ACCESS DENIED: ASBESTOS CONTAMINATION AS CATALYST AND HINDRANCE TO COLLECTION RETRIEVAL AND PRESERVATIONVIRGINIA M. DEUCHER, TAMURA L. MOORE, & STEVE HEMLIN

ABSTRACT—ABSTRACT—Asbestos abatement industry standards for items exposed to a contaminated environment generally call for disposal. This option is not acceptable for museum objects that have been contaminated by asbestos. For many years the Smithsonian Institution has worked to define and refine artifact asbestos decontamination procedures and approaches. The Building 17 Artifact Asbestos Decontamination Project plan was developed through a series of institution-wide meetings that ensured sufficient staff and other resources existed to meet contractual obligations and that provided a clear work process under which the project could proceed. After the project started, the plan, which was always considered to be dynamic, was altered to accommodate the many known and unknown challenges and hazards discovered within the space. Working with collections at risk forced the museum to make difficult collections management and preservation decisions and to remain dynamic and flexible in the management of the project. The purpose of this article is to review the planning process, to examine the balance of decontamination methods with preservation practices, to discuss the various decontamination protocols planned, and to outline the differences between what had been planned and what was discovered during implementation. TITRE—Acc�s interdit: la poussi�re d'amiante en tant que catalyste et entrave � la r�cup�ration et la pr�servation des collections. R�SUM�—Selon les normes d�velopp�es par l'industrie de l'enl�vement sanitaire de l'amiante, on doit g�n�ralement se d�barasser des objets qui ont �t� expos�s � la poussi�re d'amiante. Cette option n'en est pourtant pas une pour les objets de mus�e qui ont �t� expos�s � la poussi�re d'amiante. Depuis plusieurs ann�es, des chercheurs au Smithsonian Institution ont travaill� pour �laborer et perfectionner des approches et proc�dures pour l'enl�vement sanitaire de la poussi�re d'amiante sur les objets. Le projet d'enl�vement de la poussi�re d'amiante des objets de l'�difice no. 17 fut �labor� durant une s�rie de r�unions du personnel de toute l'institution, ce qui permit non seulement d'assurer qu'il y avait une main d'oeuvre et des ressources suffisantes pour r�aliser ce projet selon les obligations contractuelles, mais aussi d'�tablir clairement un plan de travail en vue de passer � l'�tape de la mise en oeuvre du projet. Une fois le projet en marche, divers changements ont �t� apport�s au plan original, qui d'ailleurs avait �t� con�u de fa�on � �tre souple, afin de faire face aux divers d�fis et dangers, anticip�s ou non, que l'on rencontra dans l'espace en question. Le travail avec ces collections qui posent un risque � la sant� obligea le mus�e � prendre des d�cisions difficiles quant � la pr�servation et la gestion de ces collections, tout en demeurant flexible et dynamique dans la gestion du projet. Cet article a pour buts de pr�senter le processus de planification du projet, d'examiner la recherche d'un �quilibre entre d'une part les m�thodes d'enl�vement sanitaire de la poussi�re d'amiante et d'autre part la pr�servation des objets, de pr�senter les diff�rents protocoles d'enl�vement de la poussi�re qui ont �t� planifi�s, et enfin de souligner les diff�rences entre ce qui avait �t� pr�vu au d�part et ce qui fut d�couvert lors de la mise en oeuvre du projet. TITULO—Prohibida la entrada: la contaminaci�n con asbestos como catalizador e impedimento para el acceso y la preservaci�n de las colecciones. RESUMEN—Los estandares de la industria de supresi�n de asbesto para objetos contaminados por el ambiente exigen que estos sean desechados. Esta es una opci�n que no es aceptable cuando se trata de objetos de museo que han sido contaminados por asbestos. Durante muchos a�os la Instituci�n Smithsonian ha trabajado para definir y refinar los procedimientos y acercamientos en el proceso de descontaminaci�n de asbestos. El “Proyecto del Edificio 17 para la descontaminaci�n de objetos contaminados con asbesto”, se desarrollo por medio de una serie de reuniones interinstitucionales, para garantizar que hubiera suficiente personal y que otros recursos estuvieran disponibles, para cumplir obligaciones estipuladas en los contratos, y que ofrecieran un proceso de trabajo claro, bajo el cual se pudiera proseguir. Depues de que el