TECHNICAL EXAMINATION OF THE CLASSICAL BRONZE HORSE FROM THE METROPOLITAN MUSEUM OF ARTKate C. Lefferts, Lawrence J. Majewski, Edward V. Sayre, Pieter Meyers, R.M. Organ , C.S. Smith , Edward V. Sayre , Robert H. Brill , I. Lynus Barnes , Thomas J. Murphy , & Frederick R. Matson

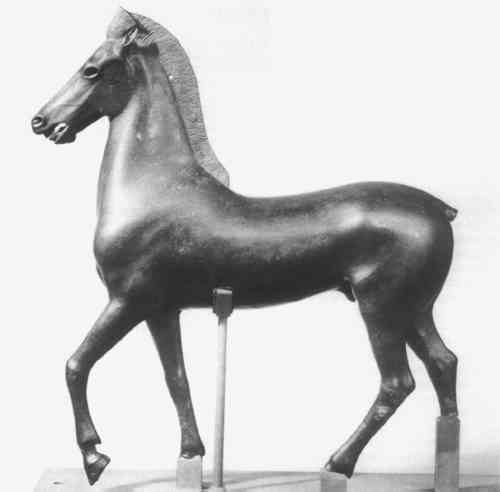

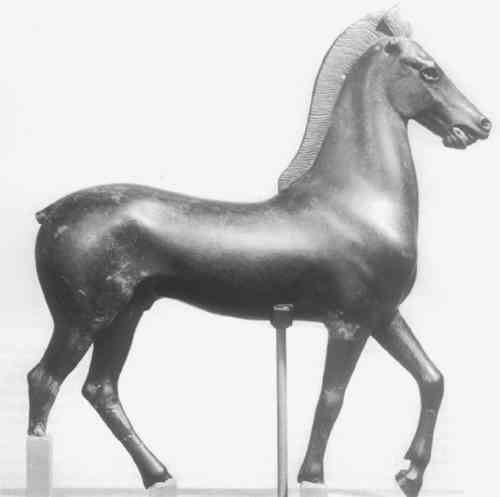

ABSTRACT—A through technical examination of the Metropolitan Museum of Art Bronze Horse (Acc. No. 23.69) has revealed that the technical evidence used to condemn it does not hold up under critical evaluation. The composition of the metal and core, the nature of the corrosion and its method of manufacture are consistent with the object being of ancient origin. Thermoluminescence experiments performed on the ceramic core material of the horse have proved that the bronze horse was manufactured in antiquity. THOSE CONCERNED WITH the authentication of art works by means of the evaluation of technical evidence know how difficult it is to establish a certain attribution. We examine as many aspects of structure, composition, and condition as possible, and if one, or more, of these is clearly inconsistent with an assumed origin, then technical evidence can be said to have disproved the proposed attribution. However, even if all traditionally understood properties are found to be consistent with an attribution, it can be argued that a very clever forger could have had the knowledge and foresight sufficient to employ appropriate materials in authentic ways. Only when new analytical criteria are established can, as a consequence, previously unknown aspects of earlier technologies be established as standards for attribution. Only when we can be certain that all technical factors, as revealed through modern analytical methods and including some which would have been unrecognized at the time of the object's original publicizing, are consistent with the technology of the period to which the object is attributed, and also only when independent parameters of an age can be established through recently developed absolute dating techniques, can the antiquity, if not precise attribution, of the object be determined. Through the efforts of a large number of collaborators a sufficient body of such evidence has been accumulated to reestablish the antiquity of the Metropolitan Museum of Art's bronze horse, whose authenticity has been questioned on technical grounds. In December 1967 at the close of the third of the Art Forgery Seminars held at the Metropolitan Museum of Art, Joseph V. Noble, Vice Director for Administration of the Museum and chairman of the session, announced his conclusion that the Museum's bronze horse, Accession No. 23.69 (Figs. 1 & 2) which had been dated 480 to 470 B.C. and attributed to Greece, was a forgery made in the early 20th century, possibly in France; the Museum had purchased the bronze from a dealer in Paris in 1923.1 His primary important technical argument against the authenticity of the horse

These arguments were countered at the time. It was pointed out by people familiar with ancient Greek casting practices that iron armatures and other supports had been used frequently in classical times. Carl Bl�mel, retired Director of the Berlin State Museum, noting the presence of such armatures in the core of the bronze Kouros discovered at Piraeus and dated by the National Museum in Athens to the 6th to 5th century, B.C., in the Charioteer in the Archaeological Museum at Delphi, and in some unspecified bronze castings in the Berlin State Museum, felt the support as described was a sign of authenticity.2 Bruno Bearzi, master Florentine metal caster, stated he had found evidence of an iron support in the Kouros from Piraeus and in other ancient castings.3 Also, among other examples of ancient metal castings in which we have observed internal iron supports are the serpent head from the Delphi tripod in the

The bronze horse was submitted to the Conservation Department of the Metropolitan Museum on January 3, 1968, for examination by the authors, to study further the method and date of its manufacture. The first structural details to be examined were the mold lines between the forelegs, across the barrel 2 cm to the left of center and down the left hind leg. Surface examinations established that the bronze was coated with rather thick, opaque layers of black and green pigmented wax, of a type frequently applied to archaeological bronzes at the Museum and elsewhere in the 1920's and 30's. In order to observe the condition of the surface, the pigmented wax was removed with xylene. With its removal, the mold lines disappeared. There remained only a depressed line on the face of the horse running up from the nose to between the eyes, but not up to the forelock as had been stated (Fig. 4). The mold lines were in the wax coating and not on the surface of the bronze. Presumably, they indicate the edges of the piece mold that was made for reproducing plaster casts of the horse which were sold for many years at the Museum's sales desk and at Brentano's bookstores.

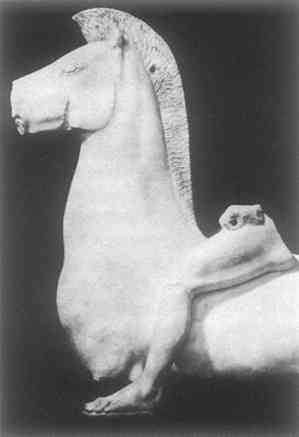

Dr. Bl�mel, accepting as correct Mr. Noble's assertion that a mold fin existed in a vertical medial plane in the metal of the horse, suggested the possibility that the horse could have been cast in two halves and then soldered together.2 Dr. Claude Rolley, also accepting the statement that the horse had a medial seam, suggested that it could have been cast by the lost wax method as a single unit over a wax model constructed in two halves joined together around a core.4 However, neither of these authors could have known that the reported “fin” was only in the wax coating and not a part of the bronze. The line remaining on the horse's face is incised and has no flange or step. It has been studied also by Cyril S. Smith, Institute Professor Emeritus, Department of Humanities, Massachusetts Institute of Technology, by John Spring of the Modern Art Foundry, and by Bruno Bearzi, none of whom consider it a mold line. Bearzi points out that the horse would have taken many months to create, whereas the line could have been obliterated in a few minutes. The surfaces around the line have been chased and filed, which indicate that the line has been deliberately preserved. Moreover, similar incised lines modeled in marble sculptures appear on the heads of two horses in the National Museum of Athens (Accession No. S 399) and in the Agora Museum at Athens (Fig. 5). Since there can be no question of mold marks on carved marble and since these markings are similar to that on the bronze horse, the latter also can be accepted as a modeling line deliberately created by the sculptor.

Mr. Noble criticized the horse on stylistic grounds: first, that the hole in the mane was misplaced for supporting a harness; “the harness straps should tie right behind the ears.”5 This point was answered with the following two observations. First, with the removal of the wax coating, two small round holes, 2 mm in diameter and about 10 mm deep, were uncovered 10 mm behind each ear (Fig. 6). He had not been able to locate them through the wax. The right one is full of sandy accretions and the left contains material that gave a positive micro-chemical test for iron and calcium carbonate. The presence of iron suggests that a bridle trapping was originally attached by means of two iron pins. Secondly, the large hole in the mane, which is indeed too high for a rein, is in a similar position to that on an Etruscan relief of terracotta pegasoi, where the hole holds a votive offering, a medallion on a chain. The Horse with Rider in the Acropolis Museum in Athens has a hole in a similar position (Fig. 7). Could not the hole in the Museum's horse also have been for a votive offering? Drill marks indicate it was made after the casting.

Mr. Noble further argued that a vertical hole in the center of the forelock (Fig. 8) was illogical as its only purpose would have been to hold a bronze or iron spike, a

Mr. Noble felt that the patina was poor, but he could only observe the pigmented wax coating, which obscured the actual surface. He also felt that the statue had suffered “deliberate mutilation of the legs and tail.”6 However, examination of the broken tail and two right legs showed that they are coated with appreciable layers of corrosion products. Thus none of the arguments upon which the horse had been declared a forgery stood up to critical investigation, and recent investigations of ancient metal casting practices explain logically many of the points that were raised. However, since the authenticity of the horse had been questioned, it seemed necessary that a thorough technical investigation of it be undertaken. Since 1968, many specialists have examined the horse by various methods and have performed a number of analyses of the material of which it was made. Their full reports are included in the appendices and summarized below. 1 CONDITION AND STRUCTURE OF THE HORSEThe bronze is 40 cm high and 33.5 cm long. It weighs 11.6 kg and its overall specific gravity is 4.6. Its condition is reasonably good compared with other ancient bronzes and, in fact, it exhibits a relatively light degree of corrosion penetration. The surface has been mechanically cleaned, as indicated by scratches and file marks which interrupt the corrosion layer. There still remain, however, considerable deposits of There are many signs of wear. The edges of the empty eye sockets, undercut and scored to hold inlays, are abraded and broken (Fig. 10). The left ear is abraded and nicked and the upper part of the right ear is missing. There are signs of wear along the edge of the mane, and the fine lines of the mane hairs are somewhat abraded. The hoof and nostrils also exhibit signs of wear. The tail is missing and the right foreleg and left rear leg are both missing below the pastern joint. The right rear leg is missing from 5 cm below the hock. There is a small rectangular indentation (4 by 5 mm and 1 mm deep) at the outside of the right fore pastern which held a repair plug. The hoof would be apt to break naturally at such a point of weakness.

