THE RATIONALE FOR MICROABRASIVE CLEANING: A CASE STUDY FOR HISTORIC GRANITE FROM THE PENNSYLVANIA CAPITOLJ. CHRISTOPHER FREY, & TIMOTHY NOBLE

ABSTRACT—Specialized microabrasive cleaning treatments used for historic masonry have seen widespread use in recent years—in both architecture and sculpture. As these technologies continue to gain acceptance, it is important to develop a greater understanding of their practical applications, capabilities, and limitations. This article presents a case study on the rationale for selecting the JOS/Quintek Microabrasive System to clean granite on the Pennsylvania Capitol in Harrisburg, Pennsylvania. The selection of this treatment resulted from a one-year conservation study that characterized problematic conditions and evaluated a series of potential treatments to address them.Factors that included the nature of the stone, historic finishing patterns, previous chemical treatments that may have been applied inappropriately, and aggressive weathering had created problematic conditions such as heavy soiling, color change, metallic staining, and decreased surface permeability. The authors developed a two-tiered conservation study to evaluate the effects of several different cleaning treatments (pressure washing, JOS/Quintek microabrasives, Fa�ade Gommage, and chemical restoration cleaners) on several critical physical properties. The first tier of testing assessed the effects of each treatment in terms of soil removal, surface topography, tooling patterns, safety, and efficiency. The second tier of testing was designed to further evaluate the effects of the JOS/Quintek System, which was established as the most successful treatment examined in the first tier. The rationale for completing a focused assessment of the JOS/Quintek System was the fact that a limited number of comparable cleaning programs had been completed with the system and that few case studies addressing its potential effects had been published at the time. Assessment techniques were designed to evaluate impact on both surface and microstructural levels and involved a series of in situ and laboratory investigations, including treatment mock-ups, permeability testing, scanning electron microscopy, polarized light microscopy, reflected light microscopy, and colorimetry. TITRE—Une justification pour le nettoyage micro-abrasif: une �tude sur le traitement du granite d'�poque au Capitole de la Pennsylvanie. R�SUM�—Les traitements micro-abrasifs sp�cialis�s pour le nettoyage de la ma�onnerie ancienne sont devenus tr�s r�pandus ces derni�res ann�es, tant dans le domaine architectural que sculptural. Puisque ces technologies sont de plus en plus adopt�es et utilis�es, il est important de d�velopper une meilleure compr�hension de leurs applications pratiques ainsi que de leurs avantages et d�savantages. Cet article pr�sente une �tude de cas et explique les raisons derri�re le choix du syst�me JOS/Quintek de jet d'eau et de microabrasif utilis� pour nettoyer le granite du Capitole de la Pennsylvanie, dans la ville de Harrisburg. Le choix de cette m�thode de traitement a �t� bas� sur une �tude qui a dur� un an, dans laquelle on a caract�ris� les probl�mes qui �taient pr�sents et �valu� une s�rie de traitements possibles pour les r�soudre.La nature de la pierre, les rev�tements anciens, les traitements chimiques ant�rieurs qui ont possiblement �t� appliqu�s de fa�on inconsid�r�e et les alt�rations dues � l'exposition aux intemp�ries sont tous des facteurs qui ont cr�� des conditions probl�matiques, comme de la salet� incrust�e, une alt�ration de la couleur de la pierre, des taches m�talliques et une diminution de la perm�abilit� de la surface. Les auteurs ont d�velopp� une �tude de conservation en deux phases, afin d'�valuer les effets de divers types de traitements de nettoyage (lavage avec pression, micro-abrasif JOS/Quintek, le syst�me Fa�ade Gommage et divers nettoyants chimiques) sur diverses propri�t�s physiques critiques de la pierre. Dans la premi�re phase des essais, on a �valu� pour chaque traitement le degr� d'enl�vement de la salet�, les effets sur la topographie de la pierre, la pr�servation des traces d'outils � la surface, la s�curit� de la m�thode et son efficacit� g�n�rale. La deuxi�me phase des essais avait pour but de mieux �valuer les effets du syst�me JOS/Quintek, avec lequel on avait obtenu la meilleure performance lors de la premi�re phase d'essais. Le syst�me JOS/Quintek fut �valu� de fa�on tr�s TITULO—Evaluaci�n del sistema de limpieza microabrasivo: estudio de caso del granito hist�rico del Capitolio de Pensilvania. RESUMEN—Los tratamientos especializados de limpieza microabrasiva usados en mamposter�a hist�rica se han extendido, tanto en arquitectura como en escultura. A medida que estas tecnolog�as van ganando aceptaci�n, es importante desarrollar un mejor entendimiento de sus aplicaciones pr�cticas, capacidades, y limitaciones. Este art�culo presenta un estudio de caso sobre el razonamiento seguido para la elecci�n del sistema de limpieza microabrasiva con agua JOS/Quintek, a usar en la limpieza del granito del Capitolio de Pensilvania en Harrisburg. La elecci�n de este tratamieno es el resultado de un estudio de conservaci�n de un a�o de duraci�n, en el cual se caracterizaron las condiciones problem�ticas y se evaluaron una serie de tratamientos potenciales para encararlas.Factores como la naturaleza de la piedra, los acabados hist�ricos, los tratamientos qu�micos previos que pudieran haber sido aplicados inapropiadamente, y el clima, hab�an creado condiciones problem�ticas, tales como: dep�sitos mayores de suciedad, cambios de color, manchas met�licas, y disminuci�n de la permeabilidad de la superficie. Los autores desarrollaron un estudio de conservaci�n en dos niveles para evaluar los efectos de varios tratamientos de limpieza (lavado a presi�n microabrasivo JOS/Quintek, Fa�ade Gommage, y limpiadores qu�micos de restauraci�n) sobre varias propiedades f�sicas cr�ticas. El primer nivel de pruebas evalu� los efectos de cada tratamiento en t�rminos de remoci�n de dep�sitos, topograf�a superficial, marcas en el tallado de la piedra, seguridad y eficiencia. El segundo nivel de pruebas se dise�� para evaluar con mayor profundidad los efectos del sistema JOS/Quintek, el cual hab�a sido establecido como el m�s exitoso durante el primer nivel de pruebas.El razonamiento para completar una evaluaci�n del sistema JOS/Quintek fue que hab�an sido completados un n�mero limitados de programa de limpieza con este sistema, pero en su momento se publicaron pocos casos que tratasen sus efectos potenciales. Las t�cnicas de evaluaci�n fueron dise�adas para evaluar el impacto del tratamiento, tanto en la superficie como en los niveles micro-estructurales, e involcraron una serie de investigaciones de laboratorio in situ que incluyeron: tratamientos sobre maquetas, pruebas de permeabilidad, microscop�a de escaneo elctr�nico, microscop�a con luz polarizada, micros-cop�a con luz reflejada, y colorimetr�a. 1 INTRODUCTIONThis article summarizes the findings from the masonry cleaning component of a one-year conservation study for exterior granite from the 1906 Pennsylvania Capitol. The authors designed and administered the study in 1997–98 under a professional contract awarded to Perfido Weiskopf/Graves/Noble Joint Venture by the Department of General Services of the Commonwealth of Pennsylvania. The conservation study was broken down into two specific areas of research and testing: (1) the characterization of the stone and its deterioration mechanisms and (2) the identification of treatments to correct problems described in the initial portion of the study. The results of the study provided the basis for specifications that addressed a series of remedial procedures, including conservation cleaning, repointing, stone repair, removal of metallic stains, and removal of biological growth. The capitol building is the architectural centerpiece of the government of the Commonwealth of Pennsylvania, a distinction that automatically imparts to it a great deal of significance and symbolism. Designed by architect Joseph M. Huston and 2 RATIONALE FOR THE STUDYThe analytical program developed during this study determined that problems with the stone had resulted from a combination of factors, including its physical properties and mineralogical composition, the manner in which it was tooled, the effects of previous cleaning treatments that were likely applied inappropriately, and exposure to weathering. The primary objective of this research was to establish a conservation program that would remediate specific physical and aesthetic conditions that had developed primarily at or near the surface of the granite. Additionally, in light of the limited number of published case studies addressing the effects of microabrasive cleaning technologies on historic granite, a secondary goal of the study was to contribute to the existing knowledge base for the conservation of granite.1 3 ANALYTICAL TECHNIQUESThe characterization of problematic conditions and assessment of potential remedial treatment involved a combination of in situ and laboratory testing and examination. The authors completed an assessment of surface conditions before and after the execution of in situ testing mock-ups using 7–30x field microscopes. Laboratory evaluation of surface and subsurface conditions employed a combination of reflected light microscopy (RLM) and polarized light microscopy (PLM). Chromatic values for selected samples were established with a Minolta Chroma Meter CR-221. Microchemical testing provided for qualitative analysis of soluble salts. Carl Moses of the Lehigh University Department of Earth and Environmental Sciences used a combination of RLM, PLM, and x-ray diffraction (XRD) to complete petrographic analysis. Although Moses

