LEAF CASTING ON THE SUCTION TABLE

Robert Futernick

4 LEAF CASTING ON THE SUCTION TABLE

UNTIL RECENTLY, the suction table has been primarily used for washing, drying, stain removal, and lining operations. With only slight modification, the suction table can also be used for localized leaf casting. While hand pulp method remains the simplest and most direct approach for small holes, leaf casting on the suction table may be specially useful under certain conditions:

- In the absence of a conventional leaf casting apparatus.

- When the art object or document is larger than the dimensions of the leaf casting machine.

- When the loss is large and requires a particularly even fill.

- When the texture of the original sheet is an aesthetically important element and the repair calls for articulation of paper texture.

4.1 Advantages of suction table casting

- The entire sheet does not always have to be wet before casting.

- When water-sensitive media are present, another liquid such as alcohol may be utilized to carry the pulp into place.

- Pulp deposition on the original paper is avoided, since very little liquid is used and only a small area of the original is exposed.

- The quality of the join can be improved in cases where strength is important by casting half the fill and then turning the sheet over to complete the fill. This creates an actual encasement or overlapping of the edge on both sides. This variation is not only strong but offers the additional advantage of obscuring a dirty edge.

4.2 Modification of Suction Table for Leaf Casting

With only slight modification, many vacuum/suction table designs may be used for leaf casting. A major issue is the ability of the system to handle safely a gallon or more of water at one time. The liquid should be disposed of before it reaches the suction device. This can be accomplished in several ways:

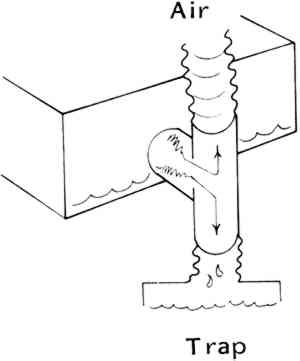

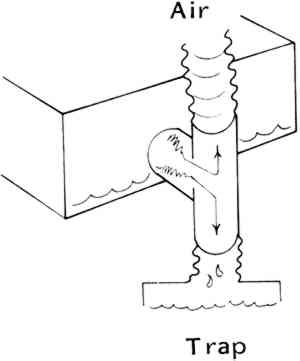

- Installation of a tee in the tubing leading to the pump/fan. The pipe fitting should be placed so that liquid will fall into a trap for collection and future disposal (see figure 1). Plastic (PVC) tubing and fittings are especially useful for the plumbing. The pipe can be easily cut to size with a handsaw and simply slip-fitted for connection. Though joins can be welded with solvent for permanent high pressure usage, this is not recommended. It is an advantage to be able to undo a connection for later adjustment or alteration.

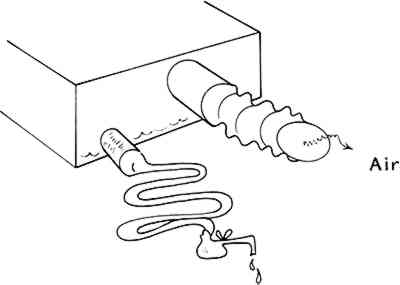

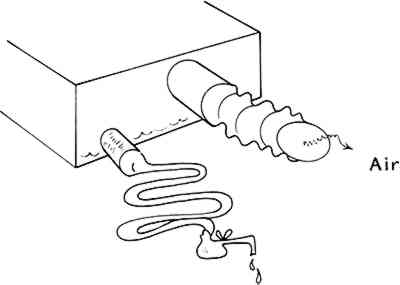

- Water collection in the plenum space below the table surface. If this space is large enough and waterproof, it can serve as a trap. Vacuum input must be placed high with a removable plug positioned at a low point for water removal (see figure 2).

Fig. 1.

Tee-joint water trap for the suction table.

|

Fig. 2.

Plenum space used as a water trap and fitted with a drain.

|

4.3 The Process

Leaf casting on the suction table does not differ in principle from the conventional method except that the casting fluid is contained only in the area directly above the loss. A discussion of the process follows:

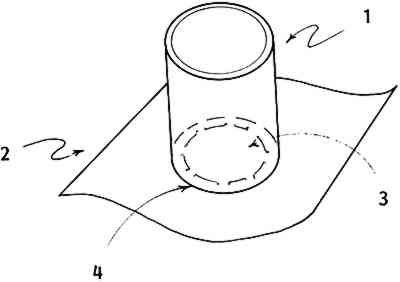

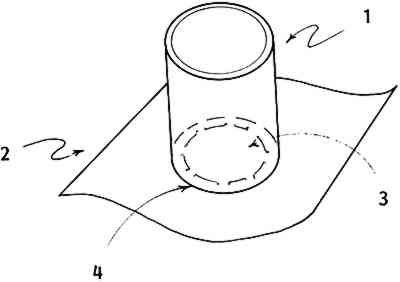

- The pulp container (see figure 3). Round plastic tubing can be procured in various sizes (2″ to 6″ in diameter) and easily cut into 4″ lengths [1]. (Containers for larger losses are easily fashioned by heating and bending plexiglas sheeting into a rectangular shape, slightly larger than the hole). Thin plastic film (.002″) is cut into a rectangular shape several inches larger than the diameter of the tubing [2]. Then a hole, larger than the loss but slightly smaller than the opening of the container tube, is cut in the center of the rectangle [3]. Silicon adhesive applied to the bottom edge of the tube affixes the container to the plastic mask [4]. This pulp mold will seal itself when suction is applied without harmful downward pressure of the mold on the paper artifact.

