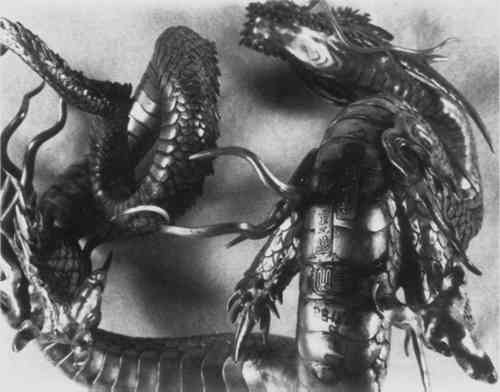

TREATMENT OF A SILVER DRAGON FOR THE REMOVAL OF SILVER CYANIDE AND CHALCONATRONITEDonna K. Strahan

5 CHALCONATRONITEBLUE CHALCONATRONITE, a hydrated sodium copper carbonate, has previously been reported by Gettens and Frondel9 and by Horie and Vint.10 Its initial discovery by Gettens and Frondel on an Egyptian bronze led to the conjecture that its presence was due to the dry alkaline burial condition of the object. Gettens and Frondel gave detailed crystallographic properties and x-ray powder diffraction patterns. Horie and Vint then reported that chalconatronite was also produced on corroded bronzes which had been treated with sodium sesquicarbonate. The recent analytical results of the silver dragon indicate chalconatronite is more common than anticipated and may be caused by other treatments. While the occurrence of cyanide salts on the dragon could be explained by the cyanide bath, the explanation of the occurrence of chalconatronite and its close proximity to the silver cyanide is less clear. There are several possible explanations. The sodium present in the chalconatronite may have come from the cyanide cleaning solution as an added component or from a degraded bath while the object was immersed. Normally sodium and potassium cyanide are continually added to cleaning or plating solutions to keep them saturated with these substances. If they are not replenished, the cyanide slowly oxidizes to a cyanate which hydrolyzes to a carbonate and ammonia is evolved.11 This could produce carbonate ions and ammonia in the bath available to attack the copper component of the silver alloy, although the small amount of ammonia evolved from hydrolysis of the cyanide solution is not likely to have contributed to the corrosion products. Another source for the sodium aside from the sodium cyanide solution may have been an alkaline rinse used after the cyanide bath, such as NaOH or Na2CO3. The carbonate in the chalconatronite may have developed from the absorption of carbon dioxide from the atmosphere by the highly alkaline solution. It is also possible that the carbonate developed from the deterioration of the cyanide solution, or, further, it may have come from an alkaline rinse. The copper in the chalconatronite may have come either from a contaminated bath or from the alloy itself. If the copper was derived from the alloy, then this would explain why the two corrosions occurred together rather than scattered separately over the object's surface. The areas which had been corroded by the cyanide were Tests were run to determine whether sodium carbonate would react with the small percentage of copper present in sterling silver. A solution of 14% sodium carbonate was placed on a sterling silver blank in a humid atmosphere and removed after twenty-four hours. Blue crystals were produced and confirmed as chalconatronite by x-ray diffraction analysis.13 Considering chalconatronite can be formed on sterling silver over a long period of time, it is unlikely that it would form during a brief rinse such as the dragon may have undergone. However, it may have had time to form from the solution which was left behind on the interior after the treatment was completed. Although it would be interesting to observe cyanide attack a sterling silver blank, tests were not conducted because of the inherent dangers of handling the test solutions. In summary, chalconatronite seems to be most likely formed by cyanide trapped within the dragon's body slowly seeping out and reacting with the silver alloy. All of the constituents necessary to form both corrosion products were present, and through recrystallization both cyanide and carbonate compounds products could be found adjacent to one another.

|