CONSTRUCTION HISTORY IN ARCHITECTURAL CONSERVATION: THE EXPOSED AGGREGATE, REINFORCED CONCRETE OF MERIDIAN HILL PARKLORI AUMENT

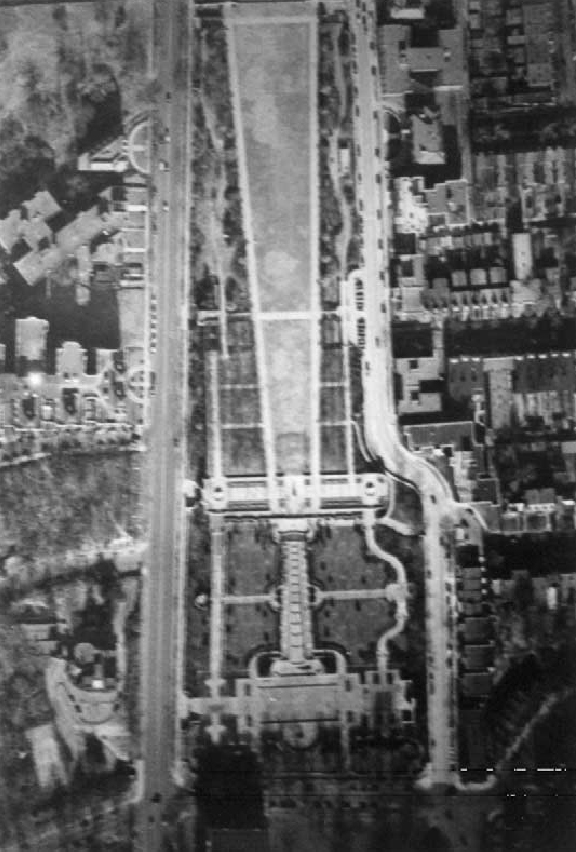

ABSTRACT—To inform the concrete restoration work proposed for Meridian Hill Park in Washington, D.C., constructed 1915–36, research was conducted to document the construction history of the exposed aggregate, reinforced concrete and to investigate the role of John J. Earley, the man responsible for much of the experimentation in the early concrete work at the park. Several stages of experimentation during the construction of Meridian Hill Park were identified: preliminary experimentation with the concrete finishes in 1915–16, development of improved finishes and forms in 1917–18, and dissemination of the improved techniques to other contractors who worked at the park from 1919 to 1936. The materials and techniques of construction for each period are described. General guidelines are given for future treatment and restoration work at Meridian Hill Park, which should be sensitive to the distinctive finishes for each period of experimentation. TITRE—L'historique de la construction � l'appui de la conservation architecturale: le b�ton arm� et les rev�tements � granulats apparents dans le parc Meridian Hill. R�SUM�—Une recherche a �t� entreprise afin de documenter l'historique du b�ton arm� et des rev�tements � granulats apparents utilis�s en construction, afin de fournir des renseignements d'appui � un projet de restauration d'oeuvres en b�ton datant de 1915–1936 et situ�es dans le parc Meridian Hill � Washington, D.C. La recherche avait aussi pour but d'�tudier le r�le qu'a jou� John J. Earley, l'homme qui fut en grande partie responsable d'une s�rie d'essais qui a eu lieu avec ces mat�riaux au d�but des travaux dans le parc. Il a �t� possible d'identifier diverses phases parmi les essais qui eurent lieu lors de la construction du parc: la phase pr�liminaire des essais sur les rev�tements pour le b�ton qui eut lieu entre 1915 et 1916; le d�veloppement de rev�tements et de formes am�lior�es, en 1917 et 1918; et l'adoption de ces derni�res techniques de la part des autres parties contractantes qui travaill�rent dans le parc entre 1919 et 1936. Les mat�riaux et les techniques utilis�s au cours de chaque phase sont d�crits. Des recommandations sont donn�es pour de futurs traitements ou projets de restauration dans le parc Meridian Hill, qui tiennent compte notamment du fait que les oeuvres produites lors de chacune de ces phases ont des rev�tements distincts. TITULO—Historia de la construcci�n en conservaci�n arquitect�nica: el hormig�n armado con agregado expuesto del parque de Meridian Hill. RESUMEN—Para obtener la informaci�n necesaria para comenzar el trabajo de restauraci�n propuesto para el parque de Meridian Hill de Washington, D. C., construido en 1915–1936, se llev� a cabo una investigaci�n para documentar la historia de la construcci�n del hormig�n armado con agregado expuesto, y para investigar el papel que jug� John J. Early, quien fue el responsable de la mayor�a de trabajos de experimentaci�n en las primeras �reas de hormig�n construidas en el parque. Se identificaron varias etapas de experimentaci�n durante la construcci�n del parque de Meridian Hill: experimentaci�n preliminar con acabados de hormig�n de 1915 a 1916; elaboraci�n de terminados y formas mejoradas de 1917 a 1918; y, diseminaci�n de estas t�cnicas mejoradas a los dem�s contratistas que trabajaron en el parque de 1919 a 1936. Los materiales y las t�cnicas de cada periodo son descritos. Pautas generales para futuros tratamientos y trabajos de restauraci�n para el parque de Meridian Hill son listadas, teniendo en cuenta que tales trabajos deben ser apropiados para los diferentes terminados co-rrespondientes a cada periodo de experimentaci�n. 1 INTRODUCTIONMeridian Hill Park in Washington, D.C., constructed 1915–36, is currently undergoing a long-term restoration plan for both its landscape and concrete elements under the direction of the National Park Service, the administrator of the park. Research was undertaken to document the construction history of the exposed aggregate, reinforced concrete work in order to guide future restoration work. Historical 2 MERIDIAN HILL PARK2.1 DESCRIPTIONMeridian Hill Park is located on two city blocks in Washington, D.C., with the long central axis running north-south. The park is bounded on the east by 16th Street, on the west by 15th Street, on the south by W Street, and on the north by Euclid Street (fig. 1). The park area is delimited by perimeter walls with textured panels and heavily rusticated posts. The north end of the park is a level rectangular area planned on axis in the manner of a French formal mall. Two main converging paths lead to the central Grand Terrace. Here, there was once an unobstructed view over the city of Washington. At the Grand Terrace, the topography dramatically drops to the plaza area at the southern end of the park. A series of basins form a cascading water feature, inspired by Italian Renaissance gardens, that leads down the center of the slope, flanked by descending walks on either side (fig. 2). On the lower plaza level, the park opens onto a paved reflecting pool area with a semicircular sitting area to the south, known as an exedra. A low-level balustrade lines the extreme southern end of the park. All the architectural features and decorative elements found at Meridian Hill Park are executed in concrete. Throughout the park, elements as varied as fountains, benches, the massive retaining wall of the Grand Terrace, paving, planting beds, and urns are all constructed of exposed aggregate, reinforced concrete. These features are remarkable for their exposed aggregate finishes, exhibiting a wide array of aggregate sizes, creating subtle textures and colors while defining crisp corners and turning smooth curves (figs. 3–4).