proceso comenzo, el plan que siempre fue considerado dinamico, fue alterado para acomodar los muchos retos conocidos y desconocidos que se fueron descubriendo dentro del mismo. El trabajar con colecciones a riesgo forz� al museo a tomas decisiones dificiles respecto a la gesti�n y la preservaci�n de las colecciones, y a permanecer flexibles y din�micos en la gesti�n del proyecto. El proposito de este articulo es revisar el proceso de planeaci�n, examinar el balance de los m�todos de descontaminaci�n con las practicas de preservaci�n, discutir los varios protocolos de descontaminaci�n planeados, y describir las diferencias entre lo que se hab�a planeado y lo que se descubri� durante la implementaci�n. 1 1. OVERVIEWThe National Museum of American History's (NMAH) off-site storage program includes three facilities: the Silver Hill Facility and the Museum Support Center, both in Suitland, Maryland, and the Fullerton Objects Storage Facility located in Springfield, Virginia. The facilities total 190,500 sq. ft., and house approximately 50% of the museum's holdings. The NMAH off-site storage program is managed by the Office of Curatorial Affairs, Collections Management Services Department. Building 17, one of seven NMAH storage buildings at the Silver Hill Facility and the largest at 27,000 sq. ft., over a period of several years had become increasingly contaminated by delaminating, friable asbestos wall and ceiling insulation that released hazardous fibers into the ambient air (fig. 1). The fibers settled onto the surfaces and into the interiors of the approximately 100,000 museum objects stored in the space. This contamination prompted a closure of the building to staff in 1980 until an appropriate artifact asbestos decontamination plan could be developed and implemented. In addition to the asbestos contamination issue, Building 17 was not climate-controlled, secured, or equipped with fire suppression, which put the collections at additional risk.

It should be noted that this was not a preservation-driven project but an asbestos decontamination project first and foremost. In aiming to make the objects accessible again, normal preservation concerns and practices became secondary to the asbestos decontamination methods. For example, the consolidation of flaking surfaces and the protection of historic deposits were impossible to accomplish in this environment, as a treatment of this type would lock down any asbestos fibers on the object surfaces and seriously hinder the ability of the decontamination contractors to remove the asbestos. It was determined early in the planning phase that these circumstances would represent “acceptable losses”; the future accessibility of objects was the driving force of the project and the “greater good” in a conservation triage situation. Adjusting to this deviation from normal collection management practices was a challenge for both conservators and museum collections managers. 2 2. DEFINITIONSThe following list of definitions is necessary for a clearer understanding of the nature of asbestos, the risk factors involved, and the reasons behind the required safety precautions. Abatement: Removal of friable asbestos and encapsulation of underlying surface area. ACM:Asbestos-containing material. Material with contents greater than 1% asbestos is considered ACM and therefore is regulated. Amosite:A specific type of asbestos: brown, water-resistant, straight fiber. (Building 17 contained 1 to 3 in. of sprayed-on fireproofing asbestos insulation on the ceiling and walls. In one-half of the building, the asbestos was 30-35% crysotile, while the other half of Building 17 contained asbestos that was 85-95% amosite.) Asbestos:A naturally occurring mineral used to insulate against heat, cold, fire, and sound. It is chemical-resistant and nonconductive, as well as durable and water-resistant. Asbestos has been used in the construction, shipbuilding, automotive, and textiles industries. Clearance:Passing visual or aggressive air sampling tests based on OSHA NIOSH 7400 or 7402 protocols and AHERA regulations for clearance testing of buildings. Crysotile:A specific type of asbestos: white, serpentine fiber. Decontaminate(as related to this project): To clean of asbestos fibers to acceptable airborne clearance level of less than .01 fibers per cu. cm. of air, as measured by NIOSH Method 7400. Encapsulation:Treating ACM with a liquid that hardens to keep fibers from being released. Enclosure:An airtight