SYNTHETIC FILL MATERIALS FOR SKIN, LEATHER, AND FURSLINDA NIEUWENHUIZEN

ABSTRACT—This article describes some synthetic fill materials for use with processed and minimally processed skins and furs. The applications outlined illustrate the production of versatile and flexible fills in stable skins and leather products with losses. All repairs have been made on artifacts that were in good condition but visually disrupted by losses in the skin, leather, or fur. The first two applications are based on the search for a bulked flexible resin or resin mixture that can be easily used and manipulated to form a cohesive fill. The third example illustrates the use of a synthetic fabric fill for a natural history specimen with hair. TITRE—Mat�riaux synth�tiques pour le remplissage de pertes sur les peaux, cuirs, et fourrures. R�SUM�—Cet article d�crit quelques mat�riaux synth�tiques qui peuvent �tre utilis�s pour la compensation de pertes sur des peaux et des fourrures trait�es ou l�g�rement trait�es. Les exemples d�crits montrent la production de r�parations souples et flexibles pour des objets stables. Toutes les r�parations ont �t� faites sur des objets en bon �tat mais dont les pertes sur la peau, le cuir ou la fourrure d�rangeaient visuellement. Les deux premiers exemples sont bas�s sur la recherche d'une r�sine �paissie flexible ou d'un m�lange de r�sine qui pourrait �tre ais�ment utilis�s et manipul�s pour former une r�paration coh�rente. Le troisi�me exemple montre l'utilisation d'un produit de remplissage de textile synth�tique sur un sp�cimen d'histoire naturelle poilu. TITULO—Materiales sint�ticos para reponer faltantes en piel, cuero y piel con pelo. RESUMEN—El art�culo describe algunos materiales sint�ticos para reponer faltantes en piel y en pieles con pelo procesadas y m�nimamente procesadas. Las aplicaciones que se rese�an ilustran la producci�n de materiales de reposici�n vers�tiles y flexibles, para ser utilizados en pieles y productos de cuero estables y con faltantes. Todas las reparaciones fueron hechas en artefactos en buenas condiciones pero visualmente interrumpidos por los faltantes. Las primeras dos aplicaciones se basan en la b�squeda de una resina o mezcla de resinas con cuerpo y flexibles, que puedan ser f�cilmente utilizadas para formar un relleno con cuerpo y cohesi�n. El tercer ejemplo ilustra el uso de una tela sint�tica utilizada para reponer un faltante un esp�cimen de historia natural con pelo. 1 INTRODUCTIONSkin, leather, and fur are materials abundantly found in natural history, ethnographic, historic, and decorative arts collections. Leather is hide or skin that has been chemically treated (tanned) to make it imputrescible. The terms “hide” and “skin,” in the leather industry, are used conventionally: the difference is one of size, weight, and thickness. Hide usually refers to a large, heavy skin such as that obtained from a buffalo, cow, or horse. Skin is simply a small hide or the skin of a small animal such as a bird, rodent, or reptile. Fur is the hair projection of an animal. Skin products are proteinaceous in their original chemical composition but have been treated in a variety of ways to obtain products tailored to different uses as well as different physical characteristics, i.e., tanned, tooled, grained, or waterproofed (Fogle and Raphael 1984). A variety of conservation issues arise with skin products, dealing with the protein chemistry, shrinkage temperature, tannage interferences, and other matters. Among the variety of One should be cautioned, however, to use the proposed fill materials only on stable skins and leather. Before considering treatment, an accurate assessment of the hydrothermal stability (shrinkage temperature) of the collagen fibers of the artifact should be conducted (Young 1990; Larsen et al. 1993). The following suggestions for fill materials should not be used as a “cookbook” for leather conservation. Fills in skin products must fit the criteria of appropriate strength, stability, flexibility, adhesion, aging, appearance, and ease in identification. Common drawbacks of fills in skin products are the following:

All these negative aspects of fill materials for skin products could contribute to the loss of physical and aesthetic continuity. Some are also deleterious to the skin to be conserved. In addition, it should be noted that degraded skin products exhibit more severe results than those in good condition. Hydrothermal stability testing is of paramount importance in order to assess artifact condition. Generally, fills in skin products are accomplished using a standard method: a backing is applied to bridge the area of loss when possible (Dignard 1992), and then a fill material is inserted into the area of loss. Most commonly used materials for backings are inert fabrics coupled with either resins, starches, or cellulose ethers with evaporative solvents, or resins or systems requiring the use of a heat-seal process. Popular suggestions for fill treatments for leather and skin have included a variety of standard and uncommon materials: other skins, gelatin, wax, wax and rosin, white glue emulsions, polyurethane, resins, and pastes made of resins bulked with various materials, such as collagen fibers, cellulose fibers, or glass microspheres. The following materials have been used by the author to produce versatile and flexible fills in skins and leather products. The first two applications are based on the search for a flexible resin or resin mixture that can be bulked and easily used and manipulated to form a cohesive fill. The third example illustrates the use of a synthetic fabric fill for a natural history specimen with hair. All examples have been made on skins, leather, and fur in good structural condition but are visually disrupted by losses in the skin, leather, or fur. The author has utilized these fill materials on a variety of leathers and skins including 20th-century American commercially chrome-tanned leather and suede materials, 18th-century Italian and French vegetable-tanned 2 APPLICATIONS2.1 BULKED BEVA 371 FILMThe materials used for this repair are standard for conservation: polyester spun-bonded fabric (i.e., Reemay or Hollytex), BEVA 371 film, glass microspheres, and dry pigments. The only other items needed are a heated spatula, texturing implements, and inpainting materials. BEVA gel (O'Donnell 1996) and BEVA 371 (Kaminitz and Levinson 1988; Jones 1996) have also been used in similar applications. Because of the solvent content in these BEVA formulations, however, and the shrinkage of the fill due to the evaporation of solvent, BEVA 371 film is suggested for use. 2.1.1 RecipeIngredients:

For mixing, use a glass or metal container and a heated spatula with a small tip. For the greatest degree of success, a G. Engelbrecht ERSA heated spatula with a small infilling spatula is suggested. Wearing a particle mask to avoid inhalation of the microspheres, mix the BEVA 371 film and glass microspheres together with the heated spatula. The melting point of BEVA 371 film is 65�C. Mixing will be somewhat difficult because the BEVA 371 film must melt in order to incorporate the microspheres. Mixing in only 5 cc of microspheres at a time is suggested. After the microspheres are incorporated, add dry pigments to tone the fill material to the appropriate color. Mix the pigments into the BEVA 371 film and microsphere mixture with the heated spatula. When ready to use, simply scoop the fill material with the heated spatula and apply it to the area of loss. Take care to limit the contact of the heated spatula only to the area of fill material to avoid heat damage to the original skin artifact. Texture the fill while warm. The fill material cools very quickly and will need to be warmed in the area to be textured in order to properly imprint. Rough sandpaper and stencil brushes may be rubbed onto the surface to mimic suede. A finer sandpaper may be used to achieve a nubuck appearance. Silicone-coated polyester film may be used to smooth a surface. Molds can be taken of adjacent areas; the mold may then be pressed onto the fill surface to achieve the desired texture or pattern (Larsen 1981). To avoid the problem of dust adhering onto the BEVA 371 fill, it is recommended to use a paint that has a medium with a high glass transition temperature. A glass transition temperature of BEVA 371 film cannot be given (Chludzinski 1997). The fill is easily reversed mechanically,or with heat or petroleum benzine applied sparingly.

Figures 1 and 2 demonstrate the use of the fill material to conserve a damaged skin drum from the Northwest Coast. This drum was manufactured from a deerskin, which upon examination appeared to be minimally prepared by soaking, scraping, and then stretching the skin. In this instance, there

In a similar treatment, this fill mixture was used in the restoration of a monitor lizard that was part of a larger Mario Merz installation, Untitled, 1989. The lizard had been dried, stuffed with sawdust, and mounted by inserting a metal armature. A tear at the abdomen-tail junction had been created as a result of the strain placed in this area by the weight of the tail while it was on exhibit in a vertical position. In this application, a backing of spun-bounded polyester was adhered to the underside of the tear with BEVA 371 film and the aid of a tacking iron. The fill material was then applied on top of the spun-bounded polyester platform. The BEVA 371 film-glass microsphere-pigment mixture was placed in the area of loss. A mold was taken of the surrounding skin pattern and used to impart texture to the fill. The fill was made warm with the tacking iron and the mold pressed with gentle pressure onto the fill material to receive the texture. The fill was painted with Winsor & Newton gouache colors and glazed with Paraloid B-72 and dry pigments. In addition, it was necessary to have a mount fabricated to reduce the strain on the lizard abdomen-tail junction. This mount braced the tail and was affixed to the wall for the installation. Figures 3–5 show the BEVA fill application.

