CONSERVATION OF A LYRE FROM UR: A TREATMENT REVIEWVIRGINIA GREENE

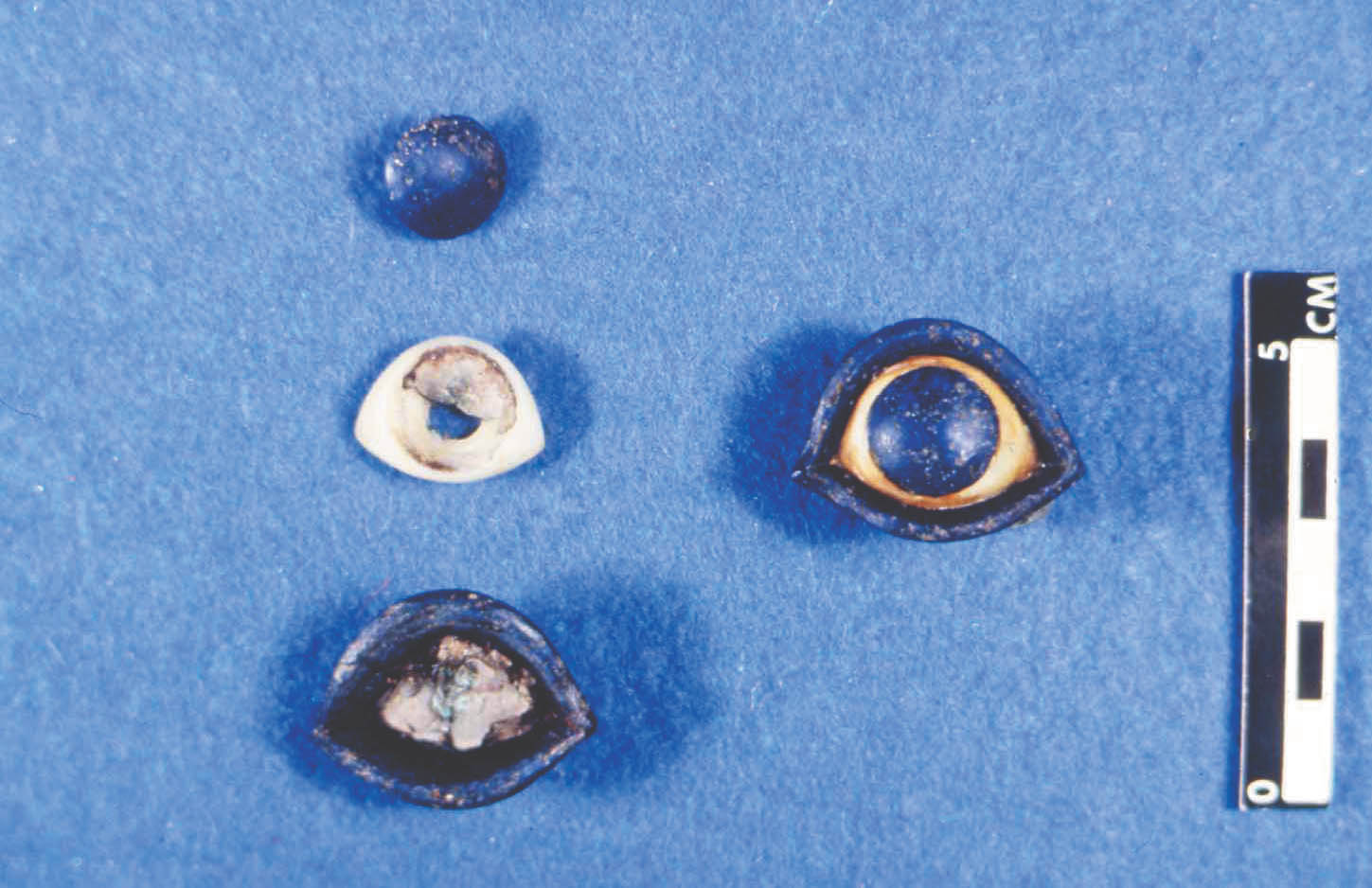

2 DESCRIPTION OF THE HEADTo provide a reference point for the description of the treatment, the materials and original construction of the head are presented first. It must be kept in mind that most of this information was not known at the time the treatment began and was revealed only as the work proceeded. All conclusions relating to the proposed original construction were reviewed and approved by the curatorial staff. 2.1 THE HEAD, EARS, AND HORNSThe front and sides of the head are formed of a single piece of gold sheet, with openings for the eyes, hair, and beard, as well as small holes for pegs that held the ears in place. A second rectangular piece of gold sheet forms the back of the neck, overlapping the front section under the horns (fig. 2a). Two small holes, about 1 mm diameter and 7 mm apart, are visible near the proper right edge of the strip, and there are traces of two similar holes on the left edge. There are matching pairs of holes on the edges of the gold sheet forming the head. No evidence of a support system was found inside the head, which was most likely manufactured by hammering the gold sheet around a solid wood core (palm and poplar wood, among others, were available locally). Both ears and horns also had wood cores. Each ear was formed of a single piece of gold sheet, with a seam running from the tip of the ear down the upper edge and along the back of the ear near one side. The upper part of the seam was hammered; the lower part, along the back of the ear, was secured with four gold tacks (fig. 2b, see page 246). The tacks remain on the proper right ear; on the left ear only the holes can be seen. Small holes in the gold sheet of the head indicate that the ears were secured to the head with pegs, probably made of wood. Each horn was also covered with a single piece of gold sheet, with a narrow seam running the length of the horn. The seam was