ACCESS DENIED: ASBESTOS CONTAMINATION AS CATALYST AND HINDRANCE TO COLLECTION RETRIEVAL AND PRESERVATIONVIRGINIA M. DEUCHER, TAMURA L. MOORE, & STEVE HEMLIN

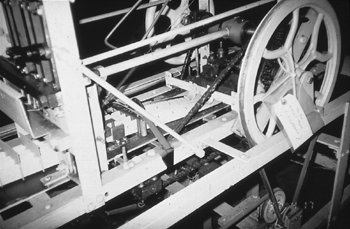

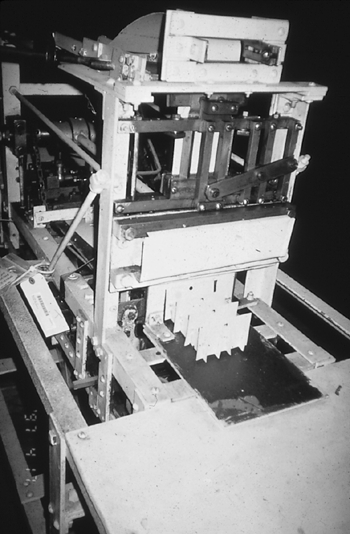

6 6. IMPLEMENTATIONThe collections stored in Building 17 ranged from large industrial machinery and farm equipment to delicate 19th-century patent models and textiles. Artifacts were stored in boxes, cabinetry, and crates, on open shelving and the floor. It was determined during the planning phase that objects would be removed from all crates, boxes, and storage units. Although a percentage of the Building 17 collections was inventoried to the item level, inventory data were more commonly assigned to the exterior of storage units or entire densely-packed sections, without clear knowledge of the type of objects, materials, or actual numbers of objects represented. Based on what was readily visible and the inventory data that had been gathered, the project team tried to anticipate the unknowns. During implementation, artifacts were prepared by NMAH off-site staff prior to decontamination by the contractor. Objects were removed from storage containers and bar-coded with location information, and appropriate color tags were attached to specify the proper decontamination method. Color tags were used for ease in communication with the contractor; for example, a green tag indicated HEPA vacuuming only, a yellow tag designated washout. Caution tags in Spanish and English were also used to identify fragile parts or hazards such as broken glass, mercury, torn fabric, and sharp points or edges. Original manufacture or catalog tags were placed into bags and reattached to the object with cable ties to prevent damage during the decontamination process. Constant adjustments to the decontamination procedures based on object fragility and material type proved to be an absolute necessity. A balance between the decontamination of collection items, minimization of object damage, and cost considerations was sought. The NMAH conservator and collections managers worked with the contractor and industrial hygienist to reduce the anticipated “acceptable losses.” For example, fragile surfaces were identified, such as decorative paint or historic labels, which required a gentler decontamination process. There were concerns over the water pressure when the washout procedure was used, and the damage that might occur from water remaining on wooden surfaces, in joints, or inside moving mechanical parts. This hazard was alleviated through close work with the contractor to ensure that fragile objects were decontaminated with lower water pressure. The use of compressed air (also adjustable pressure) was added to drive any excess water from object parts. With these adjustments, concerns over the effects of the decontamination process on the objects were allayed, as objects of different material types cleared the testing chamber. To help prevent rusting, Ballistol, a biodegradable, lanolin-based lubricating agent, was carefully applied to the moving parts of many industrial and mechanical objects. Ballistol was not applied until the object was removed from the containment, as clearance test results would have been affected by temporarily holding asbestos fibers in place. The uneven, porous surfaces of items such as paper, textiles, furs, and feathers represented another decontamination challenge because of the propensity of asbestos fibers to snag or embed on those surfaces. Consequently, NMAH and the contractor believed successful decontamination of these objects was questionable. These concerns proved to be unfounded, as demonstrated by one of the earliest and most encouraging successes, an egg-carton-making machine. The object was “threaded” with strips of cardboard, which emerged from the machine as a formed egg carton (figs. 3a–3b). The cardboard was in good condition and represented a small but critical portion of the overall object. Rather than automatically removing the cardboard, NMAH staff worked with the decontamination contractor to develop a multiprotocol approach: the cardboard was vacuumed and blown with compressed air, the area in the immediate vicinity of the paper was wet-wiped, and the rest of the machine received the washout procedure. Validation of this approach was borne out by the clearance testing: objects decontaminated with these customized procedures routinely passed the PCM tests.