More than two dozen rectangular plugs are on the surface of the bronze. A few are exceptionally large, while most are small and nearly square. Five of the larger ones include two approximately 1 cm square and a rectangular one 2 by 0.8 cm on the left side of the neck and one 0.1 by 0.8 cm on each hind leg. These large plugs are not magnetic and are typical of plugs used to cover casting flaws throughout the history of casting. Most of the small square plugs are points to which a magnet is attracted. Radiographs reveal that they cover the remains of iron chaplets which supported the core within the mold during casting, which extend from the plugs into the core (Fig. 11). The presence of these chaplets is in itself convincing evidence that the horse was not cast by a sand casting technique, for chaplets such as these, which penetrate a short distance into the core but do not traverse it, would not effectively support the relatively loosely bound core used in sand casting. On the other hand, such chaplets are customary in hollow lost wax castings.

As an integral part of the bottom of the left hoof there are three edges of a slightly raised square plate with a small square hole in the center discovered during examination (Fig. 12) This indicates that in the original casting the hoof may have been attached to a base.

To obtain a section of iron armature for analysis, the plug in the left rear leg was removed as a unit by gentle tapping with needles and scalpels after hand-drilling the corners (Fig. 13). The character is similar to plugs observed by the authors on several classical bronzes. The interior surfaces are coated with black, green and orange-red corrosion products. The two long sides are bevelled, as are the sides of the hole in the horse. Under loose corrosion, the bottom of the hole is solid bronze which had been scored.

We drilled through the metal beneath the plug to a depth of about 19 mm. The leg is hollow without core material, and the inner surface of the bronze casting could be viewed. This inner surface is not granular as is the case with sand castings but has runs of metal similar to those observed in lost wax castings. The internal structure of the sculpture is best revealed in the radiographs (Figs. 11a & b). Restudy of the earliest radiographs, taken in 1967 with iridium-192 radiation, Further radiographs of the body of the horse taken at various angles with several types of radiation—high energy x-ray, cobalt-60 gamma ray, and cesium-137 gamma ray, as well as iridium-192 gamma ray—show the armature to be defined by edges of higher density. Its structure when viewed horizontally across the horse has a variable thickness of 1.5 to 2.5 mm. When viewed vertically down through the body, it is several times broader, varying quite unevenly between 10 and 15 mm. The edges of the armature are much more sharply defined when viewed from the side through its greatest thickness, as would be expected. When the support is viewed from angles oblique to its flat orientations, it is possible to observe continuous spreading of thin edge views into broader, more perpendicular views. The irregularity of the residual structure would indicate that it was originally a crude, uneven strap approximately 2 by 12 mm in cross section. Its irregularity suggests rough hand fabrication. It does not appear to be a uniform machine-made rod such as is commonly used in modern castings. Excavation of the core material in the region of the support structure failed to produce any uncorroded iron metal. The detection of a high iron oxide concentration found in the region surrounding this structure indicates that it was indeed made of iron and that the original metal has corroded extremely. The tapered iron chaplets run only a short distance into the core. One through the left hind quarter, 26 mm long and approximately 2 mm square, shows quite clearly on the earliest radiographs. Others can be seen at either side of the body of the horse. At the eye socket, where iron oxide was found, and in front of the throat, there are Iridium-192 radiographs of the legs show that three legs were cast solid with iron armatures, which show as darker lines running up into the core. The armature in the right hind leg leads to a surface deposit of iron oxide at its lowest extremity, confirmed by x-ray diffraction. The right foreleg is without armature and has been cast onto the body of the horse. At the join, the leg extends slightly out beyond the body. This leg would appear to have been a repair made at the time of the original casting, as its metal alloy and the corrosion products on it are similar to those of the main body of the horse. Below the join there is a semicircular hairline crack (Fig. 14). The radiograph shows that a pour of metal filled the gouged-out core for 30 or 40 mm, locking the leg to the body. The prevalence of irregularities and blow holes in the legs indicates their casting may have been a problem to the founder. The alloy (see Table I), low in lead and without zinc, has been described by foundrymen consulted as difficult to cast, as it is sluggish and does not pour easily.

Table I There is another type of repair on the left hind leg (Fig. 11b). Radiographs show that the iron armature stops just below the hock and that the lowest 35 mm of the leg is a solid casting of a denser alloy with a significantly different composition. This leg The presence of armatures in three of the solid legs is additional conclusive evidence that the direct lost wax casting technique was employed. If the horse had been cast by either the sand casting technique or the indirect lost wax method, there would be no need for an armature in the legs as they would have been solid. However, if the artist followed the traditional direct lost wax technique and shaped the core for the body and neck, then executed the model in wax over the core, modelling the legs and tail entirely in wax, he would have needed an armature to support the wax sections during creation of the figure. The thickness of the bronze in the body of the horse varies considerably, from 5 to 7 mm at the top of the quarters, 5 to 7 mm along the back, 7 to 8 mm along the neck, and 10 to 15 mm along the belly. There are also sudden variations at the withers and at the center of the barrel which indicate that the core was trimmed back during the modelling of shoulders and quarters. Whenever it became apparent to the sculptor during modelling that the wax walls were becoming too thin for proper casting, he would have resorted to such trimming of the underlying core. The bronze was cast in one piece. There are no signs of rivets or welds. The metal is quite porous and the blow holes and plugged repairs show that difficulty was encountered in the casting process. All the structural evidence indicates that the horse was cast by the lost wax casting technique, the wax having been modelled directly over a core: 1) lack of any mold marks, 2) non-uniformity of wall thickness, 3) apparent cutting back of the core, 4) use of armatures in the solid legs, 5) use of chaplets, and 6) interior runs of bronze as observed under the removed plug are all highly characteristic of the direct lost wax process. 2 SURFACE ACCRETIONS AND CORROSION PRODUCTSFairly heavy deposits of whitish accretions lie over much of the surface. They form an almost continuous outer layer on the mane and are heavy over the top of the right foreleg, around the plugs, inside the mouth and below the mouth and chin. The deposit on the mane was determined to contain sand and calcium carbonate by microchemical testing. Underneath it there are deposits of green over red corrosion products. Many investigations have shown that the natural corrosion products on archaeological bronzes include a red copper oxide (cuprite) layer under a green layer of a copper hydroxy carbonate (malachite) or a copper hydroxy chloride (atacamite or paratacamite). X-ray diffraction measurements confirm the presence of cuprite and of copper hydroxy chloride. A thick deposit on the tongue was determined microchemically to be calcium hydroxy carbonate. Below it also lie green and red corrosion products. X-ray diffraction analysis carried out at the Conservation Center of the Institute of Fine Arts, New York University, identified the deposit on the right foreleg to be calcite (calcium carbonate) and a combination of calcite and silicon dioxide The bronze is coated extensively with a smooth, thin, well-attached layer of brownish black corrosion product which appears in part to have been removed mechanically, in some areas down to the surface of the metal, notably on the left foreleg. A sample taken from the right rear leg, similar in appearance to the crust on the nose, was determined by x-ray diffraction in the Analytical-Conservation Laboratory of the Smithsonian Institution to be bornite (Cu5FeS4), a natural mineral difficult to manufacture artificially. Its presence is not usual on ancient bronze. X-ray diffraction carried out at the Conservation Center showed the black deposit on the left rear leg also to contain bornite together with copper and cuprite, and that from under the right rear leg to be djurleite (Cu1.96S), a natural mineral. The finding of these minerals is consistent with a long-term natural corrosion process. X-ray diffraction analysis of a green sample from the right flank showed it to be paratacamite. A later x-ray diffraction analysis of a green sample from the right flank identified it as a mixture of paratacaamite and atacamite. On the inner wall of the bronze where it was drilled at the square plug on the leg, on the edge of a bronze flow at a depth of 4 to 5 mm, there is a green corrosion product which was analyzed by x-ray diffraction to be a mixture of paratacamite and atacamite. The analyst, Seymour Z. Lewin, claims that if the patina contains atacamite or a mixture of atacamite and paratacamite, then the probability is very great that the patina is false.8 However, examinations of many bronzes of unquestioned antiquity at the British Museum9 and at the Metropolitan Museum10 have shown that genuine, naturally formed corrosion often contains a mixture of paratacamite and atacamite. Furthermore, experiments by Pieter Meyers and E.V. Sayre have demonstrated that when copper metal is immersed for a period of days in aerated sodium chloride solutions buffered to an acidity similar