barrier installed between friable asbestos and the building environment. Fiber Size:Need to protect against asbestos fibers >5 μms in length with a 3:1 ratio of length to width. Friable:Able to be pulverized to powder by hand pressure when dry. PCBs:Polychlorinated biphenyls (carcinogen, skin absorption risk). Primary Risk Factors:Inhalation risk, can cause asbestosis, mesothelioma, and lung cancer. Latency period is 10-40 years. Elevated fiber counts, length of exposure, smoking, and personal susceptibility are also risk factors. Protocol:Application of decontamination methods to specific object, surface, or material type. 3 3. INTRODUCTIONSThe asbestos decontamination requirements for Building 17 are regulated by the Occupational Safety and Health Administration (OSHA) under the Code of Federal Regulations (CFR) parts 1910 and 1926, which govern general industry and construction exposure and surveillance standards. These regulations provided a basis for determining proper personal protection and acceptable exposure risk for staff working in the building and a baseline for the development of testing and clearance standards for releasing artifacts from the containment after decontamination was completed. Asbestos abatement work for the construction industry is divided into four classes of hazard severity based on the level of activity and the type of building material being removed or disturbed. Decontamination of objects is not specifically defined by OSHA standards but could be interpreted as between Class III (disturbance of asbestos materials in the repair or maintenance of an area or item) and Class IV (maintenance cleaning). These classifications also relate to different levels of training and engineering control measures. Although the decontamination work involved the removal of friable fibers from object surfaces, the volume of delaminating insulation material in the building and the potential for elevated ambient air contamination levels warranted more protective measures. As the Smithsonian Institution generally approaches personal protection in hazardous situations conservatively, NMAH required its staff to take the more stringent Class III training classes and wear respirators with a higher protection factor (powered air-purifying respirators). This requirement entailed additional staff training time and costs to certify personnel to enter the containment, and increased equipment costs, as powered air-purifying respirators cost significantly more than the respirators used in less hazardous asbestos work. Additionally, staff costs were affected by this decision, as increased staffing was necessary to complete a daily rotation of three-hour shifts. The shifts were divided largely because of the strain of wearing full protective gear for long periods of time in a non-climate- controlled environment. 4 4. PLANNINGPlanning for Building 17 proceeded along several tracks simultaneously. The goal was to ensure that sufficient resources, such as staff, equipment, and funding, existed to address the situation safely and that the project was completed on time and within the $1.9 million budget. The planning team members included internal and contract architects, engineers, industrial hygienists, conservators, curators, collections managers, and asbestos decontamination professionals. This group reviewed all aspects of the project to identify potential problem areas and issues. Two concerns repeatedly arose during this planning process: a lack of adequate staffing and the need to define the artifact decontamination methods and clearance protocols. It was also clear to the Building 17 planning team that the artifact decontamination segment of the project would require contractor assistance to perform technical work, such as construction and maintenance of the asbestos containment, as well as the decontamination of artifacts. To ensure proper contract support, NMAH also established a series of six meetings with the asbestos decontamination firm, LVI, and the environmental monitoring firm, Law Engineering, after award of the contract. The meetings centered on the development and finalization of decontamination and clearance protocols. They led to a confirmation of staff resources needed for both the contractor and NMAH, in this case a 3:1 ratio respectively within the containment. NMAH doubled its staff number to ensure that the workload outside the containment, which involved object stabilization, movement, tracking, and storage, would also be met. Finally, NMAH held a series of meetings with the curatorial units affected by the project. These meetings served as a conduit through which curatorial concerns and ideas were voiced and addressed. In this team-based approach, NMAH defined staffing requirements, addressed risk management issues and safety concerns, began the artifact decontamination work, and established a process through which changes to the plan could be considered and implemented. 