ALVAR AND BUTVAR: THE USE OF POLYVINYL ACETAL RESINS FOR THE TREATMENT OF THE WOODEN ARTIFACTS FROM GORDION, TURKEYKRYSIA E. SPIRYDOWICZ, ELIZABETH SIMPSON, ROBERT A. BLANCHETTE, ARNO P. SCHNIEWIND, MAURAY K. TOUTLOFF, & ALISON MURRAY

ABSTRACT—Archaeological excavations conducted by the University of Pennsylvania Museum of Archaeology and Anthropology from 1950 to 1973 at the ancient capital of Gordion in central Anatolia uncovered impressive remains of the material culture of ancient Phrygia. During the early years of the project, the exploration of three massive earthen burial mounds or tumuli in the royal necropolis led to the discovery of one of the most important collections of wooden furniture and objects to emerge from the ancient Near East.Composed of a surprising variety of woods, the artifacts ranged in condition from poor to excellent. Initial attempts to treat the furniture and wooden objects on-site included the application of Alvar, a polyvinyl acetal resin. Soon after, most of the pieces were transferred to the Museum of Anatolian Civilizations in Ankara, where they remained in storage until a rescue program was initiated by the University of Pennsylvania Museum of Archaeology and Anthropology in 1981. Consolidation of the wood with Butvar B-98, a polyvinyl butyral resin, was the procedure adopted after testing to successfully retreat 37 pieces of ancient furniture and more than 50 small wooden objects from the three royal tombs.An assessment of the effects of both resins on the ancient woods is presented here, followed by a description of recent scientific tests conducted on samples of Butvar B-98.These tests include scanning electron microscope studies to determine the extent of penetration of Butvar B-98 into treated samples, hardness testing to assess the strengthening effects of the consolidant on the wood, and exposure to intense environmental conditions to determine the aging characteristics of Butvar B-98 films.The treatment of the Gordion wood has provided a unique opportunity to document and characterize the behavior of two related wood consolidants over a 40-year period. This contribution to the growing body of literature on the subject should assist conservators in making informed decisions when called upon to treat dry archaeological wood. TITRE—L'Alvar et le Butvar: l'utilisation des r�sines d'ac�tal de polyvinyl pour le traitement d'objets en bois du site de Gordion, en Turquie. R�SUM�—Les fouilles arch�ologiques effectu�es de 1950 � 1973 par le University of Pennsylvania Museum of Archaeology and Anthropology (mus�e d'arch�ologie et d'anthropologie de l'universit� de Pennsylvanie) � Gordion, capitale de la Phrygie antique en Anatolie centrale, ont mis � jour des vestiges importants de cette culture ancienne. Durant les premi�res ann�es des fouilles, trois �normes tumuli de la n�cropole royale ont �t� explor�s, ce qui mena � la d�couverte d'une des plus importantes collections de meubles et d'objets en bois du Proche-Orient antique.Les art�facts sont compos�s d'une vari�t� �tonnante d'essences en bois et leur �tat varie du pi�tre � l'excellent. Les essais initiaux de traitement des objets en bois et des meubles sur le site m�me inclurent l'utilisation d'Alvar, une r�sine � base d'ac�tal de polyvinyl. Peu apr�s leur traitement, la plupart des objets furent transf�r�s au mus�e de la civilisation anatolienne � Ankara. Ils y demeur�rent en r�serve jusqu'en 1981, lorsque le mus�e d'arch�ologie et d'anthropologie de l'universit� de Pennsylvanie entreprit � leur �gard un programme de conservation d'urgence. Apr�s des essais pr�liminaires, 37 pi�ces de mobilier ancien et plus de 50 petits objets en bois provenant des trois tombes royales furent consolid�s � nouveau et avec succ�s � l'aide du Butvar B-98, une r�sine � base de butyral de polyvinyl.Cet article pr�sente une �valuation de l'effet des deux r�sines sur les bois anciens, ainsi qu'une description d'essais scientifiques effectu�s r�cemment sur des �chantillons de Butvar B-98. Ces essais incluent des examens au microscope �lectronique � balayage afin de v�rifier le degr� de p�n�tration de cette r�sine dans le bois; des mesures de duret� afin d'�valuer les caract�ristiques de consolidation que la r�sine impartit au bois; et enfin l'exposition de couches minces de TITULO—Alvar y Butvar: el uso de resinas de acetal de polivinilo para el tratamiento de artefactos de madera de Gordion, Turqu�a. RESUMEN—Las excavaciones arqueol�gicas llevadas a cabo por el Museo de Arqueolog�a y Antropolog�a de la Universidad de Pensilvania desde 1.950 hasta 1.973 en la antigua capital de Gordion, en Anatolia Central, revelaron restos impresionantes de material cultural de la antigua Frigia. Durante los primeros a�os del proyecto, la exploraci�n de tres grandes entierros en barro, tipo mont�culos o t�mulos, en la Necr�polis Real llev� al descubrimiento de una de las m�s importantes colecciones de mobiliario y objetos en madera provenientes del antiguo Cercano Oriente.Compuestos de una sorprendente variedad de maderas, las condiciones de los artefactos variaban de pobre a excelente. Intentos iniciales para tratar el mobiliario y objetos de madera in-situ incluyeron la aplicaci�n de Alvar, una resina de acetal de polivinilo. Seguidamente, la mayor�a de las piezas fueron transferidas al Museo de las Civilizaciones Anatolianas, en Ankara, donde permanecieron en almacenamiento hasta que se inici� un programa de rescate hecho por el Museo de Arqueolog�a y Antropolog�a de la Universidad de Pensilvania en 1.981. Despu�s de reaplicar exitosamente Butvar B-98, una resina de butiral de polivinilo, a 37 piezas de mobiliario antiguo y a m�s de 50 objetos peque�os de madera provenientes de tres tumbas reales, se adopt� este procedimiento para la consolidaci�n de la madera durante el proyecto.El resultado de los efectos de ambas resinas sobre la madera antigua es presentado en este trabajo, seguido de una descripci�n de pruebas cient�ficas recientes llevadas a cabo sobre muestras de Butvar B-98. Estas pruebas incluyen estudios de microscop�a electr�nica de barrido para determinar la extensi�n de la penetraci�n de Butvar-98 dentro de las muestras tratadas, pruebas de dureza para examinar los efectos de fortalecimiento del consolidante sobre la madera y exposici�n a condiciones ambientales intensas para determinar las caracter�sticas de envejecimiento de las pel�culas de Butvar B-98.

