PAPER COMPLEXITY AND THE INTERPRETATION OF CONSERVATION RESEARCHAntoinette Dwan

2 PAPER AS A COMPOSITE MATERIAL“A COMPOSITE MATERIAL, although itself made up of other materials, can be considered to be a new material having characteristic properties which are derived from its constituents, from its processing, and from its microstructure.”1 Materials that are readily recognized as composites are metals, fiber glass, and laminated woods. Paper is a composite material, and its composite nature is a major factor in its wide variability.2 Within each fiber type there are differences in cell length, fibril angle, cellulose content, lignin content, and extractives chemistry. This variability is produced within the same tree due to factors such as early wood vs. late wood, juvenile vs. mature wood, and sapwood vs. heartwood, with additional effects from bark and other contaminates.3 Variability in properties due to variability in plant composition is also present in fibers such as flax, cotton, grasses, hemp, and jute.4 Most papers are composed of a combination of several fiber types. Additional variation is caused by variations in cooking (sulfate, sulfite, soda), bleaching, and refining (procedures for modifying the physical properties of the fibers, such as beating). The papermaking process induces variation in addition to that caused by differences in pulp stock composition. Using the same pulp but changing paper machine variables can produce papers with very different physical properties. For example, changing the machine speed alters the fiber orientation, resulting in different strength properties especially in the machine-direction and the cross-direction of the sheet. Various wet pressing conditions alter the density, porosity, optical, bonding, and strength values. Calendering affects surface and strength properties. Although the chemistry of several papers could be the same, the physical properties could be quite different resulting in very different papers. Composite variables are separated into two types: furnish (pulp composition) and formation (manufacturing). Furnish variables include the types of refining, the fiber sources and chemistry, the fiber dimensions (length, width, and fibril angle), furnish composition (ratio of fiber types), sizings, fillers, and coatings. Formation variables include the extent of beating, fiber direction, basis weight, wet pressing, drying, fiber distribution, and calendering.