5 5. DECONTAMINATION METHODS AND CLEARANCE PROTOCOLSThe planning team estimated that more than 95% of the objects could be decontaminated and removed from the building. One basic premise governed the decontamination methods: all objects would be decontaminated for “normal museum use,” which meant the objects could be handled, examined, moved, cleaned, exhibited, rehoused, or photographed without requiring personal protective equipment. One cautionary note: normal museum use did not include disassembly of objects. The planning team's goal in developing the decontamination protocols was to determine a balance between staff safety (keeping ambient air fiber counts low) and effective decontamination methods based on object material types and surface fragility. Objects or surface types were divided into categories such as metals, sealed woods (painted or varnished), unsealed woods, glass, textiles, paper, plastics, rubber, fiberglass, and hazardous collections. These categories were then matched to an appropriate decontamination method that would do the least harm to the object, yet sufficiently remove the asbestos. Throughout the planning phase, the asbestos-removal contract consultants indicated that, from their experience, the most effective and efficient method for decontaminating items was the use of water amended with surfactant (liquid soap) to bind the asbestos fibers for easier removal (fig. 2). However, the planning team recognized that not all objects could withstand this wet method, and so other decontamination methods were developed. These included, from the most to least intrusive:

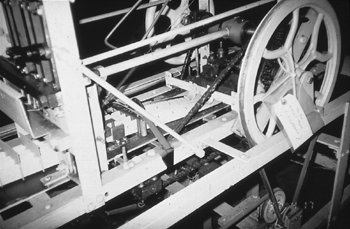

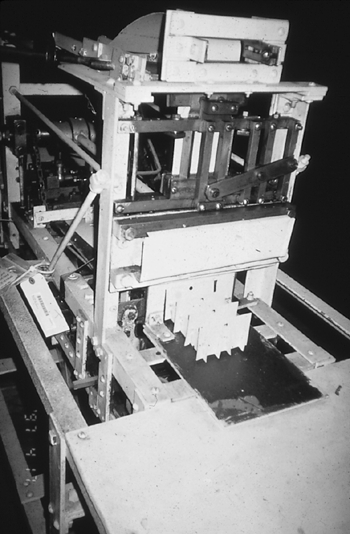

After an object had been decontaminated through the application of a single or in some cases a combination of cleaning methods, the object was ready for clearance testing, a procedure performed prior to releasing the objects from the asbestos containment. The purpose of clearance testing was to ensure that the asbestos fibers had been successfully removed to within the decontamination clearance levels established for this project. Clearance testing fell into two primary categories—visual or aggressive air sampling. The visual procedure was valid only for objects with flat surfaces and consisted of a visual review of surfaces free of holes and crevices or gaps for signs of residual asbestos insulation, as well as a hand-wipe over the artifact to look for cleanliness. If there was no evidence of residual insulation, dirt, or other surface debris, the object passed. The air-testing procedures included the use of an air-sampling pump with tubing, a cassette with cellulose filter, a leaf blower, and fans. Air in the test chamber was disturbed by a leaf blower, after which fans were left on in the chamber in order to keep fibers (if any) aloft during the testing. The sampling pump drew air through the filter into a cassette at a minimum of 1,200 l of air over approximately 2 hours. This procedure is directly analogous to the “aggressive” air sampling method typically conducted in a building for the purpose of cleaning the area for reoccupancy after an asbestos abatement project. The sampling analysis consisted of either phase contrast microscopy (PCM) or transmission electron microscopy (TEM). PCM analysis costs approximately $20 per test. Slides were prepared and read on-site, with results available in about 20 minutes. PCM analysis does not differentiate between types of fibers, such as dust, paper, wood, or clothing; every type of fiber is counted in the results of the test and therefore would not provide valid results for items that were inherently fibrous, such as textiles and paper. For these materials, TEM analysis was used. To perform a TEM analysis, the cassette filters were sent to a laboratory, where all nonasbestos fibers were burned off, leaving only the asbestos fibers intact. TEM analysis also identifies the specific asbestos fiber present, such as amosite or crysotile. TEM analysis costs from $100 (for results available in 72 hours) to $200 (for results in 24 hours). During TEM testing, the test chamber was unavailable for an extended period, resulting in a slowdown of the entire project. 