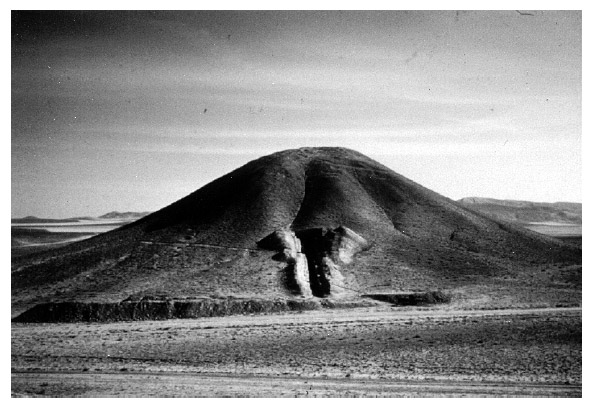

1 INTRODUCTIONBetween 1950 and 1973, the archaeological site of Gordion in central Turkey was excavated by the University of Pennsylvania Museum of Archaeology and Anthropology under the direction of archaeologist Rodney S. Young. Gordion was the capital of the ancient kingdom of Phrygia, ruled at the height of its power in the 8th century B.C. by the great King Midas. Three of the richest tombs from the Gordion necropolis—Tumulus MM, Tumulus P, and Tumulus W—date to this period. Tumulus MM, the largest tomb at Gordion, is thought to be the tomb of Midas himself (fig. 1). The three burials contained many exceptional works of art, including wooden household objects and a collection of fine wooden furniture. More than 37 pieces of furniture and more than 50 small wooden objects were excavated from these burials, now recognized as the most important collection of ancient Near Eastern wooden artifacts ever recovered. After the excavation of the three tombs between 1956 and 1959, the furniture and wooden objects were conserved using available methods, and studied briefly. Some were placed in storage at Gordion, but most of the collection was taken to the Museum of Anatolian Civilizations in Ankara. Research continued on the finds, which were published in Young's posthumous excavation report (Young 1981). It was during the preparation of Young's volume that many of the original interpretations and drawings of the wooden objects were found to be incorrect (Simpson 1996; Simpson and Spirydowicz 1999). Further attempts to study the objects revealed that the wood was deteriorating, with some pieces so fragile that they could not be handled. Because of the importance of the collection, the University of Pennsylvania Museum initiated a rescue project in 1981 to restudy, conserve, and republish the furniture and wooden objects from Gordion. 2 BRIEF HISTORY OF THE TREATMENT OF DRY ARCHAEOLOGICAL WOODA relatively large body of literature now exists concerning the treatment of waterlogged wood from archaeological sources. However, the number of publications dealing with the treatment of dry archaeological wood remains small. During the 1960s and 1970s, thermosetting synthetic resins such as epoxies and polyesters were proposed for the consolidation of degraded wooden artifacts and structures (for example, Schaffer 1971, 1974; Munnikendam and Wolschrijn 1969). However, their significant disadvantages, including lack of reversibility, unsatisfactory surface appearance, and the difficulty of control during curing (Schaffer 1971; Munnikendam 1978; Grattan 1980), were soon recognized, which led to the search for more suitable alternatives. Soluble thermoplastic resins appeared to offer a number of significant advantages over thermosetting resins. In 1980, Grattan examined a number of commercially available thermoplastic resins and found polyvinyl butyral and various acrylic resins to be the most promising consolidants (Grattan 1980). In the following year, Barclay (1981) employed polyvinyl butyral to successfully consolidate a wooden fire engine dating to the 18th century. Barclay's results influenced Robert Payton, the first conservator for the Gordion Furniture Project, to consider the use of polyvinyl butyral as a potential consolidant for the ancient wood. However, Payton selected Butvar B-98 for testing rather than Butvar B-90, the grade used by Barclay. Payton deliberately chose to experiment with the grade of resin that offered the lowest molecular weight and lowest viscosity in solution in order to promote the highest degree of penetration. When tests confirmed the suitability of Butvar B-98, Payton used it to consolidate an ornate inlaid table from Tumulus MM (Payton 1984a). The treatment originated by Payton was further developed and refined by an international group of conservators in subsequent seasons to successfully treat all of the ancient wooden furniture found in the three great early tumuli at Gordion (Spirydowicz 1996; Simpson and Spirydowicz 1999). During the mid-1980s, scientific testing of thermoplastic resins was proceeding. In 1985, Wang and Schniewind evaluated improvements in strength and stiffness in samples of bacterially degraded wood after treatment with a variety of consolidants, including polyvinyl butyral, Paraloid B-72, and polyvinyl acetate resins (Wang and Schniewind 1985). This work was followed by an assessment of the adhesive qualities of thermoplastic resins used as consolidants (Sakuno and Schniewind 1990) and, in the same year, by an analysis of the effects of solvent retention after consolidation with thermoplastic resins (Carlson and Schniewind 1990). Scanning electron microscopy was used to study the distribution of synthetic resin consolidants in samples of degraded wood (Schniewind and Eastman 1994) as well as to evaluate changes caused by the introduction and subsequent extraction of consolidants (paraffin wax

