THE EFFECTS OF RELATIVE HUMIDITY ON SOME PHYSICAL PROPERTIES OF MODERN VELLUM:ERIC F. HANSEN, STEVE N. LEE, & HARRY SOBEL

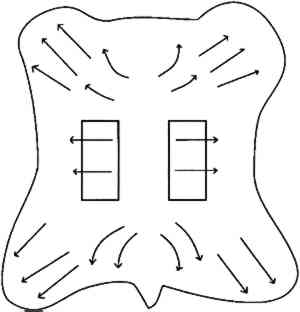

3 EXPERIMENTAL3.1 MATERIALSAs previously discussed, the distinct properties of parchment are a result of the production process, which includes drying under tension. Some “parchment” sold today is not true parchment but a formaldehyde-tanned skin. Commercial parchment may be true parchment but may include additives and softening agents. The parchment used in this study was purchased from a vendor of true parchment. The general procedure for making parchment has been previously described (Vorst 1986). The three types of vellum (parchment made from young calf) purchased were labeled, for convenience, as “modern,” “medieval,” and “talmudic.” These designations do not indicate that the tensile properties of the vellum designated “medieval” compare with the tensile properties of parchment manufactured during the Middle Ages, but rather that a particular aspect of the production process was in common with the medieval practice of parchment making. Thus, the vellum labeled “medieval” was more fully neutralized with rinsing and soaking in comparison to the vellum designated “modern.” The vellum designated “talmudic” was, in addition to being neutralized fully with ammonium chloride, also subjected to a bath that contained small amounts of oak gall. The designation “talmudic” was chosen because the ancient Jewish method for the production of parchment either included a tanning agent in a bath or the surface was subsequently finished with a tanning agent, as shown by analysis of Dead Sea Scroll samples (Poole and Reed 1962). 3.2 SAMPLE CUTTING AND CONDITIONINGThe test samples were cut from selected areas of the whole skin as depicted in figure 4, in an attempt to obtain samples with maximum similarity in the direction of the collagen fiber bundles. Dogbone-shaped samples were cut in accordance with the American Society for Testing and Materials test method (ASTM 1984). However, due to the size of the tensile testing equipment, the sample dimensions were scaled down by a factor of 2, reducing the testing width from 12.5 mm to 6.3 mm. The thickness of the talmudic-type vellum samples was 0.2 � 0.01 mm, of the medieval-type vellum samples was 0.2 � 0.03 mm, and the modern-type vellum was 0.23 � 0.03 mm.

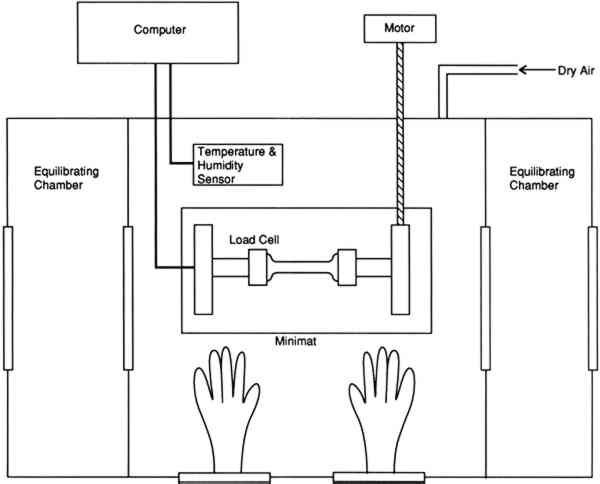

All dogbone-shaped samples were preconditioned in excess of three months prior to testing in a humidity chamber at 43%, 33%, 22%, or 11% RH, maintained by saturated salt solutions of potassium carbonate, magnesium chloride, potassium acetate, or lithium chloride, respectively. These salt solutions were chosen for their vapor pressure, which results in the desired 3.3 TENSILE PROPERTIESTensile testing and the measurement of the stress in restrained samples were performed on a Polymer Laboratories Minimat tensile testing instrument placed inside a microenvironment chamber built at the Getty Conservation Institute (fig. 5). It was necessary to have a chamber with interlocking side chambers so that samples and salt solutions could be introduced wihtout exposing the central chamber to the ambient relative humidity of the room, which is 60% RH. The vellum samples sorb water very quickly when exposed to an increased level of relative humidity.

The humidity in the chamber during testing was maintained with the same saturated salt solutions used for conditioning the samples. The gauge length was 0.050 m, and the constant rate of extension was 0.020 m per minute. Ten replicate samples of each of the three vellum skins were tested on the Minimat at each relative humidity. (These 10 samples were randomized to include samples from opposite sides of the skin in each set.) Test data were recorded on an IBM AT computer with a data acquisition program that utilizes an external I/O board that converts analog signals to digital signals. Temperature and humidity were simultaneously recorded on the computer using a General Eastern Humidity and Temperature Sensor. Collected data were saved for further analysis on the Apple MacIntosh FXII computer using Stat View and Cricket Graph software. Because of the more convenient use of a larger tensile testing instrument, tensile fracture for the samples conditioned at 60% RH was performed with an Instron Model 4201 Universal Testing Instrument in the same temperature- and humidity-controlled room. Tensile test data 3.4 FORCE DEVELOPING AT A FIXED GAUGE LENGTHFor the humidity downramping tests (successive exposure to lower levels of relative humidity), straight-edged, 0.0127 m wide samples were cut with a Thwing Albert precision sample cutter from the same areas of the skins as for tensile testing. The gauge length was 0.050 m, and the samples were held at a 2 N preload in the clamps of the tensile tester. The chamber and the sample were then allowed to equilibrate at an initial relative humidity of 60%. After equilibration, the humidity was lowered to 43% by an influx of dry air, and then this humidity was maintained with the appropriate saturated salt solution while the sample was allowed to equilibrate. (The relative humidity was decreased in a stepwise manner, rather than having the humidity reduced by equilibration with the specific salt solutions.) The chamber conditions and the developing tension were monitored with a General Eastern Temperature and Humidity Transmitter and the Minimat, respectively. Data from both instruments were recorded using an IBM AT computer and an I/O board. Data were collected at 5-minute intervals for a duration of several days; the required time was dependent on the rate at which equilibration was achieved at 43%, 33%, 22%, and 11% RH. Equilibration was assumed when the force that developed held constant for 24 hours. Each type of parchment was subjected to this procedure. |