THE TREATMENT OF AN ODILON REDON CHINE COLL� LITHOGRAPH, L'ART CELESTECAROLYN MURPHY

3 TREATMENTBefore the author received the print for treatment, it had already received partial conservation treatment. Records indicated that the object was badly foxed and in need of wet treatment to remove, or at least reduce, the staining in the paper. In addition, the two sheets of paper forming the chine coll� print had become partially separated from each other so that approximately half the chine had lifted completely away from the plate paper. The parts of the moisture-sensitive chine that were delaminated from the plate paper had, over time, expanded and contracted in response to changes in relative humidity so that the chine was no longer planar and could not be successfully readhered to the plate paper in situ. A decision was made to complete the separation of the sheets so that wet treatment and stain removal could more easily be undertaken, and to facilitate full reattachment. The sheets came away from each other easily in a water bath and were successfully washed and light-bleached to remove the staining that disfigured them. After rinsing and partial air-drying, the sheets were pressed between blotters under a sheet of glass. Numerous later attempts at registering the papers for reattachment were unsuccessful, as the papers had expanded and contracted quite differently from one another during treatment. The ink lines on the chine no longer aligned with the corresponding ink lines on the plate paper. In figure 1, the image components that

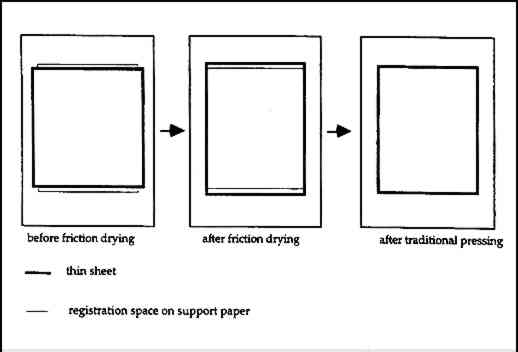

The history of difficulties associated with the reattachment of the print indicated that any procedure involving the use of water would be problematic due to the extreme moisture sensitivity of the chine and plate paper. Despite these difficulties it seemed appropriate to at least attempt readhesion with wheat starch paste, a historically appropriate, and conventionally acceptable, conservation adhesive. This first attempt at readhering the parts of the chine coll� print was based on methods described in the conservation literature (McAusland and Stevens 1979; Petukhova 1987; Burns and Potje 1990; Szczepanowska and Schuettinger 1997). It was hoped that the differences in the hygroscopisity of the two sheets could be used to advantage, through differential humidification, so that image alignment could be achieved while the sheets were damp. Once aligned, the sheets would be immediately adhered together with wheat starch paste. The chine was to be humidified enough so that it would cling to polyester film. In this way it could be fairly easily manipulated to allow registration of the sheets. The plate paper would then be humidified gradually until it registered with the humidified chine. Once alignment of the image was achieved, wheat starch paste would be applied to the humidified chine through a fine-meshed screen to achieve a thin, even film of adhesive. The mesh barrier would also prevent any potential pulling or stretching of the chine caused by the action of a paste brush over the paper surface. Positioning of the chine would then be achieved with the aid of the polyester film carrier. To experiment with and perfect this alignment procedure, mock-up objects were prepared, also with mismatching grain direction. Papers identical to those used to create the chine coll� were not available to the author for experimental purposes. Instead papers were chosen that, as far as possible, matched the object papers' properties: thickness, density, surface texture, grain direction, hygroscopicity, etc. This choice was made qualitatively and was based on an empirical understanding of the properties of the object. Alignment of the two sheets was marked around all four edges with pencil lines perpendicular to the edge of the chine and extending onto the plate paper. The sheets were washed and air-dried a number of times until the pencil marks were out of alignment. The sheets were then differentially humidified, by lightly spraying with water, until alignment was achieved. Adhesive was then applied, and the readhesion process was successfully undertaken. Having achieved reattachment of the mock-up, it was time to attempt reattachment of the Redon print. Since the object papers were not the same as those used in the mock-up, variation in the papers' response to the process was expected. Accordingly the process was altered, as seemed appropriate during treatment, The problem with this original treatment approach was that so many variables were working at the same time that it was impossible to control the process adequately. Different paper thickness, grain direction, and absorbency contributed to the difficulties. Trying to readhere the parts of the chine coll� in one continuous procedure no longer seemed feasible considering the complexity of the object. Instead, it was decided to break the treatment up into smaller, more manageable steps. Alignment of the image was dealt with separately from the reattachment process. 3.1 COMBINATION OF DRYING METHODS USED TO ACHIEVE IMAGE ALIGNMENTThe fibers in a sheet of paper are usually more or less aligned in one direction (the grain direction), due to the nature of the papermaking process. The hygroscopic nature of paper fibers is such that, when wetted, the paper sheet will expand to a greater degree in the cross-grain direction. This effect is magnified in thin dense sheets, such as the chine in a chine coll�, where there is no interfiber space to accommodate this swelling. In some cases a five- to tenfold difference, in expansion of the paper sheet (width to length), can be observed. Accordingly, a dry sheet of paper that is wetted will expand to the extent that it is able, depending on the degree of humidification. In drying, however, the expansion or contraction of a sheet of paper depends on the degree of initial humidification as well as on the method of pressing and the amount of pressure applied. The difference in the nature of the two sheets forming the Redon chine coll� (thickness, density, fiber content, grain direction, surface texture, moisture sensitivity, etc.) made realignment of the image components problematic. Alignment when the object was wet had already proved too difficult to achieve. Because of the greater degree of control that could be achieved in drying, humidification and flattening techniques were used in attempting to manipulate the size and shape of the two sheets of paper. First, the plate paper was humidified and pressed between blotters until dry. This preliminary flattening was conducted so that the discrepancy in size between the two sheets could be more easily assessed. Although there was a slight dimensional change in the plate paper, the image components were still significantly out of alignment at all four edges. Next, friction drying was attempted. Both papers were placed between Goretex and damp blotters until judged sufficiently humidified. Each paper was brushed out between sheets of dampened Japanese paper (thin mino)1 and was then pressed between blotters in a screw press to flatten. After friction drying of both papers, the hoped-for alteration in the shape and size of the two sheets had been, at least partially, achieved. Each sheet had expanded considerably more across its grain than with its grain, a result that meant that the registration of the width of the image was now accurate. However, the chine had lengthened to such an extent (approximately 5 mm) that it was now too long by about 2 mm and, though flatter, was still slightly distorted at the bottom edge. The next step in the process was to try to alter the length of one sheet while maintaining its width. The author decided to attempt a reduction of the length of the chine, rather than induce an increase in the length of the plate paper, since the chine was more responsive to moisture. It was hypothesized that by humidifying and pressing, with minimal pressure, it might be possible to induce contraction In summary, the image components were brought back into alignment by utilizing the hygroscopic nature of the paper and the opposing grain directions of the two sheets. The chine was especially susceptible to the effects of moisture and could be fairly accurately manipulated, in increments, through a judicious humidification and flattening procedure. Figure 3 illustrates this process.

