Gore-Tex: An Introduction to the Material and Treatments

by Nancy Purinton and Susan FilterIntroduction to the Material

The history of Gore-Tex started in 1958 when Wilbert Gore identified a market opportunity for polytetrafluoroethylene, or PTFE. This is better known to us as DuPont Teflon. His idea was to use it as insulation for electronic wires. Mr. Gore and his wife set up shop in the basement of their home to make PTFE-insulated ribbon cables.

In 1969, Mr. Gore's son Bob discovered that PTFE could be stretched to form a strong, porous material. This discovery came after long experimentation using high temperature and a slow stretching technique. Perhaps in frustration, the high temperature and FAST STRETCH production secret was discovered. the unique properties of this material have led to a wide variety of applications. It was patented and has the trademark GORE-TEX.

Gore-Tex expanded PTFE is chemically inert. It has a low friction coefficient, which means it is smooth to the touch. It functions over a wide temperature range and has good aging qualities. It is porous, air permeable, strong, hydrophobic, biocompatible and weather durable.

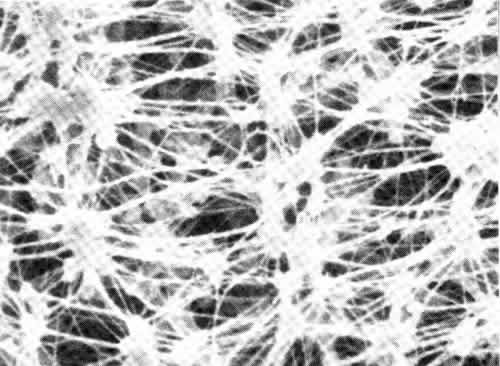

Gore-Tex expanded PTFE Structure of Nodes

Interconnected with Fibrils (6700X)

Courtesy of W.L. Gore and Associates

Gore-Tex is PTFE that has been processed into new physical forms. PTFE, or polytetrafluoroethylene, is a polymer called a perfluorocarbon resin. in perfluorocarbon resins, all of the carbon atoms in the backbone of the polymer chain are fully bonded to fluorine atoms. the carbon to fluorine bond (C-F bond) is such a strong bond that neither oxygen nor ultraviolet light are sufficiently energetic to break it. the strength of this bond is the source of chemical inertness and good aging properties. Gore-Tex has undergone tests that show it will last more than 100 years in outdoor exposure. the strength of the C-F bond is also the reason the Gore process for PTFE is possible. the strings that connect the larger areas of PTFE together in this micrograph are directly related to the strength of the C-F bond in the molecule.

The distribution of the fluorine atom" around the carbon polymer backbone balances the electronegative and electropositive charges, making PTFE non-polar. Non-polar materials are not attractive to polar substances, like water. This fully fluorinated polymer has a low surface energy which causes it to be nonwettable by water. PTFE can withstand temperatures from -240 to +280 degrees centigrade. No solvating agent is known for PTFE.

The production of ribbon cable was the first Gore commercial venture. Even though Wibert Gore imagined his new material as an insulator for wires, now pure Gore-Tex wires are used in some situations. PTFE has outstanding electrical properties and is chemically inert. Gore-Tex, porous PTFE, retains the electrical properties of that material but is also lightweight. That is possible because electricity can move through the Gore-Tex as well as it moves through the air pockets in the Gore-Tex. These wires are lightweight and transmit electricity very fast and are used in aircraft and satellites. Gore wire and cable can withstand the heat of ignition and the cold of space. on the moon, the same cables are in seismic instruments and rock-collecting shovels.

These Gore products are truly space-age materials, and yet they are used in many earthbound ways. Gore cables enable computers to transmit signals at nearly the speed of light. They are used in computer printers, underground in oil drilling operations and undersea in submarines. They are also made into tiny forms for miniature brain probe cables.

Gore-Tex expanded PTFE is also used as a replacement for human tissue. Portions of arteries can be replaced by tubes of this material because it is strong, biocompatible and able to carry blood at arterial pressures without leaking. Gore-Tex vascular grafts have been implanted in patients of all ages, and are used in practically every part of the body.