There is no evidence that natural corrosion products have been mechanically applied to the surface. Professional foundrymen John Spring and Bruno Bearzi agreed that the corrosion products were not artificially generated. Bearzi considered that the corrosion products as observed on the horse could not have formed in less than 200 years. The black patina is very hard, and he thought it could not be formed in such a hard layer artificially.3 R.M. Organ, Chief of the Conservation-Analytical Laboratory, Smithsonian Institution, studied the horse. For his metallurgical examination two specimens were taken, a core drilling from the bottom of the right rear leg and a cross section obtained by enlarging a hole already hand-drilled into the barrel of the horse (see Appendix I). The specimen from the leg revealed a dendritic structure containing interdendritic cavities and globules of lead. Although no major corrosion crust remained on this specimen, the presence of pits indicated that mineralization penetrated into the metal structure to a depth of 0.3 mm. At high magnification some replacement of a metallic phase by mineral was observed which left no doubt that some corrosion processes have taken place within the metal itself and that the mineral has not merely formed a surface layer. The cross section from the barrel, about 10 mm long, revealed a negligibly thin corrosion crust on the outer surface. The inner surface was not mineralized to any greater degree, although it did possess a number of pits that should have contained mineral if corrosion had occurred. Hairline cracks which normally accompany mineralization were absent from both samples. Interdentritic cavities free of corrosion products and very small separated globules of lead indicated that the metal had chilled unexpectedly rapidly. Organ concluded “that the results of this particular examination do little to favor a belief in the antiquity of the samples. Nevertheless, on occasion, objects that carry very little mineralization have been regarded by archaeologists as genuine and many thousands of years old.” From inside the hole under the square plug in the left rear leg, loose reddish black corrosion products and several small black pieces from the leg armature which were attracted to a magnet were shaken out. These on close inspection turned out to be a conglomerate of magnetic iron oxide (Fe2O4) mixed with core. The plug was examined metallurgically by C.S. Smith (see Appendix II). He reported that it shows a roughness on some edges which suggests ancient filing and that the dendritic structure, although fine, is characteristic for any normal cast bronze. He noted the presence of both intergranular slip-band corrosion and surface corrosion on grain boundaries near the bronze surface. He commented upon the relatively small amount of corrosion on the inner surface but suggested that possibly metal contact between the bronze and the iron armature and chaplets within the core might have protected the bronze until the iron was completely corroded. Such electrogalvanic protection could indeed have delayed overall corrosion of the bronze. Although the metal of the bronze horse is not deeply penetrated by the corrosion, other ancient bronzes of unquestioned authenticity have a similar degree of surface alteration. After examining the horse visually, Nicolas Yalouris, Inspector General of Antiquities, Minister of Culture and Science, Athens, and Director of the National Archaeological Museum in Athens, stated that many of the bronzes from Olympia showed no more degree of corrosion. Certainly the nature, ordering and 3 COMPOSITION OF THE METALA SAMPLE OF BRONZE was drilled from the barrel of the horse at 50 mm behind the forelegs and was analyzed by E.V. Sayre by emission spectroscopy (see Appendix III). A second sample from the drilling beneath the plug in the left rear leg was also analyzed, as well as samples from the break of the right foreleg and the bottom of the left rear leg, where the radiographs indicate a region of exceptionally high density. These analyses are given in Table I. It is apparent from these data that the first three samples are similar in composition. The differences occurring among them are not greater than one might expect from the non-uniformity frequently present in ancient metal alloys. As indicated in the discussion of the structure of the horse, the right foreleg was cast-on. The analytical data indicate that the metal used in this leg is not significantly different from the alloy used generally throughout the horse and hence supports the conclusion that the added leg was probably made at the time of the fabrication of the statue. The slightly lower tin and lead content in the foreleg might have resulted from removal of these metals from the alloy through oxidation upon remelting. In contrast, the high lead alloy of the repair to the left rear leg is strikingly different from that of the rest of the horse. The difference in the composition of the two leg castings would suggest they were made at quite different times. The correlations of elemental compositions to the chronology of ancient metal casting practices are published by E.R. Caley in his summary of the composition of ancient statuary bronzes.11 Based on this work, it would appear that the metal of the main body of the horse and the right foreleg was similar to that used in classical Greek bronzes but with a slightly higher lead content, while the high lead alloy of the left rear leg repair approximated that of Roman or later date. However, more recent analyses of classical bronzes modify these conclusions. The lead content of the original structure of the horse, which averages approximately 0.4%, at first seemed to be unusual because the analyses of classical Greek bronzes reported by Caley indicated a nearly total absence of lead. Also, the range of concentration initially seemed unexpected in that it appeared to be too low to represent a deliberate addition of lead, but too high to be an accidental inclusion. However, the work of P.R. Fields has shown that a small portion of natural copper ores do contain this amount of lead.12 Regardless of how this level of lead may have been introduced, it now appears upon the basis of more recent Table II Average Compositions of Classical Statuary Bronzes of Various Regions and Periods Compared to M.M.A. Classical Bronze Of particular interest to this case is the fact that only recently have we become aware that classical bronzes are likely to contain this intermediate concentration of approximately 1% of lead. All of the early analyses of classic Greek bronzes, in particular those published before the date when The Metropolitan Museum of Art acquired the bronze horse, reported no lead to be present. (Of course these early Lead isotope ratios from samples of the horse and from the left leg repair were studied jointly by R.H. Brill of the Corning Museum of Glass and I.L. Barnes, J. Murphy and W.R. Shields of the National Bureau of Standards. From such isotope ratios it is often possible to infer the geographic origin of the lead present in the alloy. The method does not provide a date for fabrication of the alloy as lead mined today from a given site will have the same isotope ratios as that mined in the same place in antiquity. Therefore, the method cannot produce proof of authenticity, but if a highly improbable geographic source had been indicated by the measurements, it would have cast serious doubt upon the authenticity of the horse. The measurements, which are described in detail in Appendix IV, indicate that the Levant and Italy are both probably sources of the lead occurring in the high-lead repair and possibly in the body of the horse. Neither lead had the isotope ratios of that of the ancient mines at Laurion in Greece thought to have been the major source of ancient Greek lead. Had lead from the European Greek mainland been added to the alloy, its isotope ratios would very probably have been those of Laurion lead. The lead in the repair must have been added; however, there is no firm evidence that there was any deliberate addition of refined lead to the alloy of the body of the horse. One cannot be sure that lead occurring as an impurity in copper ores would necessarily relate isotopically to that from a lead ore of the same region; but even if such an isotopical correlation should be proven, the indication of an Anatolian or an Italian source for the bronze does not exclude a classical origin nor one directly associated with Greek culture, since there were many major Greek cities in Anatolia and Italy. Both the elemental composition and lead isotope ratios of the bronze in which the horse was cast are clearly compatible with a classical Mediterranean origin. The fact that the alloy in its low lead content corresponds to an ancient composition which has only been recognized within the last few years is in particular indicative of the metal having been of ancient origin. There is no conclusive evidence as to when the high lead bronze repair on the left rear leg might have been applied although on the basis of our present evidence it is likely to have been Roman or later, perhaps even modern.∗