Over the past 30 years, the deterioration of archaeological wood has been more fully characterized. In a comprehensive study of samples of ancient wood recovered from Egyptian tombs and areas along the Nile Valley, Blanchette utilized transmission electron microscopy to reveal stages of decay at the cellular level as well as to identify biological and chemical agents of degradation (Blanchette et al. 1994). This followed earlier studies conducted by Blanchette and others, including an overview of the microbial deterioration of wood with reference to archaeological samples (Blanchette et al. 1990) and an examination of the log coffin from Tumulus MM at Gordion (Blanchette and Simpson 1992). 3 USE OF ALVAR AND BUTVAR ON THE WOODEN ARTIFACTS FROM GORDIONAt the time of excavation, the state of preservation of the wooden objects from Gordion varied from excellent (e.g., boxwood serving stand, Tumulus P) to poor (e.g., walnut tops of the plain tables, Tumulus MM). This range was due to a complex interaction of factors, including the inherent resistance to decay of the individual wood species used, the state of preservation of the log tombs (e.g., the structure in Tumulus MM was intact and standing when it was discovered, whereas the tomb in Tumulus P had collapsed earlier in its history), the position of the objects in the tombs, and whether the objects had been affected by water. Young's use of a water-cooled drilling rig in the initial exploration of Tumulus MM had caused a significant amount of water to enter the tomb (Young 1957). In addition, Blanchette attributed the development of soft rot in the log coffin from Tumulus MM to the earlier presence of water in the tomb, possibly at the time of its completion (Blanchette and Simpson 1992). The fragile state of many of the wooden objects when discovered led the archaeologist Rodney Young to seek advice on preservation techniques. While a few of the most important pieces, including the inlaid table and two inlaid serving stands from Tumulus MM, were treated by immersion in a bath of wax dissolved in gasoline, most of the furniture was coated with a dilute solution of Alvar, a polyvinyl acetal resin, dissolved in acetone (Spirydowicz 1996; Simpson and Spirydowicz 1999) (fig. 2). Young's field notebooks revealed that members of the field crew as well as the excavation foreman were assigned the task of “painting” the wood with an Alvar solution, an activity that no doubt resulted in many treatment variables (Young 1957). Young made it clear that this method was employed primarily as a first-aid measure so that the pieces could be removed safely from the royal tombs. When the wood was reexamined in 1981, many of the pieces previously coated with Alvar were found to be in a fragile state (Simpson and Spirydowicz 1999). In most cases, it appeared that the solution of Alvar had not penetrated much below the surface, so there was little strengthening effect. When the three-legged banquet tables found in Tumulus MM were examined, the only evidence for a previously applied coating was the presence of whitish or grayish patches on the deteriorated surfaces of the walnut tops, possibly due to application of Alvar while the wood was still damp. However, on some pieces, such as the serving stand from Tumulus W, the Alvar coating was clearly evident and, as such, had helped to preserve an essential decorative feature of the piece. Due to the thickness of the Alvar layer, the bronze studs decorating the front face of this remarkable piece of furniture were still in situ when the fragments were recovered after many years of storage in

As pieces were prepared for treatment, the previously applied Alvar coatings had to be removed. In most cases, this proved to be an easy task, as the Alvar was readily soluble in acetone. Removal of the thick film applied to the face of the serving stand from Tumulus W was facilitated by the application of gel poultices consisting of Klucel HF in ethanol or an ethanol-acetone mixture. Surface cleaning of the serving stand from Tumulus W provided clear evidence of the continuing solubility of Alvar over time. Other pieces of furniture had been treated with more dilute solutions of Alvar. In such cases, it was more difficult to detect whether the resin was removed from the surface by the cleaning process. However, it is likely that any further traces of Alvar would have dissolved in the solvents used during the subsequent consolidation process. Although the manufacture of Alvar by Shawinigan Products Corporation was discontinued many years ago, in hindsight, the choice of this resin was fortuitous, based on these observations of its behavior over time. In 1982, Payton consolidated small, unprovenanced cubes of wood from the Gordion tumuli with a 5% w/v solution of Butvar B-98 in equal parts of ethanol and toluene. The wood samples were immersed in the solution and allowed to absorb the consolidant. When the wood sank or floated just below the surface, indicating that most of the air in the wood had been replaced by the consolidant solution, the samples were removed and air-dried. Measurements taken before and after drying indicated virtually no shrinkage. This finding agreed with the results previously obtained by Barclay, who, in fact, found a minimal amount of expansion in test samples. In comparing treated and untreated portions of samples, Payton found that there was little color change. This result was considered desirable for treatment of those pieces of furniture containing inlay where color contrast between woods was an important feature of the overall design. Payton judged that a 5% concentration of Butvar B-98 imparted sufficient strength to the degraded wood, and he proceeded with treatment of the inlaid table (Payton 1984a) and the two ornate inlaid serving stands from Tumulus MM (Payton 1984b). Initially, the consolidation process involved immersion of the fragments in solution with the gradual application of vacuum pressure via a hand vacuum pump to assist penetration of the consolidant into the interior of the wood. The objects treated by Payton were in fairly sound condition, and thus a relatively low percentage of consolidant was effective in strengthening the wood. In subsequent seasons, it became obvious that the more degraded pieces, in particular the furniture and wooden objects from Tumulus P, required a higher ratio of consolidant to solvents. In 1991, a second set of consolidation tests was carried out. Small unprovenanced samples of Gordion wood were consolidated in varying concentrations of Butvar B-98 (10, 12.5, and 15% w/v in 60:40 ethanol and toluene). As a result of these tests and the scientific studies detailed below, the original consolidation procedure was modified and refined to successfully treat all of the remaining pieces of furniture (Simpson and Spirydowicz 1999). 4 ALVAR AND BUTVAR: PROPERTIES AND USESBoth Alvar and Butvar belong to the family of polyvinyl acetal resins that are formed by the reaction between aldehydes and alcohols. In industry, the Alvar was obtained by replacing the acetyl radicals in polyvinyl acetate by acetaldehyde. This resin was widely available in Great Britain and North America during the 1950s and 1960s. A brief overview of the uses of Alvar and other polyvinyl acetal resins in conservation is provided by Horie (1987). Alvar served conservators as a component of a widely used gap-filling material for ceramics known as AJK Dough. In addition, it became a favorite of paleontologists for the consolidation of fragile fossil material. However, its manufacture ceased by the mid-to-late 1960s (Howie 1984). Product literature dating from 1949 describes the Alvar class of resins as “exceptionally hard and tough.” Similarly, strength and toughness are cited as advantages of the polyvinyl butyrals in the literature of a current manufacturer (Solutia Inc. 1999). Common solvents for the polyvinyl butyrals include alcohols, glycol ethers, and certain mixtures of polar and nonpolar solvents. Alvar was soluble in a similar range of solvents. Payton selected the polyvinyl butyral resin Butvar B-98 on the basis of being able to achieve a low viscosity in solution when a solvent mixture of ethanol and toluene was employed. Glass transition temperature may also be an important factor in choosing a resin for use in hot climates. The glass transition temperature of Butvar B-98 falls between 72�C and 78�C, which is well above that of either Paraloid B-72 (40�C) or PVA resins (18-29�C). The high glass transition temperature of Butvar B-98 proved particularly advantageous when the decision was made in later years to employ Butvar B-98 as the primary adhesive in reconstructing the wooden artifacts from Gordion. 5 EXPERIMENTAL—SCANNING ELECTRON MICROSCOPE STUDIES5.1 METHODSixteen samples of miscellaneous furniture fragments consisting of small decayed fragments found in Tumulus P were used for these studies, which were conducted at the University of Minnesota. Each piece was divided in two, and half was used for consolidation and the other half left untreated. Varying concentrations of Butvar B-98 in 60:40 ethanol and toluene were used to consolidate the samples. Consolidation was carried out either by soaking the samples in solution or using a combination of soaking and application of vacuum pressure. In the first instance, the sample was lowered into solution and allowed to slowly absorb consolidant until sinking. The sample was left in the consolidant for 24 hours, drained, and then wrapped in polyethylene. In the second instance, the sample was lowered slowly into solution, and a vacuum was pulled in 5 cm (Hg) increments to 20 cm (Hg). The sample was left in solution under vacuum for half an hour, and then the pressure was released. When the sample had been immersed in the solution for a total of 24 hours, it was removed, drained, and then wrapped in polyethylene. After consolidation and drying, samples were prepared for scanning electron microscopy using