The concrete work at Meridian Hill Park is currently in remarkably good condition, given that it was constructed during a period when concrete was poorly understood and unsound concrete construction practice was widespread. In most areas, the concrete work suffers only from soiling caused by atmospheric pollution or biological growth and, in a few places, damage from vandalism. Relatively little damage has occurred from the corrosion of the reinforcement, which is more than adequately covered in most places, and there is no sign of active, aggressive

2.2 HISTORYIn 1901, the McMillan Commission was formed to develop a plan to improve the park system within the District of Columbia. Meridian Hill was marked as a property suitable for a federal park because of its exceptional views over the capital city. Congress approved an act in 1910 to acquire public land to create Meridian Hill Park as part of the recommendations set forth by the McMillan Commission. In April 1913, George Burnap, architect for the Office of Public Buildings and Grounds, proposed a design for a formal urban space at Meridian Hill Park. Horace Peaslee became the architect in charge of the park when Burnap resigned in 1917. Burnap's main design concept, consisting of a formal park on French and Italian garden precedents, remained constant throughout the 21 years of construction at the park.1

The scale of the park prohibited the use of costly stone masonry. For this reason, concrete was chosen

3 JOHN J. EARLEYJohn J. Earley 1881–1945) began his career at the age of 17 as an apprentice in his father's stone-carving John J. Earley thought of himself first and foremost as a craftsman and artist. His self-proclaimed title was “Architectural Sculptor.” Although Earley went on to serve as president of the American Concrete Institute, he maintained that his concrete work developed from an artistic and not a scientific study. He wrote: “I am a craftsman and all that I could ever do was to record sensible experiences and the conclusions drawn from them and to describe the work which resulted from those conclusions” (Earley 1938, 589). He championed the work of the craftsman who perfects a technique through pragmatic trial and error rather than scientific testing. Earley's At the time of Earley's work in concrete, the architectural community was debating the most appropriate and aesthetically pleasing expression for this relatively new material. In the search for a way to transform concrete from a construction material to one capable of complex architectural expression, the focus was on the proper form and finish of the material. Most agreed that concrete should not imitate other building materials but should be formed and finished to reveal its inherent qualities as a poured and molded material. Concrete offered the possibility of escaping the masonry vocabulary of stone laid on stone. Contemporary concrete work was constructed with perforated, monolithic walls, such as Frank Lloyd Wright's Unity Temple in Oak Park, Illinois (1904–6); formed with repetitive cast-concrete elements, as in Irving Gill's prefabricated concrete slab houses in Los Angeles, California (1910–13); and poured in organic forms, as seen in the undulating facade of the now demolished Blenheim Hotel in Atlantic City, New Jersey (1906), designed by William Price. However, concrete needed an appealing finish to be considered a true architectural material capable of performing under various aesthetic demands. In an effort to make concrete more aesthetically pleasing, many architects and contractors experimented with treating its surface. The treatments included tooling, painting and stuccoing the surface, coloring the cement, exposing the aggregate, and molding the concrete with a textured surface. Earley took part in this experimentation and achieved some of the most outstanding and enduring concrete finishes of the period. The process of exposing aggregate in concrete appealed to Earley's desire to give concrete an artistic finish that was characteristic of the material. To expose the aggregate, the concrete is removed from the mold while it is still green, meaning not fully cured. The surface of the concrete is then scrubbed to remove the exterior film of wet cement and to expose the aggregate beneath. This process gave an appealing finish while revealing elements inherent to concrete as a conglomerate material such that “any section through it would have the character desired for the surface” (Earley 1934, 251–52). Earley wrote that “it was this decision to employ finishes characteristic of the nature of reinforced concrete that gave the interest to succeeding studies” (Earley 1918, 128). To achieve artistic results in exposed aggregate concrete, Earley adopted techniques from the