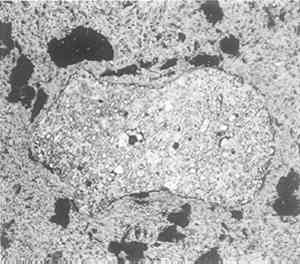

∗Dr. Bernard Keisch ran a lead 210 dating of the lead from the cast-on repair. He reported that the radioactivity level of polonium 210 was less than that of radium 226 in this lead and inferred from this observation that the repair was relatively modern. However, most of the difference in radioactivity levels was the result of a negative activity measurement for the radium 226 (−0.9 � 0.7) disintegrations per minute per gram of lead. Since a measurement of less than zero radioactivity is physically impossible and can only result from experimental error, it is questionable whether the measured difference is significant relative to the error in the measurements involved. 4 COMPOSITION AND MICROSTRUCTURE OF THE ARMATURE AND COREAN ATTEMPT WAS MADE to reach the armature through the hole made in the barrel in obtaining a metallographic specimen. At this location, the bronze casting was 15 mm thick. At the point of contact with metal the core was black but at a depth of 35 mm from the outside bronze surface it was gray. From here to 53 mm, the center of the core, it was streaked alternately light and dark gray. After removal of 95 grams of core material, at a depth of about 62 mm, the core was intermittently rust color and black. At 70 mm, it was so hard that it could not be scraped loose without first drilling with a steel drill. The iron armature was located to the right of center of the barrel at about 70 to 75 mm. Small black magnetic pieces were withdrawn along with core material stained red and black. X-ray diffraction demonstrated that the red material basically contained goethite (Fe2O3�H2O) and that the black was magnetite (Fe3O4). The largest black piece was attracted to a magnet but proved to be a mixture of sand and iron corrosion products. Of this hard region a sample initially thought to be a corroded residue of the armature was analyzed by electron microbeam probe by E.V. Sayre, who searched for slag streamer residues characteristic of crude wrought iron. No streamers were observed and the sample proved to be core material. However, iron showed up strongly throughout the finely divided binding material which contained the elemental components of clay minerals. Particles of quartz, calcite including some calcium carbonate shell, and feldspar were observed. The core was moist on removal and contained about 20% water. This was probably the result of seepage occurring when the horse was immersed in water for specific gravity measurements. Microchemical tests on the core material indicated the presence of chloride. X-ray fluorescence, spectrographic and neutron activation analyses gave silicon major, calcium 17.8%, aluminum 3.8%, which is low for clay, iron 3.0% and a fraction of a percent of magnesium, sodium, copper, titanium, and traces of other elements. Water extractable chloride ion was 1.37 per cent. As a test for ammonium ion was negative and only 0.3 per cent sodium was found, chloride is present in some form other than ammonium or sodium chloride (see Appendix III). The core material was studied petrographically in thin sections and in powder mounts by F.R. Matson (see Appendix V). He also analyzed it chemically by a glass bead microprobe technique and observed color changes produced by experimental firings. He reported that the core is composed of “approximately equal parts of clear quartz sand and of a calcareous paste that could probably be termed a marl—a sticky naturally occurring deposit derived from an ancient sea bottom.” He found characteristic foraminifers to be present along with relatively small amounts of chalcedony and felspar. However, micas and evidence of organic material were absent. Many of the quartz grains contained well developed rutile needles. Efforts have been made to identify the geographic source of the core material on the basis of the inclusions. Marie Farnsworth in her examination of thin sections of core material found it to be dissimilar to the clays used in the Greek pottery she has studied. A quantitative estimate of the mineral content of the core based upon a rational analysis of the chemical determinations and the petrographic observations is given in Table IV. Table IV A comparison of the color of the core material to the colors produced by laboratory firings indicated that the core had been heated under strongly reducing conditions. In lost wax casting the process of heating the mold to remove the wax produces a reducing atmosphere within the core. The overall observations on the core material clearly show it to be a natural calcareous sand with a marly binder, probably a marine deposit. Analysis of Mediterranean sands have shown a very similar elemental composition. It is distinctly different in composition and character from modern casting sand, which consists of a 5 THERMOLUMINESCENCE DATING OF THE CORE MATERIALTHE POSSIBILITY OF DATING the core material of the horse by thermoluminescence, ∗ an established technique for dating of ceramic materials, was investigated. However, it was initially felt that thermoluminescence would not be applicable in the case of the core of the bronze horse, because gamma ray and x-ray radiography applied to the horse had supplied an artificial radiation dose in addition to and not distinguishable from the natural accumulated dose received by the ceramic core, thereby interfering with an accurate dating or reliable authentication. Fortunately, a sizable sample of the core material was extracted in the early stage of the technical examination before most of the radiography was done. Furthermore, recent improvements in the thermo-luminescence techniques developed at the Research Laboratory for Archaeology and the History of Art, Oxford, and at the Laboratory for Space Physics of Washington University, St. Louis, Missouri, have made possible such dating of the core material despite the radiographic dose it has received. ∗Thermoluminescence dating is based on the following principle. All ceramic materials contain small amounts of the natural radioactive elements uranium, thorium, and potassium. A fraction of the energy released in the decay processes of these radioactive elements is absorbed and stored by the minerals forming these materials. When these minerals are heated to about 500�C this stored energy will be released, some in the form of emission of light. This emission is called thermoluminescence. Dating can be applied to ceramic objects which have been fired at the time of their production; all existing stored energy will be released at that time and the dating clock is set to zero. From this moment energy will be stored at an essentially constant rate, proportional to the “dose rate,” i.e., the intensity of the radiation originating predominantly from the natural radioactive elements. The total amount of absorbed radiation is called the accumulated dose, expressed in rads. The age of an object can be determined from a simple relationship: age = accumulated dose/dose rate. The accumulated dose can be determined by measuring the amount of emitted light as a small sample is heated to approximately 500�C and comparing it with the light produced by a known lab dose. The dose rate can be calculated from the experimentally determined concentrations of the radioactive elements. The recent thermoluminescence measurements were initiated by Pieter Meyers and were carried out as a collaboration between him and David W. Zimmerman and Marjorie P. Yuhas at the Laboratory for Space Physics.15 A careful estimate was made of the received dose from radiography prior to extraction of the core sample, based on From the measured doses corrected for the dose received by radiography, estimates of the age of the core material were made for the various separated particles. A precise dating could not be expected because of limitations in the experimental procedures and also due to uncertainties of some factors such as the exact radiation dose due to radiography. Initial age determinations made upon the basis of three individual zircon particle measurements varied within the range of 1900 and 3700 years. Estimates of minimum and of maximum based upon measurements of fine grained particles were 1300 and 2800 years. Similar dating of the quartz particles was necessarily less accurate because of the relatively low natural dose they had received. However, the relatively rough estimates of minimum and maximum age based upon quartz particle measurements were 2000 and 5500 years, which under the circumstances was also felt to be reasonably consistent with other results. Improvements made recently in the zircon dating technique have allowed a more accurate estimate of the date of manufacture of the horse. Zimmerman16 has reported an age of 2250 � 210 years BP. This number was obtained as an average of measurements on a new set of three individual zircon grains. The uncertainty of � 210 years represents, according to Zimmerman, a reliable estimate of one standard deviation. He states: “the results show only that the horse was probably made between c. 50 B.C. and 500 B.C. with, for practical purposes, equal probability for any time in this period.” From the thermoluminescence results it can be concluded that the bronze horse was cast in classical antiquity. The three sets of thermoluminescence measurements are all inconsistent with the hypothesis of a recent origin for the bronze horse. 6 CONCLUSIONINVESTIGATIONS OF THE materials and techniques of manufacture of the bronze horse by conservators, foundrymen and scientists have found that all properties are consistent with that of ancient manufacture. The few reservations expressed by Organ, Lewin and Keish we believe have been answered. The bronze alloy and its corrosion products, the core with its armature, the chaplets and repairs are all characteristic of bronzes cast in classical antiquity. And finally the TL dating of the core material between about 500 B.C. and 50 B.C. provides conclusive evidence that the horse cannot be a modern forgery. The horse can now find its rightful place in history. REFERENCESNoble, J.V. ‘The Forgery of Our Greek Bronze Horse,’ The Metropolitan Museum of Art Bulletin, February 1968, 253–356. Bl�mel, C., ‘Das Bronzepferd in New York ist keine F�lschung,’ Die Weltkunst, Heft12 (1968), 568. Bearzi, B., Private communication during examination of horse and ‘II Bronzo Nella Antichita,’ La fonderia italiana, XV, 2 (1966), 1. Rolley, C., ‘Fouilles de Delphes V : Monuments Figures, Les Statuettes de Bronze,’ Editions de Boccard, Paris (1969), 169-ff, pls. LI & LII. Noble, op. cit., p. 256. Ibid., p. 256. Ibid., p. 255. Lewin, S.Z., ‘A New Approach to Establishing the Authenticity of Patinas on Copper-base Artifacts,’ Application of Science in Examination of Works of Art [Ed.W.J.Young), Museum of Fine Arts, Boston (1970), 62–66. Werner, A.E.,Letter to K.C. Lefferts 2/2/68. Meyers, P., and VanZelst, L., verbal report. Caley, E.R., Analysis of Ancient Metals, MacMillan Co.New York (1964), 116–117. ‘Chemical Composition of Greek and Roman Statuary Bronzes,’ Art and Technology (Ed.A.Steinberg), M.I.T., Cambridge1970, 37–49. Fields, P.R.et al., ‘Copper Artifacts: Correlation with Source Types of Copper Ores,’ Science1152 No. 3728 (1966), 1504–1506. Cesareo, R.et al., Non-Destructive Analysis of Ancient Bronzes,’ Studies in Conservation, 18 (1973), 64–80. Craddock, P.T., ‘The Composition of Copper Alloys Used by the Greek, Etruscan and Roman Civilizations:’ ‘1. The Greeks before the archaic period,’ Journal of Archaeological Science, 3 (1976), 93–113; 2. The Archaic, Classical and Hellenistic Greeks, Journal of Archaeological Science, 4 (1977), 103–123; 3.Origins and Early Use of Brass, Journal of Archaeological Science, 5 (1978), 1–16. Zimmerman, D.W., Yuhas, M.P., Meyers, P., ‘Thermoluminescence Authenticity Measurements on Core Material from the Bronze Horse of the New York Metropolitan Museum of Art,’ Archaeometry, 16 (1974), 19–30.