2.2 BULKED ACRYLOID F-10This treatment is a variation on the use of a bulked resin to form a flexible fill. In this example, Acryloid F-10 is mixed with glass microspheres to form a paste that can be applied to a loss directly or used as a formed film made by applying the paste to a mold. Acryloid F-10 is a homopolymer of butyl methacrylate with a low glass transition temperature of 20�C. When the glass microspheres are added to the solvated resin and the solvent is allowed to evaporate, the rheological properties of the resin change greatly to a rather static yet flexible material. To the author's knowledge, the fill material does not exhibit cold flow in controlled museum climates. 2.2.1 RecipeIngredients:

When ready to use, scoop the fill material with a spatula and apply it to the area of loss. Though it will still be sticky, the fill can be textured while solvated. Texturing can also be accomplished with the addition of solvents or with a hot spatula after solvent evaporation, utilizing the thermoplastic qualities of the resin. Molds can be taken of similarly textured areas; the fill material can be applied to the mother mold and the solvents allowed to evaporate. At least 48 hours are needed for the solvents to have evaporated enough that the film remains cohesive. Solvents will continue to evaporate after that time, leading to some shrinkage; however, the shrinkage is minimal. The fill remains slightly flexible due to the glass transition temperature of the butyl methacrylate. Cut the fill material to the desired shape. Adhere the fill in place with additional resin or heat the edges of the fill slightly with a heated spatula to adhere. Color compensation should be carried out with a medium having a higher glass transition temperature to decrease the chance of dust adhering to the fill material. Acrylic emulsion paints work well. The fill can be removed mechanically or by using either solvent or heat.

Figure 6 demonstrates the use of this adhesive and microsphere paste to replicate a taxidermy mount of black rhinoceros skin. The black rhinoceros mount is an alum-tanned skin and has been mounted to a prefabricated polyurethane form. A mold was taken of rhinoceros skin, and

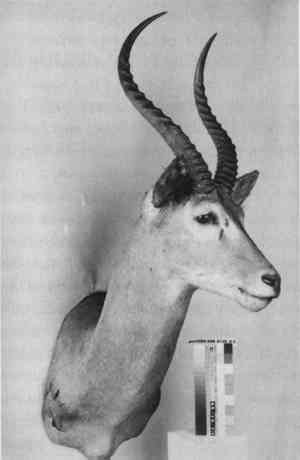

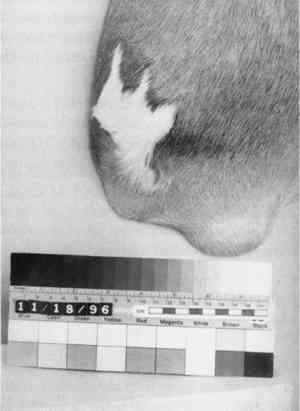

2.3 SYNTHETIC FURSFor fur or hair inserts, National Fiber Technologies, Ltd., supplies a broad assortment of synthetic fur fabrics either from their vast stock or to order. The most versatile synthetic fur is an instock white fur made from 18 denier nylon with a four-way spandex stretch backing. There are three standard fur lengths: short (2.5–5.0 cm); medium (8.0–10.0 cm); and long (10.0–15.0 cm). According to the mill where the fabric is woven, the fur can be easily colored with markers, pens, paints, or dyes before utilizing as a fill.1 An alum-tanned and mounted Western Kob (Kobus Kob) from Central Africa was fire- and soot-damaged; the fire and subsequent water damage resulted in gelatinization and shrinkage of the skin, creating a loss on the proper right shoulder. A National Fiber Technologies, Ltd., synthetic fur was utilized to fill and integrate the loss. First a template was made of the area of loss. This template was transferred to the synthetic fur, and a fill section was cut. A sharp scalpel was used to cut the nylon fur from the reverse side; care was taken to cut only the stretch backing and not the synthetic hair. The synthetic fur fill was trimmed and layered to match the hairs of the original fur. The synthetic fur was inserted into place using Acryloid F-10 in acetone: the adhesive was applied directly to the substrate (a prefabricated polyurethane Western Kob mount) by placing the edges of the fur fill directly to the adjacent sides of the extant fur and skin. The synthetic fur was toned and colored with Magna colors by brush application. Figures 7–9 illustrate this technique.