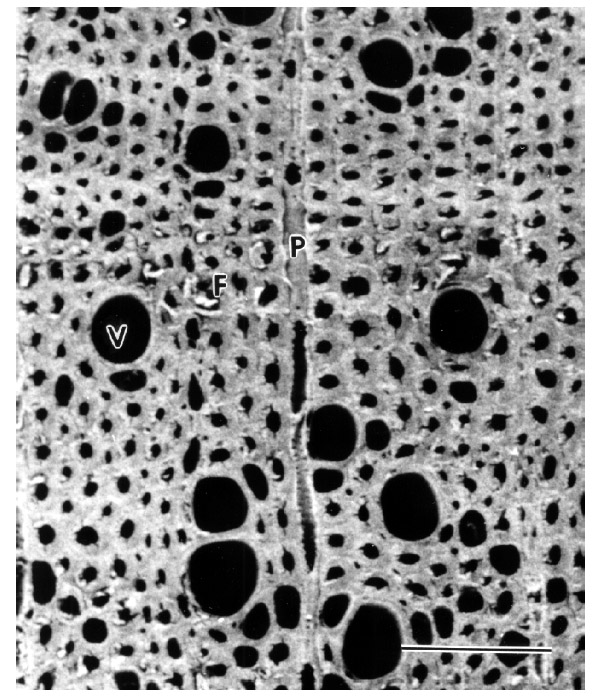

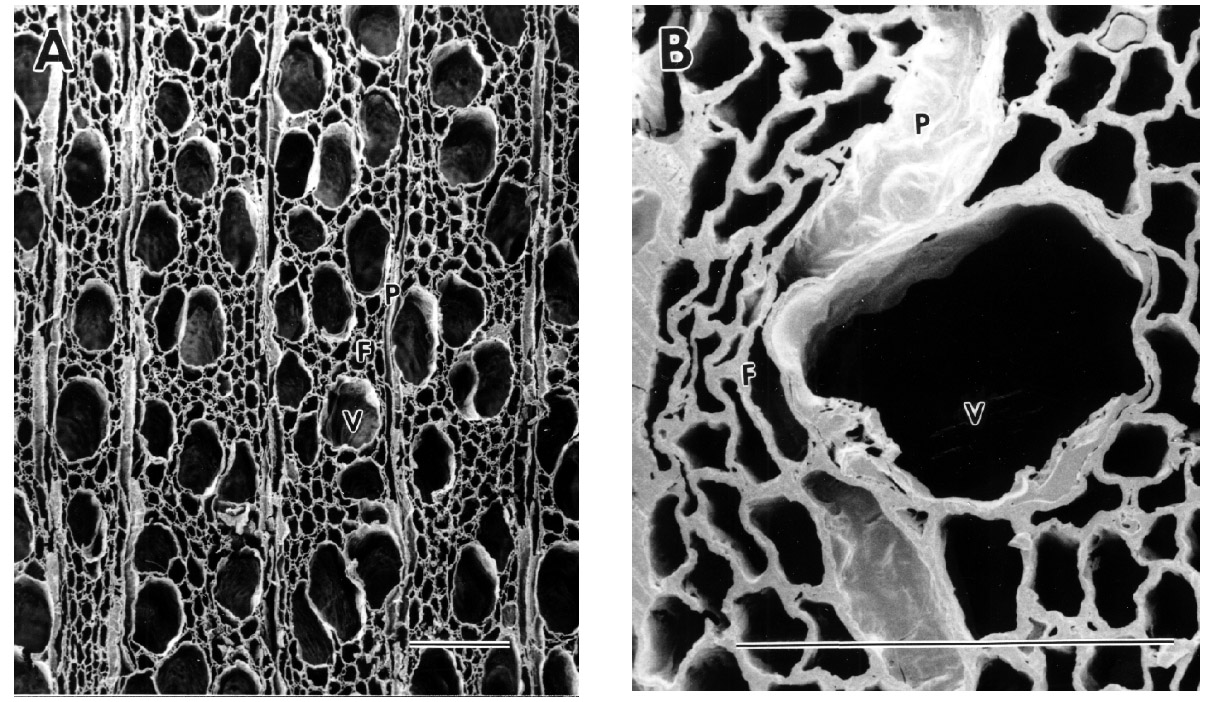

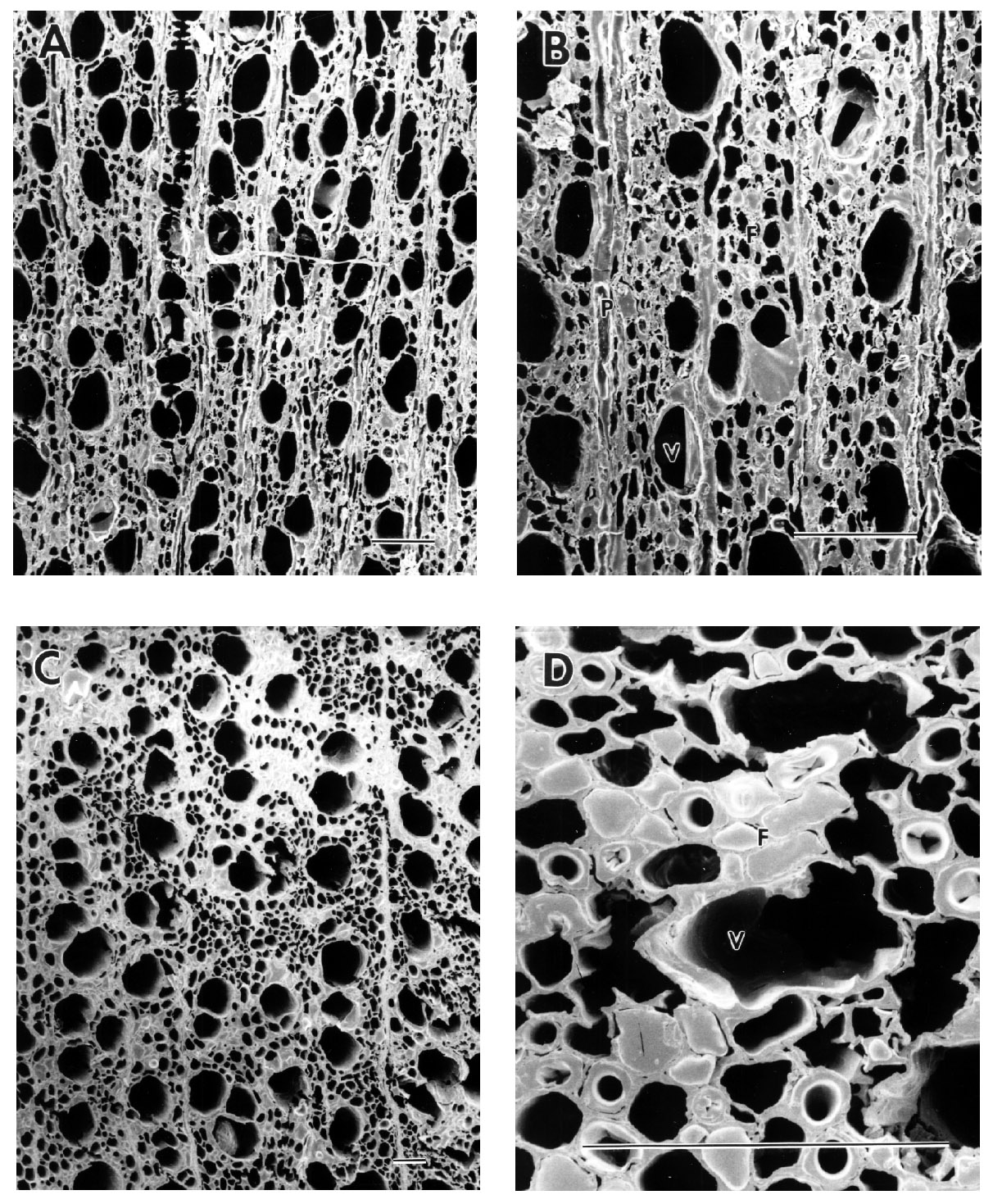

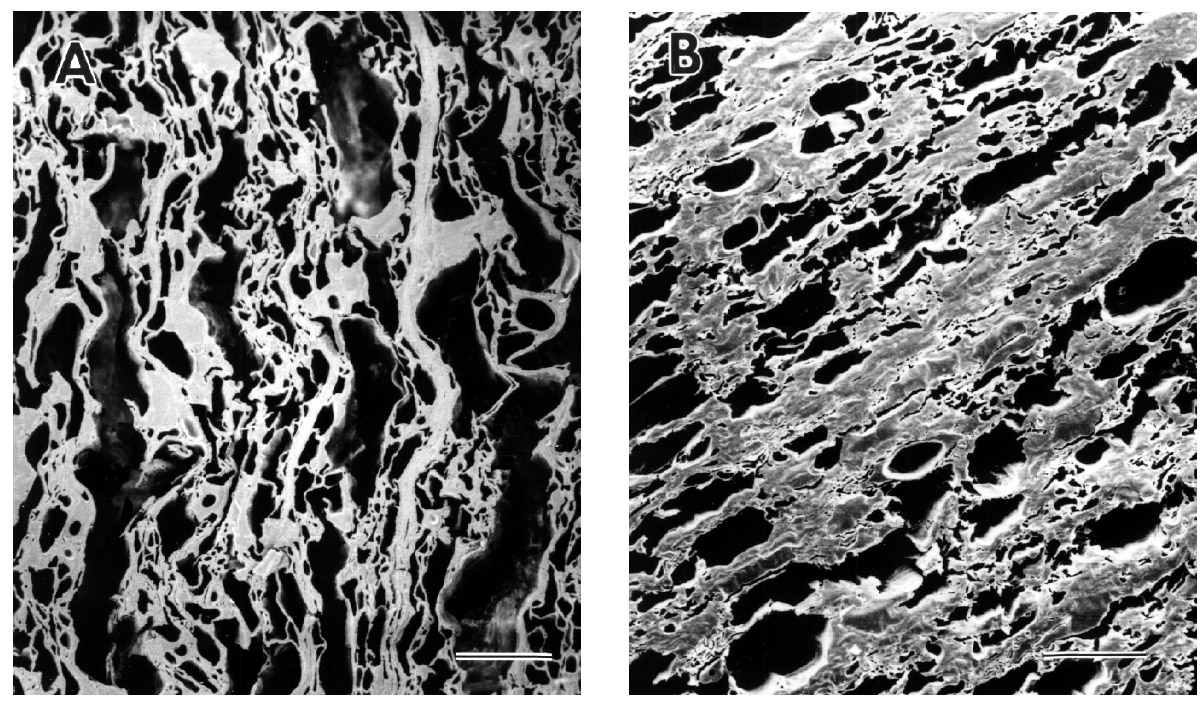

5.2 RESULTS AND DISCUSSIONFurniture samples were identified microscopically to be boxwood. This wood in a sound condition has thick-walled fibers and small-diameter vessel elements (fig. 4). The untreated samples of furniture examined had cells that were severely decayed (fig. 5). Most of the fiber cells were eroded with only a fragile, thin cell wall remaining. In a few cells, distinct cavities were observed within the fiber secondary wall, indicating that a soft-rot form of fungal attack had caused the decay. The decay had progressed to such an advanced stage that the entire secondary wall was destroyed in most cells. This type of decay had been identified and characterized previously from the wooden tomb chamber and coffin found in Tumulus MM (Blanchette and Simpson 1992; Blanchette 1998). The attack on the secondary wall region of the fibers removed the entire thick-walled region, leaving only a thin framework of middle lamella. The strength properties of this decayed wood were greatly compromised as compared to the strength of sound boxwood. In some samples, the decayed cells were distorted and had collapsed. Many adjacent cells were compressed together, while cracks and voids in the cell structure were observed in other regions. Samples consolidated by soaking or vacuum infiltration in 10% Butvar showed most cells to have a thin coating of the consolidant adhering to the cell walls (fig. 6). The cell lumina of some fibers were filled with consolidant, but vessel elements were usually not filled with the consolidant. This treatment appeared to stabilize the thin middle lamella left after fungal attack by providing a coating on the surfaces of the decayed walls. After consolidation, the anatomical structure of the wood was still distinct, and the micromorphological features of the wood were still intact. Examination at relatively high magnification showed many small-diameter fibers were filled with consolidant reinforcing these weakened cells (figs. 6b, 6d). The occluded fiber lumina were interspersed with many cells that had consolidant coating the cell walls. The consolidant that coated cell walls and filled some of the fibers provided a network of Butvar that

The distribution of the consolidant was visible only after microscopic examination. In samples of decayed wood with cells that had been crushed and compressed, the consolidant was found to have accumulated in the small-diameter spaces between crushed cells (fig. 7a). Greater numbers of cells were occluded with the consolidant than in other decayed wood samples where the morphological structure of the wood had been preserved. Severely decayed wood samples treated with a 12.5% Butvar B-98 solution had even greater amounts of consolidant evident within the crushed and collapsed wood cells (fig. 7b). In some samples where the integrity of the wood had been so greatly compromised that cracks or voids caused it to be in jeopardy of fragmenting into minute pieces, increased concentrations of consolidant provided greater binding and increased strength. The increased amounts of consolidant were visible within the crushed lumina of the fibers, but due to slightly larger pore size, the vessel elements usually did not become totally occluded. 