hammered, but no tacks were used to secure the gold to the original core. The horns had short tips made of lapis lazuli, with a narrow, tapering tenon with a crosswise hole (fig. 3a). The tenon on the proper right tip was broken through the hole; the other was undamaged. There is no direct evidence of the method originally used to attach the tip to the horn core, as no wire or other construction technique was found. One possibility is illustrated in figure 3b. A hole would have been carved or drilled in the end of the core to receive the tenon. A pin—possibly organic, as no traces of metal corrosion products were found—was inserted through the wood and the hole in the tenon, securing the tip in place. The gold sheet was then wrapped around the horn core and hammered into place. The eyeballs were made of shell and lapis lazuli. The latter formed the iris and lids, and the shell formed the white of the eye. The three parts fit closely together when assembled (fig. 4a, see page 247). The tip of the iris element, which faces the rear of the eyeball, has a biconical hole. On the proper left eye, a fragment of mineralized copper alloy wire was found in the hole and another short length of wire on the back of the eyeball assembly. A small amount of black grainy material was visible around the wire,

Figure 4b shows one possible method of assembling the eyeball without adhesive, using wire and a wooden peg. The nested pieces would be held securely by the wire tied around the peg, and the entire eyeball could then be handled as a unit as it was inserted into a hollow in the head core, using bitumen adhesive. As the shell and lapis elements were almost certainly made by a specialized craftsman, this assembly would keep the eyeballs together before they were attached to the head. The hair was composed of small lapis tesserae (73 complete, 3 fragmentary), carved to represent individual curls of hair. They were set in six horizontal rows, attached directly to the head core by bitumen.

