PAPER COMPLEXITY AND THE INTERPRETATION OF CONSERVATION RESEARCHAntoinette Dwan

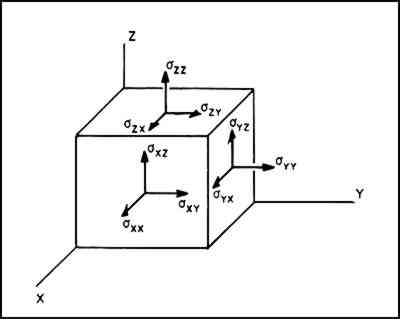

3 PAPER AS A VISCOELASTIC MATERIALPAPER'S VISCOELASTIC NATURE can cause variability in test data. Interpretation of test data requires an understanding of elasticity, viscoelasticity, stress-strain (elastic modulus), and moisture and temperature relationships. A review of elasticity prior to discussing viscoelastic properties is useful. Elasticity in solids is a function Modulus of elasticity is a conversion of Hooke's Law to make it dimension-independent by referring the force to unit area and unit length. “Stress” is the internal force per unit area which resists the external load. “Strain” is the ratio of the change in dimensions to the original dimension. The coefficient of proportionality (slope of the line when stress is plotted against strain) is the modulus of elasticity. Modulus of elasticity is a quantitative statement of the ability of a material to react to deformation, which is dependent on the order of crystallinity of the material.

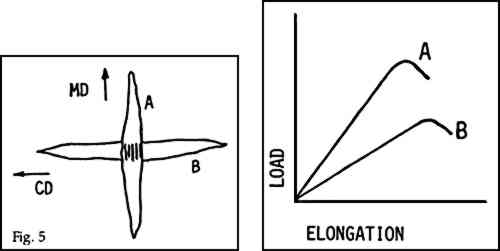

As a viscoelastic material, paper has both crystalline and amorphous areas and it exhibits elasticity and plasticity of flow. A comparison of elastic and viscoelastic responses to an exterior force (load) is shown in Figure 6.

The area marked “A” shows the elastic region where there is a linear relationship between load and elongation. Deformation in this region is elastic and recoverable depending on the amount of the load, and the length of time the load is maintained. The area marked “B” shows the viscoelastic region. Here, the response to deformation is not linear, the response is very time dependent, and there is only partial recovery to the original dimensions once the load has been removed. A viscoelastic material is malleable in that it can respond and adjust to a force or load “because of the continuing rearrangement of molecular segments.”12 Crystalline and amorphous regions influence this rearrangement and limit the return to original dimensions. Paper exhibits the following viscoelastic properties:

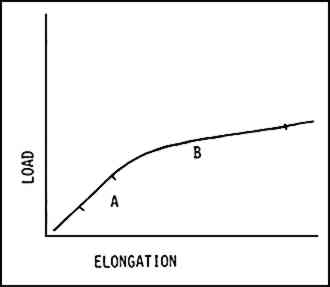

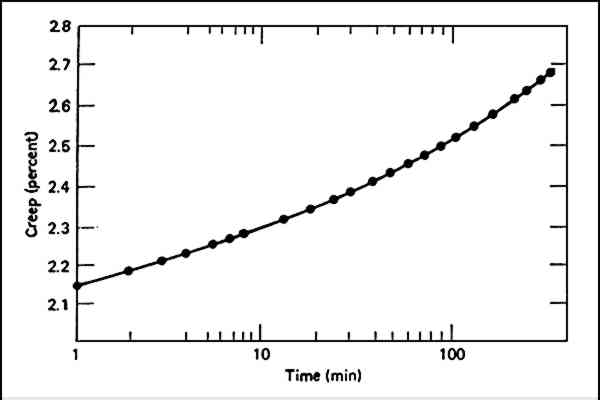

Creep and stress-relaxation are two conditions which result from nonrecoverable deformation in paper due to its viscoelastic nature. Figure 7 shows a graph of creep in paper. If a load is applied to a sample and the deformation measured, the straight line in the graph begins to curve. If the load is removed, the paper will only partially recover its former shape, and will be permanently deformed. “The paper starts out as a purely elastic body and then, after a 1 to 2 percent strain, begins to exhibit flow. If the load is held constant, the paper will flow indefinitely until it breaks.”14 Creep occurs, for example, with printing papers and wallpapers, where force has been applied to the paper and then released.

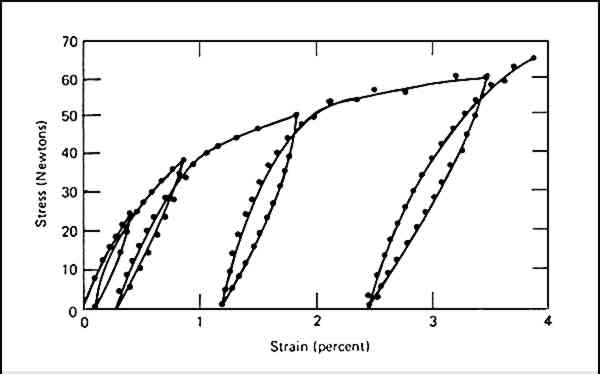

Stress-relaxation curves (Figure 8) are obtained by placing a load on a sample and then removing it, taking a measurement, and applying the load again. As the cycle of loading and deloading is repeated, an individual “profile” for that particular sheet is obtained.

All papers have creep and stress-relaxation characteristics, however, the curves obtained for each are different for every paper tested. This is another reason why it is difficult to compare two different papers, or the same sheet with part used as a “control” and the other part used as a treatment specimen. |