PARALOID B-72 AS A STRUCTURAL ADHESIVE AND AS A BARRIER WITHIN STRUCTURAL ADHESIVE BONDS: EVALUATIONS OF STRENGTH AND REVERSIBILITYJERRY PODANY, KATHLEEN M. GARLAND, WILLIAM R. FREEMAN, & JOE ROGERS

3 SHEAR TESTSLap shear tests were undertaken in October 1997 in conjunction with the design of a treatment for a fourth-century B.C. Pentelic marble lion in the collection of the Nelson-Atkins Museum. Several large sections of the sculpture, weighing approximately 4,000-5,300 Newtons (900-1,200 lbs.) and a mass of 400-540 kg each, were to be adhered to others as part of the reassembly process. Pursuing the desire that these joints be more easily reversible, the conservation staff began to evaluate the use of B-72 barriers and B-72 as an adhesive compared to more commonly used structural adhesives such as Akemi polyester and Araldite AY 103 epoxy. To more directly mirror the bonds that would be made in the project, the test coupons were made of Pentelic marble (Marble Enterprises 1999), identical to the type used to carve the lion sculpture in ancient times.

3.1 ADHESIVES EVALUATEDFive samples of each of the following adhesive groups were prepared:

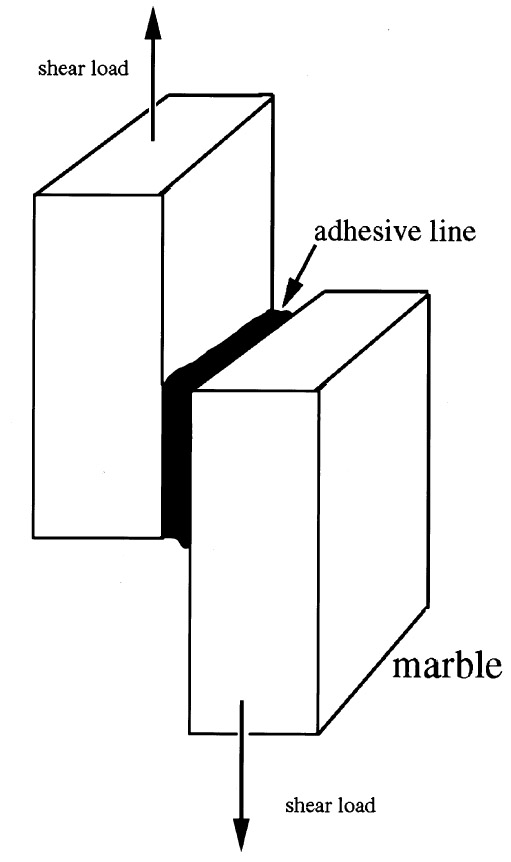

3.2 SAMPLE PREPARATIONEach sample was made of two small slabs of Pentelic marble (shear strength of 4,212 kPa or 611 psi) nominally 19 mm (0.75 in.) wide x 31.75 mm (1.25 in.) long x 9.52 mm (0.375 in.) thick, adhered with an overlap of 12.7 mm (0.5 in.) as described in ASTM D1002 (Skeist 1977; Pocius 1997) and illustrated in figure 4. Since there was a small variation from the nominal dimensions in each of the samples, the actual measured width and overlap length to the nearest 0.025 mm (0.001 in.) were used to calculate the shear area for each specimen. Even small variations in the width and lap length cause substantial changes in the calculated shear area and stress, so the accurate dimensions of each sample were used in the individual calculations. The samples were washed in a dilute Orvus (sodium alkyl sulfate) anionic detergent solution using stencil brushes, rinsed in distilled water, and then air-dried for three weeks. The samples were degreased with acetone, allowed to dry, then adhered with “finger” pressure. Excess adhesive was wiped off with acetone on a dry swab or mechanically removed after full cure. |