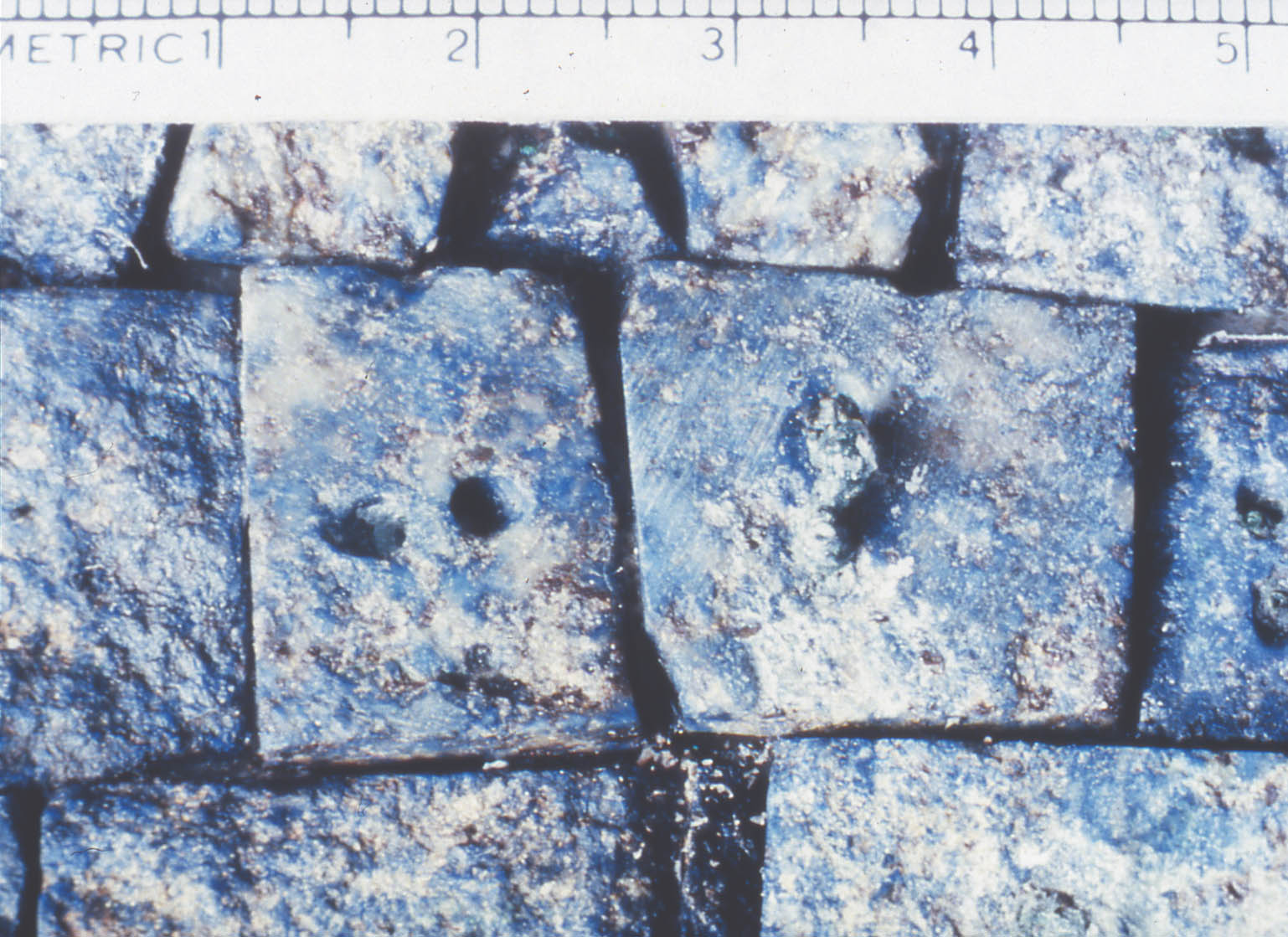

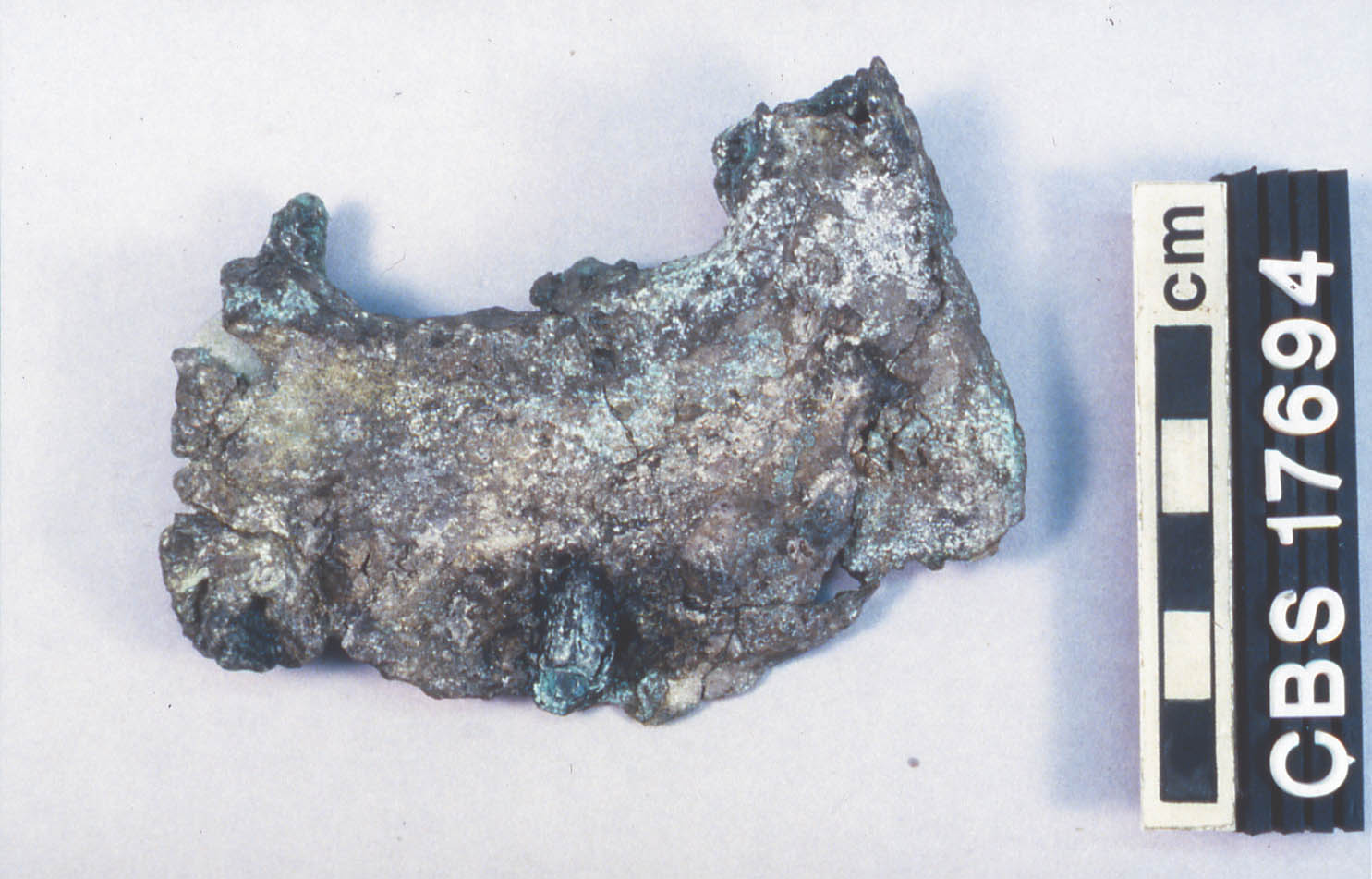

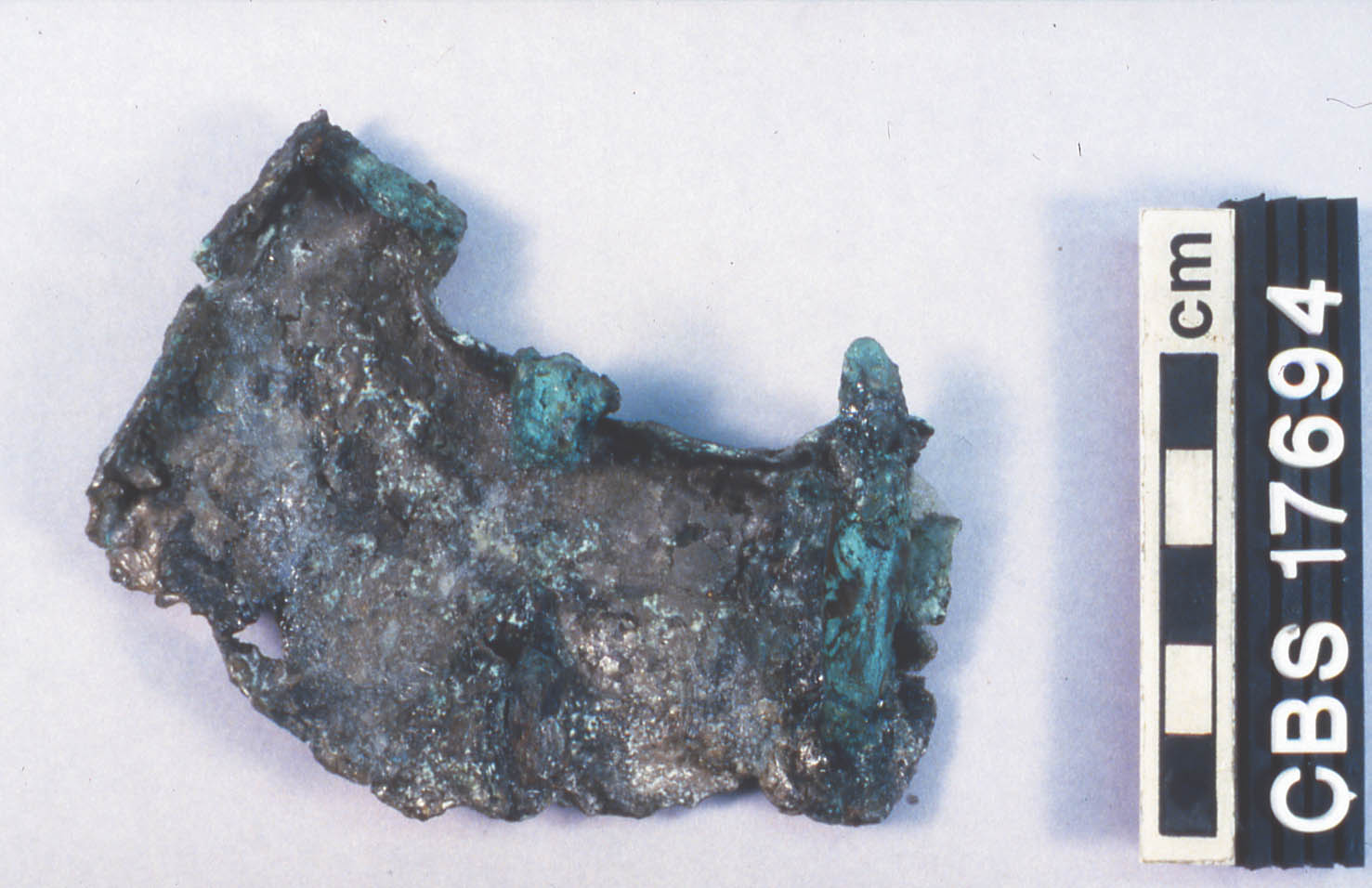

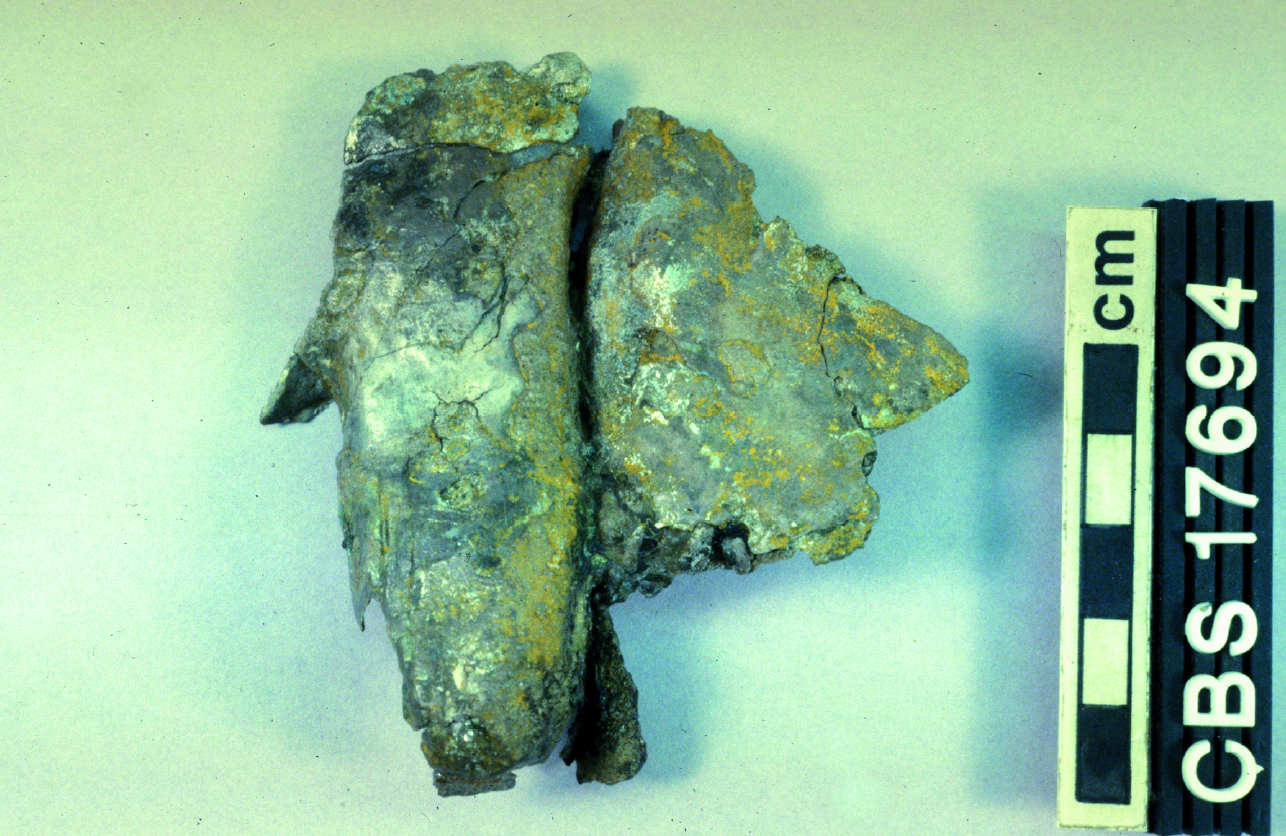

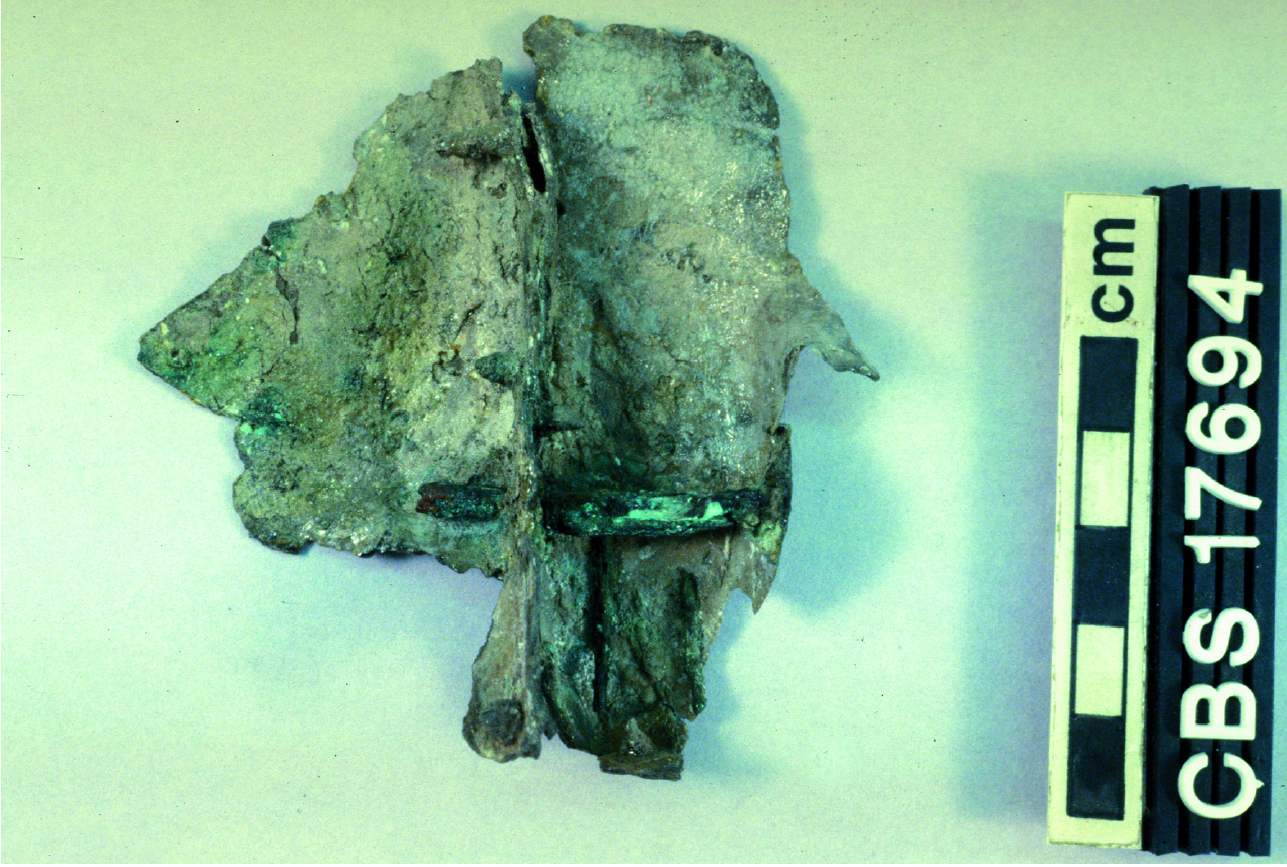

2.2 THE BEARDThe front of the beard is made of 58 lapis tesserae, arranged to form a wavy beard with six long locks in the center and three shorter curls on each side. Two additional side curls were placed on top of the main part of the beard, alongside the nose of the bull (see fig. 1a, page 246). Each tile has a biconical hole on the reverse, many of which still held the mineralized remains of copper alloy wire (figs. 5a, b; see 5b on page 247). The presence of these holes had never been recorded and was entirely unsuspected before the bull head was treated, although large shell “inlay” pieces with similar holes (some of which also have remains of wire) are known from Ur (de Schauensee 2001, pls. 33a, b, 34). Three large fragments of the original silver beard backing were found during the treatment: Fragment 1. A large flat area, broken