REGALREZ IN FURNITURE CONSERVATIONHANS PIENA

ABSTRACT—Regalrez 1094 is a hydrocarbon, low-molecular resin, soluble in aliphatic and aromatic solvents. When the elastomer Kraton G1650 and hindered amine light stabilizer Tinuvin 292 are added, it remains stable even after extensive aging. Regalrez 1094 is used on paintings for the saturation of somewhat opaque areas and as a varnish. A test on furniture showed that it has the capacity to saturate very degraded finishes. Unfortunately a finish of Regalrez 1094 becomes tacky when handled. Of the three grades of Regalrez with a higher glass transition temperature, Regalrez 1126 (Tg, 65�C) was tested. It saturates degraded finishes just as well as Regalrez 1094 does, and it does not get tacky when handled. Regalrez 1126 produces a very smooth varnish, and it can be used in a wax-resin finish. Finally, it is possible to cover Regalrez 1126 with a more polar finish. This capability enables conservators to keep a degraded finish on furniture, saturate it with Regalrez 1126, and finish it with materials like shellac or Paraloid B-72. Unfortunately, when a coat of wax is applied on top of any of the grades of Regalrez discussed here, the Regalrez immediately dissolves in the solvents present in paste wax formulations. As a top finish, therefore, Regalrez can best be used in museum settings, where the care of furniture is controlled. However, for the saturation of degraded finishes, both 1094 and 1126 can be used in a museum setting as well as in private collections. TITRE—L'utilisation du Regalrez en restauration du mobilier. R�SUM�—Le Regalrez 1094 est une r�sine hydrocarbon�e de faible poids mol�culaire, soluble dans les solvants aliphatiques et aromatiques. Lorsqu'on y ajoute du Kraton 1650, un �lastom�re, et du Tinuvin 292, un d�riv� amino substitu� qui sert de stabilisateur de l'effet photochimique, le m�lange demeure stable m�me apr�s un vieillissement prolong�. Le Regalrez 1094 est utilis� en restauration des peintures pour saturer des zones plut�t opaques et aussi comme vernis. Des essais sur du mobilier ont d�montr� que cette r�sine peut aussi saturer les couches de finition tr�s d�grad�es. Malheureusement le Regalrez 1094 demeure collant au toucher lorsqu'il est utilis� comme couche de finition. Parmi les trois types de r�sines Regalrez avec des temp�ratures de transition vitreuse plus �lev�es, le Regalrez 1126 (Tg: 65oC) a �t� retenu en vue d'essais. Cette r�sine r�ussit � saturer les couches de finition d�grad�es aussi bien que le Regalrez 1094, tout en demeurant s�che au toucher. Comme vernis, le Regalrez 1126 est tr�s lisse. Il peut aussi �tre utilis� pour produire un vernis en conjonction avec de la cire. Enfin, on peut aussi le rev�tir d'une couche de finition plus polaire, ce qui permet, par exemple, de traiter une couche de finition d�grad�e en la saturant de Regalrez 1126 et en recouvrant le tout d'un vernis tel que la gomme laque ou le Paraloid B-72. Malheureusement, les r�sines Regalrez dont il est question dans cette article se dissoudent instantan�ment dans les solvants des cires en p�te souvent employ�es pour prot�ger les meubles. Donc, comme couche de finition, le Regalrez est le plus utile en milieu mus�al, o� l'on exerce des contr�les sur les mesures de conservation pr�ventive (dont les couches de protection) appliqu�es aux meubles. Cependant, lorsqu'il s'agit de saturer des couches de finition d�grad�es, les r�sines Regalrez 1094 et 1126 peuvent servir � la fois en milieu mus�al et priv�. TITULO—Regalrez en la conservaci�n de muebles. RESUMEN—El Regalrez 1094, un hidrocarburo, es una resina de bajo peso molecular, soluble en solventes alif�ticos y arom�ticos. Cuando se le agrega el elast�mero Kraton G1650 y el estabilizador de luz de amino retardado Tinuvin 292, permanece establece aun despu�s de un extenso envejecimiento. El Regalrez 1094 se usa en pinturas para la saturaci�n de zonas un poco opacas y como barniz. Una prueba realizada en muebles demostr� que tiene la capacidad de saturar acabados muy degradados. Desafortunadamente el acabado de Regalrez 1094 se vuelve pegajoso cuando se manipula. De los tres grados de Regalrez con temperaturas de transici�n de vidrio mas altas, se prob� el Regalrez 1126 (Tg, 65C).Este satura los acabados degradados, tanto como