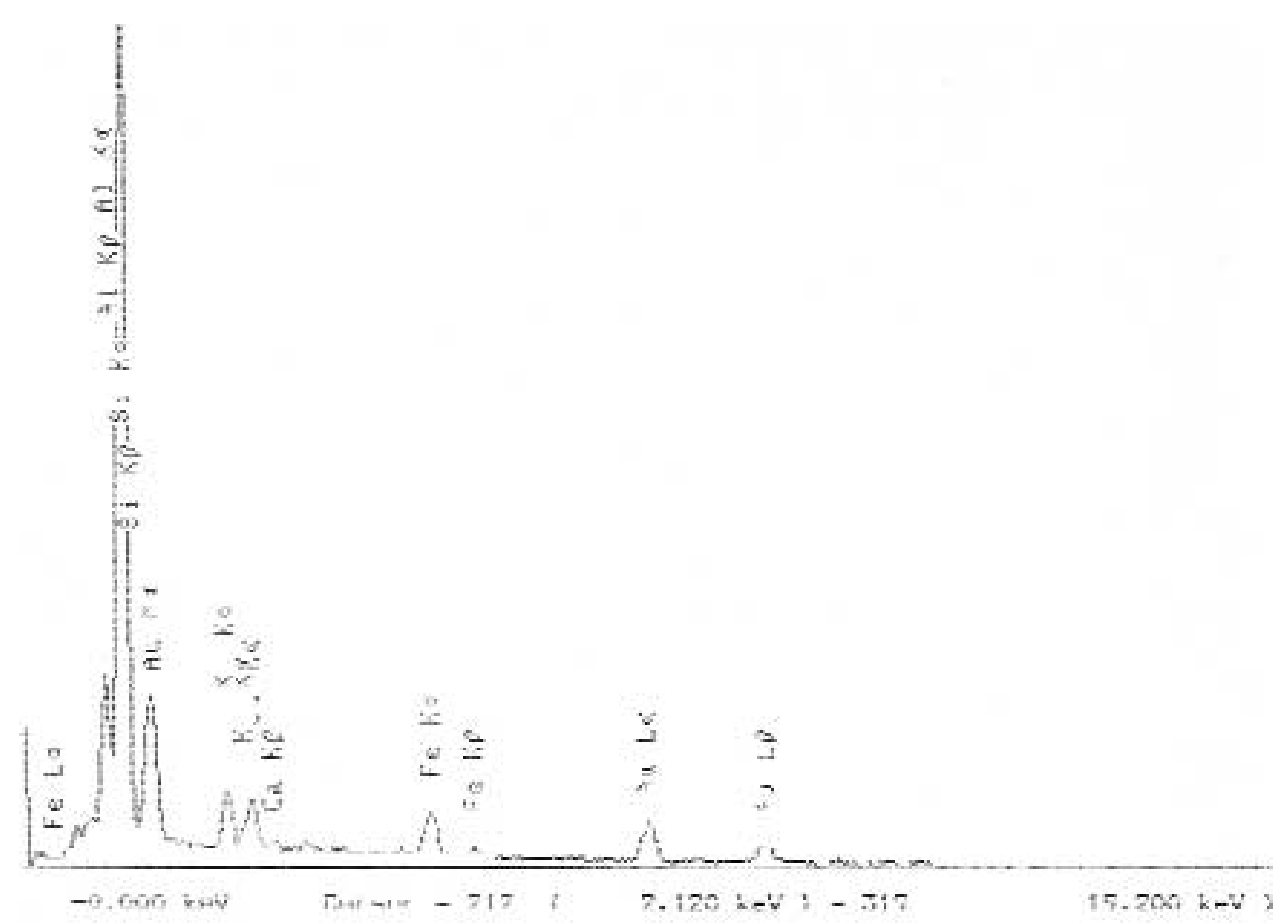

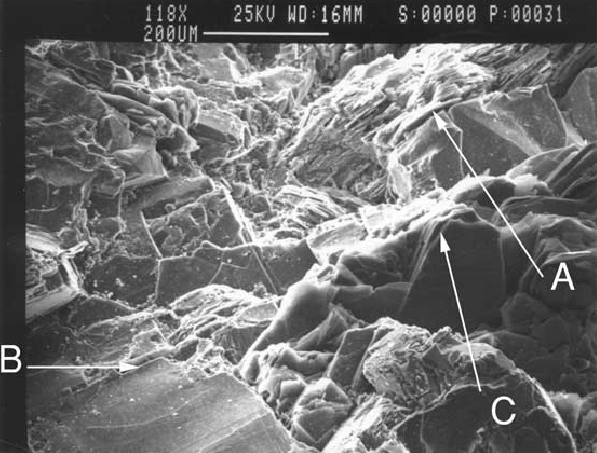

Investigations into the effects of tooling, weathering, and cleaning procedures on surface topography were completed with a combination of RLM, PLM, and scanning electron microscopy–energy dispersive spectrometry (SEM-EDS). The authors directed SEM-EDS procedures at a private materials testing laboratory. 4 WOODBURY GRAY GRANITEWoodbury Gray granite was quarried at Hardwick, Vermont, beginning in the late 19th century, competing with nearby Barre granite quarries that extracted rock from the same geological formations. Despite the lack of a proven track record in large-scale construction projects, the stone quarried at Hardwick was accepted for use, probably because it was similar to but less expensive than stone from the more established Barre quarry (Heritage Studies 1987, 103). Commissioners supervising construction of the capitol building found fault with the stone soon after it began arriving on-site, citing problems with cutting, finishing, and uniformity (Heritage Studies 1987, 176–77). After several heated discussions between the state commissioners and Huston, and the near firing of the architect, stonework was eventually completed, albeit with significant discrepancies between the original plans and the final product (Heritage Studies 1987, 181). Petrographic analyses conducted as part of this study found Woodbury Gray granite to be a biotite-alkali feldspar granite composed of 35–45% quartz, 40–45% feldspar, 10–15% biotite, and 0–10% muscovite (Moses 1997). Stones were originally tooled (probably by steam-driven pneumatic equipment) with a series of serrated channels and ridges similar to a patent-hammered finish. Although it is a common method of finishing, the impact necessary to create the desired appearance effected microstructural changes near the surface, which in turn exacerbated certain types of deterioration. Repeated strikes from finishing blades created a series of fine microcracks to a depth of 3–5 mm beneath the exposed surface. These extremely fine fissures provided avenues into the subsurface for the penetration of moisture, the migration of soluble salts, and enhanced interaction by chemicals and other contaminants, often resulting in erosion, sheet exfoliation, deep staining, and other surface degradation. 5 PROBLEMATIC CONDITIONS PRIOR TO STUDYPrior to study, exterior granite surfaces were characterized by a series of interrelated problematic conditions that had compromised both the appearance of the building and the microstructural integrity of many stone surfaces. While some conditions such as heavy soiling and superficial iron staining had developed as a result of the building's immediate weathering environment, other conditions such as physicochemical alteration, decreased surface permeability, and the formation of soluble salts were attributed to previous chemical cleaning treatments. Cleaning programs had been regularly executed throughout the building's history to address heavy soiling that began to develop soon after original construction. Newspaper accounts indicate that cleaning measures were undertaken for the base of the dome as early as 1932, and for the entire building in 1936–37. Although the nature of the dome-cleaning treatment was not disclosed, the more extensive cleaning program was reported to have employed a combination of acid solutions and steam. A similar program was undertaken in 1957 and again in the late 1960s or early 1970s under a cleaning, bird-proofing, Some previous treatments that initially achieved visually acceptable results have since been found to play significant roles in long-term deterioration (Weaver 1993, 161). Physical evidence such as bleaching, dissolved silicates, and significantly roughened surface topography suggested that previous cleaning treatments consisted of a combination of hydrochloric acid, hydrofluoric acid, ammonium bifluoride, and perhaps localized sandblasting (Weaver 1998). Previous use of chlorine-bearing (HCl) cleaners is further suggested by the presence of chloride salts, sodium chloride (NaCl) and potassium chlorate (KCl), that were confirmed by qualitative anionic analyses in multiple locations throughout the building. 5.1 ATMOSPHERIC DEPOSITIONLocated in what has historically been recognized as an area polluted by nearby railroad yards and industry, as well as by wind drift from western Pennsylvania's steel mills, the capitol building's granite walls began to exhibit heavy soiling and other deterioration within a decade after construction. Although industrial and heavy transportation emissions in the vicinity of the building had likely decreased significantly by the end of the 20th century, atmospheric deposition still was noticeable on many building surfaces. Deposition consisted primarily of dark deposits lodged both within microscopic steps and crevices on quartz and feldspar surfaces and within intergranular boundaries. Distribution was uneven, owing to poor adhesion of some grains to the smooth surfaces (Moses 1997). Heavier encrustations were present beneath the overhanging ledges of projecting elements such as cornices and belt courses, surfaces where moisture collects but that do not receive runoff during rain events (fig. 2). Six samples removed from soiled building surfaces tested positive for sulfate (SO4-) compounds using standard anionic analysis. To perform this test, samples were ground with a mortar and pestle, and the resulting powder was placed in a test tube. To the tube was added 20 cc of deionized water, and it was then shaken to dissolve soluble material. The insoluble portion of each sample was allowed to settle out at the bottom of the test tube. The resulting fluid was drained off and reacted with hydrochloric acid (HCl) and a 10% solution of barium chloride (BaCl2), forming a white precipitate in accordance with the following reaction:

5.2 CHROMATIC VARIATION AND SURFACE ALTERATIONConsiderable chromatic variation between stones was present even though all granite originated from the same quarry. Variation in color resulted from a number of factors, including the mineralogical composition of each stone, the effects of previously applied treatments, and differential weathering. Some variations were likely deliberate; for instance, the uniform pinkish hue of granite used for roof-level balustrades appears to have been a subtle design feature intended to call attention to this particular architectural element. The presence of darker, lighter, and differently colored stones within flat wall surfaces that were intended to appear monolithic, however, is more likely the result of unintended mineralogical variation. The presence of severely bleached stones is consistent with the effects of inappropriately applied, overly aggressive hydrochloric acid– and hydrofluoric acid–based treatments that physically altered many surface grains and left many more susceptible to additional weathering. When applied in appropriate dilutions and with appropriate dwell times, such cleaning treatments have been found to be effective at cleaning masonry without causing damage. However, conditions at the surface of the stone prior to this study suggest that previously applied treatments may not have been properly diluted, may have been left

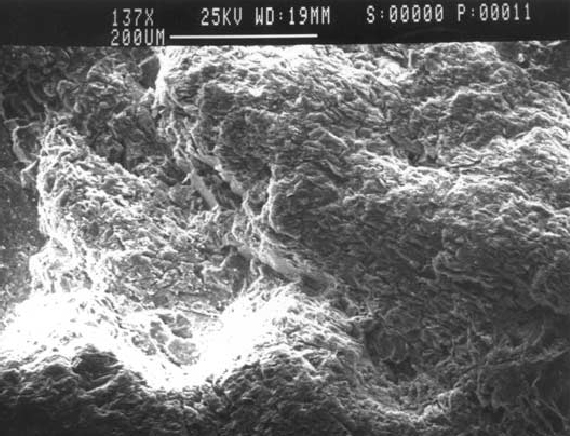

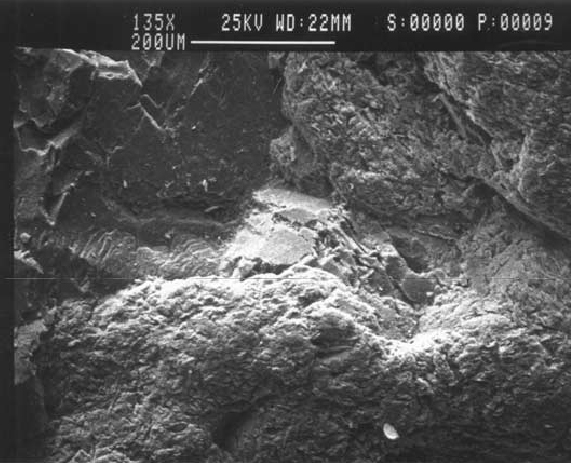

The extent to which acidic treatments altered stone color was likely enhanced by the presence of fine microcracks created during the tooling process. By opening up additional avenues for the penetration of potentially deleterious chemical compounds, microcracks allowed for additional chemical exposure to subsurface quartz, feldspar, and biotite grains. Though most pronounced at the immediate surface, some samples displayed evidence of the alteration of constituent minerals to a depth of 3–5 mm, coinciding with the depth of the microcracking. Digital chromatic assessments confirmed notable color differences between altered stone at the surface and stone directly beneath the surface that had not been subjected to weathering or treatment. While the actual readings for each sample depended in part on the specific mineralogical composition of the assessed areas, surface samples in multiple areas were found to be noticeably different from exfoliated areas, the latter of which closely matched the color of unaltered subsurface samples. On average, unaltered subsurface 5.3 DECREASED SURFACE TOPOGRAPHYWeathering and previous treatments had also substantially altered the fundamental topography of surface crystals. The weathering away of weaker minerals is a natural occurrence that explains a certain degree of loss. However, the extent of localized dissolution, erosion, and loss of detail was more consistent with chemical applications that dissolved a significant amount of surface and compromised the microstructural integrity on a localized level. Whereas the interfingering of feldspar, quartz, and biotite crystals had originally created a highly variegated surface topography characterized by sharp, angular crystalline boundaries, exposed grains had eroded to the extent that intergranular definition was substantially altered. The end effect was a muddled surface where some grains were indistinct from one another (fig. 4) and the loss of minerals that had contributed significantly to the color and depth of the stone (biotite). 5.4 LOSS OF TOOLING PATTERNSLoss of surface detail also extended to original tooling patterns. Serrations that most likely were originally sharp and distinct had become severely rounded, and many had even become completely flattened. The loss of tooling altered the appearance