5.3 CONCLUSIONThe results of the study demonstrate that treatment of decayed archaeological wood with 10% Butvar B-98 solution can be carried out without significantly altering the micromorphological structure of the wood. At relatively high magnifications with microscopic observations, the consolidant can be seen to coat the cell walls and fill some of the lumina of small diameter cells. This type of treatment greatly aids the stability of the decayed wood without significant changes to the microstructure. 6 EXPERIMENTAL—NEEDLE HARDNESS TESTINGIn order to quantify the improvement in strength

6.1 MATERIALThe samples consisted of wood fragments of irregular shape ranging in size from as little as 4 x 9 x 8 mm to a maximum of 35 x 70 x 115 mm. All the wood was selected from pieces belonging to Tumulus P that could not be identified as belonging to a specific object or piece of furniture. All the samples were cut in half using a coping saw with a fine blade. Half of each sample was set aside to provide a control while the other half was treated. A 10% w/v solution of Butvar B-98 in 60:40 ethanol and toluene was used to consolidate the samples. The method of consolidation consisted of simple soaking or a combination of soaking and vacuum impregnation. 6.2 METHODAn Instron table model testing machine was fitted with a Singer sewing machine needle, style 2020, size 110/18, no. 2085 (4758). The test procedure consisted of driving the needle into the wood samples while they were being observed with a stereoscopic inspection microscope at 10x. The load was recorded continuously. The loads at 2.4, 4.5, and 5.6 mm needle penetration were marked and recorded. In some cases, the load at the greater depths of penetration could not be determined because of splitting of the wood. For samples that were very small, the tests were discontinued after 2.4 mm penetration. 6.3 RESULTS AND DISCUSSIONResults are summarized in table 1 for loads at 2.4 mm needle penetration. Strength improvement was assessed by comparing mean values of the untreated and treated samples and expressing the change as a percentage. All the consolidated samples demonstrated a marked improvement in strength varying from 18% to 242%. Due to the small numbers of test samples available and the large variability of the data, it was not possible to draw any additional conclusions as to whether the strength of the wood was improved by varying the method of application. Considering the heterogeneous structure of wood, and especially of deteriorated wood, it is not surprising that considerable variability is present. Load values range from 236 g to 922 g for untreated samples and from 486 g to 2,048 g for the consolidated ones. There was also variation within specimens. The ratio between the lowest and the highest To investigate whether the great range of improvement values in needle hardness after consolidation was related to the variation in hardness values of the untreated samples, the data of table 1 were listed in