ATOMIC OXYGEN TREATMENT AS A METHOD OF RECOVERING SMOKE-DAMAGED PAINTINGSSHARON K. RUTLEDGE, BRUCE A. BANKS, MARK FORKAPA, THOMAS STUEBER, EDWARD SECHKAR, & KEVIN MALINOWSKI

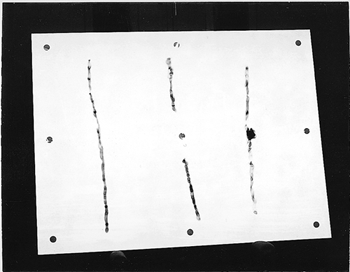

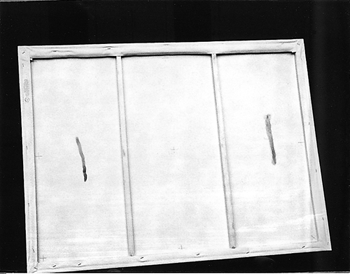

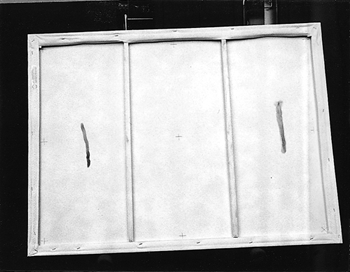

3 3. RESULTS AND DISCUSSION3.1 3.1 CLEANING OF SMOKE STREAKS FROM GESSOThe first test of the large-area treatment capability was performed on a prepared canvas that had been streaked on the front and back with soot from a wax candle flame as described in section 2.1. Figure 1a shows the front side of the prepared canvas with smoke streaks prior to atomic oxygen exposure. After approximately 14 hours of cleaning in atomic oxygen, the smoke streaks were completely removed from the gesso surface, as shown in figure 1b. The rear of the canvas remained untouched, as shown by the comparable photos of the back side of the canvas in figures 2a and 2b. This result demonstrated the ability of the system to uniformly remove soot over a large area and verified that the proximity of the back side to the plate would prevent atomic oxygen from arriving at the unprimed canvas on this side. Exposing canvas directly to atomic oxygen for too long can cause removal of the sizing and weaken the canvas if not shielded from atomic oxygen arrival during cleaning. This outcome has been observed with some long exposures of unprimed canvas. Light cleaning of the stretcher and canvas on the back side could be achieved with a short exposure to atomic oxygen at the start of cleaning the primed and painted side. The cleaning would be achieved by moving the stretcher farther away from the ground plate so that there would be a gap of greater than 1 in. between the stretcher and plate.

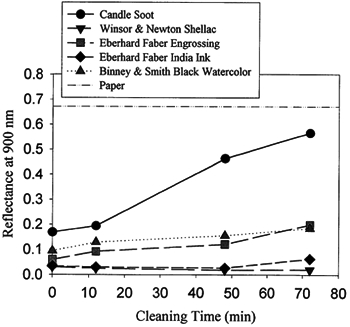

3.2 3.2 CLEANING OF ROY LICHTENSTEIN INK DRAWING ON PAPERThe Lichtenstein drawing proved to be a very difficult test subject for several reasons. Black ink typically contains a carbon pigment, so it was unknown whether the cleaning process could preferentially remove the soot without also removing the ink. Also, the paper appeared to have experienced thermal decomposition, as evidenced by a dark yellowing and browning and an increased brittleness. Therefore, it would probably be difficult to remove this damage from the paper without weakening it. Before attempting to clean the drawing, it was necessary to determine whether soot could be removed more quickly than ink. In order to test this possibility, 1.9 cm wide strips of various types of ink and watercolor, listed in figure 3, were applied to the surface of watercolor paper. A wide soot streak was also applied across the clean paper by passing it over the flame of a wax candle. The reflectance of light provided by a quartz halogen lamp, as described in section 2.3, was then monitored from each type of drawing medium and from the candle soot at various intervals during the atomic oxygen cleaning process. The resulting graph shown in figure 3 indicates that the candle soot is removed much more rapidly than the media tested, and the soot-coated paper is quickly brought back close to its original reflectance, as shown by the dashed and dotted reference line. All the tested media experienced some loss of material after about an hour of cleaning, except for the shellac-filled ink, which appeared to be very durable. This ink probably contains inorganic pigment that would greatly slow down the loss of the carbon in the ink due to reaction with atomic oxygen.