1 INTRODUCTIONDiscussion surrounding the cleaning of varnishes on furniture has not yet been as intense as that surrounding the cleaning of varnishes on paintings. However, in the last two decades some furniture conservators sought to save old finishes as much as possible. They believe that the uncritical removal of old finishes often results in a piece of furniture looking far too new, with an appearance unrelated to its true age. Moreover, the removal of old finishes also destroys evidence concerning the technology and materials originally used to finish the object. This new awareness does not mean that every degraded finish has to be accepted as is, but new techniques have been developed to retain as much as possible of the existing layers, while at the same time achieving an aesthetically pleasing result (Landrey 1990; Schoeler and Stoian 1994). Many of the aging phenomena of old finishes are caused by the instability of the natural materials originally used. For this reason new resins were tested to see if they could attain higher standards of stability. Other criteria are that they should dissolve in solvents of low toxicity and that applying or removing the resin should not affect the old varnishes underneath. Some synthetic materials fulfill these criteria better than natural materials traditionally used in furniture conservation. This article deals with such a material, a synthetic resin called Regalrez produced by Hercules that can be used as a new top varnish on furniture and as a means to saturate degraded varnishes. Hercules manufactures chemical raw materials, including hydrocarbon resins. Around 1983, Hercules introduced four low molecular-weight (LMW) hydrocarbon resins: Regalrez 1018, 1085, 1094, and 1126 (see table 1). Two more were introduced in 1991, Regalrez 1128 and 1139. The first “1” in the code stands for 100% hydrogenated, and the last three numbers stand for the softening point (�C). Regalrez is a copolymer of styrene and styrene derivatives. The first two grades contain monomers like alpha methyl styrene and vinyl toluene to lower the softening point; therefore, they might not be as stable as the higher grades (Smit 1999). The higher grades are pure copolymers. Hercules suggests using these resins as additions in plastics to improve properties such as gloss and sealing temperature. Because of their adhesive properties and UV stability, Regalrez resins are used on a large scale for the assembly of double glazing. In conservation, Regalrez 1094 has been suggested as the main component for picture varnishes (Rie and McGlinchey 1990; Rie 1993). Its gloss, saturation, and refractive index are comparable with those of dammar and mastic varnishes (Whitten 1995b), but Regalrez 1094 is far more stable. To further improve its properties, the elastomer Kraton G1650 and hindered amine light stabilizer (HALS) Tinuvin 292 may be added. Without Kraton G1650, Regalrez 1094 is as brittle as dammar (Rie 1993). Tinuvin 292 inhibits photochemical degradation reactions, thus keeping Regalrez 1094 soluble over a longer period of time. Compatibility with aliphatic solvents of low aromaticity enables Regalrez to be safely used on top of more polar varnishes or retouches. The aliphatic solvents needed to dissolve Regalrez are less toxic than aromatics. Finally, Regalrez 1094 gives a high saturation to degraded synthetic and natural varnishes (Whitten 1995b). Despite its good properties, Regalrez has not yet been widely used in furniture conservation. Yellowed and crazed top varnishes on furniture are often regarded as unsalvageable and are therefore removed. Nonetheless, furniture conservators have developed many different techniques for saturating old varnishes. They can partly be solved and reformed by powerful solvents, or they can be saturated with natural resins. Another common practice is to apply a new coat of wax and melt it in with a hot-air gun. Finally, furniture reviver, which is a mixture of linseed oil, turpentine, ethanol, and vinegar, can be used. Many of these methods are intrusive and irreversible, or they add unstable materials to the old varnish. 