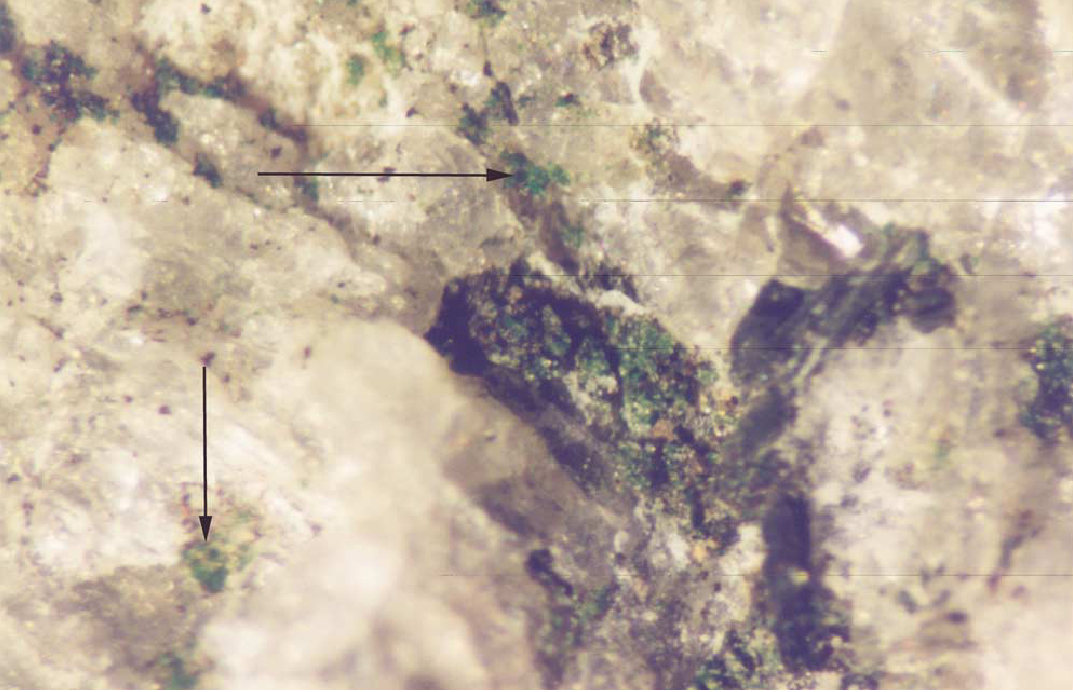

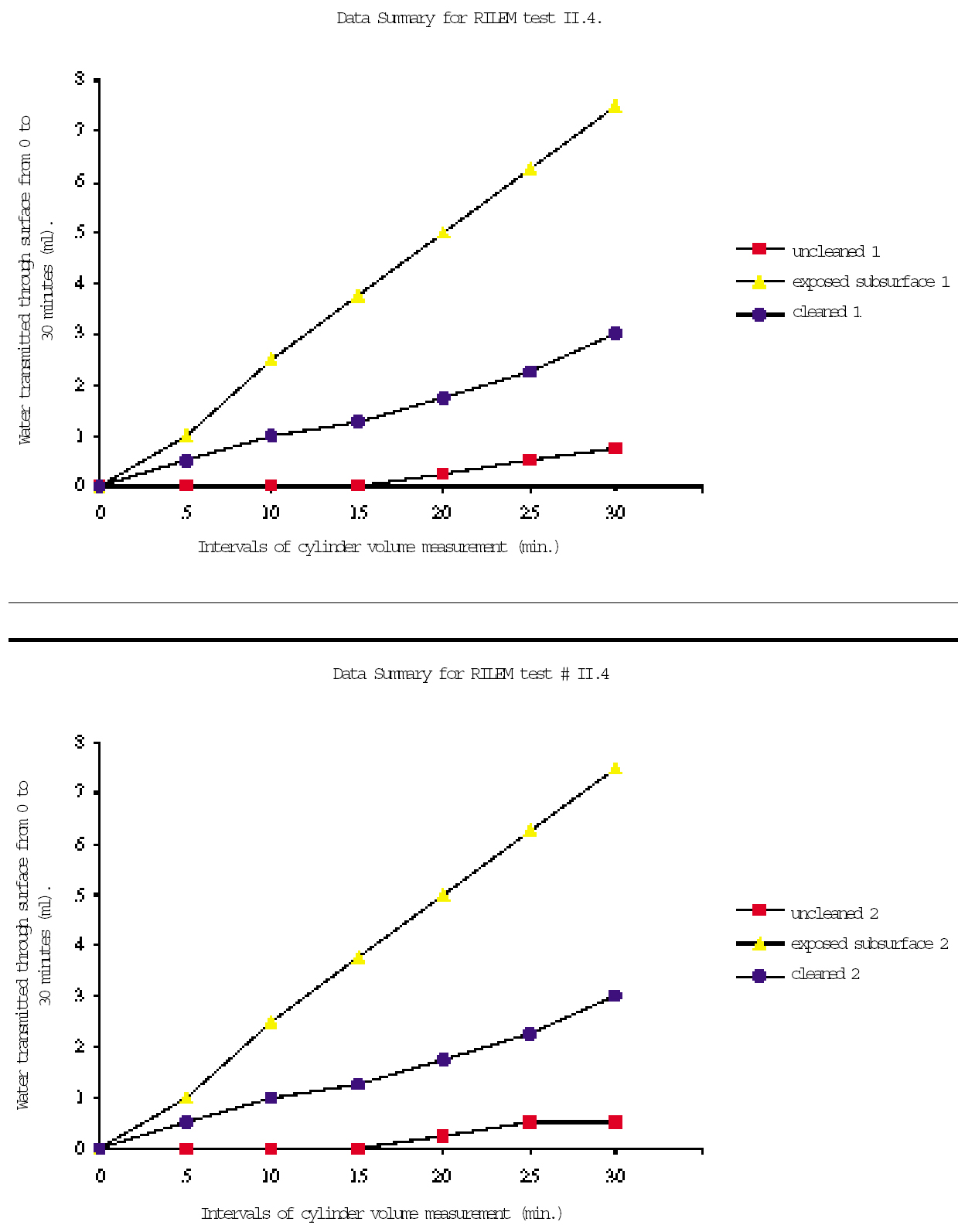

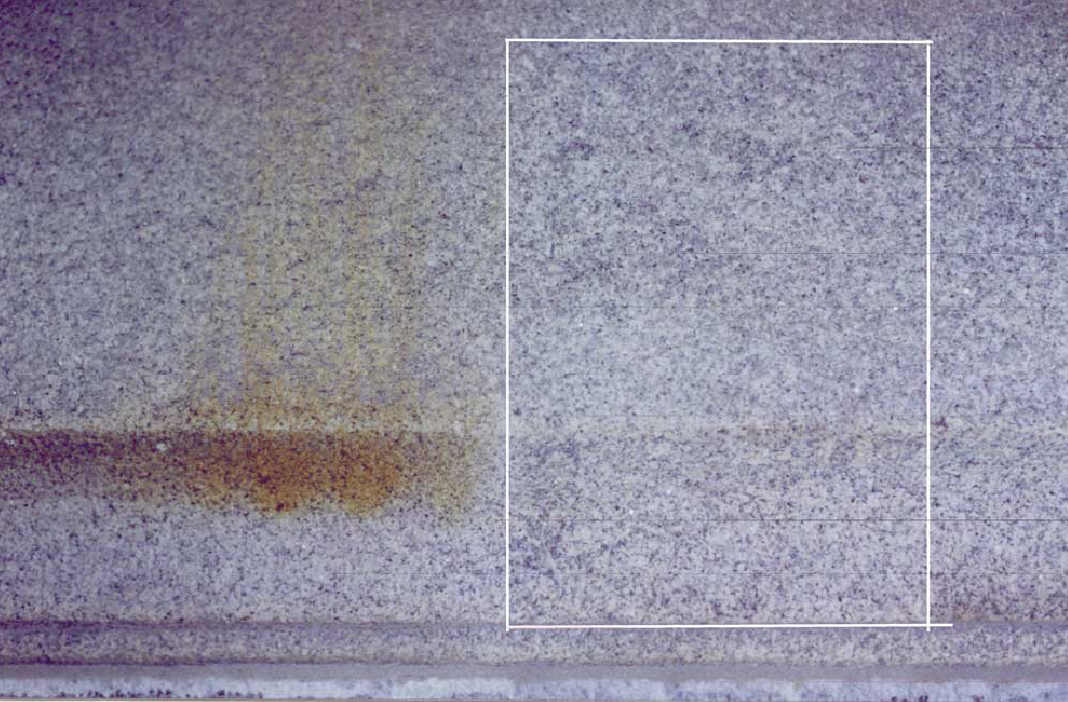

5.5 DECREASED SURFACE PERMEABILITYThe compromised surface and 3–5 mm zone of alteration displayed evidence of decreased surface permeability compared to unaltered stone. Surface and immediate subsurface pores within the 3–5 mm zone of alteration had become clogged both by pollutant particulates and by dissolved mineral fragments, particularly fine-grained clays and chlorite that are produced by the weathering of feldspars and biotites, respectively. Tests executed in accordance with RILEM II.4, Water Absorption Under Low Pressure, were conducted in areas where surface alteration was intact as well as in areas where the zone of alteration had been lost due to exfoliation and the unaltered subsurface had become exposed. Exfoliated surfaces absorbed greater quantities of water than surfaces where the zone of alteration was intact, further suggesting an inverse relationship between degree of alteration and surface permeability. The decreased permeability of the altered surface created a performance imbalance whereby the surface of the stone 5.6 LOCALIZED IRON STAININGSEM-EDS determined that fine-grained material present within intergranular boundaries was iron-bearing, consisting of iron oxides that most likely were either deposited on the surface before migrating into the stone or formed as certain stone constituents weathered (fig. 5). RLM and PLM further confirmed the presence of iron oxides in the form of orange-brown streaks within feldspar cleavage planes. Macroscopically, the presence of iron oxides translated to highly visible orange and yellowish-brown stains. The presence of oxides was attributed to a number of factors, including: (1) the oxidation of iron-bearing pollutant particulates that had been carried by wind drift to building surfaces from nearby railroad yards; (2) the release and subsequent oxidation of free iron that occurs naturally with the weathering of biotite (K [Mg, Fe]3 [(OH,F)2 / AlSi3O10]) and more aggressively in the presence of hydrochloric acid (Tabasso 1988); (3) the impact of machinery and tools such as steel snow shovels against ground-level surfaces; and (4) deposition from corroding architectural fixtures, hardware, and mechanical equipment. Staining was most severe on building elements that are subject to accelerated wet-dry cycles, such as the tops of both balustrade capstones and belt courses, as well as on the entire south facade of the building's south wing. In most locations, staining was superficial; areas subjected to chronic deposition and oxidation, however, had stains that were several millimeters deep. 6 EXECUTION AND DISCUSSION OF EXPERIMENTAL PROGRAMIn light of the negative consequences of natural weathering and previous cleaning treatments, it was deemed appropriate to undertake an experimental testing program to evaluate the potential utility of several widely accepted cleaning techniques. Along with the primary goal of cleaning the building to improve its appearance (an intervention that had been recommended in a previous preliminary study), addressing certain performance characteristics of the stone, which had been obviously compromised by previous treatments, was deemed equally important. Entering the experimental program, it was recognized that full restoration of all original properties of the stone was neither practical nor possible. For instance, completely removing the alteration layer across 400,000 sq. ft. of building surface would have required aggressive mechanical methods and would have resulted in the undesirable loss of significant quantities of historic material (3–5 mm from the surface of each stone on the building). Such an approach neither would have been ethical nor could it have been achieved without considerable expense and potential damage. Treatments that would have altered the chemical composition of the stone were similarly deemed inappropriate. While it would not have been possible to completely remediate micro-cracking caused by tooling, removing surface contamination that could continue to negatively impact the stone offered a means to reduce the likelihood of additional subsurface alteration and subsequent damage. The treatment options that follow were selected by virtue of the facts that they had been used successfully on previous projects where similar cleaning scopes were required and that they possessed the potential to address all critical existing conditions, including soiling, surface alteration (including clouded and crazed quartz), and iron staining. While the list represents a broad range of treatment options, the scope of testing within this study is not intended to represent a comprehensive range of all available conservation treatments, which might include various alkaline cleaners, nonionic detergents, poultice

6.1 SELECTION AND ASSESSMENT OF POTENTIAL CLEANING TREATMENTS (FIRST TIER)Potential cleaning treatments were subjected to a two-tiered analytical program that was intended to: (1) provide basic performance data for a wide range of typical cleaning treatments and (2) establish more substantial performance data for the treatment that appeared to best meet the following criteria in accordance with widely held conservation standards (Tabasso 1988; Winkler 1994):

The first tier of treatment assessment included the execution of in situ mock-ups for a range of procedures and products. These mock-ups were evaluated visually with a 30x field microscope and, where required, subjected to assessment with a Minolta Chroma Meter CR-221. First-tier assessments (table 1) were completed for:

6.1.1 Pressure WashingAs tested, pressure washing with fan-tip nozzles spraying potable water was evaluated at three pressure variables: 300–500 psi, 600–800 psi, and 1200 psi (measured at the nozzle tip) at a distance of 12–24 in. (30–60 cm) from the surface. Variables that affect the success of this treatment include application pressure, nozzle type, angle of application, angle of spray at the nozzle, dwell time, and distance of application. These variables were examined during in situ tests. Low-pressure (300–500 psi) water washing removed very little soil and had no visual effect on clogged pores or crazed-clouded minerals within the zone of alteration, and thus was deemed unacceptable. Higher pressure (600–800 psi) effectively removed more soil but caused some surface roughening and resulted in an uneven appearance. Even higher pressure (1200 psi) resulted in additional surface roughening and the loss of tooling patterns. While low-pressure washing did not significantly affect tooling patterns, some erosion was noted at high pressure. Employing only clean, potable water, these procedures were deemed to entail no significant health or property risks. Furthermore, since chronic moisture was found to be problematic in many areas of the building, it was deemed inadvisable to pursue a treatment that might introduce significant quantities of moisture into the building's walls. Considering its failure to meet several critical performance criteria, pressure washing was immediately removed from consideration. 6.1.2 Acidic CleanersTwo cleaning compounds whose predominant reagent is hydrofluoric acid (SureKlean Heavy Duty Restoration Cleaner and SureKlean Restoration Cleaner) were identified as treatments with the potential to address all surface conditions. Each was brush-applied in dilute concentrations (1:3, 1:4, and 1:6 in water) at various dwell times before being rinsed and neutralized. These cleaners function by dissolving soil on the surface of the stone, but they also dissolve silicate portions of the stone itself. Variables that affect the impact of such cleaners include method of application (brush or spray), concentration, and dwell time. Understandably, higher concentrations of reactive compounds increase the effects that those compounds will have; similarly, increased effects can be expected the longer a compound is provided the opportunity to react with a treated surface. Lower concentrations (1:6 and 1:4) generally removed soil, but higher concentrations (1:3) and longer dwell times were required to remove altered material from surface pores. The higher concentrations and increased dwell times that were necessary to address all surface conditions increased the potential for damage. Test panels indicated that higher concentrations and increased dwell times resulted in both the dissolution of silicate-rich quartz veins and further erosion of tooling patterns, the end result being a roughly textured, streaky appearance. In addition, the potential risk to health and property associated with the use of strong acids was of concern, especially in light of the fact that cleaning would occur on a fully occupied building that has hundreds of windows and is closely surrounded by pedestrian walkways and parking areas. The manufacturer identifies the cleaners as corrosive products that are harmful to wood and glass and states that substantial protection of such materials is required when they are used (SureKlean Restoration Cleaner and Heavy Duty Restoration Cleaner product data sheets, 2002. Available at www.prosoco.com). Also noted was the possibility that strong acidic applications could leave behind residual reactive chemicals that might contribute to the development of future problematic conditions unless completely neutralized. It is important to recognize that the criteria that led to the removal of these products from consideration are project-specific (due in part to the previous damage to the stone) and also relate to the success of other treatment options that more closely matched the project's overall goals. 6.1.3 JOS/Quintek Microabrasive SystemAs part of the study, the authors investigated the effects of the JOS/Quintek System. Equipment is now provided under the Quintek Rotec Vortex The JOS/Quintek System uses a low-pressure blasting apparatus that combines different types of fine, nonreactive microabrasive media with a minimal amount of water in what the manufacturer refers to as a swirling “vortex” motion (fig. 6). Compressed air forces fine media through hoses into a nozzle, where it is combined with water into a stream before being applied to a selected surface. Cleaning is followed by a gentle, low-pressure water rinse (typically similar to the amount of pressure that would emanate from a garden hose) to remove residual media from the cleaned surface. Variables that impact the intensity of treatment include the type of media selected, the pressure at which it is applied, the distance of the application from the surface, and the amount of media that is mixed into the application stream. JOS/Quintek requires that the manufacturer certify all applicators. This testing program evaluated several media types, which differed by composition, particulate size, and particulate angularity. M1035 is a fine, nonreactive milled glass. M1040 is compositionally identical to M1035 but slightly finer. Dolomitic media is composed primarily of ground calcium–magnesium carbonate and is more angular than the M1035 (table 2). M1035 media, applied 35 psi, 12–24 in. (30–60 cm) from the surface, effectively removed both soil from the surface and deteriorated material from clogged pores at the surface of the zone of alteration.