Zimmerman, D.W., unpublished communication to P. Meyers. APPENDIX1 APPENDIX I1.1 Examination of Mineral Incrustations and Two Metal Sections of the Metropolitan Museum of Art Bronze HorseR.M. Organ Conservation Analytical Laboratory, Smithsonian Institution, Analysis of Metal and Corrosion (CAL 0579)The various samples have now been examined in detail. They comprise:

Results:

∗Bornite is a mineral found widely distributed in ore deposits. Daubr�e reported its occurrence on Roman coins and medals found in French mineral springs (R.J. Gettens, Corrosion Products of Metal Antiquities, Smithsonian Institution, 1964, p. 555). In this instance the iron present in the mineral was presumably acquired from the mineral water that surrounded the copper coins. In the object under present consideration the metal is reported to contain only 0.06% iron, scarcely adequate to supply the 11% of iron present in Cu5FeS4 if this mineral did develop in situ as a result of corrosion processes. It may be concluded that either the object corroded in the presence of ground-waters contained iron—and the presence of calcite supports this belief—or it was corroded deliberately in water enriched in iron and calcium carbonate, or the mineral has been applied externally. Examination of other samples may throw light on these various possibilities. This section reveals a negligibly thin corrosion crust on the end representing the outer surface. 325X reveals that the entire crust has a thickness of only 0.05 mm in the area examined. Here the crust contains isolated thin patches of grey mineral in contact with the metal. This mineral was at first believed to consist of cuprous chloride, and it contains two rounded particles of what appears to be pure copper. Beyond this are patches of cuprite, orange when viewed between crossed polars and no more than 0.02 mm thick. Beyond this again lies a rather particulate mixture of what could be azurite and tin oxide. The surface of this layer is bounded by a line of isolated unidentified small black crystals. This outer mineral crust has few of the characteristics of a protracted natural development. A layer of cuprous chloride can indeed be expected in the position found and pure copper can appear within it as a result of a corrosion process, but in the size observed it could also be generated on modern material within a period of only a few months. Actual experiment, directed to confirming the presence of cuprous chloride by exposure of the cross-section to 100% relative humidity for five days, failed either to confirm it or to initiate any observable corrosive activity whatever. Cuprite also should be present in the observed location but in much greater thickness. Furthermore, orange cuprite like the present example can be formed from cuprous chloride during only a few hours of exposure to an alkaline solution. The particulate outer layer is also unnatural, and its surface has clearly been brushed over with a dressing of black particles. The end representing the inner surfaces is little better mineralized, although it does possess a number of pits that should contain mineral if corrosion processes had taken place. The filling in these pits is actually a visually black material which appears grey when examined at high magnification. Its nature has not been determined but it does contain isolated siliceous particles. Over the length of the edge of the section examined (about 5 mm) only about 0.25 mm retains residues of identifiable mineral (325X). A layer of cuprite closely adjacent to the metal is only about .006 mm thick. It is rather particulate and associated with black material that could be cupric oxide. Both of these oxides form on cooling metal in the presence of oxygen. Sufficient oxygen could be present in a porous core to yield this result. Some of the black particles are displaced into an adjacent mass of green-colored material which might conceivably result from a corrosion process. Its maximum depth is about 0.1 mm. The pits present on this surface probably do not result from corrosion processes since they do not contain the normal minerals and cannot be activated by high relative humidity. They cannot be used as evidence of degree of corrosion. 2 CONCLUSIONS

It may be concluded that the results of this particular examination do little to favor a belief in the antiquity of the samples. Nevertheless, on occasion, objects that carry very little mineralization have been regarded by archaeologists as genuine and many thousands of years old. APPENDIX1 APPENDIX II1.1 Metallographic examination of two samples from the Metropolitan Museum of ArtC.S. Smith Massachusetts Institute of Technology, Dept. of Humanities.Results of samples submitted on 13 December 1968.

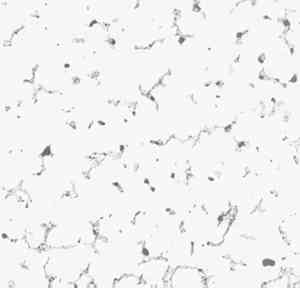

2 THE ARMATURESample No. 1 is magnetic and had a rather well defined shape suggesting that it might be metallic, but when fractured it was seen to consist of a compact conglomerate of sand particles and a dark mineral. The present surfaces are, probably, mainly a result of the mechancial operations involved in extracting the sample and do not represent its form in situ. Figure 1 shows the microstructure of the sample after sectioning, grinding, and polishing. It consists of quartz particles (sand) with iron corrosion products completely filling the interstices and cementing the whole into a hard lump. The formation of an inner layer of magnetic corrosion product on ancient iron is quite common, though the identification of it as true magnetite Fe3O4 or as the magnetic form of hematite has not been made. It would eventually turn to ordinary rust on further exposure to a moist atmospere. The sample is not a piece of metal but adjacent sandy core material into which the expanding corrosion products of iron have grown, which tells nothing about the shape or composition of the armature itself beyond the fact that it is mostly iron.

Early radiographs seemed to indicate that the armature was not a rod but rather a strip bent into a circular or ‘Z’ section. The uncertainty in its profile is now explained by the extensive corrosion. Nothing in the radiographs suggests any technique beyond the capacities of a Greek founder. It would be necessary to compare the radiographs with those of other bronzes of similar shape and style before any conclusions could be drawn regarding authenticity. 3 THE BRONZE PLUGSample No. 2 varied in thickness from 1.8 to 2.4 mm, in width from 6 to 6.2 mm, and in length from 6.7 to 7.5 mm. Two of the edges had been damaged by the drill used to free the plug from the body; the other edges had a rough array of irregular deep scratches of the kind usually associated with ancient filing. (See, for example, the filed bronze wire in H. Hoffmann, Early Cretan Armorers [Cambridge, Mass., 1972, plate 55, Fig. 2]). The flat surface is rough and oxidized, and is probably the original surface of a thin plate cast in a mold without any further mechanical treatment. The other side (the outer surface when in place) was presumably finished in the same way as the bronze surface of the rest of the horse.

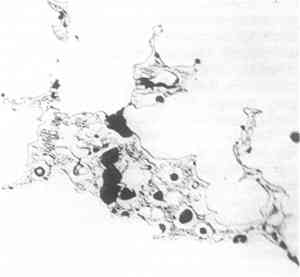

The longer edge that had been damaged by drill holes was ground and polished for There is a perceptible difference in grain size between the upper and lower parts. The top corresponds to the rough surface; the bottom represents metal solidified more quickly because it was near a cool mold surface. Both top and bottom of the piece show evidence of slight local cold work such as a chiseling operation, and the fitted edges are more heavily deformed (especially the one to the left of Fig. 2); but there is no evidence of intentional gross deformation of the piece, nor any that it had been given heat treatment after casting. The microstructure at higher magnification is shown in Figs. 3, 4. It has a perfectly normal structure for a lead-free cast bronze with occasional shrinkage cavities and with the usual inter-dendritic areas, which at high magnification (Fig. 4) are seen to be the typical duplex structure of the alpha/delta eutectoid with some slate grey inclusions, either oxide or, more probably, sulphide.

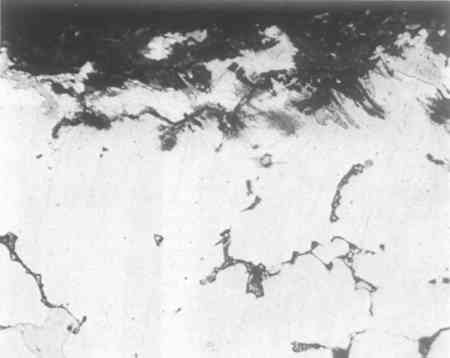

There are some special features to be noted, however. First, the left side of the sample shows unmistakable evidence of slight deformation, visible at low magnifications as curvature in the dendrites and at high magnification as slip lines in certain crystals (see Fig. 3). The deformation appears mainly at the edges, and probably arose during the fitting of the plug in place. Some may have occurred during removal for examination, but certainly not all, for there are places near the surface where corrosion has followed the slip lines (see Fig. 5, a cross section including at the top what had been the original outer surface of the horse).

Figure 5 was photographed unetched in order to show the corrosion products better. It should be compared with Figure 6, a photograph of the other side of the section, including the original inner surface of the plug. The surface is of smaller grain size, and is considerably smoother than the other, and, more important, is less corroded. The metal near the original outer surface (see Fig. 5) shows corrosion along the