6 6. IMPLEMENTATIONThe collections stored in Building 17 ranged from large industrial machinery and farm equipment to delicate 19th-century patent models and textiles. Artifacts were stored in boxes, cabinetry, and crates, on open shelving and the floor. It was determined during the planning phase that objects would be removed from all crates, boxes, and storage units. Although a percentage of the Building 17 collections was inventoried to the item level, inventory data were more commonly assigned to the exterior of storage units or entire densely-packed sections, without clear knowledge of the type of objects, materials, or actual numbers of objects represented. Based on what was readily visible and the inventory data that had been gathered, the project team tried to anticipate the unknowns. During implementation, artifacts were prepared by NMAH off-site staff prior to decontamination by the contractor. Objects were removed from storage containers and bar-coded with location information, and appropriate color tags were attached to specify the proper decontamination method. Color tags were used for ease in communication with the contractor; for example, a green tag indicated HEPA vacuuming only, a yellow tag designated washout. Caution tags in Spanish and English were also used to identify fragile parts or hazards such as broken glass, mercury, torn fabric, and sharp points or edges. Original manufacture or catalog tags were placed into bags and reattached to the object with cable ties to prevent damage during the decontamination process. Constant adjustments to the decontamination procedures based on object fragility and material type proved to be an absolute necessity. A balance between the decontamination of collection items, minimization of object damage, and cost considerations was sought. The NMAH conservator and collections managers worked with the contractor and industrial hygienist to reduce the anticipated “acceptable losses.” For example, fragile surfaces were identified, such as decorative paint or historic labels, which required a gentler decontamination process. There were concerns over the water pressure when the washout procedure was used, and the damage that might occur from water remaining on wooden surfaces, in joints, or inside moving mechanical parts. This hazard was alleviated through close work with the contractor to ensure that fragile objects were decontaminated with lower water pressure. The use of compressed air (also adjustable pressure) was added to drive any excess water from object parts. With these adjustments, concerns over the effects of the decontamination process on the objects were allayed, as objects of different material types cleared the testing chamber. To help prevent rusting, Ballistol, a biodegradable, lanolin-based lubricating agent, was carefully applied to the moving parts of many industrial and mechanical objects. Ballistol was not applied until the object was removed from the containment, as clearance test results would have been affected by temporarily holding asbestos fibers in place. The uneven, porous surfaces of items such as paper, textiles, furs, and feathers represented another decontamination challenge because of the propensity of asbestos fibers to snag or embed on those surfaces. Consequently, NMAH and the contractor believed successful decontamination of these objects was questionable. These concerns proved to be unfounded, as demonstrated by one of the earliest and most encouraging successes, an egg-carton-making machine. The object was “threaded” with strips of cardboard, which emerged from the machine as a formed egg carton (figs. 3a–3b). The cardboard was in good condition and represented a small but critical portion of the overall object. Rather than automatically removing the cardboard, NMAH staff worked with the decontamination contractor to develop a multiprotocol approach: the cardboard was vacuumed and blown with compressed air, the area in the immediate vicinity of the paper was wet-wiped, and the rest of the machine received the washout procedure. Validation of this approach was borne out by the clearance testing: objects decontaminated with these customized procedures routinely passed the PCM tests.

