THE DEVELOPMENT OF THE HUMIDITY CONTROL MODULE AT FIELD MUSEUMCATHERINE SEASE

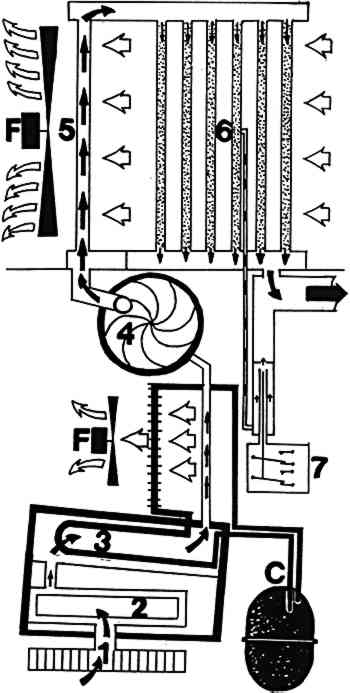

2 THE HUMIDITY MODULETHE DELETERIOUS effects of the lack of relative humidity control on museum objects has long been recognized (Macintyre et al. 1934). Considerable effort has been made by scientists, engineers, conservators, and other museum personnel to control the relative humidity in exhibit areas. Today, new museums are constructed with heating, ventilation, and air-conditioning (HVAC) systems capable of controlling the relative humidity to the strict standards set by preservation needs. While older structures can have new HVAC systems installed (Briggs 1980), they appear to be less effective than those in new structures, as the buildings were not originally designed to meet these environmental standards. Since large HVAC systems are costly to install and maintain, other alternatives to humidity control have been sought. Most of The prototype of Field Museum's humidity module was designed by Stefan Michalski of the Environment and Deterioration Research Division of the Canadian Conservation Institute (CCI) in Ottawa (Michalski 1982). Instead of trying to condition the museum as a whole or exhibit halls as discrete spaces, this module provides humidity control of only those cases containing moisture-sensitive objects. The module is a small, compact, and simple machine that provides low-cost, low-maintenance control of relative humidity in enclosed spaces (fig. 2). It is a small-scale mechanical control system, featuring a blower, a heat exchanger to keep the conditioned air at room temperature, and a silica gel column to smooth out the humidity output of the humidifier and dehumidifier. Each module measures 20.5 � 22 � 59.5 in and requires a standard electrical outlet, a plumbed-in source of water, and a drain.

The module is easily connected to each case with a system of plastic tubing. A 2-in diameter main supply tube extends from the module, with 1/2–1 in diameter supply tubes branching off it to enter each case. These smaller tubes are sized individually for each case to control the airflow to that case. Exhaust is provided simply by natural leakage through seams in the case. A single module can be used to control more than one display case. The total volume and the seal of the cases are the deciding factors in determining the number of cases a single module can control. Michalski (1985) calculated that one module can control approximately 2,700 cu ft of air if the cases are reasonably well sealed. This figure was later revised by Michalski (1987) to 3,500 cu ft. Since connecting a case is simply a matter of drilling a small hole and inserting the plastic tubing, installation is not a major job involving significant costs. As a result, the module allows for extreme flexibility in designing and changing exhibition areas. If the contents of a case are changed and no longer require humidity control, the tubing can be pulled out. As existing display cases The module will produce and maintain a level of relative humidity within a range of 40–60% with variation around a given relative humidity set point of no more than � 3% (Michalski 1985). The humidity output of the module is dependent on the uniformity of the temperature throughout the room in which the cases are placed. The module does not control the temperature of the conditioned air but rather actively follows the temperature of the room. Therefore, if the temperature inside a case is warmer or cooler than the air surrounding the module, the relative humidity inside that case will be lower or higher, respectively, than the output of the module. As long as there are no major temperature differences between the inside and outside of the case, the system should work well. One advantage of the module is that, unlike most mechanical systems, it is slow to produce extremely high or low relative humidity levels even if it malfunctions. Should the module fail to produce humidity, overhumidify, or stop altogether, the humidity levels in the case will not rise or fall drastically within the space of hours. The silica gel buffer column provides a slow response to a sustained change in the humidity. Instead of rising or falling immediately, the relative humidity in the case will gradually move toward the ambient relative humidity over a period of 9 or 10 days. In well-sealed cases, the column acts as a built-in safeguard against malfunction of the module. The advantages of the module are that it is mechanically simple, extremely flexible, able to control large volumes of display cases, relatively inexpensive ($8,750 at the time of writing), and easy to maintain. It appears to be ideal for museums that cannot consider strict climate control of the entire building yet have too many cases to make a buffer system too costly and labor intensive. |