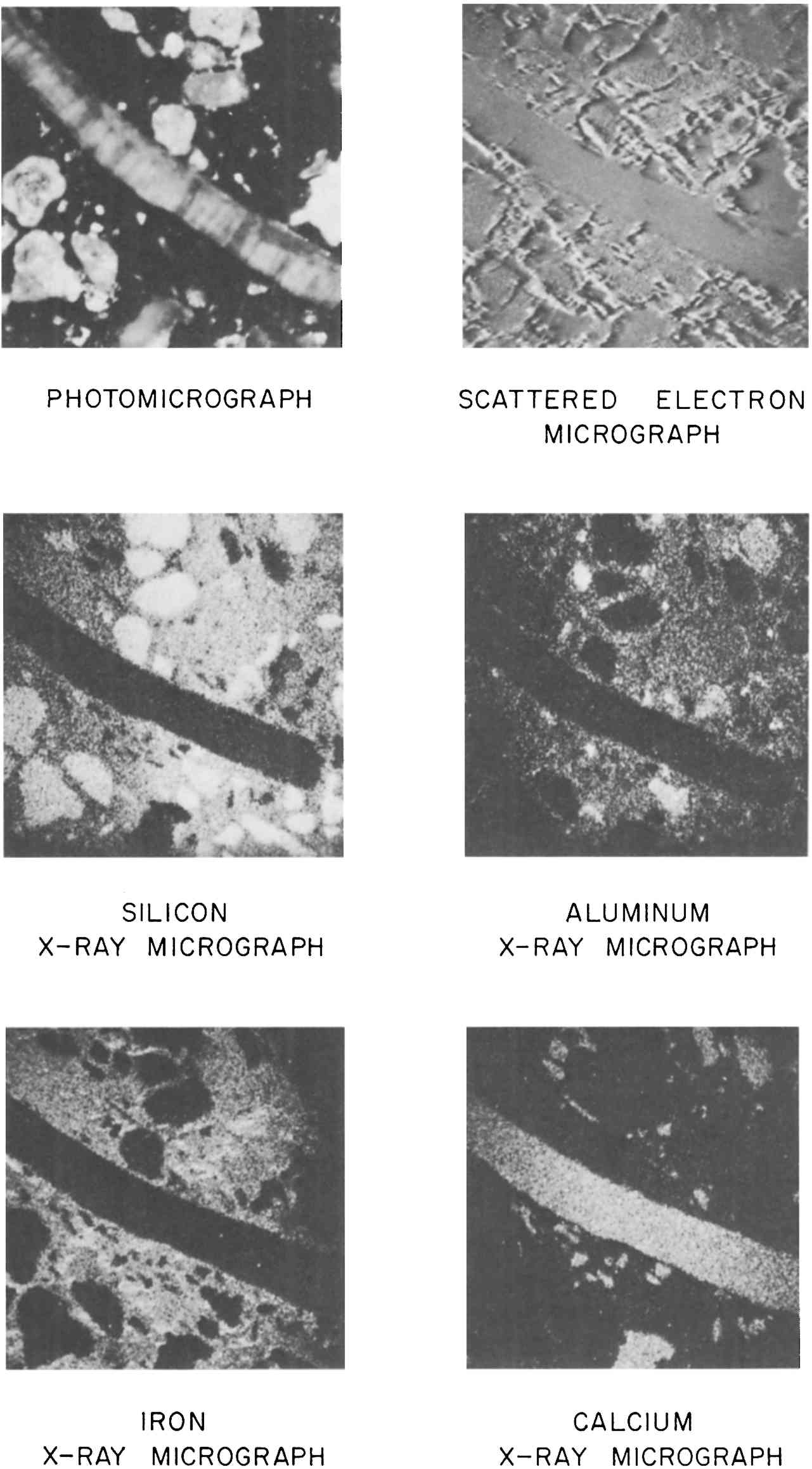

Most ancient bronzes that I have examined have been from the Near East and show intergranular corrosion to a greater extent than this. I would have expected the corrosion to penetrate around the side of the piece to the back side. However, the corrosion that is observed would have certainly taken a very long time to occur, and if the iron armature had been in contact with the bronze and anywhere near the locality of the sample, it would have provided good electrolytic protection for as long as metallic continuity was maintained. It seems very unlikely that a modern repairer would chisel out a rectangular hole halfway through the piece and insert a filed cast piece of the kind studied above. In conclusion, there is nothing in any of this that is inconsistent with ancient origin, and the general character of the patches rather strongly suggests ancient repair. APPENDIX1 APPENDIX III1.1 Determinations of the Composition and Nature of the Metal and the Core Material of the Bronze HorseEdward V. Sayre Senior Chemist, Brookhaven National Laboratory1.1.1 Emission Spectographic Analysis of Metal Specimens from the Horse.Small specimens were taken by drilling from four separate locations. Three samples were considered to be specimens of the original metal out of which the horse had been cast, as they were taken from sites that appear to be continuous with the body of the horse (1, the rear underbelly; 2, the lower right foreleg, drilled at the bottom of the broken end; and 3, the upper part of the left rear leg, drilled into the metal exposed upon Five-milligram specimens of these turnings were placed into graphite cup electrodes which were arced to complete burning in the stand of a three-meter grating spectrograph. Similar specimens of seven separate standard bronze and brass alloys were similarly arced for calibration. The optical densities of selected lines of the elements determined (two for each element) were measured by means of a photoelectric densitometer. From the measured line optical densities of the standard specimens, concentration calibration curves were plotted from which the concentrations in the object specimens were determined. The error of determination of an individual specimen was estimated to be about 20% of the reported value. It was recognized that the three small five-milligram specimens taken from the original metal of the horse would not individually be fully representative of the composition of the metal. Collectively, however, they should provide a reasonable estimate of the overall metal composition. The results of the analysis of these specimens are given in Table 1 in the general text. A comparison between the average basic composition of the bronze of the horse, the average of a number of published analyses of Greek bronzes of the Classical period and the analysis of the Manship bronze are given in Table 3 in the general text. The degree of agreement between alloy compositions would allow one to conclude that the bronze of the Metropolitan horse is consistent in composition with that used in pre-Hellenistic Greece. Sixty-one analyses of early bronze objects are summarized in Table 3 in the general text. Since this summary was made, an additional 700–800 analyses of such bronzes have been reported; however, Table 3 may still be considered to be reasonably representative of such analyses. The repair cast on to the lower end of the left rear leg has a significantly different composition, one with nearly 19% lead. The analysis of it is given in Table 2 of the general text. In a Western context, bronze with this high a lead content was not prevalently produced until the Hellenistic period. From that time on, however, high concentrations of lead have frequently characterized bronzes as they often do today. To the extent that one might accept the original atribution of the horse to the Classical Greek period one could argue that the repair was added at least a century or so after its original casting. However, the possibility of the repair being even a recent addition cannot be ruled out on the basis of composition. 1.1.2 Structural Studies of Material from the CoreSome small lumps, a few cubic millimeters in volume, of a nearly black composite of particles well cemented together had been removed by probing from the core of the bronze horse in a region that gamma-ray radiographs of the horse show to have contained a supporting metal structure. X-ray diffraction patterns of this black material have shown it to be rich in the magnetic oxide of iron, Fe3O4. It is presumed that the iron oxide is a corrosion product of a wrought iron band, but it was initially questioned whether the iron-oxide-rich composite represented the immediate residue of the oxidized iron band or was ceramic core materical near the band into which iron had migrated during the corrosion process. If the material represented an immediate residue of the supporting iron and if this had been a crude wrought iron, as would have been characteristic of fifth century B.C. iron, then one might have expected to find slag streamer residues within it. Such streamers would most likely appear as irregularly shaped filaments of a complex alumino-silicate glass containing a variety of metallic elements as impurities. On the other hand, if the specimens were of the ceramic core material into which the iron had migrated, they would likely contain a variety of particles similar to those observed in tempered pottery. Two specimens of the sample were mounted in an epoxy resin, ground and polished for microscopic examination at Brookhaven National Laboratory. Photomicrographs, an electron scattering micrograph and a series of electron beam microprobe x-ray micrographs were taken of one of these specimens

The photomicrograph shown in this figure was taken with polarized illumination and a polarizing analyzer in the microscope oriented at an extinction position relative to the incident light. Under these conditions one tends to see below the surface of a particle into its inner stucture. It is apparent that the long filamentary inclusion which nearly crosses the micrograph has quite a complex striated structure. The electron scattering micrograph, which was taken by the electron microprobe, shows only the surface structure of the region investigated. It tends to resemble a photomicrograph taken with bright field illumination without polarization. The elemental x-ray micrographs are taken by the microprobe by scanning the electron beam in a raster over the area being studied. X-rays generated as the electron beam strikes the specimen surface are analyzed by the instrument, which is capable of limiting its response to individual x-rays arising from individual chemical elements. The intensities of these individually characteristic x-rays are correlated with the position of the electron beam as they are generated during the scan and are registered in a coordinated scan upon an oscilloscope screen, rather like a television picture. The resultant pictures show the distribution of individual chemical elements throughout the surface of the region scanned. The occasional fading of general intensity at the edges of some of the x-ray micrographs is an artifact of the instrument response and should not be considered as an actual reduction of concentrations at the sides of the fields. The silicon x-ray micrograph shows several of the embedded particles to have a high silicon content. Also the fine-grained material in which the particles are embedded is rich in silicon. Notably, however, the large filamentary inclusion contains little or no silicon. The aluminum x-ray micrograph shows that some of the silicon containing inclusions also contain significant concentrations of aluminum while others do not. The fine-grained embedding matrix contains a significant concentration of aluminum but the rod-like inclusion is relatively free of aluminum. Iron shows up strongly throughout the fine embedding material, but with an uneven distribution. None of the inclusions are particularly rich in iron. The calcium x-ray micrograph reveals that the large rod-like inclusion and a few other particles contain considerable calcium. All of these calcareous particles are relatively free of the other elements measured. Additional x-ray micrograph scans for manganese and phosphorous, not shown in the figure, indicated that only small amounts of these elements were present with no pronounced regions of increased concentration. The evidence of these micrographs is consistent with the conclusion that these specimens are of the iron-impregnated ceramic core and that this core is similar in composition to sandy earth which included some calcium carbonate shell and possibly marble fragments. The core might have been made of a clay to which a sea sand containing shell fragments had been added. The fine-grained embedding material contained sizeable concentrations of both silicon and aluminum with only a small amount of calcium. Such relative proportion of components would be typical of the composition of a clay. The particles in which only silicon was observed are in all probability silica grains. Those containing both silica and alumina would likely be alumino-silicate rock minerals such as feldspars. One would normally expect both such minerals to be present in a sand. The particles which show only calcium would very likely be calcium carbonate, which is also likely to be in a sand, particularly a sea sand, in the form of bits of marble or shell. X-ray diffraction has confirmed the presence of quartz and calcite in the core material. The fact that the iron is concentrated predominantly in the fine matrix material only would be consistent with it having entered the structure in solution. We 1.1.3 Chemical Analysis of the Core MaterialSamples of the general core material were analyzed for their elemental contents by the methods of neutron activation analysis and emission spectroscopy. Additional special determinations of the sodium and chlorine contents were made by atomic absorption and x-ray fluorescence. Chlorine was found to be present to the amount of 1.37 percent, a concentration commensurate with the small concentrations of sodium, potassium and magnesium found. This significant chlorine content could indicate the inclusion of clay or sand of a marine origin or the penetration of sea water into the core. The compositional analyses are presented in the accompanying table. Most of the trace impurities occur at concentration levels of about one-third of the values normally encountered in Eastern Mediterranean clays and pottery. However, the relative pattern of these trace impurity concentrations roughly conforms to that of the clays and pottery. The calcium oxide concentration and the estimated (by difference) silica concentration are much higher than we normally encounter in pottery. It would seem most likely, therefore, that the core material was composed of a clay or soil to which a relatively high concentration of a calcareous sand had been added. ANALYSIS OF CERAMIC CORE MATERIAL FROM WITHIN BRONZE HORSE (M.M.A. 23.69) APPENDIX1 APPENDIX IV1.1 Lead-Isotope Studies of the Bronze Horse from the Metropolitan Museum of ArtRobert H. Brill∗∗Research Scientist, The Corning Museum of Glass, Corning, NY 14830 I. Lynus Barnes††Dr. Lynus Barnes, Research Chemist, Mr. Thomas J. Murphy, Research Chemist, National Measurement Laboratory Center for Analytical Chemistry National Bureau of Standards, Washington, D. C. 20234 Thomas J. Murphy†