3.2 READHESION OF THE CHINE COLL�An attachment process was now required that would not alter the relative size and shape of the two sheets of paper and would allow careful manipulation of the chine during the attachment process, so that the slight distortion at the lower edge of the sheet could be worked out. The difficulties encountered during the previous reattachment attempt indicated that any dampening of the sheets would probably result in loss of image alignment. Accordingly, a nonaqueous readhesion procedure was sought. An attachment method using Klucel G (hydroxy propyl cellulose) in ethanol was devised, tested on a mock-up, and then successfully implemented to readhere the object. The reverse of the chine was coated with 5% w/v Klucel G in ethanol. The adhesive was applied with a squeegee through a finemeshed screen to achieve a thin, even layer. The adhesive was placed in the middle of the screen and squeegeed to the edges of the chine to prevent any adhesive getting under the edges and onto the front of the chine. The paper was peeled off the screen. At the corners, where the object was held to lift it away from the screen, the adhesive layer was disrupted. A brush was used to reapply adhesive to these areas. The adhesive layer was dried with a hair dryer set on low heat. The dry plate paper was then placed on the vacuum suction table on a sheet of blotter. Under suction, the dry chine was positioned on the plate paper. Exact alignment could be fairly easily achieved on the suction table, since the adhesive was not activated until after the image was aligned. When the two sheets were in position, the adhesive, on the reverse of the chine, was reactivated by lightly spraying the face of the object with ethanol. Gradually more ethanol was sprayed over the object until the chine was about half-wet. At this stage the chine began to expand, forming small bubbles as the chine lifted up from the plate paper. It was left under suction, and as it dried out the bubbles went down, aided by gentle burnishing with a septum elevator tool After a few hours the object was checked and found to be dry to touch and fully adhered. The image components were in alignment at all four edges (fig. 4). It was left in the screw press another 3 days and was then transferred to new blotters and placed under one sheet of glass. The following week the object was checked. The sheets were fully adhered, but the object had a concave bowing. This bowing could probably have been rectified through carefully humidifying and flattening the object; however, the author was concerned about any undue introduction of moisture that might upset the newly achieved union between the two sheets. Instead, a more cautious approach was chosen to rectify the problem. The object was left under glass between fresh blotters. Gradually over some months, with periodic changing of blotters, the concavity decreased until the object was flat. |