ANTIFUNGAL PROTECTION AND SIZING OF PAPER WITH CHITOSAN SALTS AND CELLULOSE ETHERS. PART 2, ANTIFUNGAL EFFECTSMARIA DEL PILAR PONCE-JIM�NEZ, FERNANDO A. L�PEZ-DELLAMARY TORAL, & HUMBERTO GUTIERREZ-PULIDO

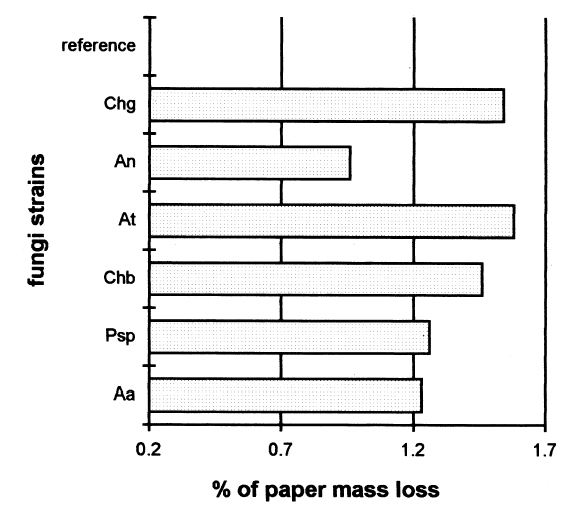

3 RESULTS3.1 RESULTS OF FUNGAL ATTACKIn figure 5, the horizontal bars correspond to the percentage of mass loss after the fungal attack. The length of the bars is equal to the cellulolytic activity of each strain. Included in the graph is a reference that had 0% mass loss.

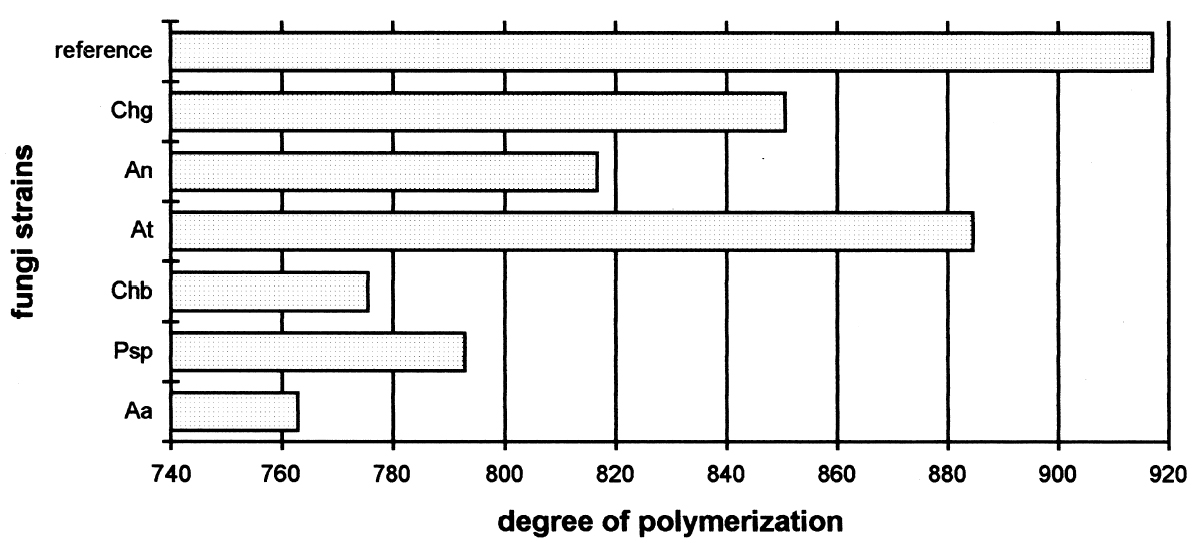

Figure 6 shows the degree of polymerization after 21 days of fungal attack. The longer bars are those with less deterioration. The length of the horizontal bars is inversely proportional to the cellulolytic activity of each strain. The longest bar represents the average degree of polymerization in reference samples without fungi. 3.2 RESULTS OF THE TREATMENT WITH 70% ETHYL ALCOHOLThe influence of alcohol on paper strength was evident, increasing the standard deviation of all the samples. The sized samples, except that with the MC size, have a general tendency to increase zero-span tensile strength (table 4). The alcohol treatment slightly altered the results, but it was the only feasible option for stopping the fungal activity and handling the samples after the biotests. Treatment with formaldehyde could greatly alter the properties of the consolidant sizes. In this stage of the experiment, an ETO sterilization chamber was not available.