ascending order of the hardness loads of the untreated specimens. As might be expected, there is some degree of inverse correlation between hardness of the untreated specimens and the improvement obtained. The two specimens with the lowest hardness showed the greatest improvement, and the lowest value of improvement is found in the upper range of hardness before treatment. It can therefore be concluded that the consolidation treatment effected significant improvement in needle hardness, with a tendency toward greatest improvement of the weakest pieces, and introduced a degree of uniformity within specimens. 7 EXPERIMENTAL—EXPOSURE TO INTENSE ENVIRONMENTAL CONDITIONSThe purpose of this study conducted at Queen's University, Kingston, was to give preliminary information about the aging characteristics of Butvar B-98 resin (Toutloff 1999). The material properties of Butvar B-98 can be found in the product literature (Solutia Inc. 1999); for example, the glass transition temperature (Tg) is stated as 72-78�C. Both chemical and physical properties were selected for analysis after the samples were exposed to intense environmental conditions. These conditions included high temperature at constant relative humidity, as the product literature implies that Butvar B-98 may cross-link upon exposure to heat. Long-wave ultraviolet light was also chosen as an experimental parameter because it would introduce energy into the system, which would increase the probability of chemical reactions that might lead to cross-linking between and within the polymer chains. Infrared spectroscopy was used to examine the samples for evidence of cross-linking after exposure. The physical properties of color, hardness, and solubility were measured to detect any differences between the exposed samples and the control group, due to chemical changes. 7.1 MATERIALSixty samples were produced by casting layers of a 15% w/v solution of Butvar B-98 in 60:40 ethanol and toluene with an average thickness of 0.03 mm onto glass microscope slides. The samples were allowed to dry for seven days to ensure complete solvent loss. 7.2 CONDITIONSGroups containing six samples each were exposed to different environmental conditions for specific amounts of time: (1) a temperature of 65�C and a relative humidity (RH) of 50% for 25 days; (2) a temperature of 65�C and 50% RH for 50 days; (3) long-wave ultraviolet radiation for 20 days (20-25�C and 50-60% RH); (4) long-wave ultraviolet radiation for 40 days (20-25�C and 50-60% RH); and (5) dark storage (20-25�C and 50-60% RH) for the control. A Tenny model TH65 Versa Tenn 65 cu. ft. temperature–humidity environmental chamber was used to obtain an environment of 65�C and 50% RH. The long-wave radiation was emitted from a 365 nm long-wave ultraviolet bulb. 7.3 METHODSInfrared spectroscopy was performed using a Perkin-Elmer Model 983G double-beam ratio recording infrared spectrophotometer. The spectra were recorded at a nominal resolution of 4 cm-1.A KBr pellet was made using 1-2 mg of sample scraped from the Butvar B-98 film. A MacBeth Color-1 Colorimeter measured L* (lightness), a* (green-red) and b* (blue-yellow), using the standard illuminant D (average daylight, 6500�K),