Another use for Gore-Tex expanded PTFE is a" an implant material. After more than 700,000 clinical uses, there are no confirmed cases of material rejection. These soft tissue "patches., as they are called, provide the strength and thickness required for the most demanding soft tissue repairs. the suppleness of the material makes it easy to work with in difficult reconstructions. the softness of the material assures patient comfort. the structure of the material does not fray so the surgeon can sew the patch into place more easily. These soft tissue patches have been used to repair both heart and stomach tissue.

Micro porous Gore-Tex expanded PTFE is a biocompatible structure into which cells can penetrate. This material is incorporated into the surrounding tissue, not encapsulated by it. This incorporation by the surrounding tissue may be the reason there is such a low incidence of infection after these implants.

During the slide presentation at the A.I.C. meeting, a micrograph was shown of another implant material, not Gore-Tex, where the implant fibers are distinctly separate from the surrounding tissue cells. the other implant material had not been incorporated into the living tissue. Another micrograph of a Gore-Tex implant was shown in which the cells had been able to grow throughout the structure of the Gore-Tex pores. It had been incorporated into the living tissue.

Another Gore-Tex material has also been used to replace ligaments in knee surgery. This material of is produced in such a way as to provide the majority of its strength in the longitudinal direction because that is where it is needed. Gore-Tex makes medical sutures that handle like silk, have extreme strength and allow for tissue attachment. These are available on special cards that release the thread without snagging or knotting. Gore-Tex also makes threads in a variety of sizes.

New composite materials made by Gore are being used in printed circuit boards for computers. the Gore company does research in polymer science that has resulted in new adhesives, sealants and coatings. Gore-Tex is used in a variety of protective clothing. in some instances they can replace vinyl or rubber suits and because of its breathability provide greater comfort. Clean room garments are made of this fabric and could be worn by conservators in situations were dirt, water or mold are serious problems. Gore-Tex can be heat sealed. This makes an infinite number of shapes possible. in addition to the fabric used for these garments, a new stretch Gore-Tex fabric is also now available.

Another material used by industries is the Gore-Tex valve stem packing material. This material may be a solution to some packing problems. the microporous nature of Gore-Tex has led to extensive filtration applications. It has been used for filtration in industry to reduce air pollution. It can filtrate plant gas streams containing corrosive chemicals like sulfuric acid and strong alkaline solids. Those interested should contact W.L. Gore and Associates through the information given at the beginning of this article.

In paper conservation, we use a specific form of Gore-Tex. We use laminates of Gore-Tex expanded PTFE film and nonwoven fabrics. the nonwoven fabric used is made by Dupont and called "Sontara". Sontara spunlaced fabric is a textile composed of fibers entangled in an unbonded structure. There are no resin binders or interfiber bonds in the fabric. Sontara is composed of 100% polyester fiber. Sontara is similar in breaking strength to finished cotton sheeting and has good resistance to tearing. It retains approximately 75% of its strength when wet. the following classes of compounds have little or no effect on the strength of Sontara: alcohols, halogenated hydrocarbons, ketones, or water. Benzene does cause a moderate strength loss. Sontara has a good resistance to aqueous solutions of acids and alkalis.

The Sontara fabric is bonded to the Gore-Tex film with a process that includes heat, so no additional adhesive is in the material we use. It is composed only of a thin film of Gore-Tex that has been attached to the fabric Sontara. White Gore-Tex, it should be noted, has no colorants in it. Pigments can be added to Gore-Tex to color it but white is the color of the basic material.

Conservators are often faced with the problem of evaluating substitutes for materials. There is a material that is similar to Gore-Tex expanded PTFE, but is not an acceptable substitute. That material is polyvinyl difluoride, or PVDF. It is a fluoropolymer and the carbon chains in fluoropolymers are not completely fluorinated. Some of the carbons, up to 50%, are bonded to halogens or hydrogen. the presence of hydrogen makes the PVDF susceptible to dehydrohalogenation, or the removal of hydrogen and halogens from adjacent carbons in the chain giving off chemically active materials. This increases the potential for degradation. Also, PVDF is soluble in some conventional solvents.

The graphs on the following pages show the greater stability of Gore-Tex, or PTFE, versus PVDF. Gore-Tex is resistant to all the solvents on these lists and PVDF is not.