into several fragments, without original (finished) edges Fragment 2. A fragment from the upper proper right corner of the central section of the beard, including finished edges on the top and sides, and parts of three copper alloy pins or nails that appear to have been used to attach the beard to the head (figs. 6a, b, see page 248). Two of the pins were clearly driven in from the back of the beard. The original length of these pins is uncertain;the surviving sections of two are ca. 5 cm long. The third pin, of which only 2 cm remains, was inserted from the side of the beard into the head core. Fragment 3. A section from the proper left side, including a finished edge. This fragment (figs. 7a, b, see page 249) consists of parts of two separate pieces of silver sheet and demonstrates that the beard was not backed as a single unit but in sections. Four small silver tacks, ca. 6–8 mm long, can be seen along the juncture of the two sections, three on one side and one on the other. The heads of two of the tacks are visible and show clearly that the tacks were inserted

Also present is part of a long copper alloy pin or nail that was used to join two of the beard sections. The original length of the pin is unknown; the existing fragment is 3.7 cm long, and copper stains on the silver suggest that it was at least 2–3 mm longer. The head of the pin is missing, but deformation of the silver sheet makes it obvious that the pin was inserted from the outside of one section, completely through that section, and into the adjacent unit. Between the pin and the silver sheet was a tiny fragment of completely mineralized wood, the only trace of the original beard support. The fragment was too small and too heavily mineralized for identification. On the inner surface of fragment 3 were two lengths of mineralized copper alloy wire (15 and 22 mm long), a small lump of bitumen, and a very small amount of a light brown powdery material that was not identified but may also be residue from a deteriorated wood backing. The wire may be the remains of wire from the beard tiles, which fell onto the silver sheet