2 EXPERIMENTAssuming that what was found to be safe on paintings would also be safe on furniture, I applied Regalrez 1094 on a privately owned bed in the Biedermeier style likely from southern Germany, dating around 1840. The old finish on the bed was somewhat opaque and had yellowed, thus obscuring the color, depth, and grain of the wood. A 10% (w/w) solution of Regalrez 1094 was used in white spirit, adding 2% Kraton G1650 and 2% Tinuvin 292 to the weight of the resin. The solution was applied with a cotton swab, and it produced a smooth finish with a pleasing depth. The undesirable effects of the yellowing and opaqueness were significantly reduced by the saturating qualities of the resin, and the varnish largely regained its transparency. The finish felt dry to the touch, but even two years after application it became tacky after a hand was placed on the surface for a short period of time. 2.1 POSSIBLE CAUSES OF TACKINESSThis tackiness may have many causes, including:

These are the possible causes tested here. 2.2 TEST METHODSSeveral different mixtures were made for the test (tables 2 and 3) following the instructions of Whitten (1995a) making a 10% (w/w) solution adding 2% Kraton G1650 and 2% Tinuvin 292 to the weight of the resin. All varnishes mentioned in this article were made using these concentrations, unless otherwise stated. The mixtures were brushed on thin glass sheets. This inert substrate was used so that any tack could be caused only by the mixture applied on top. In addition, Regalrez without any solvent was melted, and a film was poured out over glass. Each film was left to dry for three months at room temperature, after which time a hand was pressed against it for 10 seconds to detect tackiness. This test was repeated after another three months. The amount of tack was not quantified because if a finish gets tacky upon handling, it is not appropriate as a top finish on furniture, regardless of the degree of tack. The hand temperature of 15 people was measured by letting them hold the bulb of a thermometer until the temperature stabilized. The room temperature at the time was 20-22�C. The range of

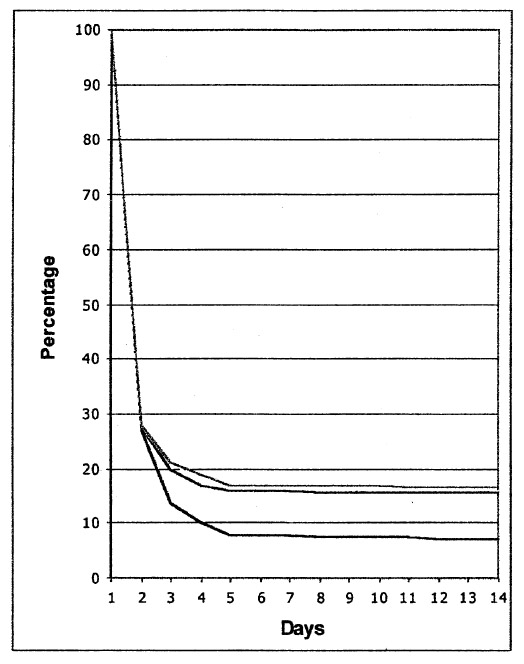

3 RESULTS3.1 THE OLD FINISHBecause the tackiness of the finish on the bed could have been caused by the substrate and not by Regalrez 1094, the same finish was applied onto glass (see table 3, no. 1) This produced a tacky finish as well, leading to the conclusion that, whether or not the old finish on the bed had contributed to some of the tack, the Regalrez 1094 varnish itself becomes tacky when handled. 3.2 THE SOLVENTSTo see if particular types of solvents would cause the tackiness, new solutions of Regalrez 1094 with six different solvents were made (see table 2). Nhexane was chosen for its high relative evaporation rate. Xylene was chosen to see if an aromatic would make any difference. Shellsol D40 and TD were recommended for use with Regalrez by the National Gallery of Art (1996), Washington, D.C. The white spirit is a proprietary product commonly used by furniture conservators in the Netherlands. Shellsol D70 was chosen for its low relative evaporation rate. The evaporation of hydrocarbon solvents from a film of a hydrocarbon resin can be slow because of the affinity between the two. However, under the same conditions, the solvent with the highest relative evaporation rate can be expected to produce a dry film sooner than the other solvents (Carlson and Schniewind 1989). Unfortunately, with the entire range of solvents discussed here, Regalrez 1094 produced a film that was tacky upon touching after three months of drying (see table 3, nos. 1-6), thus leading to the conclusion that the relative evaporation rate of the solvent does not significantly influence the tackiness. To quantify the amount of solvent retained in a film of Regalrez, solutions of the four highest grades (40% w/w) with Shellsol TD were brushed onto thin metal sheets, which were weighed before and after application. In addition, the samples were weighed once every day for a period of 