3 CONCLUSIONCohesive fills in skin products were easily made and applied in these examples using standard conservation materials and techniques. A caveat must be made in the use of these types of fill materials on appropriate skins and leathers. The fill materials should be used on skin artifacts that are stable and in relatively good condition. The fill materials cited, when used properly, will aid in increasing the aesthetic continuity of the skin artifact by filling an area of loss. ACKNOWLEDGEMENTSThe author would like to thank the many individuals who were consulted and gave generously of their time, advice, and expertise: Ellen Pearlstein, Brooklyn Museum, for support and critical review; Leslie Ransick-Gat, conservator in private practice, for her understanding, support, and guidance; Toby Raphael, National Park Service, Harpers Ferry Center, for his critical review, which yielded many insights; Paul Storch, Minnesota Historical Society, for his many suggestions and ideas; Gwen Spicer, conservator in private practice, for treatment ideas and help; Judith Levinson, American Museum of Natural History, who was instrumental in introducing BEVA 371 solution and microspheres as a fill material; Lisa Kronthal and Samantha Alderson, American Museum of Natural History, who supplied their selfless support; Alex Allardt O'Donnell, conservator in private practice, for her time and expertise with leather conservation; Christine Giuntini, associate conservator, Metropolitan Museum of Art, for fun fur and dye information; and Gregory Young, conservation scientist, Analytical Research Laboratory, Canadian Conservation Institute, for shrinkage temperature information and expertise. Special thanks go to Maria Berman, Colleen Brady, Michaela Neiro, Nathan Otterson, Eugenie Milroy, and my past and present staff at Give Me a Break Conservation Services, Inc. NOTES1. Nylon fun furs can be dyed with acid or premetalized dyes according to the manufacturer's directions at pH 5.5 and pH 7 or slightly above, respectively. The dyed fabric must be subjected to an after-scour at 140�F. REFERENCESChludzinski, G. R.1997. Personal communication. Chemical engineer and proprietor of Conservator's Products Co., Chatham, N.J. Dignard, C.1992. Tear repair of skins with minimal access to their backs: The treatment of a kayak. Leather Conservation News7(2):1–8. Fogle, S., and T.Raphael. 1984. Leather conservation terminology. Leather Conservation News1(4):39–51. Jones, F.1996. IIC-CG seminar vegetable-tanned leather review. IIC-CG Bulletin21(2):5–8. Kaminitz, M., and J.Levinson. 1988. The conservation of ethnographic skin objects at the American Museum of Natural History. Leather Conservation News5(1):1–7. Larsen, E. B.1981. Moulding and casting of museum objects. Copenhagen: School of Conservation, the Royal Danish Art Academy. Larsen, R., M.Vest, and K.Nielsen. 1993. The determination of hydrothermal stability (shrinkage temperature) of historical leather by Micro Hot Table technique. Journal of the Society of Leather Technologists and Chemists77:151–56. O'Donnell, A.1996. Personal communication. Conservator in private practice, Portsmouth, R.I. Wolthman, K.1996. Personal communication. Synthesis chemist, Rohm and Haas Laboratories. Young, G.1997. Personal communication. Conservation scientist, Analytical Research Laboratory, Canadian Conservation Institute, Ottawa, Ontario, Canada. Young, G.1990. Microscopical hydrothermal stability measurements of skin and semi-tanned leather. In ICOM Committee for Conservation preprints, 9th Triennial Meeting, Dresden, Germany. Paris: ICOM. 3:626–31. FURTHER READINGASTM. 1980. Standard definitions of terms relating to leather, D 1517-80. In Annual book of ASTM standards. Philadelphia: American Society for Testing and Materials. Belitz, L.1970. Step-by-step: Brain-tanning the Sioux way. Pine Ridge, S.D.: Pine Ridge Indian Reservation. Boulton, A.1986. The examination, treatment and analysis of a pair of boots from the Aleutian Islands including a note about possible pesticide contamination. Journal of the American Institute for Conservation, 25:1–13. Calnan, C.1991. The aging of vegetable-tanned leather in response to variations in climatic conditions. In Leather: Its composition and changes with time, eds.C.Calnan and B.Haines. Northamptonshire, Eng.: Leather Conservation Center. 41–50. Calnan, C., R.Selm, and B.Haines. 1990. Conservation of automobile and carriage leathers. Leather Conservation News7(1):7–8. Clark, T.1985. Conservation of an aboriginal wallaby skin water bag. In Recent advances in leather conservation, ed.S.Fogle, T.Raphael, and K.Singley. Washington, D.C.: Foundation of the American Institute for Conservation. 62–64. Collins, C.1986. Conservation techniques for ethnographic leather artifacts: Application to the Paul Kane Collection. Leather Conservation News3(1):14–16. Cruikshank, P.1987. The conservation of a model Eskimo kayak involving the treatment of gut. Leather Conservation News4(1):1–12.