Applied at slightly higher pressures (50 psi), M1035 media was slightly more aggressive, causing minor erosion of tooling patterns and a slight increase in surface relief. Applied at pressures of 35 psi and 50 psi, M1040, dolomite media and stone powder were slightly less effective at soil removal and did not result in the noticeable color correction associated with the removal of severely deteriorated bleached material. Since the overall performance-criteria values were more desirable for the M1035 at 35 psi than for these treatments, these did not merit significant additional consideration. 6.1.4 Fa�ade GommageAs tested, the Fa�ade Gommage system projects a very fine, nonreactive microabrasive glass slag powder in a direct, low-pressure stream onto the surface. The process employs a compressed-air and vacuum system that distributes the media and then removes them from the surface. Fa�ade Gommage is a proprietary system that can be applied only by professionals of the parent company. Fa�ade Gommage performed moderately well,

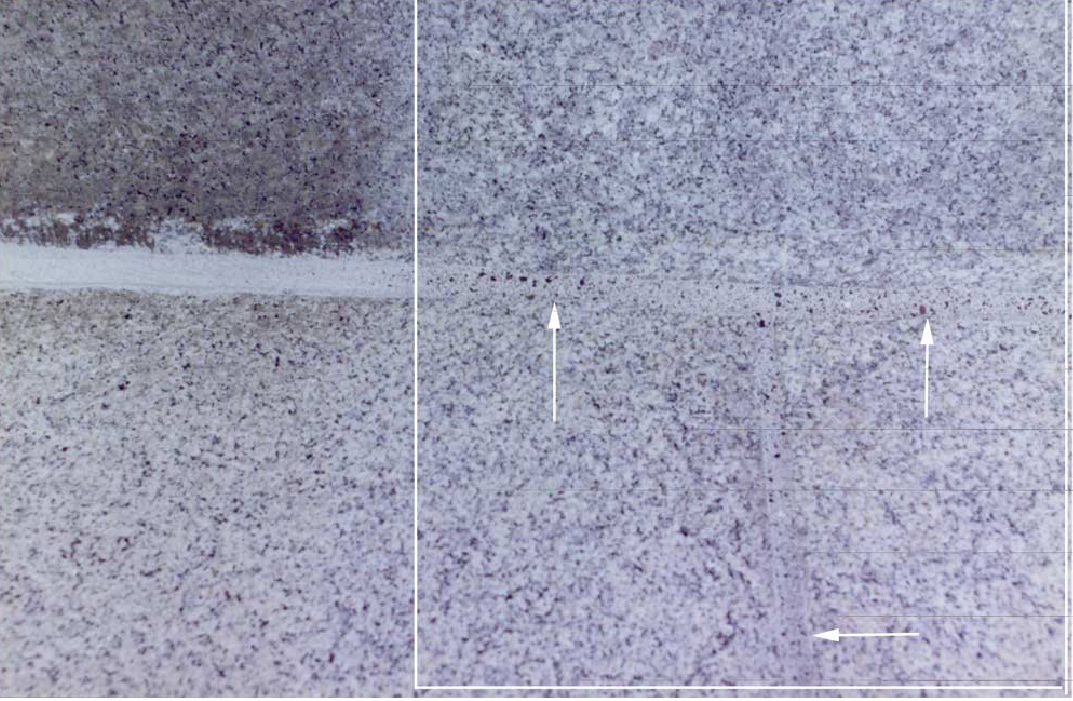

6.2 ADDITIONAL TESTING FOR SELECTED TREATMENT (SECOND TIER)Having established that many problematic surface conditions resulted from a combination of micro-cracking, previous treatments, and aggressive weathering, it was reasoned that a treatment that removed alteration products and restored certain beneficial natural properties would be appropriate. Since there were no unweathered building surfaces present that would provide direct data on the stone's original performance, subsurface samples were removed from several inches behind the weathering surface for comparative testing. The subsurface samples were only partially representative of the material characteristics of the original stone surface as they were not tooled and therefore did not contain the microcracking prevalent on the original stone face. However, they did provide value as a benchmark of representative data on several of the stone's original properties, specifically color, unaltered constituent minerals, and permeability. The subsurface samples were also used for a comparative assessment on the effects of the treatments on weathered and fresh stone. The second tier of testing entailed a more detailed analysis of the treatment that was established as the most successful from the first tier of testing: #1035 media at 35 psi, applied 12–24 in. (30–60 cm) from the surface. This additional round of testing was conducted primarily to provide additional information When applied with low pressure (35 psi) from a distance no closer than 12 in. (30–60 cm), the selected microabrasive cleaning treatment (1) successfully removed soiling, (2) partially restored the original stone color and transparency, (3) caused no apparent microstructural damage, (4) improved surface absorption capacity to levels closer to what existed originally, and (5) effectively removed superficial iron stains. 6.2.1 Soil Removal and Chromatic ImpactWhen applied as indicated above, the treatment successfully removed soil from the surface of the granite, including both general atmospheric deposition and heavier encrustations. While a single pass with the nozzle was generally sufficient to remove light soiling that was prevalent on all building surfaces, heavier depositions often required pretreatment and decreased application distances (fig. 7, see page 68).3 This treatment improved the overall color of previously weathered and treated stone without abrading or altering sound material immediately beneath the altered surface. As with most chemical cleaning and high-pressure water-washing, microabrasive treatments may be expected to remove a certain amount of substrate material from the surface. In the case of this treatment, the loss of barely perceptible amounts of severely deteriorated stone was justified by the fact that the material that was removed was dominated by weathering by-products. This intervention resulted in the removal only of compromised material at the immediate surface, with no appreciable effect on the remainder of the 3–5 mm alteration layer. Using unweathered samples to provide benchmark information on the original color of the stone as well as data on the predominant color of stone surfaces prior to cleaning, this treatment was found (via the removal of alteration products) to return the stone's color to more appropriate values (table 3). Cleaned samples were found to be medium gray, with an average color space of Munsell 2.42GY 6.51/0.40. When compared with the medium gray (Munsell 2.37GY 4.08/0.46) registered by the unweathered subsurface samples, this change represents a noticeable improvement over the predominant light olive gray (Munsell 4.86Y 5.34/0.98) surfaces that were prevalent before cleaning. Prior to treatment, exposed surfaces were characterized by a significant loss of surface topography due to the substantial surface erosion of exposed grain surfaces (fig. 8). Cleaning resulted in a moderate restoration of natural surface topography by removing both surface contamination and partially dissolved mineral components. This outcome reestablished the presence of clear angular quartz, feldspar, and biotite grains at the surface (fig. 9). While increased surface topography is sometimes viewed as an undesirable consequence of treatment, it was justified in this instance since it reestablished relationships between individual surface grains comparable to what they may have originally been. The reestablishment of comparatively sound crystal surfaces created a more dense, less reactive overall weathering surface. While the selected treatment effected a positive chromatic change in many locations and resulted in a more uniform appearance to the building, it proved impossible to completely restore color to original or near-original shades in all areas. Specifically, areas that had been subject to chronic moisture ever since construction and those that possessed extensive discoloration prior to the start of cleaning generally retained some degree of discoloration even after work was completed. Pre-existing color variation included both light, severely bleached stones and dark core sections exposed by exfoliation and aggressive weathering. 6.2.2 Tooling PatternsAlthough many surfaces had previously lost evidence of original tooling patterns, the selected cleaning treatment proved to be gentle enough to have no discernible effect on tooling patterns where they still survived. By predominantly removing altered material from the surface and leaving the stable material beneath it intact, the treatment

6.2.3 PermeabilityCleaning resulted in a slight improvement in overall surface absorption capacity, but did not result in permeability values comparable to those established for unweathered subsurface samples. Cleaned surfaces were found to absorb more water than uncleaned surfaces, but less water than unweathered surfaces exposed by exfoliation (fig. 11, see page 69). Some differential between subsurface areas and