14 days. The relative humidity ranged from 50% to 60%, the temperature from 18�C to 22�C. The amount of Shellsol TD in Regalrez 1094 dropped to 7.8% after five days, depending on the grade of Regalrez used (fig. 1). The other three grades contained approximately 16% at that moment. The remaining solvent evaporated very slowly. Regalrez 1094 still contained 7.2% of the original amount of solvent after 14 days and was tacky when handled. The higher grades 1126, 1128, and 1139 were not tacky even though they still contained about 16% solvent. The final thickness of the film was 10-20μm. 3.3 THE COMPONENTSTo see which component caused the tackiness— Regalrez 1094, Kraton G1650, and/or Tinuvin 292—a series of mixtures was made, each containing 10% of one of the three ingredients (table 3, nos. 7-9). In addition, films made of melted Regalrez without any solvent were tested (table 3, nos. 13-16).

Whitten (1995a, 127) writes that dissolving Kraton G1650 in solvents with little or no aromatics content will make more viscous solutions. On the other hand, it is difficult to dissolve Kraton G1650 in a pure isoparaffin like Shellsol TD. Without using any heat, Kraton G1650 tends to swell to a transparent gel that does not mix well with the other components. Only xylene and white spirit with 23% aromatic content easily dissolved Kraton G1650. At least 10% of xylene had to be added to the other solvents to do the same. Kraton G1650 is a triblock copolymer made up of a poly-ethylene-butylene block at the center and polystyrene blocks at each end. It has a solubility parameter range of 7.7– 9.4 (Shell Chemical Co. 1995, 34-36). As table 2 shows, the solubility parameters of the aliphatic solvents used are too low to fall within this range. Solvents at the lower end of this range dissolve the elastomer blocks at the center but not the polystyrene blocks at each end. This result can produce a mixture of high viscosity or merely swelling, in which case Kraton G1650 forms into a gel. If one does not want to use any aromatics, however, Kraton G rubbers can be dissolved in aliphatic hydrocarbon solvents if there are approximately 50% of naphthenics in the solvent. Of the aliphatic solvents used, only Shellsol D40 and D70 have 45% of naphthenics, and they dissolved Kraton G1650 reasonably well. Furthermore, the addition of resins can lower the viscosity of mixtures with solvents at the lower end of the range (Shell Chemical Co. 1995, 36-37). Although not extensively tested, Kraton G1650 dissolves best in Shellsol D40 and D70 if it is added after the Regalrez is dissolved. 4 DISCUSSIONThe tests indicate that the tack is caused by the nature of Regalrez 1094 and not by the solvents or other additions. A recent product data sheet issued by Hercules gives Regalrez 1094 a Tg of 33�C (Hercules 1998c). The Tg measured by de la Rie and McGlinchey (1990, 168) is 43.8�C. The difference may be due to the methods used or to a change in the product. As we found, 33�C is also the temperature at which Regalrez 1094 gets tacky. Nevertheless the Tg alone is not enough to explain why a polymer is sticky at a certain temperature. Long molecules, intermolecular forces such as hydrogen bonds, and cross-linking are among the most important reasons many polymers with an even lower Tg are not sticky at 33�C (Horie 1994). Conversely, Regalrez 1094 has small molecules and few intermolecular forces, and it does not cross-link. These characteristics probably explain its tackiness at a relatively low temperature. A varnish that gets tacky around 33�C might not be a serious drawback for paintings if the varnish is not touched and if the painting is kept in a climatecontrolled room. On the other hand, Horie (1994, 18-20) states that the effective Tg is much lower when measured over a period of one year or more. This finding means that dust pickup could result even with temperatures below 33�C. Dust pickup is actively taking place on the bed discussed at the beginning of this article, even though the temperature in the room has never reached 33�C. From these observations it seems that Regalrez 1094 is not a suitable top finish. To benefit from the good