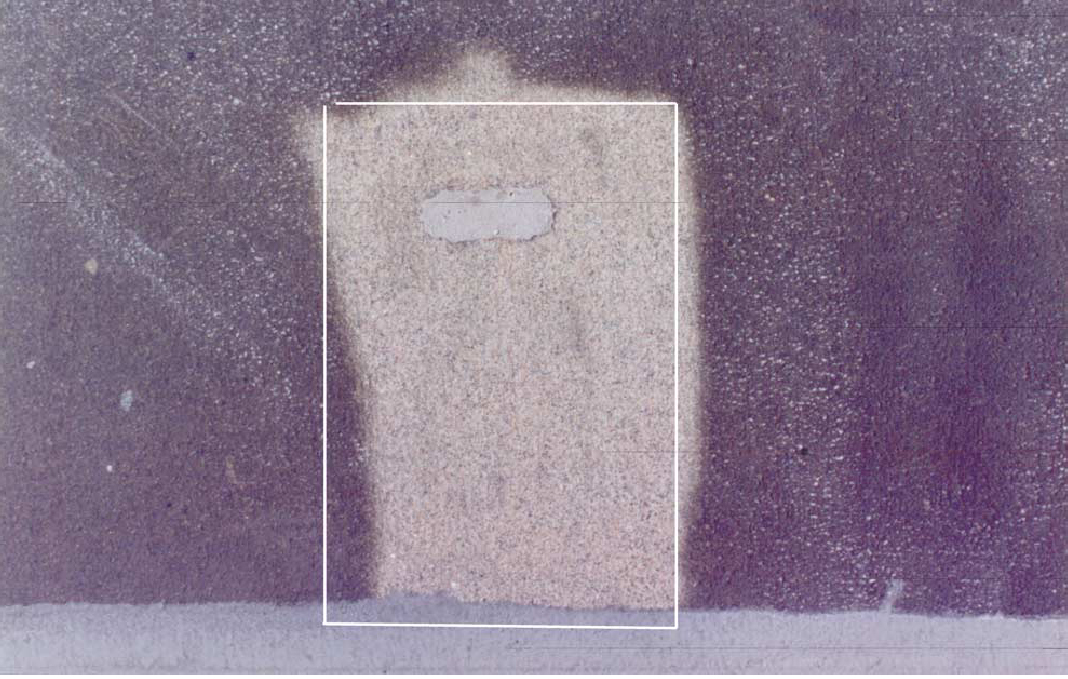

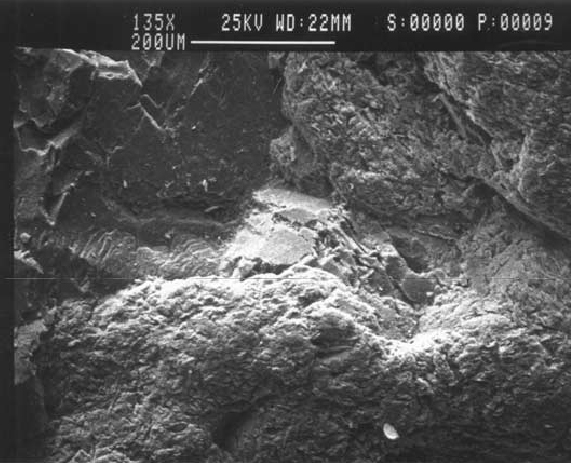

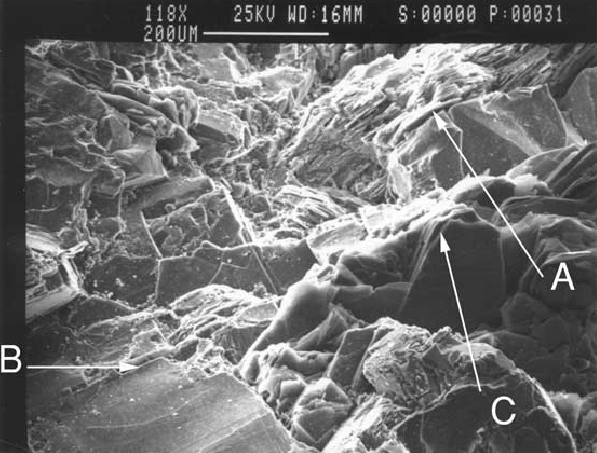

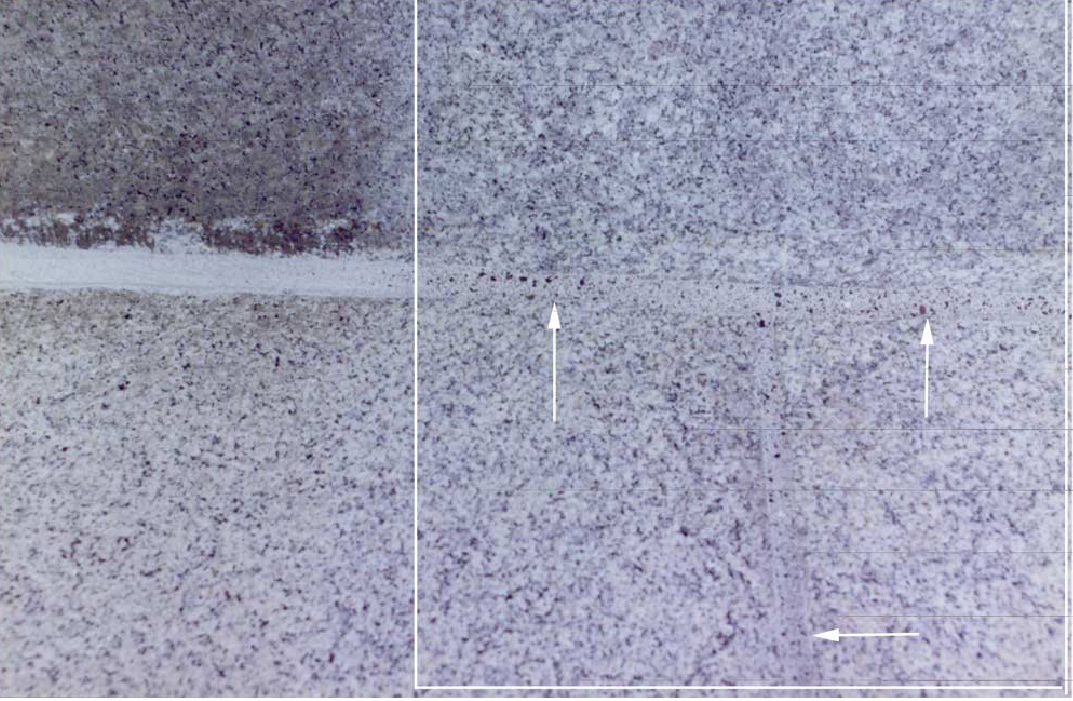

6.2 ADDITIONAL TESTING FOR SELECTED TREATMENT (SECOND TIER)Having established that many problematic surface conditions resulted from a combination of micro-cracking, previous treatments, and aggressive weathering, it was reasoned that a treatment that removed alteration products and restored certain beneficial natural properties would be appropriate. Since there were no unweathered building surfaces present that would provide direct data on the stone's original performance, subsurface samples were removed from several inches behind the weathering surface for comparative testing. The subsurface samples were only partially representative of the material characteristics of the original stone surface as they were not tooled and therefore did not contain the microcracking prevalent on the original stone face. However, they did provide value as a benchmark of representative data on several of the stone's original properties, specifically color, unaltered constituent minerals, and permeability. The subsurface samples were also used for a comparative assessment on the effects of the treatments on weathered and fresh stone. The second tier of testing entailed a more detailed analysis of the treatment that was established as the most successful from the first tier of testing: #1035 media at 35 psi, applied 12–24 in. (30–60 cm) from the surface. This additional round of testing was conducted primarily to provide additional information When applied with low pressure (35 psi) from a distance no closer than 12 in. (30–60 cm), the selected microabrasive cleaning treatment (1) successfully removed soiling, (2) partially restored the original stone color and transparency, (3) caused no apparent microstructural damage, (4) improved surface absorption capacity to levels closer to what existed originally, and (5) effectively removed superficial iron stains. 6.2.1 Soil Removal and Chromatic ImpactWhen applied as indicated above, the treatment successfully removed soil from the surface of the granite, including both general atmospheric deposition and heavier encrustations. While a single pass with the nozzle was generally sufficient to remove light soiling that was prevalent on all building surfaces, heavier depositions often required pretreatment and decreased application distances (fig. 7, see page 68).3 This treatment improved the overall color of previously weathered and treated stone without abrading or altering sound material immediately beneath the altered surface. As with most chemical cleaning and high-pressure water-washing, microabrasive treatments may be expected to remove a certain amount of substrate material from the surface. In the case of this