Hardness was measured by indentation with a Shore Durometer A Type D, ASTM Designation D2240, which uses a pointed steel pin. The instrument had a constant load-operating stand and a deadweight of approximately 822 g. Hardness measurements were taken from three different areas on three samples for each condition, for a total of nine measurements. Two methods were used to test for solubility. The first involved placing samples in 60:40 ethanol and toluene solvent mixtures. As all samples dissolved immediately, a second method was used. A swab that was saturated with the same solvent mixture was passed over the film until the film completely dissolved. The number of passes was counted. The experiment was carried out by one person, in as consistent a manner as possible. The measurement was made twice for each condition. 7.4 RESULTS AND DISCUSSIONThe IR spectra showed little difference before and after exposure to the intense environments, indicating that there were no substantial chemical changes. No new peaks appeared after exposure that would indicate the formation of new bonds due to cross-linking. A minor change occurred around 1106 cm-1 and 1138 cm-1 in the samples exposed to high heat and humidity for 50 days, most probably indicating absorption of -OH groups due to water from the humid conditions. Color change was not apparent to the naked eye. The measurements showed that there was minimal change, which is consistent with the literature. The average δE* was over 1 only for the samples exposed to 65�C and 50% RH for 50 days (δE* = 1.62) (table 2). All samples exposed to ultraviolet light had δE* less than 1. The results from the hardness tests show that Butvar B-98 became only slightly harder after exposure to intense environmental conditions. Most of the samples showed an increase in hardness of 1 unit (from 15 units), which is very small. There were only two exceptions where one of the three areas on the samples had an increase of 2 units. These samples had been exposed to intense environmental conditions for the longer times (50 days at 65�C and 50% RH, and 40 days of ultraviolet radiation). The first solubility test demonstrated that the films were extremely soluble in the solvent mixture and could be considered reversible. The second method using solvent-saturated cotton swabs showed that samples exposed to 65�C and 50% RH for 50 days required 15 passes and were therefore the least soluble; samples exposed to ultraviolet radiation for 20 days required 13 passes; samples exposed to ultraviolet radiation for 40 days required 12 passes; samples exposed to 65�C and 50% RH for 25 days required 8 passes; and the control required 9 passes. 7.5 CONCLUSIONThe results from the infrared analysis taken in conjunction with the results of the physical tests indicate that the Butvar B-98 resin film remained fairly stable under the intense environmental conditions of the experiment. The group that showed the most change in all cases was the set exposed to a temperature of 65�C and 50% RH for 50 days. These results concur with the product literature, which 8 CONCLUSION—USE OF BUTVAR B-98 AS AN APPROPRIATE CONSOLIDANT FOR DRY ARCHAEOLOGICAL WOODThe treatment of the Gordion wooden objects is now complete (Simpson and Spirydowicz 1999). Four of the most ornate pieces of furniture have been reconstructed and are currently on display at the Museum of Anatolian Civilizations in Ankara. All of the remaining wooden objects in the collection have been repaired and placed in protective storage in the museum. The results of scanning electron microscopy studies have shown that the use of a 10% w/v solution of Butvar B-98 is effective in coating cell walls and thus significantly improving the stability of severely degraded wood. Needle hardness testing has demonstrated a marked increase in strength in a limited number of test samples. Exposure of films of Butvar B-98 to intense environmental conditions has indicated that the resin is able to withstand harsh test conditions with few chemical changes occurring. In the opinion of the authors, the use of Butvar B-98 as an effective consolidant for the treatment of ancient wooden artifacts has been demonstrated. The useful properties of polyvinyl butyral resins, including strength, low viscosity, and versatility, have led to their acceptance as a standard treatment for the conservation of dry archaeological wood. ACKNOWLEDGEMENTSThe contribution of Dr. H. F. Shurvell, Professor Emeritus in the Department of Chemistry at Queen's University, with regard to the Fourier transform infrared spectroscopy is gratefully acknowledged. REFERENCESBarclay, R.1981. Wood consolidation on an eighteenth century English fire engine. Studies in Conservation26(4):133–39. Blanchette, R. A.1998. A guide to wood deterioration caused by microorganisms and insects. In The structural conservation of panel paintings, ed.K.Dardes and A.Rothe. Los Angeles: Getty Conservation Institute. 55–68. Blanchette, R. A., J. E.Haight, R. T. J.Koestler, P. B.Hatchfield, and D.Arnold. 1994. Assessment of deterioration in archaeological wood from ancient Egypt. Journal of the American Institute for Conservation33:55–70. Blanchette, R. A., T.Nilsson, G.Daniel, and A.Abad. 1990. Biological degradation of wood. In Archaeological wood: Properties, chemistry, and preservation, ed.R. M.Rowell and R. J.Barbour. Advances in Chemistry series 225. Washington, D. C.: American Chemical Society. 141–74. Blanchette, R. A., and E.Simpson. 1992. Soft rot and wood pseudomorphs in an ancient coffin (700 BC) from Tumulus MM at Gordion, Turkey. International Association of Wood Anatomists Bulletin13:201–13. Carlson, S., and A. P.Schniewind. 1990. Residual solvents in wood-consolidant composites. Studies in Conservation35:26–32. Grattan, D. W.1980. Consolidants for degraded and damaged wood. In Proceedings of the Furniture and Wooden Objects Symposium. Ottawa: Canadian Conservation Institute. 27–42.