qualities 5 POSSIBLE USE OF REGALREZ 1126 IN FURNITURE CONSERVATION5.1 CHARACTERISTICS OF REGALREZ 1126Apart from their molecular weight, the three highest molecular weight grades of Regalrez—1126, 1128, and 1139—are chemically identical to Regalrez 1094 and produced a varnish that did not get tacky when touched (table 3, nos. 10-12). Until now these grades have never been tested for conservation purposes. Because the molecular weight of 1126 is closest to 1094, we decided to explore its benefits. Regalrez 1126 dissolves more slowly in nonpolar solvents, is more viscous, and retains its solvent a little longer than Regalrez 1094 (see fig. 1). Nevertheless, when it still contains 16% of the original amount of solvent, the varnish, while soft, is not tacky. 5.2 EXPERIMENTSFor tests, several colleagues kindly provided scrap parts of furniture with heavily crazed and yellowed varnishes that would normally be considered unsalvageable. On these degraded varnishes, several concentrations of Regalrez 1126 were applied and subsequent gloss and saturation were examined. Another important aspect of Regalrez is its compatibility with wax. Wax can be an effective means of lowering the gloss of a varnish, and after having French-polished or varnished a piece, many furniture conservators apply a final coat of wax for this purpose. The irregular crystalline structure of wax tends to scatter light in different directions, producing a surface that is more matte. Because Regalrez has a very hard gloss, it was mixed with beeswax as a matting agent. Finally, several mixtures of Regalrez 1126 with beeswax were tried as a better alternative for the traditional wax-resin finishes, which contain less stable resins such as dammar. 5.3 REGALREZ 1126 FOR SATURATION AND AS A VARNISHA range of 10%, 20%, 30%, and 40% (w/w) of Regalrez 1126 in Shellsol TD was brushed on the degraded varnishes, and the subsequent gloss and saturation were observed and discussed with several colleagues. To explain the term “saturation,” we agreed on these four definitions: 1. The irregular surface of a degraded varnish causes most light to reflect in many directions, thus producing a whitish matte look. A new varnish applied on top smoothes out these irregularities, causing part of the light to be reflected in one angle only while the rest of the light penetrates the varnish layer. 2. A degraded varnish can have many internal voids and fissures, scattering the light both as it passes into the finish and as it returns through the finish after being reflected off the wood surface. Thus the degraded varnish has a somewhat opaque or even crazed appearance. A new varnish that has penetrated and filled the porous structure of a degraded varnish improves the transparency. 3. Degraded varnishes are often only partly bonded with the wooden substrate, so the wood is only partly visible. With the penetration of a new varnish the interface between varnish, and wood can be reestablished so the light gets all the way to the wood. The wood then shows up more vividly. 4. The fibrous surface of the wood is highly irregular and reflects light in all directions. When the new varnish gets through the degraded varnish and penetrates into the wood, there is a comparable refractive index between the now-saturated degraded varnish and the wood itself. Less light will be reflected off the wood, and more light will penetrate into the wood. Of the wavelength frequencies that penetrate the wood, all colors are absorbed except the wood's own color, being a shade of brown in the case of most antique furniture. This results in the absorption of most frequencies, and the wood looks considerably darker after saturation. In the senses defined above, Regalrez 1126 was found to be very effective in saturating degraded varnishes. The low relative evaporation rate of the aliphatic solvent and the low viscosity of the mixture To build up a top varnish, 20-40% (w/w) solutions were found to most workable. Probably because of the low viscosity of the mixtures and the low evaporation rate of the solvent, they flow out very evenly, producing a very smooth surface. A Regalrez 1126 top varnish can have a