Despite customized procedures, all objects could not be saved in their entirety. Exposed yarns and sections of woven fabric on unprotected looms could not be decontaminated and were removed. In the case of exposed bolts of material, contaminated outer layers were cut off and the remaining material was salvaged. However, yarns, fabric, raw fibers, and similar materials in more protected circumstances, such as lockers or crates, or wrapped in paper, had limited exposure to the delaminating asbestos and thus were less contaminated. These materials readily passed the clearance tests. Feathers, furs, and other inherently fragile natural fibers were TEM tested prior to decontamination to minimize any possible damage and to identify actual asbestos fibers. There were occasional failures, which prompted careful decontamination of the objects with a HEPA vacuum along with a full decontamination of the testing chamber itself. Additional collection concerns included mold, infestation, and hazardous materials. To address active mold on wood, metal, and glass surfaces, a diluted solution of Lysol concentrate (1 capful per 1 qt. water) was applied to clean cloths and wiped on the objects. This step was done prior to asbestos decontamination to minimize the spread of the mold spores. Lysol was used rather than bleach or ethanol as it could be used on a variety of object finishes and was less of an irritant for the staff in a confined space. Evidence of rodents and insects, including dermestids and webbing clothes moths, was found throughout the collections as well. Historic debris from grain processing on some agricultural machinery had attracted grain beetles. These objects were heavily coated with flour-like agricultural residues and insect debris, which were vacuumed prior to decontamination. After removal from the building, these items were monitored in storage to determine if there was further insect activity. Objects that were damaged beyond recovery from mold, infestation, or the inability to decontaminate were disposed of through a streamlined deaccession procedure. The same procedures were followed for other collections that were inherently hazardous. Flammables, reactives, acids, regulated materials, chemicals in leaking or leaching containers, unknown substances, and radioactive materials were all present in the building. These items were segregated, identified, containerized in plastic bins, and disposed of by a hazardous materials handling company (Clean Ventures Inc.) (fig. 4). Disposal charges for these materials were approximately $20,000.

The discovery of explosives, including blasting caps and shotgun shells, prompted a telephone call to the Prince Georges County bomb squad to review the materials. The bomb squad determined that these items were unstable and required staff to evacuate the building while they were removed. Polychlorinated biphenyls (PCBs) were found in the antioxidants on the surfaces of medical equipment and in the sealed oil reservoirs, some of which were damaged, of industrial machinery. Cleanup of the exteriors of the medical equipment was required prior to asbestos decontamination because of the safety issues involved in handling objects coated with PCBs. Objects were double-washed with mineral spirits to reduce the PCB levels in the antioxidant coatings. Labor and disposal costs for this process were $18,000. At times, movement of objects caused unanticipated oil leaks in objects with damaged oil reservoir seals, which also required spot cleanups with mineral spirits and the purchase of spillproof pallets to contain further leakage. PCBs in sealed reservoirs did not present an immediate handling risk and therefore were not addressed until the objects cleared the asbestos testing chamber, at which time the interior reservoirs were tested and drained if the PCB levels were greater than 50 ppm. The fee for testing and disposal of these oils was an additional $15,000. Finally, mercury was present in medical equipment, electrical tubes, and barometers. Mercury spill kits (Hg Absorb) were placed inside the building and were used several times for small spills. The mercury-contaminated materials were then disposed of as hazardous waste. Despite these challenges, the overall clearance rate was excellent. The objects emerged from the containment in better condition than anticipated during the planning phase, and the amount of object damage was minimal. In conclusion, the Building 17 Artifact Decontamination Project was a dynamic team effort, involving difficult collections decisions and hidden costs, and recognizing and adjusting to changing variables while retrieving objects, as carefully as possible, from an inhospitable environment. AUTHOR INFORMATIONVIRGINIA M. DEUCHER received a B.A. in anthropology from the State University of New York at Stony Brook in 1972. In 1979 she received an M.A. in museum studies with a concentration in ethnographic conservation from George Washington University. She attended the 1981 conservation science course at the International Center for Conservation in Rome (ICCROM.) She has 17 years' experience in preservation and museum collections management. She has worked for the National Museum of American History since 1989 as the NMAH Museum Support Center move coordinator and conservator and additionally has served as the NMAH off-site conservator. Address: Smithsonian Institution, National Museum of American History, Paul E. Garber Facility, Building 18, 3904 Old Silver Hill Rd., Suitland, Md. 20746 TAMURA L. MOORE graduated from James Madison University in 1983 with a B.A. in art history. She is a museum collections manager with 15 years' professional experience, having served as the NMAH Museum Support Center move coordinator for 5 years, and is currently serving as the assistant offsite storage manager for the National Museum of American History. Address as for Deucher. STEVE HEMLIN is currently the program manager for the National Museum of American History. He has 15 years' professional experience in project and collections management, and graduated from Ohio Wesleyan University in 1984 with a B.A. in history. Address: National Museum of American History, 12th St. and Constitution Ave., Washington, D.C. 20560

Section Index Section Index |