Regarding solvent use with Gore-Tex, quick tests to determine if only the vapors of a solution will penetrate Gore-Tex can be done. As an example, a drop of water sits on top of Gore-Tex. in comparison, a drop of ethanol immediately penetrates the Gore-Tex surface. a 10% mixture of ethanol and water will change the properties of water for use with Gore-Tex. the percentage could be smaller, so be sure to test any solutions before you use them.

Ethanol is only slightly less polar than water compared to many organic solvents, so all organic solvents will penetrate Gore-Tex. If you use Gore-Tex with solvents, and the previous charts showed you can do that safely, you may not necessarily be using solvent vapors. Do not rule out Gore-Tex use with solvents, however. the Gore-Tex allows a controlled application of solvent and that can be extremely useful.

With regard to enzymes, I would also like to note that I have been informed that the pore size in the Gore-Tex laminates would allow enzyme solutions to pass through the pore-, once the surface tension with the aqueous solution is broken. Breaking that surface tension could be a procedure that involves using ethanol immediately before applying water. This type of procedure has not, to my knowledge, been applied yet in a conservation treatment.

The second part of this paper will discuss some ways Gore-Tex has been used in treatments at the Conservation Center for Art and Historic Artifacts.

Chemical Compatibility Guide

This information and the micrograph on the first page are courtesy of W.L Gore and Associates, Inc.

| ACIDS | PTFE | PVDF |

| Acetic Acid, 5% | R | R |

| Acetic Acid, Glacial | R | N |

| Boric Acid | R | R |

| Citric Acid, 0.7% | R | R |

| Formic Acid | R | R |

| Hydrochloric Acid, Conc. | R | R |

| Hydrochloric Acid, 6NR | R | R |

| Hydrofluoric Acid | R | N |

| Nitric Acid, Conc. | R | N |

| Nitric Acid, 6N | R | R |

| Sulfuric Acid, Conc. | R | N |

| ALCOHOLS | ||

| Amyl Alcohol | R | R |

| Benzyl Alcohol | R | R |

| Butyl Alcohol | R | R |

| Ethyl Alcohol | R | R |

| Isobutyl Alcohol | R | R |

| Methanol | R | R |

| AMINES | ||

| Diethyl Acetamide | R | N |

| Dimethyl Formamide | R | R |

| Bases | ||

| Ammonium Hydroxide, 6N | R | N |

| Sodium Hydroxide | R | R |

| ESTERS | ||

| Amyl Acetate | R | R |

| Ethyl Acetate | R | N |

| Isopropyl Acetate | R | R |

| ETHERS | ||

| Dioxane | R | N |

| Ethers | R | L |

| Tetrahydrofuran | R | L |

| HALOGENATED HYDROCARBONS | ||

| Butyl Chloride | R | R1 |

| Carbon Tetrachloride | R | R |

| Chlorobenzene | R | R2 |

| Chloroform | R | L |

| Methylene Chloride | R | N |

| Perchloroethylene | R | L |

| Trichloroethane | R | R |

| Trichlorethylene | R | R |

| HYDROCARBONS | ||

| Benzene | R | L |

| Gasoline | R | R |

| Hexane | R | R |

| Kerosene | R | R |

| Pentane | R | R |

| Phenol (0.5%) | R | R |

| Toluene . | R | N |

| Xylene | R | N |

| KETONES | ||

| Acetone | R | N |

| Cyclohexanone | R | R |

| Methyl Ethyl Ketone (MEK) | R | L |

| Methyl Isobutyl Ketone | R | L |

| ALDEHYDES | ||

| Formaldehyde | R | R |

| Benzaldehyde | R | R |

| POLYALCOHOLS | ||

| Ethylene Glycol | R | R |

| Glycerol | R | R |

| MISCELLANEOUS | ||

| Acetonitrile | R | R |

| Cresol | R | N |

| DMSO | R | N |

| Freon TF | R | R |

| Hydrogen Peroxide, 30% | R | L |

| Nitrobenzene | R | L |

| Petroleum Base Oils | R | R |

| Pyridine | R | R |

| Silicone Oils | R | R |

| Water | R | R |

MT/cp 5/15/90

Rl - Use up to 135ºC

R2 - Use up to 75°C

®Teflon :s a registered trademark of E. I. du Pont de Nemours & Co., Inc.