high gloss, whereas the addition of up to 10% beeswax helps to lower the gloss. The brittleness of the higher molecular weight grades of Regalrez has not been tested. Nevertheless, on furniture even more so than on paintings, it is important to lower the brittleness of Regalrez. Regalrez 1094 without Kraton G1650 is as brittle as dammar, which is far too brittle to be used as a top finish on furniture. De la Rie (1993) showed that adding 10% Kraton G1650 made Regalrez 1094 as resistant to scratching as Paraloid B-72. Thus, when using Regalrez 1126 as a top finish, 10% Kraton G1650 should be added. Adding more Kraton G1650 is not recommended since the elastomer is the less stable component. Schoeler and Stoian (1994) found that the hydrocarbon resin Regalite R91, mixed with 33-50% of the high molecular weight Plexigum PQ610, gave a durable topcoat. Regalite is not as stable as Regalrez because it is not fully hydrogenated. It would be useful to undertake more research into the stability of a combination of Regalrez 1126 and Plexigum PQ610. It is difficult if not impossible to apply a final coat of wax on top of Regalrez because Regalrez immediately dissolves in the solvents present in paste wax formulations. This characteristic makes Regalrez 1126 problematic as a top varnish for privately owned pieces because there is no control over how the piece will be treated. However, one can cover the Regalrez 1126 with French polish or shellac or apply a coat of Paraloid B-72 (in polar solvents) with a brush. This procedure makes it possible to keep a degraded finish, saturate it with Regalrez 1126, and finish it with the more traditional French polish or the more stable B-72. 5.4 WAX-RESINBecause Regalrez is very compatible with waxes, it can be mixed with waxes, such as beeswax. Thus one can prepare a wax-resin finish without having to use the faster-aging dammar. For our purpose, a mixture of Regalrez 1126, beeswax, and white spirit (10:30:60 g, respectively) was brushed on and evened out with a cotton pad, which was dipped in the same white spirit. When the finish was dry, it was buffed up like a normal wax coat. Adding up to 25% of Regalrez 1126 to the beeswax produces a satin gloss comparable to a wax coat. If more is added, the finish starts to behave like a varnish and cannot easily be further buffed up. As explained earlier, the saturation on a piece of furniture is sometimes regained by melting in a new coat of wax with a hot-air gun. The wax-resin mixture described above can give a comparable saturation without having to use any heat on the object. 6 CONCLUSIONSRegalrez 1094 is used in paintings conservation for saturation and as a top varnish. It can also be used for saturation on furniture. Unfortunately, Regalrez 1094 gets tacky by the warmth of one's hand, thus making it less useful as a top finish. The higher molecular weight grade of Regalrez 1126 does not get tacky when handled and forms an alternative in furniture conservation both for saturation and as a top finish for furniture. Regalrez 1126 can produce a very smooth top varnish with a 20-40% (w/w) solution. Moreover, it is very effective in saturating heavily degraded varnishes; usually only a 10% solution or less is needed. Thus it allows conservators to retain varnishes that might otherwise be removed. Shellac or Paraloid B-72 can be applied on top and taken off without affecting the finish. Because most old varnishes on furniture are polar, applying or reversing a film of Regalrez is likely to cause less damage to the Furthermore, because Regalrez is compatible with waxes, Regalrez 1126 is also a good alternative for dammar in wax-resin finishes. Due to the fact that Regalrez easily dissolves when a coat of wax is applied on top, it might not be suitable as a top varnish on furniture in private collections. Saturating a degraded finish, with whatever material, is by definition irreversible because there is no way one could get the material all out again. Saturation should be undertaken only when the finish would otherwise be removed and with the most stable materials. In this perspective, Regalrez is a better alternative than the more