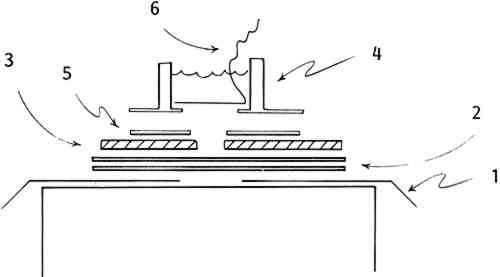

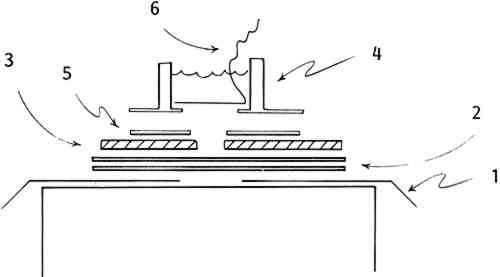

- Arrangement of materials on the suction table (see figure 4). A piece of thin plastic film cut larger than the top of the suction table is placed on the surface so that the extending edges hang over the table [1]. A hole in this film is cut centrally, its dimension slightly larger than the opening of the container mask. Two layers of non-woven spunbonded polyester fabric (Reemay, number 2014 or 2114, from Dupont) are placed over the opening to provide a surface on which to cast [2]. Reemay, an especially suitable material, aids in creating very even pulp formation and imparts a texture much like that achieved by contact with papermaker's felts. The damaged original is set on the Reemay so that the loss is located over the opening in the table [3]. The container can be set directly on the surface of the paper [4]. However, the opening in the mask will not conform exactly to the contour of the loss. If precision in casting is required, pulp deposition in areas other than the hole can be avoided by cutting and properly placing a Reemay mask onto the paper [5]. This extra step can be done quickly and enables one to use just a few different-sized containers for most castings.

- Delaying drainage. An interval of time is needed for filling the container with water and pulp. A removable plug can be fashioned using plastic film, cut so that it just fits in the container tube (see figure 4 [6]). A string or narrow strip of plastic affixed to one edge of the plug facilitates removal. The plug, inserted inside the container just prior to applying suction, is pulled tightly against the container mask forming a temporary bottom to the container when suction is activated. Lifting the attached string removes the plug, allowing the slurry to be pulled into the area of loss. Larger areas of loss are plugged better if several pieces of plastic film (each with a tail) are placed to overlap each other slightly. Multiple plug removal becomes a louvre action, thus avoiding tidal waves.

- Selection and processing of pulp. The quality of a casting and its adhesion to the artifact is dependent on many factors: the type of fiber, the nature and duration of processing, and the method of casting and drying. Pulp selection and beating is a complicated issue. The Petherbridge article noted in the bibliography provides a good starting point. However, experimentation and experience is invaluable here. In some cases, it is possible to obtain very satisfactory results by using pulp derived from old, good quality papers beaten in a household blender. The use or addition of linters or commercially processed pulps can provide special advantages in terms of bonding strength and textural quality.

- Correct addition of pulp to casting liquid. Too much pulp yields a fat, irregular, uneven casting and too little will produce transparency and thinness. (As previously mentioned, it may be desirable in some cases to cast a thin fill from one side, turn the paper over, and complete the casting from the other side. This encases the edge of the original, providing more strength at the join, while perhaps hiding a dirty edge.) The achievement of a fill that has comparable thickness to the original as well as appropriate texture and opacity is a complicated matter, and practicing on holes in mock-ups is necessary to master this technique. However, it is helpful to have a starting point, and the following indicates a method:5,6Cast, press, dry, and cut a rectangle of paper to a convenient size (e.g., 20cm � 25cm). Measure and record the thickness and weight of the sample (e.g., .0125cm thick and 4.0 grams).Determine volume-per-gram by multiplying the length of rectangle times the width times the thickness and divide by the weight of sample (e.g., 20cm � 25cm � .0125cm divided by 4 grams = 1.563 cm3/gram).Find the area of the loss and measure the thickness of the damaged artifact. Counting squares of graph paper or outlining the perimeter of the hole with a planimeter are two methods that have been used to approximate area. Either technique is adequate for occasional casting. However, if the volume of leaf casting activity is high, it may be worth speeding area calculation with the aid of a microcomputer. Simply tracing the outline of the loss with a “light pen” on a Graphics Tablet connected to an Apple Computer, for example, will yield a very quick and accurate area measurement.Determine the weight of pulp required for the casting by dividing the volume of the loss by the volume of a gram of pulp (e.g., area of loss 150cm22 � thickness of artifact .017cm divided by volume/gram 1.563cm33 = 1.63 grams).It is convenient to refrigerate pulp in solutions of known concentration (e.g., 1%) for storage. It is then easy to mix different colored pulps, test the resulting color by drying, and pour out the required amount (e.g., 1.63 grams is approximately equal to 163ml of a 1% solution). The addition of a small quantity of fungicide to the solution will prevent bacterial and mould growth.