after the disintegration of the wood beard support. After the head had been dismantled and cleaned, additional fragments of the original silver beard backing, which had been cataloged under a different accession number, were discovered in storage (fig. 8). These included the proper right-side section of the beard, corresponding to part of fragment 2, and 19 smaller pieces. One was L-shaped, with a short length of copper alloy pin inserted through the side near a silver tack; three other fragments also had silver tacks. One flat fragment had the remains of a piece of copper alloy wire adhering to it. In addition, there were 11 loose silver tacks, a length of copper alloy pin, and the head from another similar pin. The location of the fragments of silver sheet in relation to the beard tiles is illustrated in figures 9a and b. As found in the first restoration (fig. 9a), the silver does not correspond to the outline of the beard. In the proposed original layout, illustrated in figure 9b, the outlines correspond, and the beard can now be seen as a discrete unit. The beard was fabricated in three sections, each with a wood support onto which the lapis tiles were mounted with bitumen. As with the eyeball assembly and hair tiles, the beard tiles were made by a craftsman who specialized in stone. The wires on the reverse of the tiles suggest that after manufacture the lapis tesserae were arranged in their proper configuration and attached to a thin layer of organic material (fabric or leather). Attaching the assembled tiles to a thin backing would ensure that they could be transported and mounted easily when the head was assembled. The wire ends would also act to secure the tesserae in the adhesive. Silver sheet was then placed over the back of each section of the beard and hammered around the sides to cover the wood support, with small silver tacks used to hold the sheet in place. The three sections were then aligned and joined with long copper alloy pins, driven through the side sections into the wood support of the central section (fig. 10). Two pins were used on the proper right side; only one is preserved on the left side, but there is room for a second. The assembled beard was then attached to the head core with additional copper alloy pins: at least two were driven in from the back of the beard upward into the head, and at least one additional pin was inserted on each side. The beard was attached to the head directly over the gap in the gold sheet, which was probably cut for reasons of economy or, possibly, to allow a more secure attachment of the beard to the head core. The two remaining lapis curls were then adhered to the upper surface of the beard with bitumen. The system used to attach the head to the original soundbox is unknown. It is unlikely, given the weight of the head and beard, that it was mounted entirely with adhesive, but wooden dowels could have been used to provide additional support. 2.3 THE FRONTAL PLAQUEThe plaque (see fig. 1b, page 246) is composed of small shell elements set into a bed of bitumen. It may have been assembled in advance on a rigid support, which was then secured to the front of the soundbox. |