In theory, reestablishing an equilibrium of permeability values between the surface and immediate subsurface, thus allowing moisture to move freely though exposed areas, will reduce the possibility of future damage as a result of moisture being trapped behind the surface, particularly exfoliation due to freeze-thaw cycles and soluble salt crystallization. 6.2.4 Superficial Iron StainsThis treatment effectively removed superficial iron stains that were contained within the zone of alteration (fig. 12, see page 70). Cleaning also uncovered a series of more deeply rooted, persistent iron stains that were not visible beforehand because they were obscured by atmospheric deposition and/or severe bleaching. These stains were addressed with alternate treatments as necessary. 6.2.5 Removal of LaitanceAll cleaning was scheduled to be undertaken after the completion of comprehensive repointing which would replace the existing failed repointing mortar with new mortar that more closely reflected the color, texture, joint profile, and appearance of the original. Tests found that the cleaning procedure successfully removed laitance from repointed joints. The removal of laitance provided for the exposure of anthracite coal within the aggregate. Anthracite was not only a significant component of aggregate used for the original mortar; it also provided an important aesthetic device by simulating the black biotite of the granite and allowing walls to read as monolithic masonry surfaces (fig. 13, see page 70). Added benefits of using this treatment included eliminating the need for supplemental or more aggressive laitance-removal techniques.

7 ADDITIONAL CONCERNS AND RECOMMENDATIONS FOR FUTURE TESTINGHaving borne witness to unforeseen, long-term problems that have resulted from inappropriate treatments for historic masonry, including sandblasting and aggressive acidic treatments, the authors deemed it important to carefully test and evaluate selected practical potential cleaning treatments. This experimental program presents a methodology for preconstruction testing and offers an initial assessment of the results attained by using the JOS/Quintek System on this particular stone. Research using SEM, PLM, and so on suggested no potential negative effect on the long-term performance of the stone and concluded that this treatment effectively cleaned the stone and reestablished several potentially valuable attributes that will aid in long-term conservation. Accordingly, results from this testing program prompted the recommendation of the JOS/Quintek System as the primary cleaning procedure and formed the basis for specifications that guided work completed on the building from 1998 to 2000. While this study has incorporated a substantial amount of analytical testing, future studies could expand upon the effects of such treatments on different stone types, minute changes to surface roughness, and properties such as vapor transmission values. Cleaning uncovered some surface conditions that were previously obscured by soiling, such as metallic and other staining. Some stains appeared on the surface several days after treatment rather than immediately afterward. This time lapse serves to reinforce the notion that final evaluation of test panels should be conducted only after an appropriate period (Boyer 1986). While a minimum of 10–14 days between treatment and evaluation was employed for this study, The authors supervised the execution of all cleaning work on this building. Constant evaluation and adjustment to localized conditions were found to be essential components of the project and were particularly deemed necessary in light of the fact that the JOS/Quintek System was an emerging technology at the time of study, and studies assessing this technology were not widely available. While this cleaning system was determined to offer a materially appropriate solution, it is important to note that the containment, recapture, and disposal of several tons of media had to be considered in a construction project of this magnitude and therefore be among the criteria weighed in the final selection of the treatment. Ultimately, media containment and disposal issues were resolved with a combination of scaffold enclosures and collection at the base of wall surfaces. As this technology gains wider acceptance and more contractors and individuals become certified to perform the treatment, the risk of the technology's being misused or misunderstood increases. It is important to recognize the lessons afforded by previous building treatments and understand that cleaning a particular surface may result in long-term negative consequences if the treatment is applied improperly or the effect of the treatment is not fully understood. While this treatment was deemed appropriate for the stone and the conditions that are the subject of this study, it may or may not be appropriate for other masonry materials or for projects where qualified supervision cannot be provided. It is simply not sufficient to visually assess a surface as being “clean” and then declare it to be materially appropriate. Testing, assessment, specification, and execution are all greatly enhanced by the input of a qualified architectural conservator who is familiar with the nature and limitations of the treatment as well as the surface that is to be treated. ACKNOWLEDGEMENTSThe authors gratefully acknowledge the contribution of Carl Moses, associate dean of the Lehigh University College of Arts and Sciences, whose technical and petrographic studies proved to be invaluable resources throughout the course of the study. The authors would also like to express their sincere gratitude to the following professionals who assisted with the review of this article and offered invaluable expertise and insight during its development: Kate Cowing, Katherine McDowell Frey, Mark Rabinowitz, Joseph Sembrat, and Martin Weaver. Completion of the technical study that formed the basis for this research was made possible by the support of Merle H. Ryan, deputy secretary for public works of the Commonwealth of Pennsylvania, and Robert L. Glenn, director of the Bureau of Engineering and Architecture within the Pennsylvania Department of General Services. NOTES1. Although considerable attention has been devoted to deterioration mechanisms for granite (Helmi 1985; Kelly 1985; Schiavon 1993; Begonhha and Braga 1996; Jones et al. 1996), a literature search conducted during the study uncovered only a few references to the use of JOS/Quintek as a means to address problematic material conditions (Zador 1992; Winkler 1994). These sources describe the JOS/Quintek process and its selection for specific programs in general terms. While certain topics involving the use of low-pressure abrasives were found (Young and Urquhart 1992), the authors were not able to locate case studies that offered comprehensive comparative information about the selection of JOS/Quintek versus other treatments. 2. The manufacturer specifically recommends a 3–5-minute dwell time, whereas this study evaluated applications that included both the recommended dwell time and dwell times up to 10 and 15 minutes. In light of the expanse of surfaces to be cleaned, the authors determined that if either cleaner were selected as the primary treatment, it would be unlikely that the contractor undertaking the work could constantly maintain a 3–5-minute dwell time in all areas. As a practical concern, it was deemed probable that even with appropriate specifications, quality standard mock-ups, and regular supervision, 3. The application distance of 12–24 in. (30–60 cm) was deemed successful in preconstruction test panels. During construction, it became necessary to pretreat persistent, heavy crusts beneath certain overhangs with a proprietary prewash-afterwash system (SureKlean 766 Limestone and Masonry Restorer) and to reduce application distance to as little as 8 in. (20 cm). Cleaning was supervised carefully in areas where pretreatment and reduced application distances were deemed necessary. REFERENCESBegonhha, A. and S.Braga. 1996. Black crusts and thin black layers in granitic monuments: Their characterization and the role of air pollution. In Proceedings of the Eighth International Conference on Deterioration and Conservation of Stone, Berlin, Sept. 30–Oct.4, ed. Josef Riederer. Berlin: Moller Druck und Verlag. 371–75. Boyer, D. W.1986. Masonry cleaning: The state of the art. Cleaning Stone and Masonry STP 935, ed. J. R.Clifton. Philadelphia: American Society for Testing and Materials. Helmi, F. M.1985. Deterioration of some granite in Egypt. Fifth International Congress on the Deterioration and Conservation of Stone, Lausanne, France, September 25–27. Lausanne, France: Press Polytechniques. 421–29. Heritage Studies Inc.1987. The Pennsylvania capitol: A documentary history. Harrisburg, Pa.: Capitol Preservation Committee. Jones, M. S., P. F.O'Brien, S. J.Haneef, G. E.Thompson, G. C.Wood, and T. P.Cooper. 1996. A study of decay occurring in Leinster granite, House No. 9, Trinity College, Dublin. In Proceedings of the Eighth International Conference on Deterioration and Conservation of Stone, Berlin, Sept. 30–Oct. 4, ed. J.Riederer. Berlin: Moller Druck und Verlag. 211–21. Kelly, J. G.1985. Geological aspects of the decay of Irish granitic building materials. Fifth International Congress on the Deterioration and Conservation of Stone, Lausanne, France, September 25–27. Lausanne: Press Polytechniques. 431–42. Moses, C.1997. Personal and professional communications. Department of Earth and Environmental Sciences, Lehigh University, Bethlehem, Pa. Schiavon, N.1993. Microfabrics of weathered granite in urban monuments. Conservation of stone and other materials: Proceedings of the International RILEM/UNESCO Congress, UNESCO headquarters, Paris, ed. M. J.Thiel. London: E. & F. N. Spon. 271–78. Tabasso, M. L.1988. Conservation treatments of stone. In The Deterioration and Conservation of Stone: Notes from the International Venetian Courses on Stone Restoration, ed. LorenzoLazzarini and RichardPieper. Paris: UNESCO. 271–89. Teutonico, J. M.1988. A Laboratory Manual for Architectural Conservators. Rome: ICCROM. Weaver, M. E.1993. Conserving buildings: A guide to techniques and materials. New York: John Wiley. Weaver, M. E.1998. Professional communications. Martin Weaver Conservation Consultant, Nepean, Ontario. Winkler, E. M.1994. Stone in architecture: Properties, durability. 3d ed.Notre Dame, Ind.: University of Notre Dame.