arts of mosaic and painting. He showed sophistication in placing and juxtaposing small tesserae in his concrete mosaic work. The art of mosaic was easily adaptable to exposed aggregate concrete, Earley felt, as both have a surface “made up of a myriad of tiny, irregular stone chips averaging about 1/4 in. in maximum dimension, and closely grouped. Interstices are slightly tilted in various directions, resulting in a richly textured surface which, however, is held firmly in plane by the flat surface of the mold” (Earley 1940, 103). As in mosaic work, the exposed aggregate of concrete imparts not only color but also texture and radiance to the surface of the concrete. The aggregate's “small size and jagged shape results in their catching and refracting light from all directions, giving the surface a subdued ‘sparkle’ which is highly distinctive” (Earley 1940, 102). The Shrine of the Sacred Heart (1923) exemplifies Earley's concrete mosaic work, though the influence of the art of mosaic can be seen throughout his work. From the beginning of its development, Earley compared the exposed aggregate finish to the play of colors in pointillism. Earley incorporated the optical science of pointillism, where pure spots of color resolve to a uniform hue at a given distance, into exposed aggregate concrete: “By considering the particles of aggregate as spots of color in juxtaposition, all the knowledge and much of the technique of the impressionist, or the pointillist school of painting, was immediately applicable to concrete” (Earley 1925, 19). The optical science of pointillism guided the careful selection and combination of aggregate in Earley's concrete work in order to produce various visual sensations from different distances: “We have designed surfaces to fill the most exacting requirements and to meet the greatest differences in scale, surfaces which lose their texture and resolve to uniform hue at twenty-five feet, surfaces which hold their texture at five hundred feet” (Earley 1925, 21). While Earley was looking to established arts to improve the aesthetic quality of concrete, he recognized the merit of concrete as an artistic medium in itself. It was extremely durable, economic, and flexible and permitted rapid execution of forms. Earley saw concrete as a modern artistic material that could solve modern building-design problems. He wrote: “It is deceiving to see the material [architectural concrete] as a form of structural concrete elevated to the level of an artistic medium when on the contrary it is an artistic medium extended to more general use” (Earley 1938, 591). He likened his use of concrete to Luca della Robbia's development of terracotta during the Renaissance (Earley 1926b). In both instances, he felt, technology had developed new materials that were both functional and ultimately artistic, to express the architectural ornamentation of its own era. 3.1 INITIAL EXPERIMENTATION IN CONCRETE, 1915–1916Earley approached the problem of constructing the concrete at Meridian Hill Park in the spirit of experimentation. In 1915, the Earley Studio was awarded the contract for the work at Meridian Hill Park, in part because of its reputation for cement stucco work. At that time, the Earley Studio was involved in a study at the Bureau of Standards on reducing map cracking in Portland cement stucco applied over metal lath.2 Earley worked with J. C. Pearson, the bureau's cement chemist, to reduce the appearance of map cracking (Bureau of Standards 1926). These experiments were contemporaneous with the concrete work at Meridian Hill Park and led to a collaboration that directly influenced the construction techniques used in the exposed aggregate concrete there. 3.2 PRELIMINARY MOCK-UPSThe contract for Meridian Hill Park stipulated that a full-scale mock-up of a wall unit, complete in all details except for reinforcement, be approved by the Commission of Fine Arts before work could begin. The wall unit consisted of a rusticated post attached to a wall panel with a base, an inner panel with a surrounding border, and a coping with a drip edge. The form of the wall shown in the construction drawings and historical photographs of the mock-ups is almost identical to that seen in the park today. Earley made three mock-ups in total for inspection. The commission refused the first mock-up of smooth cast concrete because of its uninteresting surface. Horace Peaslee later commented that “in the first stage of the construction … the intent was to obtain interest in the surface by expedients of form alone, paneling the wall sections and rusticating the posts. An effort was made to rib the rustication in the manner of the heavy cutting of certain Italian garden work. The balusters, urns, etc., were of cast cement, smooth, cold, and uninteresting” (Peaslee 1930a, 31). While the form replicated Italian masonry, the concrete of the first mock-up failed to capture the correct color and texture. The second mock-up was essentially the same in form but an attempt was made to use textured finishes to make the wall more interesting. The surface was enlivened by texturing the surface of the concrete and by applying cement stucco to the concrete backup. The Portland cement stucco testing at the Bureau of Standards, in which the Earley Studio took part, had included test panels of cement stucco on monolithic concrete that yielded promising results (Bureau of Standards 1926). Of the second mock-up, Earley wrote:

The experiment with this technique can be seen in historical photos of the mock-up made along 16th Street (fig. 6). While the textured finishes did break up the monotony of the surface, Earley himself criticized the second mock-up for its poor color and particularly for its failure to express the character of concrete. He wrote that “the color was unsatisfactory. It was the cold gray cement color that has always been so objectionable. Every particle of sand was coated with cement and had no color value of its own” (Earley 1918, 127). The second mock-up was also objectionable because of its inability to reveal the physical characteristics of concrete. In a caption to a detailed photograph of this mock-up, Earley noted that the “textures are conventional and not characteristic of concrete” (Earley 1918, 129). This mock-up was “a plastered wall, nothing more. The construction might just as well have been of brick, terra cotta, or metal lath on channel studs so far as the appearance revealed. The wall was without scale. It did not give the appearance of strength and size equal to its task as a retaining wall” (Earley 1918, 127). The second mock-up offended Earley's aesthetic sensibilities because it was both unattractive and uncharacteristic of the material. A third mock-up, in the same form but with an exposed aggregate finish, was presented for a final review. It is unclear how exposed aggregate concrete came to be used at Meridian Hill Park. It is known that the Commission of Fine Arts desired that the walls should closely resemble the Mediterranean tuff-and-pebble mosaics found in Italian villa gardens. Cass Gilbert, a member of the Commission of Fine Arts, is credited with sparking Earley's imagination to create a similar texture in concrete (Avery 1944). The process of exposing aggregate was practiced on earlier concrete work, most notably Frank Lloyd Wright's Unity Temple (1906), but it is unclear how knowledge of the technique came to Earley or to the commission. Earley described the effect the exposed aggregate had on the surface of the concrete at Meridian Hill Park:

In contrast to the earlier mock-ups, this wall harnessed the qualities of the material by emphasizing the texture and color of the aggregate. In contrast to the earlier experiments, Earley wrote: “The wall was no longer a plastered one, but was reinforced concrete and nothing else, and it seemed big and strong enough to suit all the demands that would be made upon it” (Earley 1918, 128). The third, exposed aggregate mock-up was approved for construction in 1915, which began at the north end of the west wall. 3.3 CONSTRUCTION OF WEST WALL UNITS, 1915–1916The concrete for the 1915–16 wall units was a 1:2:4 mix, with 1 part cement to 2 parts sand and 4 parts aggregate. The cement was a white Portland cement made by the Atlas Company, which was the type preferred by Earley throughout his career (Cron 1977). The sand used in the mix was a river sand finer than 1/4 in. and was known as concrete or torpedo sand, composed of uncrushed, rounded quartz grains. The aggregate was specified as Potomac River gravel and ranged from 1 1/4 in. to 1/4 in. with the greatest proportion between 3/4 and 1/4 in. in diameter; Potomac River gravel is composed of highly colored, naturally weathered, rounded quartz. The exact grading of the aggregate for the two mixes used in the wall units is not known, but it was probably graded in a conventional manner combining aggregate graded through descending sizes. Water was added to the mix so that “its consistency was soft, so soft that it would flow readily” (Earley 1918, 130). The forms of the wall units were made of plaster waterproofed with shellac. The plaster forms fit inside standard wooden forms that supported the weight of the concrete. The walls and posts were reinforced with 1/2 and 3/4 in. twisted steel rods embedded 4 in. in the form (Meridian Hill Park Specification 1915). The west wall units, each comprised of one wall panel and post, were cast as an integral form in one pour using two concrete mixes. The range in texture of the exposed aggregate in the west walls indicates the use of two types of mixes in each wall unit, one with coarse aggregate and one with medium aggregate. The rusticated posts, coping, and base all have a coarse exposed aggregate finish, while the inner panel has a medium exposed aggregate finish. The inner border has a smooth finish that has been tooth-chiseled. Pouring of these wall units required dividers, probably of sheet metal, that separated the different concrete mixes and were raised as the pour progressed (Mann 1981). Sharp raised ridges at mix boundaries remain as evidence of the use of such dividers during construction. After 24 to 48 hours, the forms were pulled while the surface of the concrete was still green. The surfaces of the inner panel, the face of the coping, and the rusticated posts were scrubbed with a steel brush to expose the aggregate, care being taken to create an even exposure. The exposed aggregate surfaces were washed with muriatic acid to remove any excess cement film, and the walls were then hosed with water (Peaslee 1930a). The border around the panel was tooth-chiseled. Fine, crisp details such as the drip