EFFECTS OF ENCLOSURE PAPERS AND PAPERBOARDS CONTAINING LIGNINS ON PHOTOGRAPHIC IMAGE STABILITYDANIEL M. BURGE, JAMES M. REILLY, & DOUGLAS W. NISHIMURA

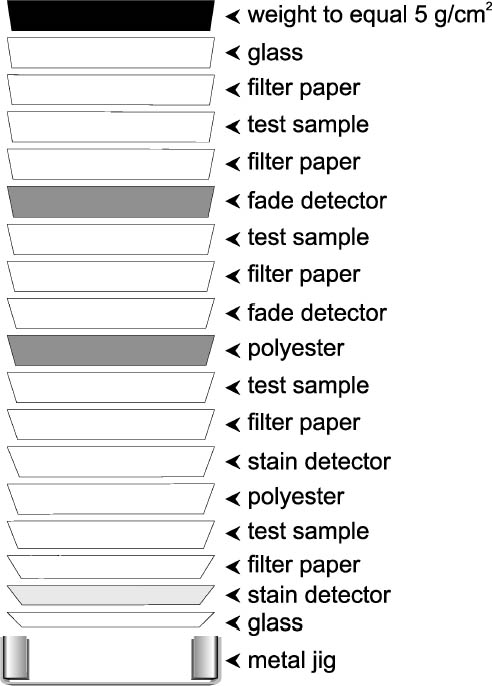

3 EXPERIMENTAL METHODS3.1 PHOTOGRAPHIC ACTIVITY TEST (PAT)The photographic activity test of ISO Standard 14523 (ISO 1999) was chosen for these experiments, as it is the sole method recognized by the International Organization for Standardization for predicting the long-term interactions between enclosures and photographs. Other test methods, such as the Oddy Test (Oddy 1973, 1975) or the Collings and Young silver tarnish test (Collings and Young 1976) may be able to screen paper and paperboards for negative reactions with metallic silver. However, those tests use silver plates as opposed to silver particles embedded in gelatin like the detector used in the PAT. Also, neither test examines the effects of materials on photographic gelatin. The PAT uses two detectors to simulate a photographic image. The first PAT detector, called the image interaction detector, consists of colloidal silver particles distributed through a gelatin coating on polyester film. This detector is used to measure oxidation and reduction reactions with silver. Such reactions cause fading, mirroring, and red spots in photographs. Fading is a loss in image density either overall or localized (localized fading is called mottling). Fading is the result of the oxidation of the metallic silver particles forming the image. The metallic particles are stripped of electrons and converted to silver ions. These ions are not visible, hence the loss in image density. Mirroring and red spots are similar to fading in that they involve oxidation, but they also involve migration of the silver ions and their subsequent reduction back to metallic silver in new locations. In mirroring, the silver ions are converted back to metallic silver at the surface of the print or film. This metallic silver forms a reflective sheen. In red spots, the silver ions are redeposited at sites seeded by embedded impurities such as metals, scratches in the gelatin, or image areas of great contrast. These deposits are reddish orange in color. The second PAT detector, called the gelatin stain detector, is a strip of white processed photographic paper. This detector is used to predict discolorations in the gelatin binder. Black-and-white photographic paper is used to avoid the complications of residual dye couplers found in chromogenic products. According to the standard, the papers being examined for photoactivity are stacked (fig. 2) with two each of the above detectors within a holding jig. Strips of Whatman no. 1 filter paper are used as interleaves between the paper samples and the image interaction detectors. Filter paper interleaves were not included in the gelatin stain tests, as it was not The PAT was used to test all the paper samples as well as the extracted versions of the paper samples.

3.2 BOX TESTThe box test used the same two detectors as the PAT. The method varied from the PAT in that the detectors were placed emulsion-up in the center of the bottom of the box. To prevent direct contact with the boxboard, the detectors were separated from the bottom of the box by a sheet of polyester (fig. 4). A box could not be made from Whatman no. 1 filter paper (the control used in the PAT), so the control box was made from the buffered, purified wood-pulp board and the same adhesive.

The PAT was also used to test the boxboard materials in direct contact in order to examine the dilution effects of the air space within the box. |