NOTES ON A PRESSURIZED SYSTEM FOR PRODUCING MAGNESIUM BICARBONATE SOLUTIONSRandall Couch

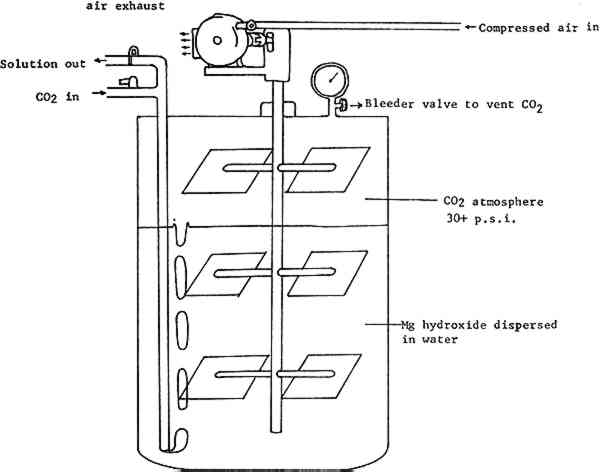

3 SYSTEMTHE SYSTEM CENTERS AROUND a modified paint-mixer made by the Binks Mfg. Co. (Fig. 1). A rotary stirrer provides horizontal and vertical agitation of the solution. The stirrer is powered by compressed air from an outside compressor. Carbon dioxide under pressure enters through a straight pipe and bubbles up through the soliution from the bottom. Eight gallons of deacidification solution are made at a time, with a carbon dioxide atmosphere filling the rest of the chamber's ten-gallon capacity. All interior surfaces of the chamber and stirrer are stainless steel.

The equipment was originally used with magnesium carbonate powder as a starting material. Since the publication in 1978 of National Archives test results showing magnesium hydroxide to have a substantially higher rate of solubility, that material has been employed. The magnesium hydroxide powder is first passed through a wire strainer to break up any lumps and then mixed with water in a blender for several minutes to disperse it further. This mixture is poured into the mixer and water is added to reach the eight-gallon mark. The chamber is capped, the stirrer and CO2 turned on, and the reaction allowed to proceed for the requisite period. The finished solution is pumped out using only the mixer's internal pressure. |