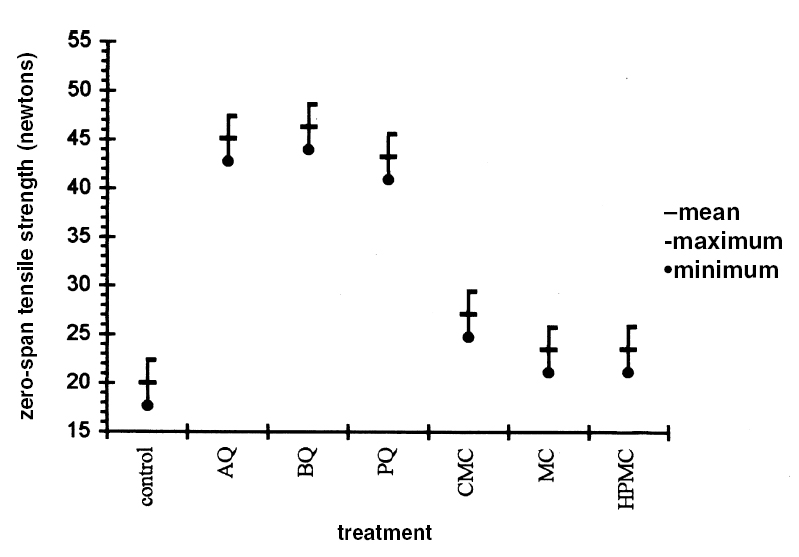

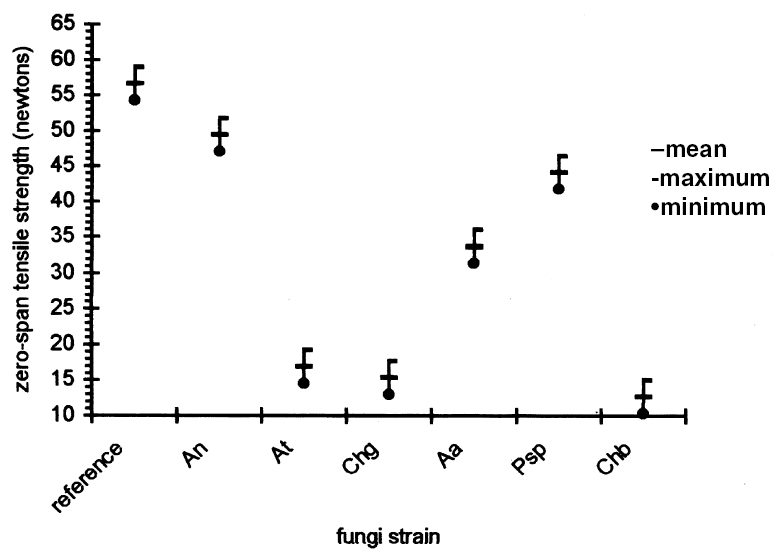

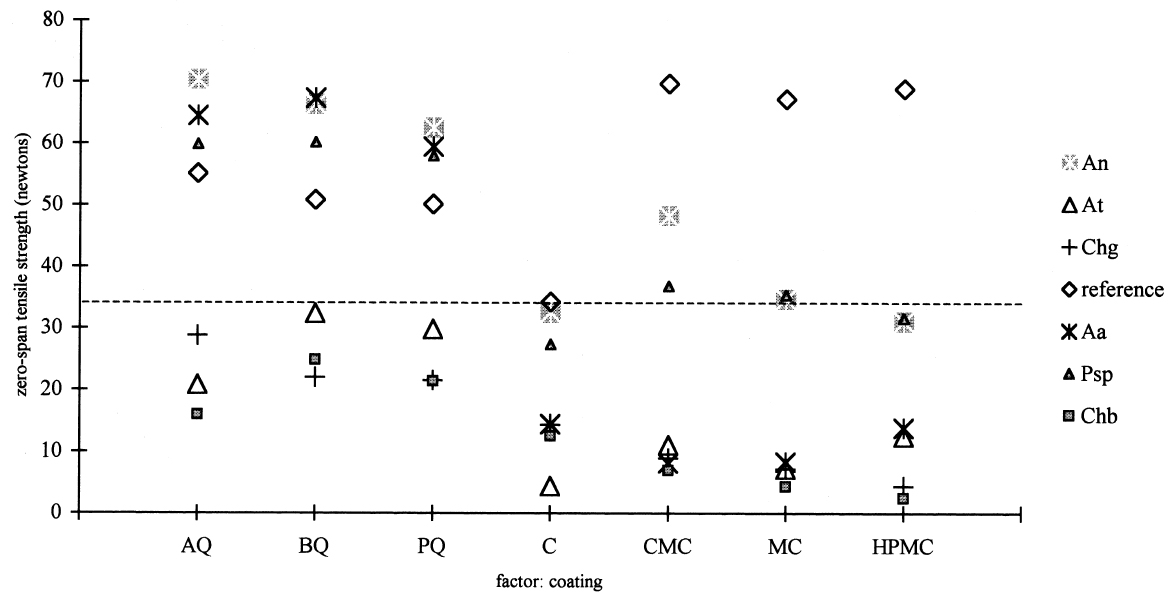

3.3 RESULTS OF THE EXPERIMENTAL DESIGNIn this experiment we evaluated two factors, strain and sizing, and each one at six levels. We used two types of sizes, the chitosan salts (Q) and the cellulose ether (E). The level of each factor—strain and coating— was considered. With seven levels for each factor, including the controls and references, analysis of variance was an appropriate standard test. Zero-span tensile strength was used to evaluate deterioration, because we observed that all the strains grew on the paper. The control samples showed the maximum development of hyphae, while the least concentration of hyphae was in samples treated with Q. The samples with E show a high density of hyphae. It was impractical to determine the percentage of invasion. The ANOVA results presented in table 3 indicate significant differences between the levels of strain and size, and there are interactions between both factors. Figures 2 and 3 show the average effects of each level for both factors (type of size and type of strain). Figure 2 shows clearly that the samples treated with AQ, BQ, and PQ had less deterioration than samples

The zero-span tensile strength of all the samples was compared for all the types of coatings, including the control, after they had been submitted to the attack of the fungal strains. We observed that, in general, Aspergillus terreus, Chaetomium globosum, and Chaetomium britannicum caused the most deterioration of the samples, while Aspergillus niger and Penicillium sp. had less effect on the zero-span tensile strength. Strain Alternaria alternata caused an intermediate loss in the zero-span tensile strength of the paper (figs. 3, 4). These averages are the results of eight replicas. The tests of zero-span tensile strength were done after the conditioning of the samples at 23�C � 1�C and 50% RH.

|