edge under the coping and the recessed groove on the panel were achieved by detachable wooden strips. These strips were loosely attached to the interior of the plaster mold and were grooved on the back to allow for expansion. After the pour, the wooden strips remained in the concrete form, protecting the fine details. The strips were released as the wood dried and shrank. The walls were carefully monitored while they dried and were wetted if they appeared to be drying too rapidly. The top of the wall coping and the top of the base received a troweled surface (Earley 1918). Construction of the west wall progressed as every other post and panel unit was poured in place. This method allowed for the ends to be coated with five-ply felt and tar to form an expansion joint. This process ensured that when the wall units were poured to fill the gaps between the previously poured units, the adjacent wall panels had sufficient strength to withstand the work performed on the new panel (Earley 1918). 4 IMPROVEMENT IN COLOR, TEXTURE, AND FORM, 1917–1918Although the exposed aggregate finish developed in 1915–16 was a great improvement over the initial mock-ups, the west wall units did not achieve the artistic finish desired by both Earley and Horace Peaslee, architect of the park. The exposed aggregate enlivened the dull gray of the cement but appeared in uneven pockets across the face of the concrete. Peaslee noted that “the earlier stages of the work showed lumps of coarse aggregate in certain sections of the panels, and sparse cement areas in others, giving decided irregularity, but even at that not an unpleasant effect” (Peaslee 1930a, 31). After discovering the potential of exposing the aggregate, Earley 4.1 IMPROVEMENT IN COLOR AND TEXTURE: STEP-GRADED AGGREGATEAt the time Earley was tackling the problem of improving the finish of exposed aggregate concrete, concrete researchers were experimenting with aggregate grading in order to achieve maximum strength in concrete. The research published during 1906–18 focused on increasing strength and durability of concrete through careful proportioning of the mix and grading of the aggregate (Thompson 1906; Abrams 1918; Draffin 1976). At this time, two methods of aggregate grading were being studied: one with aggregate graded through many descending sizes and a second with aggregate graded into fine, medium, and coarse sizes (Earley 1934). One such study of aggregate grading in concrete by M. Feret interested Earley and Pearson. Feret experimented with various combinations and proportions of aggregate of three sizes: fine, medium, and coarse. He found that the best results occurred when the intermediate medium size was omitted (Earley 1938). Pearson and Earley took these experiments a step further by exploring the relationship of aggregate of specified mean diameters to produce the best aggregate grading for an evenly distributed exposed aggregate finish (Earley 1938). The goal of the experiment was to create a surface finish with the maximum amount of aggregate possible: “If the aggregate is to be the source of color, the concrete must be so designed and manipulated as to deposit in the surface the greatest possible amount of aggregate” (Pearson and Earley 1920, 76). Pearson and Earley performed experiments with small concrete mixes of fine, medium, and coarse graded aggregates viewed under a microscope. As in Feret's experiments, Pearson and Earley achieved the best packing of aggregate when the intermediate sizes of aggregate were omitted. These tests succeeded in creating an exposed aggregate surface whose color was dependent on that of the aggregate. In 1921, Earley patented his “new and useful Improvements in Methods of Producing a Predetermined Color Effect in Concrete and Stucco,” which were devised during the period of experimentation with Pearson. Contrary to a straight-line gradation of aggregate through descending sizes, Earley patented a mix where aggregate was divided into groups of the same size and recombined according to a definite ratio of the size of the grains and the volume of each size. He named this new technique “step gradation.” In the patent, Earley specified that, upon hardening, “the larger aggregate will be found to lie in substantially a plane surface about 1/16 in. beneath the surface and may be exposed by brushing away the surface with a wire brush.” This surface could then be treated with “a weak acid to better bring out the natural color” of the aggregate (Earley 1921, p. 2, 11. 72–79). The step-graded mix gave a finished surface with closely packed aggregate faces bound by thin ribbons of cement, in some cases barely visible. Step-graded aggregate also improved the performance of the concrete. In Earley's own words, he explains the benefits acquired by the step gradation method: Improved finish and improved workability were both achieved with the step-graded aggregate concrete mix. The development of step-graded aggregate was a direct evolution from the previous work done at

