EFFECTS OF AGING AND SOLVENT TREATMENTS ON SOME PROPERTIES OF CONTEMPORARY TRACING PAPERSDIANNE VAN DER REYDEN, CHRISTA HOFMANN, & MARY BAKER

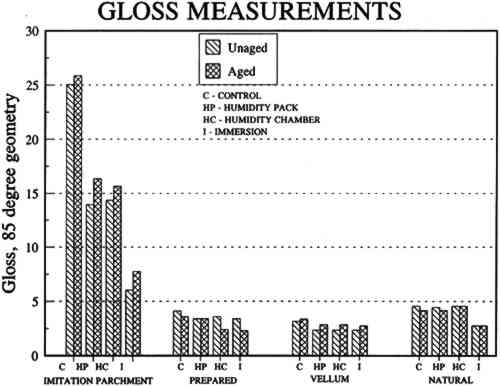

6 PROJECT 4: EFFECTS OF HUMIDIFICATION AND FLATTENING ON SELECTED CONTEMPORARY TRACING PAPERS6.1 RESEARCH PROCEDURES6.1.1 Humidification and Flattening MethodsAs noted in table 1, this project investigated the effects of three humidification techniques (using immersion, ultrasonic humidification chamber, and a humidification pack system) and two flattening techniques (on a suction table and in a traditional blotter press with ca. 1 psi weight) (Flamm et al. 1990; Hofmann et al. 1992). Sample papers, both “new” (unaged) and “old” (aged as outlined in project 2), were treated by the following techniques. HUMIDIFICATION TECHNIQUES: For humidification by immersion, the samples were first sprayed with deionized water, then immersed while supported on a polyester web and screen for 30 minutes in deionized water, followed by draining for several minutes until all standing water had evaporated. Humidification by a humidity chamber was undertaken by placing the samples on a screen between nonwoven polyester webs over a tray of hot water in a sealed chamber for 60 minutes. Humidification by a humidification pack consisted of placing the samples on a nonwoven polyester felt laminate (1/16> in thick), having a polytetrafluoroethylene membrane, on top of water-saturated, heavyweight blotters. The samples were covered with lightweight, nonwoven polyester webs and natural fiber felts for even contact, for 14 hours. FLATTENING TECHNIQUES: One-third of all the humidified samples were allowed 6.1.2 Measurement of PropertiesChanges in opacity, gloss, strength, and dimensions (table 4) were measured as outlined in section 3.1.3. 6.2 FINDINGS AND DISCUSSION FOR PROJECT 4The most severe planar distortions occurred from immersion, especially for the overbeaten natural tracing paper (table 4). Humidification using the humidification pack and chamber caused less planar distortion, probably because these techniques effectively reduce water penetration into the paper fiber structure. Immersion also caused the greatest changes in dimensions and in mechanical properties, especially in comparison to humidification with a humidity chamber. This degree of change was particularly evident for the overbeaten natural tracing paper, for which immersion caused the greatest increase in strain to break, possibly because of rebonding after the release during immersion of dried-in strain produced during manufacture. Immersion caused a greater decrease in the stress and strain to break for prepared tracing paper sample, perhaps because water initiated the breakup of the coating material. With respect to the two flattening techniques, compared to air-dried controls, suction table flattening and drying of immersed samples caused severe distortion, especially for the overbeaten natural tracing paper, as compared with flattening and drying in a traditional blotter press. Dimensional changes in the cross-grain direction were greatest for the overbeaten and calendered papers, following immersion and drying on the suction table. The coated papers were less affected dimensionally. Imitation parchment paper underwent the greatest percentage change in gloss, particularly following immersion (fig. 5). The heavily coated prepared tracing sample incurred the greatest change in opacity, becoming mottled following immersion. This change may have resulted from a breakdown in coating, which appears to have occurred in this paper with each humidification technique, to some degree, causing some loss of surface, as evidenced by SEM photomicrographs of the sample after treatment using a humidification pack (figs. 6a–d).

6.3 CONCLUSIONS FOR PROJECT 4Different techniques for humidifying and flattening tracing paper affect properties in different ways. Based on our findings, conservators who must immerse a tracing paper in water might find dimensional changes less severe if the paper is dried in a blotter press rather than on a suction table. Tracing |