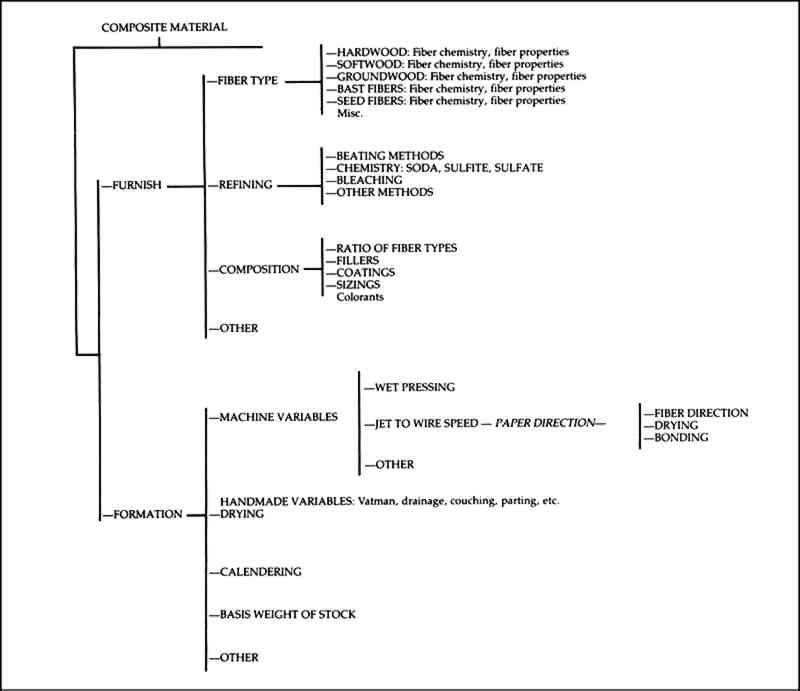

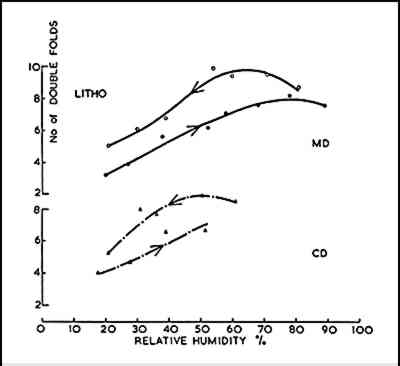

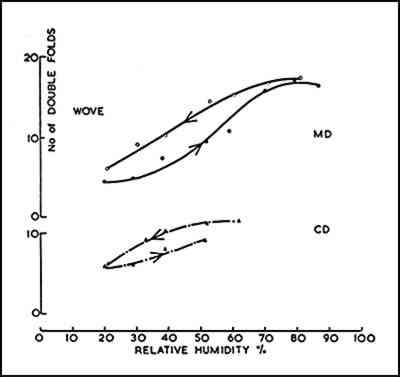

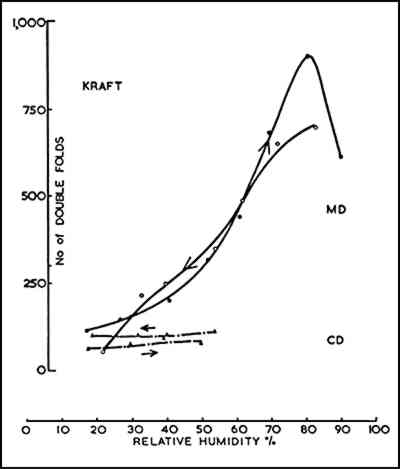

Figure 1 is an outline of the many furnish and formation variables which contribute to the composite structure of paper. The following discussion of only one of the formation variables, paper direction, should demonstrate the complexity of paper as a composite structure. The main factors controlling paper direction are fiber orientation (how the fibers are lying in the sheet), bonding, and drying conditions. There are three directions defined: the machine direction or MD, the cross machine direction or CD, and the out-of-plane or ZD direction. Paper is an anisotropic material: it has different properties depending on the direction of the sheet tested. There are nine elastic modulus measurements that can be made along the three different axes.5, 6, 7 Most measurements are made in the MD or CD

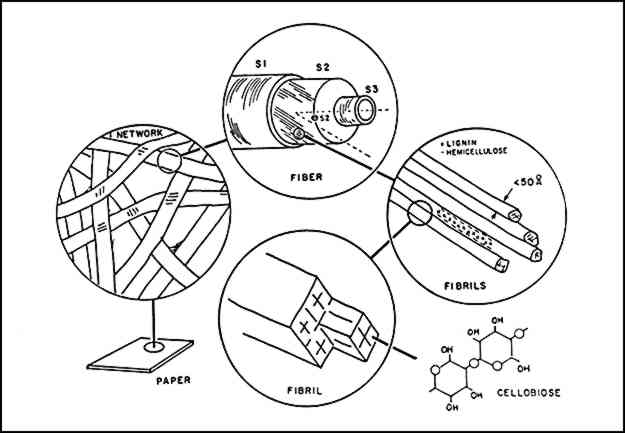

Sheet direction is largely dependent on the direction in which individual fibers are deposited on the screen during manufacture. The fibers lying lengthwise, parallel to the machine direction, contribute the properties associated with that direction (such as strength, response to moisture, and deformation). Individual fiber properties (see Figure 4) are partly responsible for this characteristic. Fibers are composed of the primary wall, and the S1, S2, and S3 secondary walls. The secondary walls contain fibrils.

The S2 layer is the dominant layer in the cell wall.8 The fibril angle of the S2 layer influences the individual fiber's physical properties and therefore sheet properties, such as direction. The fibril angle is the degree that the fibril is either perpendicular to or parallel to the fiber. Fibrils aligned with the fiber are said to have a “low” angle and fibrils not aligned are said to have a “high” angle. Papers composed of fibers with “low fibril angle” withstand greater load and less elongation than those with “high” angles. Fibril angle varies within the same fiber source depending on the variables previously mentioned, such as early or late wood, source of the fiber, etc.9 Drying conditions also influence sheet direction. When two fibers cross in a sheet, each influences shrinkage of the other. Waterhouse discusses the manner in which restraint while drying can change fiber properties. Microcompressions and crimps influence the strength properties of the paper. For example, in a conservation test intended to measure the effects on paper of different water sources, the restraint could be altered, therefore affecting the test data regarding strength properties. The data may show a change that is not related to the sources of water being tested, but instead to change in restraint between the unwetted control and the wetted specimens. This is one of many factors that make the comparison difficult of “before” and “after” treatments, or of two different papers and their response to testing. Bonding also contributes significantly to differences in sheet direction and the anisotropic properties of the sheet. However, bonding in paper is an area currently being researched and many interactions are not fully understood at this time. Network theories attempt to describe the physical properties of a paper sheet in terms of individual fiber properties such as those previously mentioned: fibril angle, paper direction, bonding, and others. Peterson discusses the history of network theories and the attempts to correlate various theories with observed data. As theories are developed to explain the complexities of paper structure, more accurate models are proposed. However, the influence of the properties of individual fibers on the overall structure of paper remains elusive. Peterson discusses thirteen theories ending with the contributions of Van den Akker. After reviewing the various theories, Peterson concludes:

Attempts to test, measure, or predict paper properties based on individual components, whether chemical or physical, have not been as successful as testing the physical properties of paper as a composite structure. The preceeding discussion of only one variable, paper direction, has shown the complexity of paper as a structure, and the contribution of many variables and their interactions to testing and the interpretation of data. |