A NEW TECHNIQUE FOR DETERMINING THE DEPTH OF PENETRATION OF CONSOLIDANTS INTO LIMESTONE USING IODINE VAPOR

RAKESH KUMAR, & WILLIAM S. GINELL

4 RESULTS

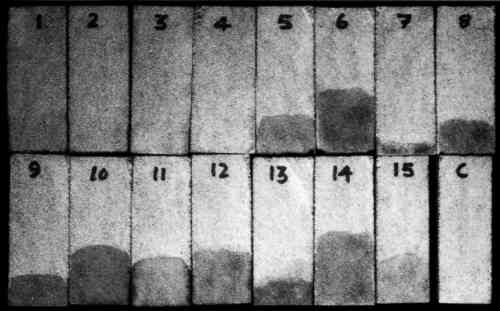

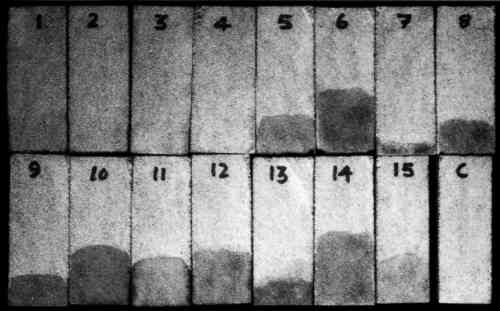

The measured depth of penetration of the various consolidants into the two types of limestones is shown in tables 1 and 2. Figure 1 shows some of the Indiana limestone samples after iodine exposure.

TABLE 1 DEPTH OF PENETRATION OF CONSOLIDANTS INTO INDIANA LIMESTONE

TABLE 2 DEPTH OF PENETRATION OF CONSOLIDANTS INTO INDIANA LIMESTONE

Fig. 1.

Consolidant-treated Indiana limestone samples after iodine vapor exposure: stone 1, Rhoplex AC-33 (10%); 2, Rhoplex AC-33 (3%); 3, Rhoplex AC-630 (10%); 4, Rhoplex AC-360 (3%); 5, Acryloid B-72 (10%); 6, Acryloid B-72 (3%); 7, Bayhydrol 121 (10%); 8 Bayhydrol 121 (3%); 9, polyvinyl acetate (10%); 10, polyvinyl acetate (3%); 11, Eponex 1510 + Jeffamine T403 (10%); 12, Eponex 1510 + Jeffamine T403 (3%); 13, carboset 514-H + ERL-4221 (11%); 14, Conservare SS-H (neat); 15, Conservare SS-OH (neat); C, untreated control

|

The samples were examined carefully in the environmental scanning electron microscope to confirm the presence of polymer at specified locations. The consolidant penetration depths, as obtained by the iodine vapor method on freshly cut sections of test samples, were marked by aluminum foil strips. Secondary electron imaging was used to locate the polymer in the treated limestone (fig. 2). The consolidant-rich to consolidant-poor areas were found to be morphologically distinguishable.

|