- With suction holding the container and plug in position, the pulp solution is poured into the container. Vacuum pressure is then adjusted. This is a matter of experience, but pressure influences flow and the flow rate will affect the casting. The tail of the plug is quickly pulled. This action opens the bottom of the container, enabling the liquid to drain.

- The casting is quite wet and much water can be removed by slipping a sheet of blotting paper between the first and second layers of Reemay. Acting as a support, the Reemay can then be lifted to move the paper to a hard-surfaced table. Rubbing over the fill with a bone burnisher while it is still wet serves to compact fibers and improve the join. Using plastic film or polyester fabric as an interleaf during burnishing will help to achieve a more sympathetic match of textural qualities. Subsequent drying of the sheet in open air is often preferable to pressing even under light weight. Remoistening for final pressing and flattening is accomplished with controlled, even water application. By this time, the joined areas are more secure and not as susceptible to splitting.Large castings have a tendency to detach at the join, a condition that is exacerbated when the artifact is particularly expansive. Pressing or slowing the drying process may be necessary to maintain the integrity of the bond.Very tender attachments or those that will have to withstand the strain of handling, can be strengthened with application of Japanese tissue along the join or all over as a lining.3

- If the addition of adhesives to the fill seems appropriate—for strength or as a sizing for later toning—then it might either be added to the casting solution or applied locally after the fill has undergone preliminary air drying.

- In special cases, it is desirable to approximate the textural qualities of the original in the casting. Articulation of laid lines in the cast area can minimize the visibility of damage. This becomes important with a work of art on textured paper scheduled for exhibition in subdued and slightly raking light. The use of a laid screen, aligned on a light table to match the laid markings of the paper and placed just under the loss during the casting process, can impart a sympathetic texture to the fill. A method for creating an assortment of laid screens for this purpose is described as follows:Make a ruled line drawing using black ink on clear acetate. The width of the lines should be drawn to equal the space in between the lines. Lay out the grid so that approximately 24 black lines are set to the inch (see figure 5).Using a photostat machine, incrementally enlarge and reduce the line drawing to achieve a desired range of sizes.Place a line drawing in direct contact with a piece of photo-silk screen emulsion. The photo-sensitive emulsion is a commercially available product mounted on a plastic film support. One company that supplies this material is J. Ulano & Company, 610 Dean St., Brooklyn, N.Y. 11238.Set a sheet of glass on top of the sandwich and expose the emulsion to light through the open areas of the line drawing. A 250 watt sun lamp is a good source and it will work well if placed 15–20 inches from the drawing. Exposure will probably be under 12 minutes but a little testing is required to achieve the proper duration (dwell time).After exposure, place the emulsion into a liquid developer specific for this purpose. Rinse according to the emulsion directions and while the emulsion is wet and sticky, press it onto a support of Reemay or fine (polyester) silk-screen fabric. Allow to dry and then remove the plastic film carrier.The dried emulsion remains sensitive to water and must be hardened before use. Expose the silk screen to the fumes generated by a formaldehyde bath and allow to dry. Then spray the screen with a material such as Scotchgard to protect the emulsion further.Repeat this process for each line drawing to create a catalog of various-sized screens that can be used again and again.It should be noted that this process is not for the creation of a perfect reproduction or a facsimile of a missing area. Instead, its use is intended to minimize the visibility of damage that would otherwise interfere with the aesthetic impact of a work of art.

- Casting with alcohol. There are instances where even partial wetting of a paper artifact is not safe. Experiments have shown that an acceptable casting can still be accomplished, providing the paper or media are not adversely affected by alcohol. The pulp is prepared by first beating it in water in the usual manner. Most of the water used in beating is extracted by pouring the slurry through a strainer. The damp fibers are transferred back to the blender where a quantity of ethanol is added for a second beating. The paper artifact is wet with ethanol prior to placement on the table and casting is performed as previously described. The resulting fill will be quite soft and felt-like because not much bonding occurs. However, this may be remedied by localized application of water or water plus a sizing agent followed by burnishing and pressing.

Fig. 3.

Pulp container for use on the suction table.

|

Fig. 4.

Suction table set up with damaged object, pulp container, and associated materials, ready for use.

|

Fig. 5.

Suitable line spacing to make a laid-line pattern in casting.

|

|