CONTROLLING THE REFRACTIVE INDEX OF EPOXY ADHESIVES WITH ACCEPTABLE YELLOWING AFTER AGINGCHRISTOPHER C. AUGERSON, & JOHN M. MESSINGER

ABSTRACT—Mixtures of Ablebond and HXTAL NYL-1 were found to produce epoxies with a range of refractive indexes from 1.515 to 1.565. Their yellowing after dark aging is measured and determined to be acceptable for glass repair. 1 INTRODUCTIONIn repairing a broken glass object, factors that will make the repair less visible are usually considered. One such factor, important in the repair of colorless glass, is the approximate match between the index of refraction of the adhesive and that of the glass (Ogden 1975; Tennent and Townsend 1984a; Messinger and Lansbury 1989). Tennent and Townsend (1984b) describe a glass repair where the difference between the index of refraction of the glass and that of the adhesive is 0.04; this repair is clearly visible. However, in another repair of the same glass, the difference of refractive indexes is approximately 0.01, and the repair is not easily visible under normal lighting conditions. Recently, Messinger and Lansbury (1989) developed a method of controlling the index of refraction of epoxy adhesives to a small degree. This control was achieved by adding a mixture of 1,2-epoxy-3-[2,4,6-tribromophenoxyl] propane and 1,2-epoxy-3-[2,4,6-triiodophenoxyl] propane to either of two commercially available epoxies. Ablebond mixed with such additives produced a range of refractive index from 1.565 to 1.59. The resulting adhesives were found to have yellowing characteristics within acceptable standards when aged at room temperature in the dark as defined by Down (1984). HXTAL NYL-1 mixed with such additives produced a range of refractive indexes from 1.515 to 1.545. However, the halogenated additives caused the adhesives made with HXTAL NYL-1 to yellow beyond the acceptable standards. This study was conducted to determine whether mixtures of Ablebond resin and HXTAL NYL-1 resin could be used to produce epoxies with a range of refractive index from 1.515 to 1.565, which also pass the standards of Down (1984) for yellowing. 2 EXPERIMENTALHXTAL NYL-1 resin and Ablebond resin were mixed in a variety of weight percent (100:0, 87.5:12.5, 75.0:25.0, 62.5:37.5, 50.0:50.0, 37.5:62.5, 25.0:75.0, 12.5:87.5, 0:100). Two separate sets of mixtures were prepared, from two separate resin batches. Each resin mixture was prepared in a clean, glass test tube and stirred thoroughly All epoxy mixtures were cast into small blocks measuring 3 � 12 � 20 mm. This size is required to fit the sample window on the Abbe refractometer. These mixtures were cured at 59–60 �C for 6 hours. After cooling overnight, the indexes of refraction were measured with an Abbe refractometer, according to the method ofMessinger and Lansbury (1989). Refractive indexes were similarly measured after one year of dark aging. The UV-visible absorbance of the adhesive blocks was also measured after one year of dark aging, according to the method of Messinger and Lansbury (1989). As in their study, the degree of yellowing was represented by the value of At, calculated according to the method of Down (1984).1 3 RESULTSAll samples prepared were found to harden into rigid solid blocks as expected (manual flexing could not crack the blocks and a fingernail could not dent them). 3.1 INDEXES OF REFRACTION

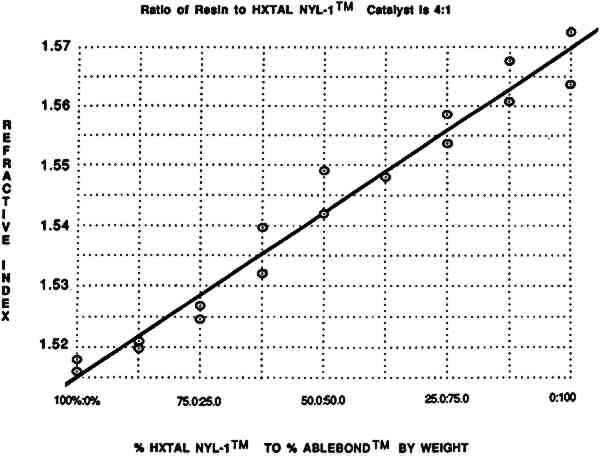

Figure 1 illustrates the data for the initial measurements of refractive indexes of the different adhesive mixtures (prior to the aging period).

