AN INVESTIGATION INTO THE REMOVAL OF ENZYMES FROM PAPER FOLLOWING CONSERVATION TREATMENTTHERESA MEYER ANDREWS, WILLIAM W. ANDREWS, & CATHLEEN BAKER

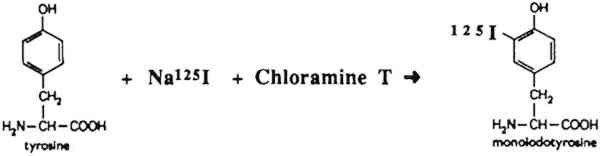

2 EXPERIMENTAL MATERIALS AND METHODSWe chose to concentrate on two α-amylases used on two very different types of papers commonly encountered by paper conservators. We selected a dense, wove, naturally aged, gelatin Because radioactive materials were being used, large sheets of paper that would more realistically resemble an artifact could not be used. Maneuvering radioactive papers of such a large size would have been impossible behind the lead shields and would have created large amounts of radioactive waste. The ratio of surface area of the experimental paper sample to the volume of radioactive enzyme solutions and subsequent rinses used was estimated using a large sheet of paper and appropriate volumes of solutions as models. The ratio used in the experiments was 1 ml of solution per sq cm of paper. Two α-amylases were chosen for the experiment. One was a highly purified bacterial enzyme from a Bacillus species (Sigma catalog no. A6380), and the other was a crude fungal enzyme preparation from Aspergillus oryzae (Sigma catalog no. A0273). These specific enzymes were chosen because they appear in conservation literature and represent a range of amylases from pure to crude. From information supplied by Sigma Chemical Company, the A6380 amylase had an activity of 2080 units/mg solid and the A0273 had an activity of 31 units/mg solid. Activity is an indication of how many units of the enzyme are found in the protein content of the solid. Both amylases are assayed at pH 6.9 at 20�C. An assay at this pH favors the A6380 amylase, as the pH is closer to its optimum of pH 6.0 than to the optimum of pH 5.0 for the A0273 amylase. We estimated that if we used the A6380 amylase at 1/10 the concentration of the A0273 amylase, the activities of both would be roughly the same.3 The enzymes were iodinated by the chloramine-T method illustrated in figure 1(Hunter and Greenwood 1962; Greenwood et al. 1963). This method specifically iodinates tyrosine residues in proteins forming a stable, covalent protein-125I bond. The method is generally accepted to be mild enough so as not to affect the activity of the protein being labeled, in this case the ability of the amylase to degrade starch. The details of the procedure are as follows: 0.5 millicurie (mCi) of Na125I (5 μl) was added to 5 μl of deionized H2O and 10 μl of 0.25 M sodium phosphate, pH 7.5. This solution was stirred in a polypropylene test tube, and the following solutions were added in sequence: 10 μl of 0.5 mg protein/ml amylase in 0.05 M sodium phosphate pH 7.5; 10 μl of 5 mg/ml chloramine-T in 0.05 M sodium phosphate pH 7.5; and 100 μl of 1.2 mg/ml sodium

To separate unincorporated 125I from the iodinated protein a centrifuge column packed with Sephadex G-25 Fine was used after the method described by Penefsky (1979). Briefly, a 3 ml syringe was plugged with glass wool and filled with a slurry of Sephadex. This was allowed to drain, and the column was equilibrated with 10 ml of 0.05 M sodium phosphate, pH 7.5. The syringe column was then spun for 2 minutes in a swinging bucket clinical centrifuge to remove excess buffer from the column. The iodination mixture (0.24 ml) was applied to the top of the Sephadex bed5 and the column was again spun for 2 minutes at the same rpm. The eluate from the column contained the radioactive enzyme, while the unincorporated 125I was retained in the Sephadex bed. A small sample of the radioactive enzyme was added to 5 μg of the nonradioactive enzyme and was subjected to sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) on a 12% gel (Laemmli 1970). The gel was stained for protein by Coomassie blue, dried, and exposed to x-ray film overnight. Exposure of the paper samples to the radioactive enzyme was performed as follows: A nonradioactive solution of the enzyme was prepared, 0.1% (w/v) for the A6380 amylase and 1% (w/v) for the less pure A0273 amylase. The radioactive enzyme was added to this solution to make 100,000–700,000 cpm (counts per minute) per ml (generally 1 μl of the radioactive enzyme was added per ml of enzyme solution). This solution was thoroughly mixed, and 1 ml was dispensed onto each paper sample (1 square cm). The samples were exposed to this solution for 45 minutes, removed, touched briefly to filter paper, and put into the first rinse. Rinses were 2 ml each, and rinse time was 5 minutes for each rinse. The samples were briefly touched to filter paper between rinses. In all the experiments, the enzyme solutions and all the rinses were used at room temperature. Two controls were routinely performed: (1) a paper sample that was not rinsed, and (2) a sample that was rinsed on a Millipore suction device with 2 ml of buffer followed by 5 ml of deionized water. This latter control was considered to represent the most thorough rinsing possible. After rinsing, the samples were dried and counted in a Beckmann gamma counter for 125I. A portion of the original enzyme solution was also counted. The percentage of the radioactivity remaining on the paper was obtained by dividing the cpm on the paper after rinsing by the initial cpm per ml of enzyme solution. Percentages are listed in tables 1–3. TABLE 1 α-AMYLASE A6380 TABLE 2 α-AMYLASE A6380 TABLE 3 α-AMYLASE A0273 |