traditional materials and methods used in furniture conservation, such as natural resins, furniture reviver, or melting in a new coat of wax. ACKNOWLEDGEMENTSThe author wishes to thank the following people for their useful comments concerning the article: Jaap Boonstra, Marie Laibinis, Gregory Landrey, Ren� de la Rie, and Ren� Smit and Bob Wherry of Hercules. I also wish to thank Maurice Steemers, Bart Gogherman, Marieke Hengeveld, and Jimya Hoevers for supplying scrap parts of furniture and for their help with the tests. REFERENCESCarlson,S. M., and A. P.Schniewind.1989. Residual solvents in wood-consolidant composites.Studies in Conservation35:26–32. Hercules Inc.1998a. Regalrez 1018, 1085, 1094, and 1126 hydrocarbon resins. Product data sheet. January 27. Wilmington, Del. Hercules Inc.1998b. Regalrez 1128 and 1139 hydrocarbon resins. Product data sheet. January 27. Wilmington, Del. Hercules Inc.1998c. Regalrez hydrocarbon resin. Product data sheet. January 27. Wilmington, Del. Horie, C. V.1994. Materials for conservation, organic consolidants, adhesives and coatings. Oxford: Butterworth-Heinemann Ltd. Landrey, G. J., 1990. The use of fluorescent microscopy in furniture conservation. ICOM Committee for Conservation preprints, 9th Triennial Meeting, Dresden. Paris: ICOM. 2:835–39. National Gallery of Art, 1996. Synthetic low molecular weight resins: Europe information sheet. October 31. Washington, D.C. Rie, E. R. de la.1987. The influence of varnishes on the appearance of paintings. Studies in Conservation32:1–13. Rie, E. R.de la.1993. Polymer additives for synthetic low-molecular-weight varnishes. ICOM Committee for Conservation preprints, 10th Triennial Meeting, Washington, D.C. Paris: ICOM. 2:566–73. Rie, E. R.de la, and C.W.McGlinchey. 1990. New synthetic resins for picture varnishes. In Cleaning, retouching and coatings,ed.J. S.Mills and P.Smith. London: International Institute for Conservation of Historic and Artistic Works. 168–73. Schoeler, C. von, and R.Stoian1994. Transparante kunstharzgebundene Retuschen auf historischen Holzoberfl�chen? Lassen sich Untersuchungen zu synthetischen Gem�ldefirnissen auf Probleme der M�belrestaurierung �bertragen und nutzbar machen? Zeitschrift f�r Kunsttechnologie und Konservierung8(1):150–57. Shell Chemicals Co.1995. Kraton polymers for coatings. Product data sheet. SC: 1757-93R. July. Houston, Texas.

Smit, R.1999. Personal communication. Hercules Inc., Rysw�k, the Netherlands. Whitten,J.1995a. Low-molecular-weight resins for picture varnishes.AIC postprints, American Institute for Conservation 23d Annual Meeting, St. Paul, Minn.Washington D.C.: AIC.124–29. Whitten,J.1995b. Regalrez 1094: Properties and uses.WAAC Newsletter17:11–12. SOURCES OF MATERIALSRegalrezHercules Inc. Resin Division 500 Hercules Rd. Wilmington, Del. 19808-1599 www.herc.com/businesses/resins.htm Kraton G1650, Shellsol TD, Shellsol D40, Shellsol D70Shell Chemical Co. Houston, Tex. 77251 Tinuvin 292Ciba-Geigy Additives Division Hawthorne, N.Y. 10532 White spiritKwastex B.V. Postbus 219 7600 AE Almelo The Netherlands n-hexane, xyleneAristoforma–Interchema Postbus 75560 1118 ZP Schiphol The Netherlands AUTHOR INFORMATIONHANS PIENA received his M.Sc. in archaeology at the University of Amsterdam (1992) and his B.A. in the conservation of furniture and interiors at the University of Professional Education (1995) in Amsterdam. Pregraduate internships included work in the furniture conservation laboratories at the Rijksmuseum in Amsterdam and the H. F. du Pont Winterthur Museum in Wilmington, Delaware. Piena is currently the head of wood conservation at the Regional Conservation Laboratory of the Province of Gelderland, where he is responsible for the preventive and active conservation of wooden objects of the 130 museums and 75 historical societies in the region and the training of conservation interns and museum personnel. He was recently appointed as senior tutor for the conservation of furniture at the University of Professional Education in Amsterdam. Address: Gelders Oudheidkundig Contact, Postbus 4040, 7200 BA Zutphen, The Netherlands. E-mail: H.Piena@chello.nl

Section Index Section Index |