treatment, the loss of barely perceptible amounts of severely deteriorated stone was justified by the fact that the material that was removed was dominated by weathering by-products. This intervention resulted in the removal only of compromised material at the immediate surface, with no appreciable effect on the remainder of the 3–5 mm alteration layer. Using unweathered samples to provide benchmark information on the original color of the stone as well as data on the predominant color of stone surfaces prior to cleaning, this treatment was found (via the removal of alteration products) to return the stone's color to more appropriate values (table 3). Cleaned samples were found to be medium gray, with an average color space of Munsell 2.42GY 6.51/0.40. When compared with the medium gray (Munsell 2.37GY 4.08/0.46) registered by the unweathered subsurface samples, this change represents a noticeable improvement over the predominant light olive gray (Munsell 4.86Y 5.34/0.98) surfaces that were prevalent before cleaning. Prior to treatment, exposed surfaces were characterized by a significant loss of surface topography due to the substantial surface erosion of exposed grain surfaces (fig. 8). Cleaning resulted in a moderate restoration of natural surface topography by removing both surface contamination and partially dissolved mineral components. This outcome reestablished the presence of clear angular quartz, feldspar, and biotite grains at the surface (fig. 9). While increased surface topography is sometimes viewed as an undesirable consequence of treatment, it was justified in this instance since it reestablished relationships between individual surface grains comparable to what they may have originally been. The reestablishment of comparatively sound crystal surfaces created a more dense, less reactive overall weathering surface. While the selected treatment effected a positive chromatic change in many locations and resulted in a more uniform appearance to the building, it proved impossible to completely restore color to original or near-original shades in all areas. Specifically, areas that had been subject to chronic moisture ever since construction and those that possessed extensive discoloration prior to the start of cleaning generally retained some degree of discoloration even after work was completed. Pre-existing color variation included both light, severely bleached stones and dark core sections exposed by exfoliation and aggressive weathering. 6.2.2 Tooling PatternsAlthough many surfaces had previously lost evidence of original tooling patterns, the selected cleaning treatment proved to be gentle enough to have no discernible effect on tooling patterns where they still survived. By predominantly removing altered material from the surface and leaving the stable material beneath it intact, the treatment