Table from Fisher Filtration Catalogue, 1985 Fisher Scientific

Introduction to Gore-Tex Treatments Susan Filter

Gore-Tex has been used in many area. of conservation, and although there have been innovative uses of Gore-Tex by other conservators, I will only be discussing treatments done on paper and parchment at the Conservation Center for Art and Historic Artifacts.

The most useful characteristic of Gore-Tex is its versatility for humidity control. When used correctly, it can evenly humidify an object in an incredibly delicate manner, and at the same time it gives you a greater amount of control of this humidity.

Here are some ways the humidification function and other unique characteristics of Gore-Tex can be applied.

Gore-Tex can be used:

- To evenly humidify objects with sensitive media or supports in a controlled way - overall or locally.

- To humidify large objects.

- To slow down drying.

- As a resistant barrier on the suction table which also allows air and vapor to flow through.

- -As a flexible, non-stick, non-abrasive surface. -As a support.

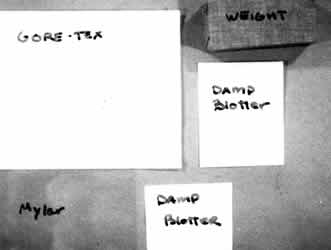

The basic sandwich set-up for humidification of objects using Gore-Tex:

Plastic cover sheet or mylar -Damp blotter -Gore-sex (smooth side against object) -Object -Gore-Tex (smooth side against object)

- Damp blotter

- Gore-Tex (smooth side against object)

- Object

- Gore-Tex (smooth side against object)

- Damp blotter

Throughout this paper, unless otherwise noted, I will be referring to Gore-Tex used in this way.

Care should be taken when handling the Gore-Tex material. It is an expensive and delicate fabric that can be easily creased or punctured.

Do not use excess weight, like glass or weights on top. Too much pressure will force water through the membrane. Liquid water can also penetrate at cracks and holes. If the artifact must be held in plane, only use as much weight on top a. necessary to achieve this; a felt or a piece of Plexiglas will do.

To humidify an object use damp or humid blotters, or lightly spray the felt side of the Gore-Tex. Be sure to check your object often, at least every fifteen minutes. Although Gore-Tex usually humidifies slowly, some objects tend to get damp quickly. If after an hour or two you feel you need more moisture to get the desired humidification results, spray the blotters again. Remember, 100% humidity is water. a saturation point can be reached by using too much water or weight with Gore-Tex. Saturated blotters are excessive.

Once one becomes familiar with the way Gore-Tex works, the different components can be changed. for example, to humidify an object from one direction, remove the top or bottom two layers of blotter/Gore-Tex. Or, create a small vapor chamber by placing a mylar or Plexiglas box over an object covered with Gore-Tex and place a damp blotter inside the enclosure. the porous interior structure of Gore-Tex will evenly diffuse the humidity.

Before treatment, careful testing of supports and media with small pieces of Gore-Tex is recommended. the following treatments are some examples where Gore Tex performed as an indispensable tool.

Humidification to Flatten an Object With Sensitive Media:

Figure 1

Figure 2

The first treatment I will discuss is an Italian, eighteenth century gouache painting of Mount Vesuvius on wove paper. the support had severe planar distortion and was very dry and brittle. the objective was to humidify this piece very, very slowly, so that the media and paper would expand at the same rate. a more conventional means of humidification might have cracked the media.

The painting was humidified in the Gore-Tex pack over an eight hour period with barely damp blotters. It was then allowed to dry slowly in the Gore-Tex pack replacing the damp blotters with dry. Not only was the distortion in the support of the painting reduced, but the paper was much more flexible. the media was undisturbed (Figure 1 and 2).

If an object shows evidence of mold, this might not be the best method of humidification. Be sure to check an object frequently when humidifying it, both for mold and the degree of dampness of the object.

Humidification of an Object With Delicate Support and Media:

The second treatment is a Mickey Mantel baseball card, an offset lithograph on laminated card stock. There was a deep crease across the top right corner. Collectors of baseball cards will know, that the better the condition, the more valuable the card is.