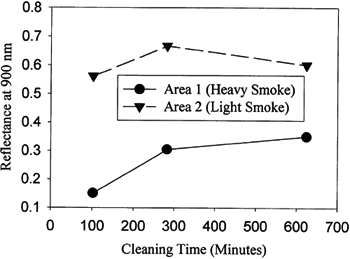

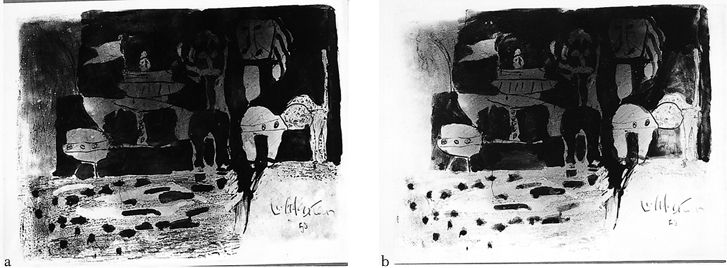

Each soot deposit from a fire will be of different composition according to the nature of the fire and the types of objects burning around the artwork. Therefore it is difficult to accurately determine the reaction rate for a specific drawing or painting. Some careful testing of the surrounding objects, such as a section of the frame, an edge of the painting, and other nearby objects, can give information about how long it will take to remove the soot deposit under the cleaning conditions that will be used. Eventually it is necessary to mask off all but a representative edge of the painting and expose this to atomic oxygen. This procedure will not only give an estimate for the cleaning time but also help to ensure that the pigments are safe for cleaning with atomic oxygen. Because the ink samples tested appeared to be a little more resistant to oxidation than first believed, it was decided to try first to clean an exposed corner of the Lichtenstein drawing, to determine if the paper could be lightened and if the type of media used for this drawing could be cleaned without being removed. The Lichtenstein drawing was masked with a sheet of polyimide Kapton roughly 0.005 cm thick by laying the Kapton over the drawing so that an edge of the drawing was exposed, and then taping the Kapton down to the matting around the drawing. Mylar or other polymer sheeting can also be used as long as it has been tested first to ensure that its reaction products will not transfer onto the painting surface as it oxidizes. After an initial cleaning of approximately 12 minutes, a visual inspection showed some lightening of the surface without affecting the ink areas. The mask was then removed, and the entire surface was cleaned for intervals of 12, 30, and 60 minutes. At this point, cleaning was stopped because it did not appear that the paper background could be lightened further without loss of some of the thinner ink features. At the request of the conservator, we masked off the bulk of the ink areas and tried to further lighten the paper in the upper left corner of the drawing. We again used a Kapton mask, but rolled up the edges of the mask to create a graduated cleaning that would prevent sharp cleaning lines from appearing on the surface. Figure 4 shows the reflected light data from two areas on the paper that were being cleaned, one with a light smoke residue and the other with a much heavier deposit. After a total cleaning exposure of about 300 minutes, there was no noticeable improvement in the drawing. The area still had a light yellow cast, which was likely due to thermal damage of the paper. Figure 5 shows photographs of the Lichtenstein drawing before and after cleaning with atomic oxygen.