Hatchfield, P. B., and R. J.Koestler. 1987. Scanning electron microscopic examination of archaeological wood structure altered by consolidation treatments. Horie, C. V. 1987. Materials for conservation. Oxford: Butterworth-Heinemann. Howie, F. M. P.1984. Materials used for conserving fossil specimens since 1930: A review. In Adhesives and consolidants, ed.N. S.Brommelle et al. London: International Institute for Conservation of Historic and Artistic Works. 92–97. Munnikendam, R. A.1978. Consolidation of fragile wood with low viscosity aliphatic epoxy resins. In Conservation of wood in painting and the decorative arts, ed.N. S.Brommelle et al. London: International Institute for Conservation of Historic and Artistic Works. 71–73. Munnikendam, R. A., and Wolschrijn, T. J.1969. Further remarks on impregnation of porous materials with monomers. Studies in Conservation14(3):132–35. Payton, R. E. 1984a. The conservation of an eighth century BC table from Gordion. In Adhesives and consolidants, ed.N. S.Brommelle et al. London: International Institute for Conservation of Historic and Artistic Works. 133–37. Payton, R. E.1984b. The conservation of screens A and B from Gordion. Unpublished typescript. Museum of Anatolian Civilizations, Ankara. Sakuno, T., and A. P.Schniewind. 1990. Adhesive qualities of consolidants for deteriorated wood. Journal of the American Institute for Conservation29:33–34. Schaffer, E.1971. Consolidation of softwood artifacts. Studies in Conservation15(3):110–13. Schaffer, E.1974. Consolidation of painted wooden artifacts. Studies in Conservation19(4):212–21. Schniewind, A. P., and P. Y.Eastman. 1994. Consolidant distribution in deteriorated wood treated with soluble resins. Journal of the American Institute for Conservation33:247–55. Simpson, E.1996. Phrygian furniture from Gordion. In The furniture of Western Asia: Ancient and traditional, ed.G.Herrmann. Mainz: Philipp von Zabern. Simpson, E., and K.Spirydowicz. 1999. Gordion wooden furniture. The study, conservation and reconstruction of the furniture and wooden objects from Gordion, 1981-1998.Ankara: Museum of Anatolian Civilizations. Skeist, I., ed.1977. Handbook of adhesives. New York: Van Nostrand Reinhold. Solutia Inc.1999. Butvar, polyvinyl butyral resin, properties & uses. Publication 2008084D. St. Louis, Mo. Spirydowicz, K.1996. The conservation of ancient Phrygian furniture from Gordion, Turkey. In Archaeological conservation and its consequences, ed.A.Roy et al. London: International Institute for Conservation of Historic and Artistic Works. 146–50. Toutloff, M.1999. The effect of intense environmental conditions on Butvar B-98. MAC research project report. Kingston, Ontario: Queen's University. Wang, Y., and A. P.Schniewind. 1985. Consolidation of deteriorated wood with soluble resins. Journal of the American Institute for Conservation24:77–91. Young, R. S.1957. Field notebook, vol. 63. University Museum, Philadelphia. Young, R. S.1981. Three great early Tumuli: Gordion excavations final reports, vol. 1. Philadelphia: University Museum. AUTHOR INFORMATIONKRYSIA E. SPIRYDOWICZ is associate professor in the Art Conservation Program, Queen's University, Kingston, Ontario, Canada. From 1979 to 1985, she held the position of coordinator of the Art Conservation Techniques Program at Sir Sandford Fleming College, Peterborough, Ontario. Her research interests include the conservation of ELIZABETH SIMPSON, Ph. D., is associate professor of Ancient Art with the Bard Graduate Center for Studies in the Decorative Arts in New York. In 1981, she established the Gordion Furniture Project for the purposes of conservation, research, and publication of the royal wooden furniture from Gordion, Turkey. As director of the project, she has published extensively on the subjects of Phrygian furniture and ancient woodworking technology. In 1995, she organized an important international conference to discuss issues surrounding the restitution of cultural property looted during World War II, and she subsequently edited the volume of conference papers entitled Spoils of War. Address: Bard Graduate Center for Studies in the Decorative Arts, 18 West 86th Street, NewYork, N. Y. 10024 ROBERT A. BLANCHETTE, Ph. D., is a professor in the Department of Plant Pathology at the University of Minnesota. His research activities on wood microbiology and biodeterioration have focused on elucidating degradation processes in archaeological wood from different environments. His most recent work involves an assessment of biodeterioration in extreme environments, ranging from the historic huts of the Ross Sea Region of Antarctica to the buried tomb within Tumulus MM at Gordion, Turkey. Address: Department of Plant Pathology, 1991 Upper Buford Circle, 495 Borlaug Hall, University of Minnesota, St. Paul, Minn. 55108-6030. E-mail: robertb@puccini.crl.umn.edu ARNO P. SCHNIEWIND is Professor of Forestry, Emeritus, and has been associated with the Forest Products Laboratory of the University of California since 1956. He became interested in the application of wood science to the conservation of wood artifacts in 1982, and has been a member of AIC since 1984. He has recently been working on a book on conservation of wood artifacts together with a husband-and-wife team in Germany. Address: University of California, Forest Products Laboratory, 1301 South 46th St., Richmond, Calif. 94804-4698 MAURAY K. TOUTLOFF received her B. Sc. in biology from the University of Regina in Saskatchewan in 1996, and her M. A.C. from Queen's University in 1999. She is currently working as a private conservator in Victoria, British Columbia. Address: 125 Kingston St.,Victoria, British Columbia, V8V 1V3, Canada ALISON MURRAY is assistant professor in the Art Conservation Program at Queen's University, Kingston, Ontario. She received her honors B. Sc. in chemistry from McGill University and her M. Sc. and Ph. D. degrees in materials science and engineering with a specialization in conservation science from a joint program between Johns Hopkins University and the Smithsonian Institution. She has held fellowships at the Analytical Research Services Division, Canadian Conservation Institute, and in the Scientific Department, National Gallery, London, the latter funded by the Samuel H. Kress Foundation. Her areas of research include the investigation of degradation in art objects using microscopy, nondestructive methods, and other analytical techniques, as well as the identification of artists' materials and techniques. Address as for Spirydowicz

Section Index Section Index |