After trying local applications of humidity and Ethulose to reduce the crease, Gore-Tex was finally tried and the card humidified overall. the crease was then lightly pressed down with a bone folder through silicon release mylar. It was then flattened between the hard surface of mat boards. I believe this worked because all the layers of the card were equally humid, allowing the broken fibers to be pushed back into place.

Figure 3

Here are the components of the Gore-Tex set-up I used: Gore-Tex, damp blotters, mylar cover sheet. and weights (Figure 3).

Local Humidification:

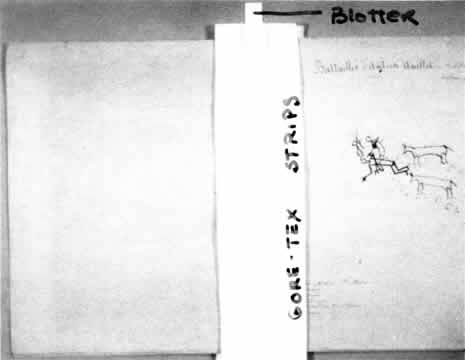

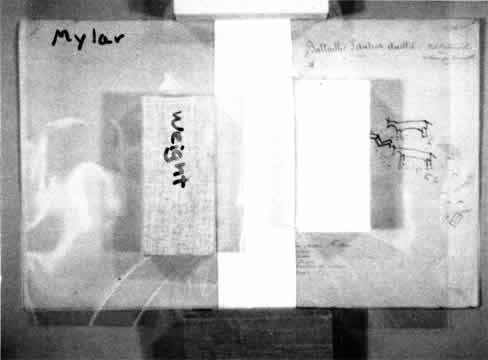

A good example of local humidification using Gore-Tex are these drawings of battle scenes. They were done with iron gall ink on thin, blue wove writing paper by a Blackfoot Indian chief, c. 1850. the drawings were originally bound by Jesuit missionaries. They were disbound recently for exhibit purposes. the sections, adhered together with water soluble adhesive, had to be separated. There were about seven folios adhered together in each section. the sensitivity of the iron gall ink and the surface coating of the paper prohibited water immersion. Methylcellulose was tried first as a poultice to introduce moisture, but by the time the adhesive softened, the paper was too wet to safely separate the folios.

Figure 4

Figure 5

Small pieces of Gore-Tex and damp blotter strips were used to just cover the central adhered area (Figures 4 and 5). the adhesive became soft enough so that the folios could be separated one by one, replacing the Gore-Tex set up each time. By the time the adhesive was removed mechanically from one folio, the next one adhered in the section was ready to be lifted off, that is, the adhesive was moist enough to release it.

Backing Removal of Thick Cardboard Supports:

Gore-Tex is also very useful in backing removals. This early twentieth century lithograph poster printed on thin wove paper was adhered to a thick cardboard support (Figure 6). in this case, the use of the Gore-Tex pack allowed the composite elements of the poster and the multilayered backing to slowly humidify overall. the poster and backing were then equally expanded when placed in a bath, where the two were separated. Therefore, there was no fast expansion where the possibility of tearing in the primary support could occur.

Figure 6

In another case, a large (5'x 5') printed (lithograph) map with hand coloring on very thin wove paper had a cardboard backing twice as thick and dense as this one. Almost all the colors were soluble with water when tested. Removing it mechanically with a scalpel proved extremely difficult because the cardboard was very dense.

Gore-Tex was used to humidify the map in order to soften the board. the backing could then be pared off easily in sheets saving an enormous amount of time. the media was undisturbed.

Humidification of Parchments:

Because Gore-Tex disperses humidity so evenly, it is an effective tool to humidify parchments. After humidifying a parchment in the Gore-Tex sandwich it can be put on the suction table for flattening and drying. Wrinkles can gently be pulled out while it is under tension, and can be pressed out with a bone folder through mylar. Mylar strips have to be used at the edges of the parchment while it is on the suction table to hold it down. When the parchment is sufficiently flat, it is covered with Gore-Tex, which acts as a barrier holding it down on the suction table and allowing air to flow through at the same time to dry the parchment.