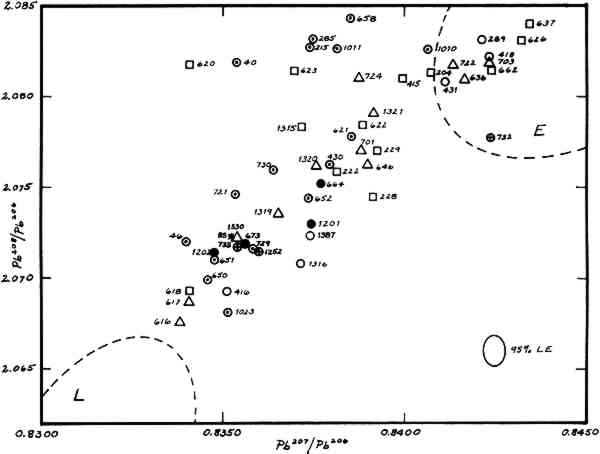

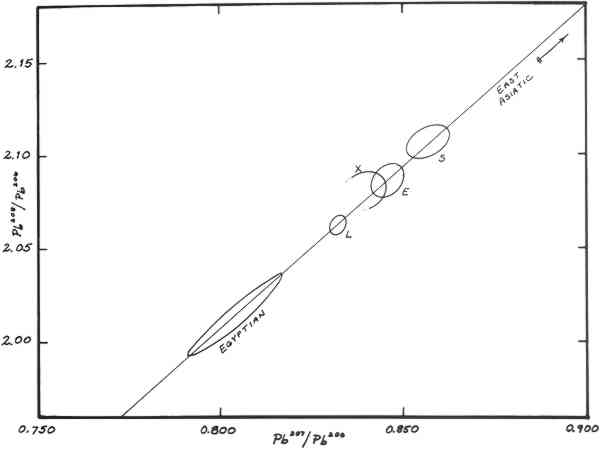

2 INTRODUCTION AND BACKGROUNDOf four metallic samples of the bronze horse submitted to the authors for lead isotopic analysis, two (nos. 664, 1201) came from the original casting. Previous spectrographic analyses indicated that these samples contained about 0.5% lead. The other two samples (nos. 673, 1202) came from the cast-on repair of the lower section of the left hind leg and contained about 20% lead. The objective of isotopic analyses was to determine from what mining regions the lead in these two alloys might have come. The hope was that such information would be of value in deciding upon the provenance of the object. The determination of lead-isotope ratios has become a routine method for studying the lead in early artifacts with a view towards establishing what ancient mining regions could have provided the ore from which the leads were smelted (Brill & Wampler, 1962; Brill 1970). In general this consists of matching isotope ratios from objects with ratios from galena ores from different mining regions. The method is applicable not only to metallic leads, but also to lead extracted from a wide variety of ancient leadcontaining materials, including Greek and Roman coins and other bronzes. The advantages and limitations of lead isotope studies have been discussed in detail elsewhere but two limitiations must be mentioned here. While individual ore deposits are characterized by their isotope ratios, these ratios are not necessarily unique to individual mines. Galena ores occurring in widely-separated areas may sometimes be nearly identical. Consequently, one can usually state without ambiguity that a given specimen could not have come from some particular deposits, but in making an attribution, one can go only so far as to state that a lead came either from some particular deposits or from some other deposit (known or unknown) which has similar ratios. This is termed “overlapping.” In addition, if leads from different sources are melted down together and reused, the resulting isotope ratios lie somewhere between the original leads. This is termed “mixing.” Also, the method does not distinguish between ancient metallic objects and modern objects made from melted-down ancient metals. Figure 1 summarizes data for some 800 specimens of ancient leads and ores analyzed previously. Group L consists of a suite of ores from the Laurion region in Greece, and of objects which are believed with good reason to have been made of Laurion lead. Group E contains many leads from England, some from European mines, and, towards the upper left part of the loop, several from objects associated with Constantinople and its environs. Group S contains relatively few samples, mostly from Spain, Wales, and Sardinia. Early Egyptian leads fall off to the left.

The area of the graph between the Groups L and E (partially overlapping Group E) has 3 RESULTSThe isotopic analyses were carried out at the National Bureau of Standards employing high-accuracy methods of mass spectrometry (Barnes et al. 1974). Results are compiled in Table 1 and plotted in Figure 2, along with a selection of other ancient leads. Duplicate determinations were run on samples 664, 1201, and 1202. The results agree closely with one another, so only the mean values for each sample are plotted. Because sample no. 673 was so small only a single determination could be run. The caption gives a key whereby samples with regional associations can be identified. The regions involved are Laurion, Italy (really Etruria and southward), Greece, The Levant, Constantinople, and Asia Minor. As can be seen in the graph, the alloys of the horse are clearly within Group X. TABLE I

