OBSERVATIONS ON THE DRYING OF PAPER: FIVE DRYING METHODS AND THE DRYING PROCESSJANE E. SUGARMAN, & TIMOTHY J. VITALE

4 EXPERIMENT 1: EVALUATION OF DRYING AND FLATTENING METHODSThis experiment explored the effects of five different drying procedures on the surface qualities of 12 historic papers (Sugarman 1985). The five drying methods (summarized in table 1) were chosen to: compare a new, experimental drying method—the “early restraint” method and a variant—with two common drying methods, the “traditional” (and a variant, the “uncushioned method”) and “air-dried–humidification” methods. The common drying procedures, altered somewhat in this project for research purposes, were developed over a long period of craft experimentation. The primary development criteria appear to have been to meet the needs of private practice (speed and large numbers of artifacts) and the need to achieve consistently satisfactory results on a variety of paper types. The “early restraint” method was developed (and continues to be modified) by the Paper Laboratory at the Winterthur Museum to achieve the minimum alteration in surface texture. TABLE 1 SUMMARIES OF DRYING METHODS 4.1 DRYING METHODSTwelve historic papers were selected to include a range of surface characteristics resulting from variations in pressing, sizing, and fiber furnish (table 2). Samples were all cut from the same sheet into 2 � � 2 � in test blanks and bathed in water for � hour. They were then dried by the methods described below. TABLE 2 TEST PAPERS 4.1.1 Early restraint method 1 (A)The samples were removed from the bath to a blotter on a nylon mesh support. When the luster left the paper and the surface of the paper regained its original appearance, the samples were placed between fresh blotters, dimensions of which were well in excess of the samples' edges. The blotter was covered with a foam rubber pad. After about 2 minutes the blotters were changed, and the samples (between bloters) were placed between � in thick felts and under plate glass. The blotters were changed the next day, after 1 week, and after 3 weeks.2 4.1.2 Early restraint method 2 (B)This method is the same as the above, but with lens tissue placed in contact with both sides of the object in the “sandwich.” This variation on method A was selected to observe what the effect of subtle differences in the texture of the material closest to the object might be. 4.1.3 Traditional method (D)The samples were removed from the bath on a nylon mesh and allowed to drain. The samples were placed on a blotter with uniform contact between samples and blotter and allowed to dry 15 minutes (until approximately “⅔ dry”). They were then placed between two blotters, on top of a thick (� in) foam rubber pad, under a sheet of glass with two 5-lb weights on top. The blotters were changed after 5 minutes, 10 minutes, 30 minutes, 1 hour, 4 hours, and the next day. 4.1.4 Uncushioned method (E)The samples were removed from the bath, placed on a blotter, and allowed to dry 15 minutes (as above). They were dried between blotters, under glass and two 5-lb weights. The blotter changes were the same as in method D. 4.1.5 Air-dried–humidification method (F)The samples were removed from the bath (as above), placed on a blotter, and allowed to dry completely. They were placed in a humidification chamber. The relative humidity in the chamber rose slowly to 95%. The samples remained in the chamber until they were relaxed, for a total of 5 hours. The samples were then dried between blotters and felts, under glass and two 5-lb weights. The blotters were changed after 10 minutes, 1 hour, and the next day. 4.2 EXPERIMENTAL DESIGNThe method used for analysis was visual examination by trained observers. Statistics are employed to determine if drying methods can be distinguished from one another. The samples were assessed by 18 trained observers (16 conservation students and 2 professional paper conservators) under raking light in a uniform experimental protocol. An evaluation of the relative success of the drying procedures focused on subtleties of surface qualities.3 Each person completed a survey form, making an independent judgment of the relative amount of change (scale 1–5) of each treated sample compared with the untreated control. Thus a sample that had no change in surface texture would be assigned a value of 1, while a sample with major change would be assigned a 5. Sheet cockling is not a phenomenon that could be observed in this study because the samples were too small. The periodicity of Analysis of the entire data pool using simple statistical methods was carried out to determine the significant difference in (1) and 12 papers, and (2) the five drying methods. Figures 1 and 2 show the results of the mean and standard error calculations. The statical error bars reported in figures 1 and 2 consist of the mean, plus and minus 1 standard error times t for a two-tailed 95% confidence interval. The full bar indicates the data population at a 95%-confidence level. Data populations for which error bars fall beyond each other are considered significant at a 95%-confidence level or greater. Standard error is standard deviation (calculated using n-1) divided by the square root of n, times the “t” value for a confidence level of 95%, at the appropriate degree of freedom.