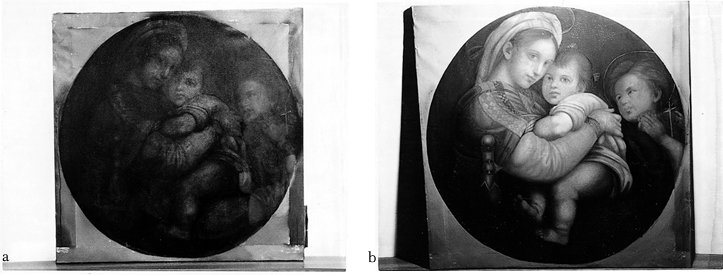

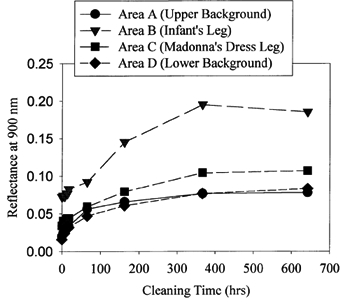

Some of the important lessons learned from the cleaning of this drawing were that areas could be successfully masked for cleaning without creating cleaning lines, and that ink and soot are removed at different rates. 3.3 3.3 CLEANING MADONNA OF THE CHAIRThe Madonna of the Chair painting posed a different type of challenge (see fig. 7a). This work had experienced very heavy smoke damage and some thermal decomposition. Areas of the varnish were charred in appearance. Prior to treatment, several areas were chosen on the painting for reflected light measurement at selected intervals during cleaning in order to determine the end point of the treatment process. The upper and lower background areas were selected because these should remain relatively dark and approximately the same during cleaning. The Madonna's garment was selected because it should clean to a higher level of reflectance than the background. The greatest contrast between the untreated and treated piece was expected to be the reflected light from the infant's leg. Cleaning would be considered complete when a change in the diffusely reflected light from these surfaces would no longer be measurable.

Figure 6 contains the reflected light data for the Madonna painting as a function of cleaning time. After approximately 350 hours, the majority of the darkened varnish was removed from the surface. There were still some thin streaks on the surface. The majority of these were removed after approximately 600 hours of treatment. Treatment was allowed to progress part of the way into the binder in order to remove the damaged portion as much as possible. This extent of cleaning was chosen for this painting because of the severe nature of the fire damage and the desire of the owners to bring the pigment back to the surface as much as possible. The process can be stopped earlier so as to minimize or prevent removal of the binder if desired. At the conclusion of the cleaning, the paint pigment was loosely bound on the surface. Because the atomic oxygen reaction is confined to the surface, it will remove binder that is in between and on top of pigment particles but will leave a small amount underneath that loosely attaches the particle to the surface. This result has been observed with early scanning electron microscope studies of oil paint exposed to atomic oxygen (Rutledge et al. 1994). Because the attachment point is small, it would be possible to remove pigment by mechanical contact with the surface such as brushing. Therefore, with the guidance of the conservator from the Cleveland Museum of Art, a fine spray mist of Grumbacher aerosol dammar varnish was applied to fix the pigment to the surface. A brush was then used to apply a thicker coating of Winsor & Newton dammar varnish over the surface. Figure 7 contains photographs of the Madonna painting as received (fig. 7a) and after cleaning with atomic oxygen and application of varnish (fig. 7b). The details of the painting are now clearly visible.

There is a potential for dehydration shrinkage during the treatment process because it is performed under a partial vacuum. For this painting, there was no deformation observed during treatment. It appeared that if dehydration shrinkage did occur, the canvas, paint, and stretcher shrank at approximately the same rate because no additional cracking beyond that originally present on the painting was observed after treatment. This result may not be the case for every material combination. A risk assessment should be made prior to treatment in this manner to determine if the shrinkage of the base material and the medium are closely matched or not. Paintings on some types of wood may be more at risk. This technique has typically been used to restore severely damaged objects, so the benefit of being able to salvage it has been much greater than the risk of shrinkage. Removal of all of the varnish on the surface and the top layer of binder material is not necessary in all cases. Some fire-damaged works, however, may require extreme cleaning to be restored so they can be enjoyed again. The authors were unable to obtain a photograph of the painting before the fire damage occurred, so it was difficult to determine if there were any shifts in paint coloration due to the treatment process. A number of oil paints have been tested for changes in coloration using reflectance spectroscopy before and after exposure to atomic oxygen (Rutledge et al. 1994). Changes in coloration were not observed for these materials, but they consisted of more modern paint formulations. Caution must be used when treating an untested paint medium using atomic oxygen if the cleaning will progress into the paint layer. A representative corner or edge of the painting that contains most of the paint colors present should be treated using atomic oxygen, with the remainder masked off, so that a determination can be made if this process will be safe for the pigments present. Organic pigments will experience oxidation and removal, so care must be taken during cleaning to minimize their loss. As more testing occurs, a greater knowledge base will be developed as to what types of paints and varnishes can or cannot be treated using this technique. With the proper precautions, atomic oxygen treatment does appear to be a technique with great potential for allowing previously unrestorable art to be salvaged. Further testing of this cleaning technique is being conducted to determine its effectiveness for cleaning smoke-damaged acrylic paintings and watercolors. |