4.2 IMPROVEMENT IN FORM: CONTROL OF WATEREarley's investigations into the grading of the aggregate evolved into a new hierarchy in the importance of the components of concrete. Cement and water had important roles within the cement mix but were subordinate to the aggregate. Earley wrote: From the experiments carried out at Meridian Hill Park, Earley had begun to formulate a new theory of concrete based on the grading and characteristics of the aggregate. Cement was necessary to bind the aggregate together while water was manipulated for optimum workability and set. The initial experimentation in control of water in the concrete mix occurred at Meridian Hill Park during the construction of the balusters of the main 16th Street entrance (fig. 7). To successfully fill the baluster molds, the cement mix required an excess of water. Two recurring problems hindered the successful pouring and finishing of the balusters. First, the step of stripping the forms while the concrete was still green created suction forces between the mold and the still wet concrete, leaving pockmarks on the casts. Second, the balusters would crack at their thinnest points from shrinkage during curing. Earley discovered that withdrawing the excess water from the cement mix after it had been poured in the forms would give the concrete the early strength that was needed to expose the aggregate for the finish and also prevent excess shrinkage. It is interesting to read Earley's own description of this experimentation at Meridian Hill Park: Earley and his studio had discovered that the excess water needed for workability could be withdrawn through capillary action during the set. In a 1918 publication, Duff Abrams, a chemist affiliated with the Portland Cement Association, concluded that the grading of the aggregate determined the amount of water needed for a workable mix. In turn, the amount of water needed for workability controlled the amount of cement needed to achieve optimum strength. As had been long known through empirical knowledge, too much water weakened the concrete and caused excessive shrinkage during cure. According to Abrams, the size and grading of aggregate could vary widely without affecting the strength of the concrete as long as the water-cement ratio remained constant (Abrams 1918). Abrams's publication reached a wide audience, and the concept of an ideal water-cement ratio greatly influenced the concrete industry and is still in use today (Draffin 1976). Earley held to Abrams's assertion that the water-cement ratio needed for concrete to set at maximum strength was a constant. In practice, however, the water-cement ratio needed to be exceeded to create a workable concrete mix that could successfully fill certain molds. One water-cement ratio held for maximum strength while “the other water relation … has to do with the mobility of the mass and not with its strength” (Earley 1927, 477). Earley achieved greater complexity in form through the understanding of these two water ratios. The idea that water could be added and removed from the mix as needed—that it was not a fixed factor—allowed for more complex forms to be cast and finished. The time between pouring and set of the concrete allowed for the excess water needed for increased

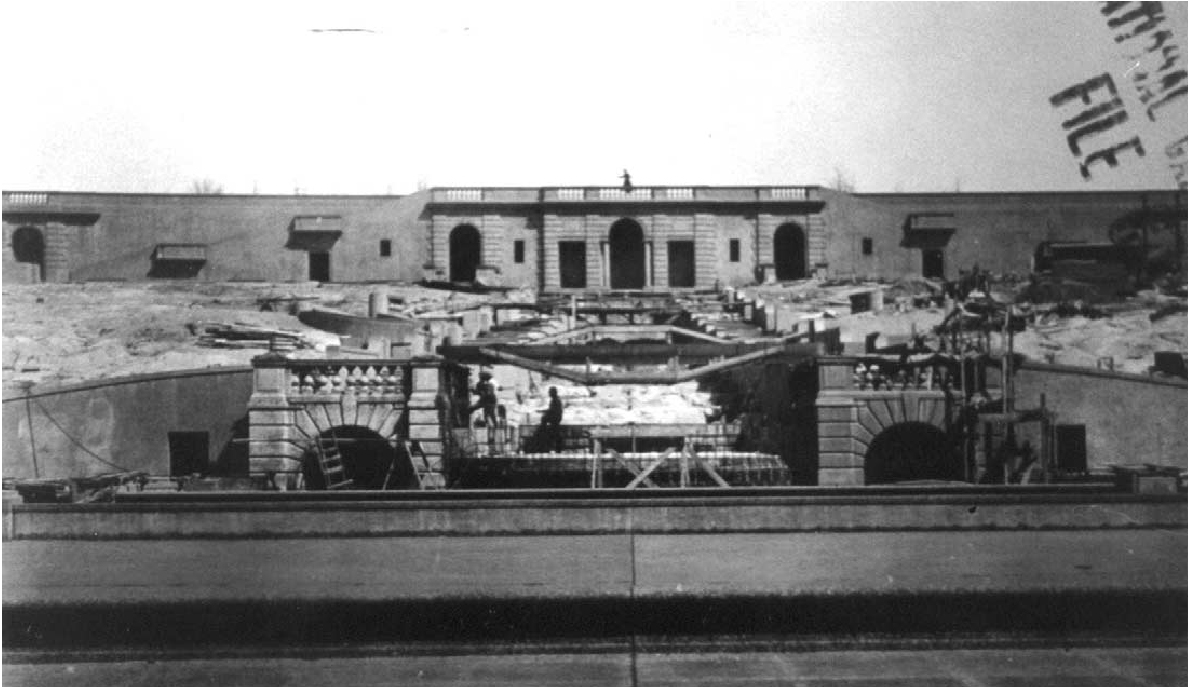

Control of water accounted in part for the quick set and early strength of the concrete made at the Earley Studio, which could accommodate complex forms and allow for finishing within 24 hours. The removal of excess water was thought to actually increase the strength of the concrete. In 1927, a Portland Cement Association publication, Concrete in Architecture, discussed Earley's control of water and stated that the removal of excess water “increases the density, strength and impermeability—and consequently the durability—of the concrete and diminishes the shrinkage or tendency of the concrete to draw away from the molds during the process of hardening” (Portland Cement Association 1927, 56). Through this control, Earley was capable of filling complex molds and creating concrete that could produce almost any form demanded. 4.3 CONSTRUCTION OF THE MAIN 16TH STREET ENTRANCE, 1917–1918The main 16th Street entrance was constructed between 1917 and 1918 using the step-graded concrete mix and the control of water to cast forms (fig. 8). Two wall panels with integrally cast benches curve in from the 16th Street sidewalk to the entrance, which is flanked by massive grooved pilasters that rise to a stylized, neoclassical entablature. The entrance is on a simple rectangular plan with steps that lead up from the street on the west into the structure under a barrel vault and then turn south up to the park level. The top of the structure is crowned with the balustrades that spurred Earley to experiment with removing excess water from poured forms. The concrete work dating from this period includes elements that were both poured in place and precast in the studio (Peaslee 1930a). The walls of the entrance area, the upper 16th Street retaining wall, the walls flanking the south steps, and the steps and paving were all poured and finished in place. The balusters, handrails, seats, and planting boxes in the overlook area were all precast and finished in the studio and later assembled on-site (Pearson and Earley 1920). Thin precast, exposed aggregate panels were applied on the exterior and interior surfaces of the main 16th Street entrance to a structural concrete core that was poured on-site (see fig. 9 for a detail of this type of construction on the Grand Terrace wall ca. 1930). Varying textures were achieved by the use of medium or coarse exposed aggregate.