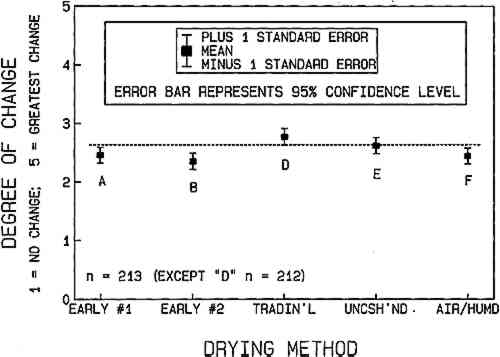

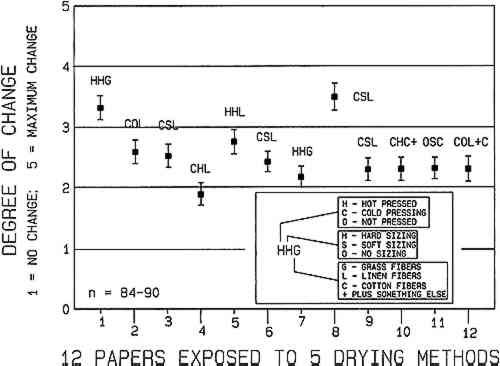

4.3 RESULTSAnalysis of the visual survey data yielded the following conclusions (see fig. 1). The early restraint method 2 (B) resulted in the least change of surface texture for the group of 12 experimental papers. The early restraint method 1 (A), without lens tissue interfacing between the samples and the blotters, could not be statistically distinguished from the traditional restraint method 2. The traditional method (D), so called because the paper is air dried for a “traditional” period on blotters prior to press drying, resulted in the greatest change in surface texture and was statistically distinguishable from the superior early restraint method 2. The uncushioned method (E), a version of the traditional method, could not be statistically distinguished from the early restraint method but could be distinguished from the early restraint method 2. The air-dried–humidification method (F), a two-stage drying method that was thought likely to be an unsuccessful drying method, could not be distinguished from either of the early restraint methods. The superiority of the early restraint method 2 is seen as significant. The method was developed within the conceptual framework of the papermaking process but without knowing how following the papermaking process might facilitate the reproduction of original surface texture. The primary goal was to develop a technique that would result in the least change in surface texture after treatment when compared to a never-treated control. It is clear that these efforts were successful. All of the drying methods produced changes in the samples with respect to the controls; that is, all of the means are above 2.3 units, with 1 unit equal to no change. The methods that showed least change (A, B, and F) have mean between 2.3 and 2.45 units, and those that showed most change (D and E) have means between 2.6 and 2.7 units. Methods A, B, and F hold the paper flat during the drying process. Methods D and E permit the paper to become two-thirds dry before the paper is held flat between drying surfaces. It is important to note that there are significant differences between methods A and B and method F. Methods A and B fix the flooded paper between smooth absorbent drying surfaces while the paper is still wet. Method F, a two-stage technique, allows the paper to dry completely; then, after humidification in the second stage, the paper is held flat between smooth absorbent surfaces. While the observers were not required to specify the nature of the changes they reported, some did comment that all of the texture changes were an expansion of the original surface texture. Expansion is perceived as an increase in the height of the high regions in relation to The results based on individual papers can be observed in figure 2. The reasons the data are considered in this manner is that it was strongly suspected that characteristics such as pressing, sizing, and fiber furnish (pulp) would have an effect on the ease or difficulty in reproducing the original surface texture of individual papers. It is clear from a review of figure 2 that some papers (those above 3 units) were difficult to dry; one (below 2 units) was relatively easy to dry; but most (ranging from 2.2 to 2.8 units) were to equal difficulty. There is no pattern for best, average, or worst performance based on any of the three characteristics—pressing, sizing, pulp—noted. Three of the samples labeled CSL (cold-pressed, soft-sized, linen) (3, 6 and 9) are all within 95%-confidence levels, but so are six of the other nine samples. Sample 8, also a CSL-type paper, is well outside the 3, 6, and 9 group, therefore eliminating the possibility that cold-pressed, soft-sized, linen paper poses only moderate soft-sized, linen paper poses only moderate drying obstacles. The two most changed papers, 1 and 8, have exactly opposite characteristics. The least changed paper, 4, is closer in characteristics to the most changed, paper 8. Of the papers in the 2.2–2.8 unit range, no single characteristics predominates: (1) two hardsized papers are in the largely cold-pressed group, (2) all sizing types are represented, and (3) all fiber furnish types are included. Lack of trends is an indication that pressing, sizing, and fiber furnish cannot be used to predict if a support will be sensitive to drying. 4.4 OTHER ANALYTICAL TECHNIQUES INVESTIGATEDIn the couse of evaluating the results of the data presented above, several other analytical methods were investigated4 to determine if changes in the treated samples could be quantified with more precision than the available with visual analysis. All attempts to analyze and compare characteristics of surface texture using the following analytical methods were inconclusive in distinguishing the subtle differences in surface texture among the test samples. The use of reflected light measurement seemed a promising source of analytical data. Intensity measurements at 0�incident/0� reflected did not allow any differentiation of texture. Reflected light intensity, from the surfaces of a set of samples at (1) 45�/0� (illumination/measurement), (2) diffuse/0� at both 8 mm and 50 mm port size, and (3) specular include and exclude on a device with an integrating sphere light source and measurement, yielded data that were either inconsistent or inconclusive. In most cases a set of samples with clearly distinguishable texture could not be separated using the means of 3–10 repetitions, let alone using standard statistical analysis, Goniophotometric analysis of the surface, where a detector passes through an arc prescribed around the incident illumination source, could distinguish between the best and worst samples of paper 8, but standard statistical analysis resulted in an indistinguishable outcome. Differentiation of samples Attempts were made to visualize differences in the treated surface using the scanning electron microscope (SEM) in hope of defining a characteristic of the modified surfaces. This methodology is often suitable in paper studies because the fibers appear solid and well defined rather than as translucent glowing bodies surrounded by a ill-defined radiant background, as seen when viewed with a light microscope. Three viewing angles were employed: direct viewing, low-angle viewing of surface texture, and cross-section viewing. While very informative and instructive, the resulting observations did not lend themselves to analytic interpretation or quantification. Report of these negative results may save other researchers some effort. Experienced observers were found to be the most sensitive judges of changes in surface texture. Surface texture is a complex intellectual integration of viewing angle, light and shadow, and experience. At the time (1986), there was no analytical technique that could equual the sensitivity and sophistication of the trained human observer in distinguishing subtle visual differences in paper surface texture.5 Eventually, complex integrations of multiple finite scans (Arney 1990) or artificial intelligence might supersede the ability of the trained observer. |