Down, J., M.MacDonald, J.Tetreault, and S.Williams. 1992. Adhesives testing at the Canadian Conservation Fogle, S.1984. Mending and filling losses in two chinese lanterns. In Recent advances in leather conservation. Washington, D.C.: Foundation of the American Institute for Conservation. Fogle, S., T.Raphael, and K.Singley. 1985. Recent advances in leather conservation. Washington, D.C.: Foundation of the American Institute for Conservation. Haines, B.1984. The conservation of leather bookbindings. In Adhesives and consolidants, ed.N. S.Bromelle, E. M.Pye, P.Smith, and G.Thomson. London: International Institute for Conservation. 50–54. Haines, B.1985. The strength of skin. In Recent advances in leather conservation. Washington, D.C.: Foundation of the American Institute for Conservation. 10–12. Haines, B.1987. Shrinkage temperature in collagen fibres. Leather Conservation News, 3(2):1–5. Haines, B.1991. The structure of collagen. In Leather: Its composition and changes with time, ed.C.Calnan and B.Haines. Northamptonshire, Eng.: Leather Conservation Center. 5–9. Hatchfield, P.1986. Note on a fill material for water sensitive objects. Journal of the American Institute for Conservation, 25:93–96. Kite, M.1992. Skin-related materials incorporated into textile objects. In Conservation of leather craft and related objects, ed.M.Kite et al. London: Victoria and Albert Museum. 33–35. Kite, M.1992. Gut, membrane parchment and gelatine incorporated into textile objects. Paper Conservator16:98–105. Krahn, A.1987. Conservation: Skin and native-tanned leather. American Indian Art Magazine (Spring):44–51. Museo d'Arte Contemporanea. 1990. Mario Merz Exhibit Catalogue. A.Barzel, ed.Prado, Italy: Museo d'Arte Contemporanea. New England Tanners Club. 1983. Leather glossary. In Leather facts. Peabody, Mass.: New England Tanners Club. Peacock, E.1983. The conservation and restoration of some Anglo-Scandinavian leather shoes. Conservator7:19–23. Pence, R. J.1966. Analyzing fur damage with a microscope. Circular of California Agricultural Experimental Stations Extension Service, 541:1–18. Plenderleith, H.1971. The conservation of antiquities and works of art. London: Oxford University Press. Rahme, L.1990. Traditional tanning and skin sewing. Leather Conservation News7(1):1–5. Raphael, T.1985. The completion of missing areas. In Recent advances in leather conservation, ed.S.Fogle, T.Raphael, and K.Singley. Washington, D.C.: Foundation of the American Institute for Conservation. Raphael, T.1986. Ethnographic skin and leather products: A call for conservative treatment. In Symposium '86: The care and preservation of ethnographic materials, ed.R.Barclay et al. Ottawa: Canadian Conservation Institute. 68–72. Raphael, T.1993. The care of leather and skin products: A curatorial guide. Leather Conservation News9:1–15. Reed, R.1972. Ancient skins, parchments, and leathers. London: Seminar Press. Reed, R., ed.1966. Science for students of leather technology. London: Seminar Press. Rose, C., and D. W.VonEndt, eds.1984. Protein chemistry for conservators. Washington, D.C.: American Institute for Conservation.