The step-graded concrete required that the standard 1:2:4 mix, cement: sand: aggregate, be abandoned during this phase of construction (Earley 1918). The mix is not specified, but the ratios probably ranged from 1:1:3 to 1:1/2:4 (Peaslee 1930a). The cement used was white Portland cement. The exposed aggregate finish required that the forms be stripped while they were still green, so Earley added hydrated lime to the mix to increase workability, Earley specified the order of mixing the concrete. First, cement was added to the water, and then sand was added so that the consistency was that of a thick soup. To this was added the aggregate. The goal was to keep the water content as low as possible to make the mix workable (Earley 1918). The exact amount of water used at this stage is not specified. The only rule was that the consistency be such that the mix would easily fill the forms. As a reference, in 1927, Earley used 4 gal. of water for each 94 lb. bag of cement used in the mix (Portland Cement Association 1927). Excess water was then removed through capillary action by placing an absorbent material over the form. The forms and molds used in this period of construction were both wooden and plaster. Detailed casts that were not repetitive were done in plaster piece molds, waterproofed with shellac. Wooden molds lined with metal were used to cast repetitive and large-scale elements (Earley 1918). 5 DISSEMINATION: WORK OF OTHER CONCRETE CONTRACTORS, 1919–1936Other Washington, D.C.–based contractors constructed the majority of the remaining concrete work at Meridian Hill Park based on the experimentation and development of new techniques by Earley and the Earley Studio. Quite possibly these firms, including Fred Drew Company and Charles Tompkins Company, produced new techniques to solve the design problems they encountered. One such technique designed by later contractors was the use of molasses to coat the molds to increase the set of the concrete so that forms could be stripped more rapidly (Mann 1981). According to Horace Peaslee, one of the achievements of Meridian Hill Park was the dissemination of these techniques to other concrete contractors. In 1930, he wrote that “although this work was originated with the experimentation of one Washington contractor, the knowledge of the process has spread so that a number of men are available for bidding and each seems to be able to improve upon the preceding work” (Peaslee 1930a, 32). Few documents survive to attest to the skill and ingenuity of these contractors in placing the concrete work at Meridian Hill Park. 6 RESTORATION RECOMMENDATIONSRestoration of the concrete at Meridian Hill Park should proceed according to the general guidelines of quality concrete repair work, with special attention to repair of the exposed aggregate finishes. The exposed aggregate finishes are distinctive for each period of experimentation and embody the various stages in the development of the concrete work within the park. Modern repair materials for concrete, such as polymer modified concrete or integrally mixed bonding agents, are not suitable for the repair of historic concrete. The aggregate for the repair should match the original aggregate of quartz and chert in size, shape, and color. Repair of cast edges and copings must be achieved with formwork rather than through troweling and shaping. Repairing elements from different periods of construction requires skill to match the distinctive finishes achieved. Further, the variety of finishes that were created, often within one integrally cast panel, necessitates matching fine, medium, and coarse gradations of aggregate within the same wall unit. While aggregate may be hand-placed in the concrete repair to match the desired finish, the aggregate must then be covered with the cement repair mix and revealed with a nylon brush after the initial set of the cement to achieve the proper exposed aggregate appearance. Highly exposed, step-graded aggregate should be treated with a cement grout to fill the interstices with cement; the cement is later removed with a nylon brush to expose the aggregate. The restoration of the concrete work should proceed with an understanding of the structural and material properties of the concrete, as well as its importance as a document of construction history. 7 CONCLUSIONSAccording to accounts by Horace Peaslee and John J. Earley, the work on the perimeter walls at Meridian Hill Park was performed as an experiment in a new construction technology based on careful aesthetic considerations. In 1930, Peaslee defended the experimental work at the park against allegations that he had wasted time and money at Meridian Hill Park. He championed the work: “Not only has the park esthetic and recreational value, but it has served as an experimental laboratory for the development of new concrete processes, the value of which to park and garden work throughout the country is being continually demonstrated” (Peaslee 1930b). The experimentation was necessary for the later development and improvement of the innovative techniques: “Casual observation shows the immense progress that has been made in both wall and walk construction since the beginning of the work. There is no comparison between the first walls and those of later development” (Peaslee 1930b). The dissemination of the new techniques originating at Meridian Hill Park was considered an important achievement of the work, contributing to concrete construction on a larger scale. Meridian Hill Park is often cited as the first project NOTES1. For more information on the design of the park, see R. T. Schnadelbach and H. Havemeyer, Ferrucio Vitale: Landscape architect of the country place era (Princeton: Princeton Architectural Press, 2001) and T.W. Dolan, “Meridian Hill Park, Washington, D.C.,” graduate thesis, School of Architecture, University of Virginia, 1983. 