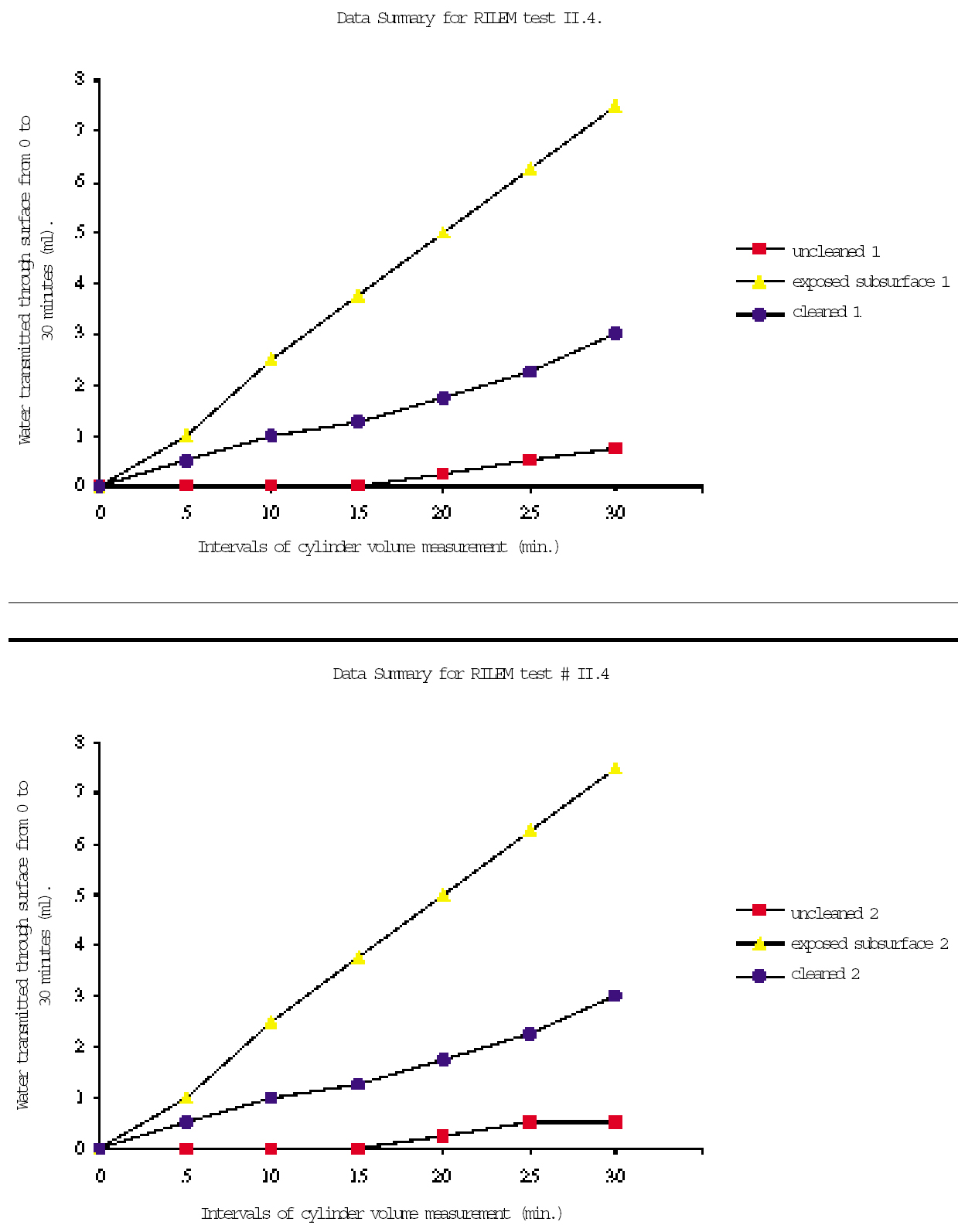

6.2.3 PermeabilityCleaning resulted in a slight improvement in overall surface absorption capacity, but did not result in permeability values comparable to those established for unweathered subsurface samples. Cleaned surfaces were found to absorb more water than uncleaned surfaces, but less water than unweathered surfaces exposed by exfoliation (fig. 11, see page 69). Some differential between subsurface areas and

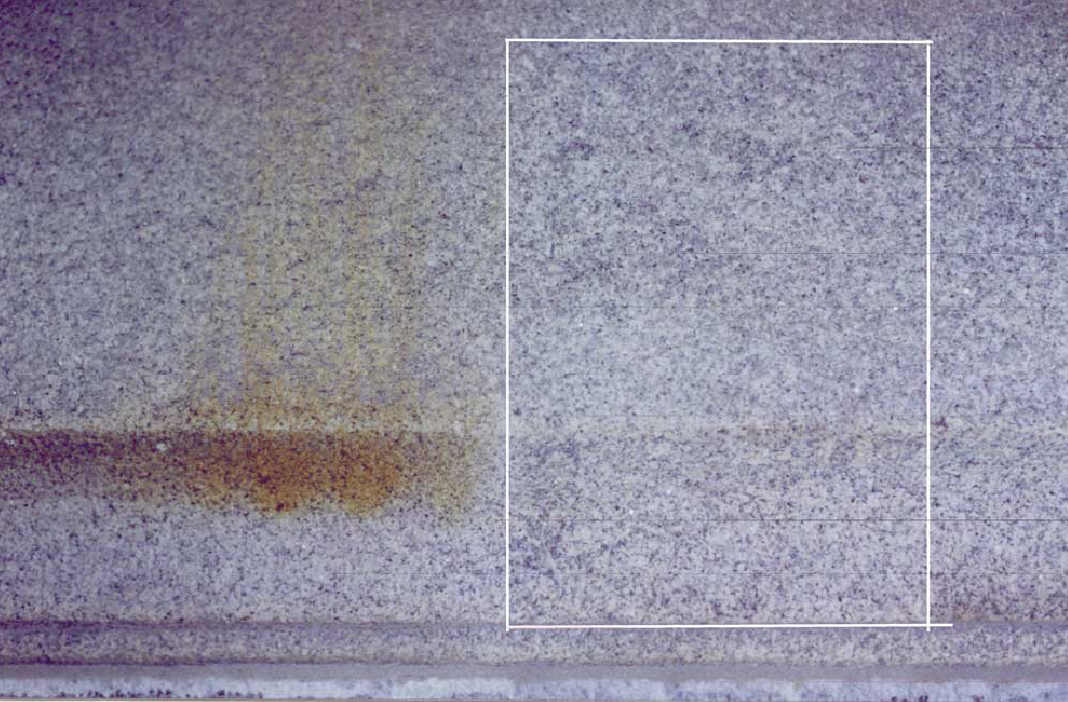

In theory, reestablishing an equilibrium of permeability values between the surface and immediate subsurface, thus allowing moisture to move freely though exposed areas, will reduce the possibility of future damage as a result of moisture being trapped behind the surface, particularly exfoliation due to freeze-thaw cycles and soluble salt crystallization. 6.2.4 Superficial Iron StainsThis treatment effectively removed superficial iron stains that were contained within the zone of alteration (fig. 12, see page 70). Cleaning also uncovered a series of more deeply rooted, persistent iron stains that were not visible beforehand because they were obscured by atmospheric deposition and/or severe bleaching. These stains were addressed with alternate treatments as necessary. 6.2.5 Removal of LaitanceAll cleaning was scheduled to be undertaken after the completion of comprehensive repointing which would replace the existing failed repointing mortar with new mortar that more closely reflected the color, texture, joint profile, and appearance of the original. Tests found that the cleaning procedure successfully removed laitance from repointed joints. The removal of laitance provided for the exposure of anthracite coal within the aggregate. Anthracite was not only a significant component of aggregate used for the original mortar; it also provided an important aesthetic device by simulating the black biotite of the granite and allowing walls to read as monolithic masonry surfaces (fig. 13, see page 70). Added benefits of using this treatment included eliminating the need for supplemental or more aggressive laitance-removal techniques.

|