Despite customized procedures, all objects could not be saved in their entirety. Exposed yarns and sections of woven fabric on unprotected looms could not be decontaminated and were removed. In the case of exposed bolts of material, contaminated outer layers were cut off and the remaining material was salvaged. However, yarns, fabric, raw fibers, and similar materials in more protected circumstances, such as lockers or crates, or wrapped in paper, had limited exposure to the delaminating asbestos and thus were less contaminated. These materials readily passed the clearance tests. Feathers, furs, and other inherently fragile natural fibers were TEM tested prior to decontamination to minimize any possible damage and to identify actual asbestos fibers. There were occasional failures, which prompted careful decontamination of the objects with a HEPA vacuum along with a full decontamination of the testing chamber itself. Additional collection concerns included mold, infestation, and hazardous materials. To address active mold on wood, metal, and glass surfaces, a diluted solution of Lysol concentrate (1 capful per 1 qt. water) was applied to clean cloths and wiped on the objects. This step was done prior to asbestos decontamination to minimize the spread of the mold spores. Lysol was used rather than bleach or ethanol as it could be used on a variety of object finishes and was less of an irritant for the staff in a confined space. Evidence of rodents and insects, including dermestids and webbing clothes moths, was found throughout the collections as well. Historic debris from grain processing on some agricultural machinery had attracted grain beetles. These objects were heavily coated with flour-like agricultural residues and insect debris, which were vacuumed prior to decontamination. After removal from the building, these items were monitored in storage to determine if there was further insect activity. Objects that were damaged beyond recovery from mold, infestation, or the inability to decontaminate were disposed of through a streamlined deaccession procedure. The same procedures were followed for other collections that were inherently hazardous. Flammables, reactives, acids, regulated materials, chemicals in leaking or leaching containers, unknown substances, and radioactive materials were all present in the building. These items were segregated, identified, containerized in plastic bins, and disposed of by a hazardous materials handling company (Clean Ventures Inc.) (fig. 4). Disposal charges for these materials were approximately $20,000.

The discovery of explosives, including blasting caps and shotgun shells, prompted a telephone call to the Prince Georges County bomb squad to review the materials. The bomb squad determined that these items were unstable and required staff to evacuate the building while they were removed. Polychlorinated biphenyls (PCBs) were found in the antioxidants on the surfaces of medical equipment and in the sealed oil reservoirs, some of which were damaged, of industrial machinery. Cleanup of the exteriors of the medical equipment was required prior to asbestos decontamination because of the safety issues involved in handling objects coated with PCBs. Objects were double-washed with mineral spirits to reduce the PCB levels in the antioxidant coatings. Labor and disposal costs for this process were $18,000. At times, movement of objects caused unanticipated oil leaks in objects with damaged oil reservoir seals, which also required spot cleanups with mineral spirits and the purchase of spillproof pallets to contain further leakage. PCBs in sealed reservoirs did not present an immediate handling risk and therefore were not addressed until the objects cleared the asbestos testing chamber, at which time the interior reservoirs were tested and drained if the PCB levels were greater than 50 ppm. The fee for testing and disposal of these oils was an additional $15,000. Finally, mercury was present in medical equipment, electrical tubes, and barometers. Mercury spill kits (Hg Absorb) were placed inside the building and were used several times for small spills. The mercury-contaminated materials were then disposed of as hazardous waste. Despite these challenges, the overall clearance rate was excellent. The objects emerged from the containment in better condition than anticipated during the planning phase, and the amount of object damage was minimal. In conclusion, the Building 17 Artifact Decontamination Project was a dynamic team effort, involving difficult collections decisions and hidden costs, and recognizing and adjusting to changing variables while retrieving objects, as carefully as possible, from an inhospitable environment. |