2. The Bureau of Standards is the earlier incarnation of the current National Institute of Standards and Technology. Initially founded in 1901 as the National Bureau of Standards, the name changed to the Bureau of Standards during 1903–34. From 1934 to 1988, the name returned to the National Bureau of Standards. In 1988, the name was official changed to the National Institute of Standards and Technology. ACKNOWLEDGEMENTSThe author would like to thank those at the National Park Service and the University of Pennsylvania who aided in the research for this article, with special thanks to Perry Wheelock, Samuel Harris, and John Keene. Lorraine Schnabel provided encouragement and constructive criticism. Finally, John Milner Associates supported the completion of the article for publication. REFERENCESAbrams, D. A.1918. Design of concrete mixtures. In Bulletin No. 1, Structural Materials Research Laboratory. Chicago: Lewis Institute. Avery, W. M.1944. Earley's mosaic concrete opens limitless vistas in products field. Pit and Quarry37(3): 131–34. Bauer, E. E.1928. Plain concrete. New York: McGraw-Hill. Bureau of Standards. 1926. Stucco investigations at the Bureau of Standards December 13, 1926. Washington, D.C.: Government Printing Office. Childe, H. L.1943. Concrete finishes and decoration. London: Concrete Publications. Cron, F. W.1977. The man who made concrete beautiful. Fort Collins, Colo.: Centennial Publications. Draffin, J. O.1976. A brief history of lime, cement, concrete and reinforced concrete. In A selection of historic American papers on concrete 1876–1926, Publication SP-5, ed. HowardNewlonJr.. Detroit: American Concrete Institute. 3–40. Earley, J. J.1918. Some problems in devising a new finish for concrete. Journal of the American Concrete Institute16:127–37. Earley, J. J.1921. Methods of producing a predetermined color effect in concrete and stucco. U.S. Patent #1,376,748. Earley, J. J.1924. Introduction to architectural concrete. Proceedings of the American Concrete Institute20:157 Earley, J. J.1925. What concrete means to the craftsmen who are entrusted with interpreting architectural design. In Substance, form and color through concrete. New York: Atlas Portland Cement Company. 15–22. Earley, J. J.1926a. Architectural concrete. Proceedings of the American Concrete Institute22:513–34. Earley, J. J.1926b. The concrete of the architect and sculptor. Chicago: Portland Cement Association. Earley, J. J.1927. Time as a factor in making concrete. Proceedings of the American Concrete Institute23:473–78.

Earley, J. J.1934. Architectural concrete of exposed aggregate type. Journal of the American Concrete Institute30:251–78. Earley, J. J.1938. Work of Committee on Architectural Concrete of Exposed Aggregate Type and Thomas Alva Edison Memorial Tower. Journal of the American Concrete Institute34:589–601. Earley, J. J.1940. Architectural concrete slabs. Architectural Forum72 (February): 101–8. Hart, W. E. and R. Wilson.1927. The painting and coloring of concrete. American Architect (December 20):833–38. Historic American Buildings Survey. 1987. Meridian Hill Park. HABS DC-532. Library of Congress, Washington, D.C.: Prints and Photograph Division. Howe, H. E.1921. The new stone age. New York: Century Co. JohnJ. Earley Obituary. 1946. Proceedings of the American Concrete Institute42 (January):8–9. Mann, J. W.1981. Letter to Paul Goeldner, Chief Historic Resource Services, May 20. Paul Goeldner, Chief Historic Resource Services, National Park Service, National Capital Region, Design Services, Meridian Hill I File. Meridian Hill Park Specification. 1915. National Archives, RG42, entry 97, box 24, file 240. Pearson, J. C., and J. J.Earley. 1920. New developments in surface treated concrete and stucco. In Proceedings of the American Concrete Institute16:70–87. Peaslee, H. W.1930a. Notes on the concrete work of Meridian Hill Park, Washington. Landscape Architecture21(1) (October):31–38. Peaslee, H.1930b. Letter to Colonel U. S. Grant III, December 9. National Archives, RG42, entry 310, box 1, folder 3. Portland Cement Association. 1927. Concrete in architecture. Chicago: Portland Cement Association. Smith, W. W.1912. Ornamental treatment of concrete surfaces. American Architect101(1883):33–42. Thompson, S. E.1906. Proportioning concrete. American architecture and building news (90):59–61. AUTHOR INFORMATIONLORI AUMENT is an architectural conservator with John Milner Associates Inc. in Philadelphia, Pennsylvania. She has previously worked with the National Park Service in Washington, D.C., and the Building Conservation and Research Team at English Heritage in London, England. She received a master's degree in historic preservation from the University of Pennsylvania. Address: 1216 Arch St., 5th floor, Philadelphia, Pa. 19107

Section Index Section Index |