Figure 7 shows a very large map, approximately 4'x 5', of early eighteenth century Lancaster, Pennsylvania. It was drawn with iron gall ink and gouache with graphite sketches around the borders. the support is made up of four pieces of parchment unequal in size and degree of thickness which are sewn and adhered together. It had been stored folded in many sections.

Figure 7

The treatment proposal called for it to be humidified and flattened. the concerns in the humidification steps were: the sensitivity of the media to moisture, evenly humidifying the different thicknesses of parchment, and how the adhered and sewn areas would react.

After mending tears and consolidating the media, a small area of the map was tested with Gore-Tex before it was humidified overall (Figure 8). It proved very successful; all areas were evenly humid and relaxed including the adhered and sewn parts. the media did not appear affected by the introduction of humidity.

Because it was such a large object and the suction table dries objects so quickly, the center of the table was blocked off with Mylar with the intention of drying and stabilizing the edges of the parchment first. Later, when the edges were somewhat dry, the suction table was turned off and the center mylar pulled out. the machine was turned back on, then allowing the entire map to be manipulated and dried as described above (Figure 9).

Figure 8

Figure 9

Lining a Large Object:

This is an example where Gore-Tex served several functions during a treatment.

- To humidify an oversize, media sensitive object.

- As a flexible, non-stick surface for lining.

- As a carrying support for a large, fragile object.

- To slow down the drying process.

This is a 4 x 8 foot painting in gouache of the Minoan frescos at Knossos on heavy, machine-made wove paper dating from the beginning of this century (Figure 10). It had a 1/2 inch thick, brittle, acidic multilayered paper board backing. It had fallen and broken in two in storage. Although treatment was very complicated, it basically consisted of surface cleaning, consolidation of media, backing removal (mechanical), mending tears and drop lining.

Figure 10

Figure 11

The painting was extremely discolored and could not be washed because of the water soluble media, but it had to be lined. When it was lined, the concerns then were the possibilities of staining in the unwashed and discolored painting from the wet lining, and of planar distortion while drying. We believed if we limited the humidity during the treatment and slowed down the drying process, we could control both.

The basic Gore-Tex set-up I described earlier was used in this treatment, but we altered it slightly by placing the object face down on Pelon and then the Gore-Tex. This arrangement allowed us to humidify, line and partially dry the object without turning it over. Because of its large size and fragility, we wanted to move the object as little as possible. the painting stayed between the Gore-Tex for the rest of the treatment. This greatly facilitated the handling of the object.

After humidifying it with Gore-Tex in preparation for lining, the top Gore-Tex sheet was partially rolled back to drop line the painting in sections, keeping the rest of the artwork humid at the same time.

After the initial immediate blotter changes, when the painting was almost completely dry and stronger, we turned it over. the table was tented with plastic to keep some humidity in and it was slowly dried over a period of a week until it was dry and flat (Figure 11). No distortion or staining in the support resulted. We believe the Gore-Tex made this treatment possible.

To close, I want to mention a few other Gore-Tex uses in treatments we have Performed at the Conservation Center:

- for backing removals on objects with friable media;

- for poulticing out discoloration by putting a sheet of Japanese paper next to the object in the Gore-Tex sandwich;

- as a means of delivering solvents; and

- because it is a flexible fabric, for the humidification of 3dimensional objects.

I hope these examples show how versatile a tool Gore-Tex can be in paper conservation treatments. Perhaps they will be an inspiration for uses in other diverse ways.

Gore-Tex fabrics are produced by

Nancy PurintonW.L. Gore and Associates, Inc. 100 Airport Rd.

P.O. Box 1550

Elkton, MD. 21922-1550

(301) 392-4440

Contact: Lowell R Perkins

Susan Filter

Conservation Center for Art and Historic Artifacts

Publication History

Received: Fall 1992

Paper delivered at the Book and Paper specialty group session, AIC 20th Annual Meeting, June 2-7, 1992, Buffalo, NY.

Papers for the specialty group session are selected by committee, based on abstracts and there has been no further peer review. Papers are received by the compiler in the Fall following the meeting and the author is welcome to make revisions, minor or major.