4 INTERPRETATION OF RESULTSIn one sense the experimental results are quite conclusive. However, the interpretation of these results, that is, the translation of comparisons made on a graph into statements regarding the proper attribution of the horse, is complicated by three factors. Two of these are the marked difference in the lead levels in the two alloys, and the question of their contemporaneity. The third complication, the “awkward” level of lead in the body alloy, is alluded to below. It is apparent from Figure 2 that the samples from the body and the cast-on leg differ somewhat from one another. The difference is greater than could have been introduced by experimental error, but nevertheless, there is a very good chance that these two leads come from the same mining region. Viewed against the whole background of leads we have studied, they are really “more alike than unlike.” It is easier to consider the cast-on leg first. Because the lead in the leg is not of the Laurion type, it is quite unlikely that this alloy, containing such a large proportion of intentional lead, could have been prepared in Greece during the Classical Period—or, for that matter, during any other ancient period. Laurion lead was so abundant throughout Greece in ancient times that we believe virtually no other types of lead found their way into alloys prepared there (except perhaps in the north.) Thus, if the leg is an ancient repair our data strongly suggest that regardless of where the horse might have been made, it was repaired in a location where Group � lead was abundant; i.e., in Italy or the Eastern Mediterranean or Asia Minor, but not in Greece. If the leads in the samples of the horse are not from the Laurion region, where then, could they have come from? It is likely that the lead in the cast-on leg came from Italy, since samples 673 and 1202 closely resemble several leads known to have come from there. Because of overlapping, however, an alternative is that the leads could have come from the same mines which supplied those found in other Group-X objects from the Levant or Asia Minor. The ore sample 85, a galena from Akdag Maden in Eastern Anatolia, is a very close match for the lead in the cast-on leg. Also, Chamberlain and Gale (1976) and Gentner et al. (1978) have reported results for ores from Western Turkey, Thasos, and Filippoi which are similar to these leads. As far as we know, none of the other mining regions of the ancient world (Greece, Britain, Wales, Spain, France, Sardinia, Egypt, or North Africa) provide this kind of lead. The comparisons from which these inferences were made can be seen from the arrangement of the data in the table, where specimens are listed according to similarity of ratios. Proximity in the table reflects similarity of isotopic ratios. Samples 664 and 1201 are from parts of the original casting. Therefore, unlike the samples of the leg, their lead is inextricably connected with the manufacture of the horse. One might be inclined to apply again the same argument used above, saying that because the lead in the low-lead alloy is not of the Laurion type, the horse itself could not have been made in Greece in the Classical or Hellenistic periods. But this would be true only if it were known for sure that the lead was an intentional additive, or that it was an impurity introduced at the founding site. Unfortunately, neither of these conditions is known to hold, so the interpretation is not straightforward. Spectographic analyses have shown that this alloy contains only about 0.45% lead. If a lead concentration is more than about 2–3% it can reasonably be considered an in tentional addition, and if it is down at about the 0.1% level it can reasonably be considered an impurity in an ore or just stray contamination. But the intermediate range, where the horse lies, is more awkward to explain. Some of the ways this level of lead could have found its way into the bronze intentionally are as an impurity in the copper, as an impurity in the tin, as an adulterant of the tin, or as a residue of some metallurgical process involving the copper or tin. Consequently, the isotope ratios may be telling us more about the sources of copper or tin than about where the horse was made. Actually, alloys containing this level of lead are frequently encountered among Classical and Hellenistic bronzes, so frequently, in fact, that there must be some systematic reason for it. (For example, there are Roman tin: lead alloys with ratios of about 20:1 of tin In any event, we have adopted a more-orless empirical approach towards this problem, and have undertaken determinations on a large suite of early Greek and Italian bronzes to see what kinds of lead they contain. Our hope is that regardless of what is ultimately found to be the explanation of this intermediate concentration of lead, the results will nonetheless show how the lead in the body of the horse compares to those in other lightly-leaded bronzes of known date and provenance. 5 COMPARISONS WITH OTHER OBJECTSThe following objects contain leads closely resembling those found in the samples of the horse. Numbers 650 and 651 are from a large bronze statue found at Casanuovo, near Reggio (Mitten and Doeringer, 1967). It dates from the 2nd cent. A. D. and is in the Museum of Fine Arts, Boston (no. 01.7524). Both samples are of the ancient welding metal used to join cast sections of the statue in its original assembly. Like the pieces they join, they are heavily leaded, containing, respectively, 19.9% and 23.8% lead (Steinberg, 1973; Brill, et al. 1973). Sample no. 46 is from a small piece of metallic lead found in an Archaic tomb in Etruria, La Montangnola, dating from the 7th cent. B. C. This lead is almost certainly of local origin (Brill and Wangsler, 1962). Sample no. 1330 illustrates the overlapping effect. It is from a lead clamp (thought to be ancient) used to mend a Phrygian pottery vessel (Simpson, 1973). The vessel, dating from ca. 625 B.C., is in the collection of the Museum of Fine Arts, Boston (no. 1971.297). Presumably the repair was made somewhere in Anatolia, and would be of a local type of lead. It is a near perfect match for the galena ore from Turkey mentioned above (no. 85), which came from Akdag Maden in Yozgat Province (Brill & Wampler, 1962). Samples nos. 721 and 729 are both from Etruscan bronzes (Mitten & Doeringer, 1967), the first from the handle of a bronze vase of the 5th cent. B.C. and the second from a bronze Lasa figure of the late 4th cent. B.C. (Fogg Museum nos. 1974.75, 1966.109). Sample no. 733 is from a piece of bronze armor found at Dendra in Greece. It is of Mycenaean date. Sample 1252 is a Greek bronze of the 4th century B.C. These two lightly-leaded samples of Greek pedigree suggest that some of the copper used for making Greek bronzes might have come from Italy (because of the similarity to heavily-leaded Etruscan bronzes) or from those regions of Turkey which produce an isotopically-similar galena ore. Sample no. 652, which falls between the points for the two body-alloy samples of the horse, is from a bronze thymiaterion in the R. H. Lowie Museum (no. 8-3406) (Mitten & Doeringer, 1967; Brill et al. 1973). Sample no. 730 is a bit problematical. It is from a figure of “Alexander with Lance” (Fogg Museum no. 1956.20), which is thought to be Italian and of Roman, or possibly, of Renaissance date. Sample 1387 is from the lead anchor stock of the 5th cent. B.C. Porticello wreck which was carrying, among other things, ingots of Laurion-type lead (Eiseman, 1978). 6 CONCLUSIONSThe leads in the cast-on leg and in the body alloy both fall in Group X. They are similar to one another, but not identical. These results are consistent with an assumption of an ancient origin for the horse, but are not sufficient to prove it is ancient. There is nothing in our findings to suggest that the horse is modern. Regardless of where the body of the horse was made, it is doubtful that the cast-on leg repair was carried out in Greece. Because many of the horse's nearest neighbors, isotopically, are attested Italian leads, we prefer Italy as the most reasonable attribution for the alloy in the cast-on leg. However, that alloy could have been prepared with lead from Asia Minor, or whatever other mining regions produced the lead used in the Levant. Until we have a better understanding of why so many early bronzes, including the body of the horse, have lead concentrations of about 0.5%, it will be difficult to interpret the lead isotope data. If it is assumed that the lead was introduced into the alloy as an impurity of the copper, it appears that the copper came from either Italy or Asia Minor. The horse could then have been made in Greece. If it is assumed that this low level of 7 SAMPLE DESCRIPTIONSThe following descriptions were provided with the samples by Ms. Lefferts and Dr. Meyers.

ACKNOWLEDGEMENTSThe authors thank the many people at the National Bureau of Standards laboratories, both regular staff members and visiting scientists, who have assisted us over the years by preparing and running the lead samples referred to here. In particular these include L. Dunston, J. Gramlich, G. N. Hanson and J. M. Wampler. We are grateful as well to the persons and institutions who donated the comparative samples listed in the table. In order of first appearance of their samples in the table they are: Arthur Beale (Fogg Art Museum), Arthur Steinberg (Massachusetts Institute of Technology), Earle R. Caley (Corning Museum of Glass), A. Neppi Modona (Museum of Fine Arts, Boston), Astone Gasparetto, Babis Deilakis (The Nafplion Museum), Jane Scott (Sardis Excavations), Cynthia Eiseman (University of Pennsylvania), The R. H. Lowie Museum, G. Bovini, M. V. Seton-Williams, Lawrence Cope, E. Oren, Erik Sj�quist, Honor Frost, David Grose, Sidney Goldstein, and Dan Barag. REFERENCESBarnes, I.L., Brill, R.H., Murphy, T.J., and Shields, W.R. (1974). “Isotope Analysis of Laurion Lead Ores.” In Archaeological Chemistry. Washington: American Chemical Society, Advances in Chemistry Series, no. 138, pp. 1–10. Brill, R.H., and Wampler, J.M. “Isotope Studies of Ancient Lead.” American Journal of Archaeology, 71, pp. 64–77. Brill, R.H. (1970). “Lead and Oxygen Isotopes in Ancient Objects.” Philosophical Transactions of the Royal Society London A, 269, pp. 143–164. This paper also appears in (T.E.Allibone, ed.) The Impact of the Natural Sciences on Archaeology, (1971). London: Oxford University Press, pp. 143–164. Brill, R.H. and Shields, W.R. (1972). “Lead Isotope Studies of Ancient Coins.” In (E.T.Hall and D.M.Metcalf, eds.) Methods of Chemical and Metallurgical Investigations of Ancient Coinage. London: Royal Numismatic Society, Special Publication No. 8, pp. 279–303. Brill, R.H., Shields, W.R., and Wampler, J.M. (1973). “New Directions in Lead Isotope Research.” In (William J.Young, ed.) Application of Science in Examination of Works of Art. Boston: Museum of Fine Arts, pp. 73–83. Chamberlain, V.E., and Gale, N.H. (1976). “Isotopic Composition of Lead in Greek Coins.” International Symposium on Archaeometry, Edinburgh.

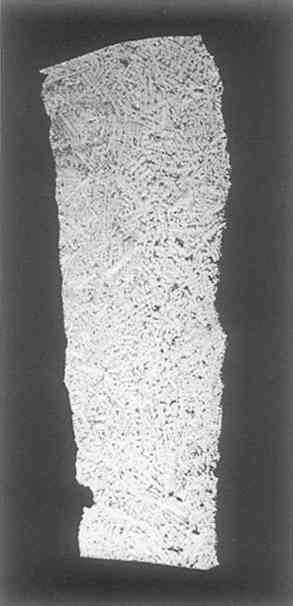

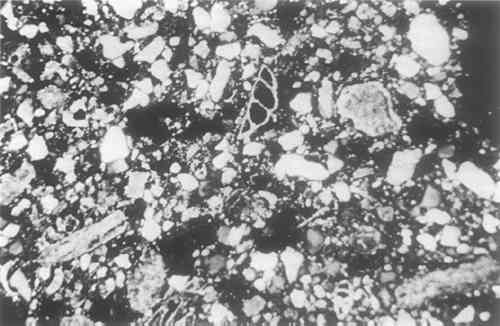

Eiseman, C.J. (1978). “The Porticello Shipwreck: Lead Isotope Data.” MASCA Journal, 1, p. 18. Gentner, W., Muller, O., and Wagner, G.A. (1978). “Silver Sources of Archaic Greek Coinage.” Naturwissenschaften, 65, pp. 273–284. Mitten, D.G., and Doeringer, S.F. (1967). Master Bronzes from the Classical World. Fogg Art Museum. Simpson, W.K. (1973). “Century Two, Collecting Egyptian and Near Eastern Art for the Boston Museum.” Apollo, 98, pp. 255–56, Plate III. Steinberg, A. (1973). “Joining Methods on Large Bronze Statues.” In (W.J.Young, ed.) Application of Science in Examination of Works of Art, Boston: Museum of Fine Arts, APPENDIX1 APPENDIX V1.1 Analyses Of The Core Sand Found In The HorseFrederick R. Matson The Pennsylvania State UniversityA sample of the dark gray core sand removed from the horse was studied. It was granular, porous and friable. A few lumps of the material retain the form of the inner surface of the casting, but these show no evidence of greater heat alteration than the rest of the core sample. Two thin sections were prepared for petrographic study. Other samples were washed with acid to remove the carbonate binder, and a magnetic separation was then made to concentrate further the minerals for study in index of refraction liquids in powder mounts. Small portions were fired at 750� and 800�C. to oxidize them for further examination. The chemical composition was determined by a microprobe analysis. From the resulting data a rational analysis was calculated to determine the approximate proportions of the components in the sand core. 2 PETROGRAPHIC EXAMINATIONA study of two thin sections of lumps of core material and the examination of acidwashed and magnetically separated grains mounted in index of refraction liquids showed that the sand consisted principally of quartz grains in a calcareous ground mass in which were some well preserved foraminifera and occasional grains of iron compounds, sandstone, feldspar and zircon. The previous texture of the thin section prepared from an uncrushed lump of the core can be seen in Figure 1.