3.2 CHARACTERISTICS AFTER ONE YEAR OF DARK AGINGAfter aging, no change in the refractive index could be observed beyond the limits of accuracy of the Abbe refractometer. At values calculated from the UV-visible absorbance of the adhesives after aging were, in all cases, acceptable according to the criteria set forth by Down (1984) (At > 0.1). In general, adhesives tended to become more yellow with increased concentration of Ablebond resin. For the mixtures containing only 12.5% Ablebond resin (87.5% HXTAL NYL-1 resin), the yellowing was quite negligible, with At = 0.0063. The single most yellowed sample, which was one of those containing 100% Ablebond resin, was still quite acceptable, with At = 0.0277. 4 CONCLUSIONSIt is possible to adjust the index of refraction of epoxy adhesives within the range 1.515–1.57 by varying the ratio of amounts of Ablebond resin to HXTAL NYL-1 resin. When the adhesives were subject to one year aging in the dark at room temperature, the amount of yellowing of the cured adhesives was found to be within acceptable limits as established by Down (1984). Many other properties of these modified epoxies, including their physical strengths, remain untested. The authors encourage the study of these and similarly modified epoxies to develop a clear understanding of their suitable and unsuitable applications in glass conservation. Any recommendation of their use, except in experimental situations, should await these tests. ACKNOWLEDGEMENTSThis paper presents the results of a project conducted by Christopher C. Augerson while he was a student in the Art Conservation Department of the State University College at Buffalo (SUCB). The authors would like to thank Prof. Jonathan Thornton of SUCB for his assistance and encouragement. NOTES. According to Down (1984) method, the degree of yellowing is represented by the value of At, as calculated by the following equation:

REFERENCESDown, J. L.1984. The yellowing of epoxy resin adhesives: Report on natural dark aging. Studies in Conservation29(2):63–76. Messinger, J. M., II, and P.Lansbury. 1989. Controlling the refractive index of epoxy adhesives. Journal of the American Institute for Conservation28:127–36.

Ogden, P. H.1975. A new glass adhesive. Minnesota 3M Research Limited, Pinnacles, England Tennent, N. H., and J. H.Townsend. 1984a. Factors affecting the refractive index of epoxy resins. In ICOM Committee for Conservation Preprints, 7th Triennial Meeting, Copenhagen. 2: 84.20.26–84.20.28. Tennent, N. H., and J. H.Townsend. 1984b. The significance of refractive index of adhesives for glass repair. In Adhesives and consolidants, ed.N. S.Brommelle et al. London: International Institute for the Conservation of Historic and Artistic Works. 205–12. AUTHOR INFORMATIONCHRISTOPHER C. AUGERSON received his M.A. in art conservation from the State University College at Buffalo in 1992. He has recently completed an advanced internship in the conservation of traditional European polychrome sculpture sponsored by the Samuel H. Kress Foundation and the Fine Arts Museums of San Francisco. He is currently the sole proprietor of Augerson Art Conservation Services. Address: 1762 Church St., San Francisco, Calif. 94131. JOHN M. MESSINGER II received his Ph.D. in organic synthesis from the State University of New York at Buffalo in 1986. Until 1993, he was associate professor of conservation science in the Art Conservation Department of the State University College at Buffalo, where he taught since 1986. He is currently a dental student. Address: School of Dental Medicine, Squire Hall, State University College at Buffalo, Buffalo, N.Y. 14214.

Section Index Section Index |