Selm, R.1991. The conservation of upholstery leather—An evaluation of materials and techniques. In Conservation of leather in transport collections: UKIC conference restoration '91. London: UKIC. Shaffer, E.1974. Properties and preservation of ethnographical semi-tanned leather. Studies in Conservation19:66–75. Spicer, G.1995. Supporting tears in leather. Leather Conservation News, 11(1, 2):4–6. Stambolov, T.1969. Manufacture, deterioration and preservation of leather: A literature survey of theoretical aspects and ancient techniques. ICOM. Amsterdam: Central Research Laboratory. Stone, T.1989. The conservation of skin and semi-tanned leather at the CCI: 3 case histories. In Postprints of the ICOM International Leather and Parchment sSmposium. Offenbach, Germany. Ottawa, Canada: ICOM. 18–23. Stone, T.1989. The Inuit skin preparation workshop. Leather Conservation News. 6(1):1–7. Storch, P.1986. A non-sewn alternative to the inlay technique: Stabilizing a native-tanned historic vest. Leather Conservation News3(1):17. Sykes, R. L.1991. The principles of tanning. In Leather: Its composition and changes with time, ed.C.Calnan and B.Haines. Northamptonshire, Eng.: Leather Conservation Center. 10. Thomson, R.1992. Leather and textiles and related objects: Leather for clothing. In Conservation of leather craft and related objects, ed.M.Kite et al. London: Victoria and Albert Museum. Volken, S., and M.Volken. 1995. The conservation of a pair of bucket top boots. Leather Conservation News11(1, 2):1–4. Vuori, J.1985. A possible adhesive for native tanned skin. Leather Conservation News2(1):6. Waterer, J.1972. A novel method for the conservation of fragile leathers. Studies in Conservation17:126–30. Waterer, J.1968. Glossary of leather terms. In Leather craftsmanship. New York: Praeger. 24–20. Waterer, J.1972. A guide to the conservation and restoration of objects made wholly or in part of leather. London: G. Bell and Sons. White, S.1992. Conservation of a Siberian parka: A joint approach. In Conservation of leather craft and related objects. ed.M.Kite et al. London: Victoria and Albert Museum. Williams, S. L.1991. Variability in measurements resulting from microscopic analyses of collagen shrinkage-temperature. Collection Forum. 7(2): 53–63. Young, D., G.Nicks, R.McConnell, and L.Suss. 1991. Birchbark industry and brain tanning in the central Canadian Subarctic. Arctic Anthropology28(1):110–23. SOURCES OF MATERIALSAcryloid F-10A butyl methacrylate homopolymer supplied in 40% solids in mineral thinner: Amsco F at 9:1, manufactured by Rohm and Haas. Amsco F is characterized as a C-8 aromatic with a flash point of 150�F. Acryloid F-10 has a glass transition temperature of 20�C. Conservation Materials, Ltd., P.O. Box 2884, Sparks, Nev. 89431 BEVA 371 filmA mixture of DuPont Elvax 150 (ethylene vinyl acetate copolymer), Allied A-C 400 (ethylene vinyl acetate copolymer), BASF Laropol K80 (cyclohexanone resin), Hercules Cellolyn 21 (phthalate ester of hydrobietyl alcohol), and paraffin (petrolatum) Conservator's Products, Conservation Materials, Ltd., P.O. Box 2884, Sparks, Nev. 89431 Bocour Magna ColorsPigments in Acryloid F-10 Bocour Artist Colors, Inc., Garnerville, N.Y. Dry pigmentsAvailable at art supply stores For the greatest degree of success, an ERSA heated spatula with a small infilling spatula is suggested. Manufactured by G. Engelbrecht, Germany. Olaf Unsoeld, Kolner L.L.C., 23 Grant Ave., New Providence, N.J. 07974 Hollytex #3529.Non-woven polyester fabric Ahlstrom Filtration Inc., Talas, N. Y. ReemaySpun-bonded polyester fabric Manufactured by DuPont Conservation Materials, P.O. Box 2884, Sparks, Nev. 89431 Rowney Cryla Artist ColorsAcrylic emulsion paints Daler-Rowney, Available at art supply stores Synthetic nylon fur with four-way stretch spandex backing18 denier nylon hair with woven nylon wrapped LycraTM backing National Fiber Technologies, Ltd., 300 Canal St., Lawrence, Mass. 01840 3M glass microspheres K-15Unicellular soda lime borosilicate glass microspheres, 3M Corp. Conservation Materials, P.O. Box 2884, Sparks, Nev. 89431 Winsor & Newton gouachePaints Winsor & Newton, Available at art supply stores AUTHOR INFORMATIONLINDA NIEUWENHUIZEN received a B.A. in art history and archaeology from the University of Missouri at Columbia in 1986 and an M.A. and certificate of advanced study from the State University College at Buffalo, N.Y. in 1990. After finishing her training, she interned and then gained employment at the American Museum of Natural History, New York City, where she worked until 1996. She is an adjunct professor at the Conservation Center of the Institute of Fine Arts, New York University, where she has taught since 1992, and is in private practice specializing in ethnographic objects and natural science materials. Address: Give Me a Break Conservation Services, Inc., 48-20 Vernon Blvd., Ste. 2, Long Island City, N.Y. 11101.

Section Index Section Index |