Young, M. E. and D.Urquhart. 1992. Abrasive cleaning of sandstone buildings and monuments: An experimental investigation. Proceedings of the International Conference, Edinburgh, UK, April 14–16, ed. Robin G. M.Webster. London: Donnehead Publishing. 129–40. Zador, M.1992. Experience with cleaning and consolidating stone facades in Hungary. Proceedings of the International Conference, Edinburgh, UK, April 14–16, ed. Robin G. M.Webster. London: Donnehead Publishing. 146–52. FURTHER READINGAmerican Society of Civil Engineers. 1878. Transactions. New York: American Society of Civil Engineers. Ashurst, J. and F. G.Dimes. 1990. Conservation of building and decorative stone. London: Butterworth-Heinemann. Ashurst, J., and N.Ashurst. 1988. Practical building conservation. Vol. 1, Stone masonry. New York: Halsted Press. Brayley, A. W.1913. History of the granite industry of New England. Boston: National Association of Granite Industries of the United States. Building Research Establishment. 1983. Cleaning external surfaces of buildings. London: Her Majesty's Stationary Office. Charola, A. E., C. A.Grissom, E.Erder, M. J.Wachowiak, and D.Oursler. 1996. Measuring surface roughness: Three techniques. Proceedings of the Eighth International Conference on Deterioration and Conservation of Stone, Berlin, Sept. 30–Oct. 4, ed. J.Riederer. Berlin: Moller Druck und Verlag. 1421–34. Charola, A. E., and S. Z.Lewin. 1982. Examples of stone decay due to salt efflorescence. In Deterioration and preservation of stone: Proceedings of the 3rd International Congress, October 24–27, 1979. Rome: ICCROM. 153–64. Ehlers, E. G. and H.Blatt. 1982. Petrology: Igneous, sedimentary, and metamorphic. New York: W. H. Freeman and Co. Elliott, C. D.1992. Technics and architecture. Cambridge: MIT Press. Feilden, B. M.1994. Conservation of historic buildings. Oxford: Butterworth-Heinemann. Frey, J. C., and T. M.Noble. 1998. Masonry conservation study for the Pennsylvania capitol. Zionsville, Pa.: Noble Preservation Services. Hurlbut, C. S., Jr.1993. Manual of mineralogy. New York: John Wiley. Ingval, M.1996. Emerging conservation issues in consequence of cleaning Scottish historic buildings. Proceedings of the Eighth International Conference on Deterioration and Conservation of Stone, Berlin, Sept. 30–Oct. 4 1996, ed. J.Riederer. Berlin: Moller Druck und Verlag. 1405–14. Kelly, K. L., and D. B.Judd. 1976. Color: Universal language and dictionary of names. Washington, D.C.: U.S. Department of Commerce. Klein, C., and C. S.HurlbutJr.1977. Manual of Mineralogy. New York: John Wiley. Laing, R. A., J.Ball, J.Scott, and M. E.Young. 2000. The implications of stone cleaning for planned building maintenance. Proceedings of the Ninth International Conference on Deterioration and Conservation of Stone, Venice, June 19–24, 2000, ed. VascoFassina. Amsterdam: Elsevier Science, B.V.813–17. MacKenzie, W. S., and A. E.Adams. 1994. A color atlas of rocks and minerals in thin section. New York: John Wiley. Matero, F. G.1984. A diagnostic study and treatment evaluation for the cleaning of Perry's Victory and International Peace Memorial. Bulletin of the Association for Preservation Technology16(3–4):39–51.

Matero, F. G., and A.Tagle. 1995. Cleaning, iron stain removal, and surface repair of architectural marble and crystalline limestones: The Metropolitan Club. Journal of the American Institute for Conservation34(1):49–68. Menhert, K. R.1968. Migmatites and the origin of granitic rocks. New York: Elsevier. Pirsson, L.1926. Rocks and rock minerals. New York: John Wiley. Rock of Ages Corp.The Barre granite industry. Barre, Vt. Sather, K. M.1990. Granite deterioration in the graveyard of Saint James the Less, Philadelphia. Master's thesis, graduate program in historic preservation, University of Pennsylvania. Urquhart, D. C. M., M.Jones, J.MacDonald, K.Nicholson, and M. E.Young. Effects of stonecleaning on granite buildings and monuments: Report to Historic Scotland, Scottish Enterprise and Grampian Enterprise, 1996. www2.rgu.ac.uk/schools/mcrg/migran.htm (accessed 1998; March 12, 2003). Van Diver, B. B.1987. Roadside geology of Vermont and New Hampshire. Missoula, Mont.: Mountain Press. Winkler, E. M.1980. Historical implications in the complexity of destructive salt weathering: Cleopatra's Needle, New York. Bulletin of the Association for Preservation Technology12(2):94–102. Young, M. E.1993. Stonecleaning of granite buildings and monuments: The use of colour measurements in stonecleaning trials. Conservation Science in the UK. Preprints of the meetings held in Glasgow, May, ed. N. H.Tennent. London: James & James Science Publishers. 20–28. SOURCES OF MATERIALS AND STANDARDSFa�ade GommageThomann-Hanry Inc. 575 Madison Ave., 25th floor New York, N.Y. 10022 (212) 755-5550 Munsell Color ServicesGretag Macbeth 617 Little Britain Rd., Suite 102 New Windsor, N.Y. 12553-6148 (800) 622-2384 Quintek Rotec VortexQuintek Corporation P.O. Box 777 Virgil, Ontario, Canada L0S 1T0 (800) 567-0053 Note: Quintek Corporation supplies both equipment and microabrasive media manufactured by Universal Ground Cullet (M1035, M1040) and Specialty Minerals Inc. (dolomite) RILEMRILEM 157 Rue des Blains F-92220 Bagneaux, France 33 1 45 36 1020 SureKlean Restoration Cleaner, Heavy Duty Restoration Cleaner, and 766 Limestone and Masonry RestorerPROSOCO Inc. 3741 Greenway Circle Lawrence, Kans. 66046 (800) 255-4255 AUTHOR INFORMATIONJ. CHRISTOPHER FREY earned a B.A. in history from Dartmouth College in 1992 and an M.S. in historic preservation from the University of Pennsylvania in 1997. He currently serves as an associate with Noble Preservation Services of Zionsville, Pennsylvania, where he focuses on the analysis and conservation of historic building materials. In addition to being listed as a professional associate with AIC in 2001, his professional and academic r�sum� includes experience with Historic Charleston Foundation (1996), University of Pennsylvania Field Conservation Program with the National Park Service (1996), the Frank Lloyd Wright Building Conservancy (1996), Fairmount Park Historic Preservation Trust (1995–97), and the Museum of New Hampshire History (1994–95). Address: Noble Preservation Services, 10 Log House Rd., Zionsville, Pa. 18092 TIMOTHY NOBLE received a B.A. from Pennsylvania State University in 1974 and earned an M.S. in historic preservation from the University of Pennsylvania in 1983. He is listed as a professional associate with AIC. Having served as president of Noble Preservation Services since 1992, he manages and supervises projects relating to architectural conservation and the analysis of historic building materials. Prior to establishing his own private practice, he was principal and president of Clio Group Inc. (1983–92) and director of Stenton (historic site, 1991–92). Address as for Frey.

Section Index Section Index |