ULTRASONIC MISTING. PART 1, EXPERIMENTS ON APPEARANCE CHANGE AND IMPROVEMENT IN BONDINGSTEFAN MICHALSKI, & CAROLE DIGNARD

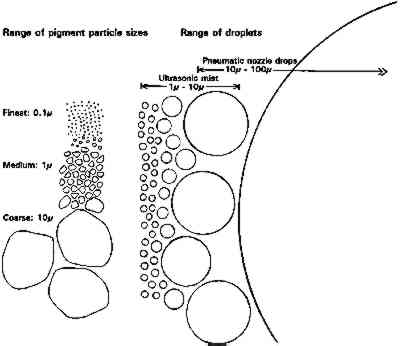

1 INTRODUCTIONThe ultrasonic mister for consolidation of powdery surfaces was first demonstrated by Stefan Michalski at the Getty Conservation Institute training course on Consolidation of Ethnographic Painted Artifacts in 1989. The assembly of the device and its method of use have been described elsewhere (Weidner 1993; Maheux and McWilliams 1995; Dignard et al. 1997; Michalski et al. forthcoming). Since development The main problem with consolidation of powdery paints is color change. Feller and Kunz (1981) tested a variety of binders mixed with ultramarine pigment and showed that the critical variable was not the type of binder but simply its amount. This amount—conventionally expressed by “pigment volume concentration” (PVC)—is the total microscopic volume of pigment particles expressed as a percent of the total microscopic volume of particles plus binder. Since this study is concerned with small amounts of binder, we have coined the parallel term “binder volume concentration” (BVC), so that a paint with very little binder can be referred to, for example, as 1% BVC, instead of 99% PVC. Feller and Kunz showed that any increase in binder in ultramarine caused measurable reduction in reflectance at red wavelengths (i.e., saturation of the blue color), but the relation between perceptible color differences and low BVC was not studied. Some pigments are definitely known to tolerate high BVC with no noticeable change in color. For example, in earlier work by one of the authors on the mechanical properties of gessoes (Michalski 1991), it was noted (as every worker in gesso will have realized) that there is no noticeable color difference between pure (0% BVC) whiting (CaCO3) and workable gesso recipes from soft (2% BVC) to hard (10% BVC). It is only with a jump to clearcole recipes (used as a base coat to ensure a good bond between the gesso and the wood) that a very noticeable darkening occurs. Clearcole recipes are about 40% BVC (Michalski 1991), so at some BVCs greater than 10% but less than 40%, gelatin binder causes a noticeable color change when added to a white pigment like whiting. Thus a preliminary answer to the question of how much binder can be added to a powdery paint before there is a perceptible change in color is that the amount appears to vary significantly with pigment, and whiting appears very tolerant. Within the various treatment options for powdery paints reviewed by Hansen et al. (1993, xlvii), ultrasonic misting aims at improving penetration of the resin through the use of multiple applications of dilute solutions and the avoidance of excess consolidant delivery. Only nonviscous solutions can mist. For example, our apparatus could mist gelatin in water at no more than 1%, or methylcellulose of 400 cps at 0.5% in water, so dilute solutions are intrinsic to the technique. A dilute solution has low viscosity so it flows quickly and continues to flow even as some solvent is lost to evaporation. Although each application results in only small increases in bonding, it also results in little to no visual change. Thus one can consolidate in subtle increments and stop before appearance changes unacceptably. Some consolidation techniques deliver too much consolidant too fast, leading to flooding of the surface and subsequent formation of a film or dark layer. However, the mister's small droplets, slow air stream, and narrow jet provide excellent control of delivery rate. Slow delivery also matches slow capillary penetration and thus avoids flooding of the surface. Pneumatic sprayers can displace particles by impact of the large droplets or by the high-velocity air stream. In comparison, the ultrasonic mister's air stream velocity is low and adjustable to zero without affecting droplet production. (Trying to lower air velocity of pneumatic sprayers by reducing the air supply simply results in malfunction of the sprayer.) Mist droplets are very small: both ultrasonic devices (Shoh 1983) and the pneumatic nebulizer (Hudson 1995) produce their droplets in the range of 1–10 μm diameter. As illustrated in figure 1, mister droplets, unlike the enormous sprayer droplets (Fair 1984), are close in size to pigment particles. They are also similar in size to the fibers and pores in paper and much smaller than pigment clusters in pastel and chalk, hence their success in treatments by paper conservators (Weidner 1993).

With pneumatic sprayers, droplets are mixed with air completely free of solvent vapor so they evaporate rapidly as they travel toward the artifact. Thus the solution reaching the artifact is much more viscous than the prepared solution. In comparison, the ultrasonic mister delivers its droplets along with an air stream saturated with solvent vapor. The region directly under the nozzle is at saturated vapor conditions. Proper misting technique involves holding the nozzle approximately 1 cm from the artifact and keeping it stationary until as much mist has wicked in as is required to just saturate the porous layer. Then the nozzle is moved just fast enough to maintain this saturating behavior. Ultrasonic misting has the following disadvantages. Viscous solutions cannot be misted. Not all solvents work well: solutions in water, ethanol, or mineral spirits do, but some solutions in fast-evaporating solvents such as acetone do not. Drops of solution may form within the delivery tube and fall on the artifact unless precautions are taken. Although the central component, the ultrasonic humidifier, is commercially available, essential peripheral components must be handmade and often fine-tuned to complete the device (Michalski et al. forthcoming). Finally, consolidation treatment is slow. This paper presents the results of consolidation tests using the ultrasonic mister on various powdery paints, determining changes in appearance, the formation of skins, and changes in cohesion or adhesion. A companion paper (part 2) describes the apparatus and a variety of treatment case histories. |