AN INEXPENSIVE METHOD FOR CONSTRUCTING STORAGE RACKS FOR HANGING ARTIFACTSDAVID LEE COLGLAZIER

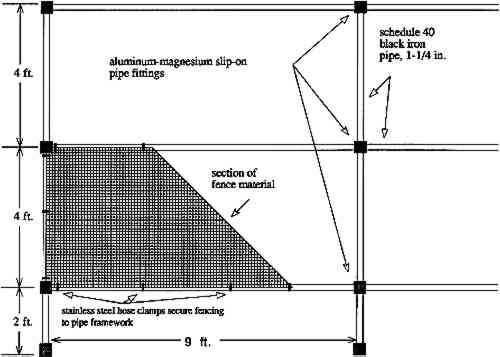

ABSTRACT—An inexpensive method for constructing hanging storage racks uses common iron plumbing pipe, stainless steel hose clamps, welded wire fencing, and aluminum-magnesium alloy fittings. In the fittings, set screws hold the cut sections of pipe together and come in many different configurations for joining angles and pieces, as they are made for several pipe sizes. Rolled fence stock is held to the pipe framework with hose clamps. Assembling the components requires hand tools and some moderate labor for cutting and handling. TITRE—Un Syst�me peu on�reux pour la construction de rayons de stockage des oeuvres suspendues. R�SUM�—Un syst�me peu on�reux de construction de rayons de stockage verticaux utilise des tuyaux de fer ordinaire, des serrejoints en inox, des fils de cl�ture soud�s et des armatures faites d'un alliage d'aluminium et de magn�sium. Dans ces installations, un syst�me de vis fixes permet de maintenir les segements des tuyaux ensemble: ces am�nagements sont r�alis�s selon plusieurs configurations qui permettent de joindre les angles aux pi�ces qui sont r�alis�es dans des tuyaux de tailles diverses. Les serrejoints servent � maintenir le fil de cl�ture sur la structure en tuyauterie. L'assemblage ne requiert que quelques outils et quelques efforts physiques pour le d�coupage et la manutention. T�TULO—Un m�todo econ�mico para construir barras de dep�sito para colgar artefactos. RESUMEN—Un m�todo econ�mico para barras colgagantes de dep�sito utiliza tuber�a com�n de hierro para plomer�a, abrazaderas de acero inoxidable para managuera, cerca de alambre soldado, y acoplamientos de aleaci�n de aluminio-magnesio. En los acoplamientos, los tornillos fijos sujetan unidas las secciones de tubo y se vienen en muchas configuraciones diferentes para unir �ngulos y piezas, ya que est�n fabricados para diversos tama�os de tubos. El material enrollado para cerca se sujeta al armaz�n de tubos con abrazaderas para managuera. Para armar los componentes requieren herramientas de mano y algo de mano de obra para corte y manejo. 1 INTRODUCTIONAre you looking for an inexpensive way to construct some vertical storage racks on which to hang artifacts? I have a method using wire fencing, black iron plumbing pipe, stainless steel hose clamps and some readily available aluminum-magnesium (Al-Mg) fittings. I have created a number of large panels of metal fencing grids upon which I have hung framed items and flat artifacts. If you can hang something on a normal wall, it can be hung on these racks. 2 DESCRIPTION OF RACKSA horizontal and vertical frame is made from the black iron plumbing pipe. It is then covered with commonly available welded steel wire fencing. The fencing comes in different grid sizes and different widths. One-hundred-ft. rolls of 4-ft. wide fencing worked well for creating 8-foot high panels. For my project I raised the bottom horizontal pipe about 24 in. off of the floor for artifact safety. Two more horizontal pipes at 4 ft. intervals were placed above this bottom pipe. These

The Al-Mg fittings are used to hold the pipes together. The fittings come in many different angle combinations and slip over the pipe sections. Allen head set screws in the fittings grip the pipe to prevent the fittings from sliding. Planning your frame in advance is helpful since stringing Al-Mg fittings onto the pipe is easy, but tedious if you have to add more after your system is partially built. However, there are some split fittings that can be added later. The fittings are bright finished and remain that way with indoor use. Once the frame is erected and secured, the fencing is applied to it. The wire fencing I have used is made of thick wires, 14 gauge (0.064 in), American Standard Wire Gauge, that are welded at each vertical and horizontal intersection and galvanized before welding. A 100-foot roll of 48-in. wide stock weighs 162 pounds. I have used 4-ft. wide fencing, which is why the horizontal pipes are spaced 4-ft. apart. A 1″ � 1″ grid fencing is used to give me the finest grid for use with “S” hooks. A small grid gives one more latitude in hanging points, allowing one to fill a panel with different objects. Fencing can be found in larger grid sizes, if one has all large artifacts to hang. 3 CONSTRUCTING THE RACKSThe fencing comes in rolls for easy transport, but needs to be unrolled for cutting and application to the pipes. The fencing wants to remain rolled, so you will need to roll it out on a floor surface, curved side down, and walk on it to help flatten it. Two people are needed to hang and secure the top edge of the fencing to the upper horizontal pipes. Stainless steel hose clamps go around the pipe and the fence wire edge. Several clamps can be loosely attached as Objects are secured to the fencing with “S” hooks or snap-eyes with hooks. A good hardware store or home center will carry a selection of “S” hooks and snap-eye combinations. They come in a variety of sizes and materials. Many are galvanized steel or other weather resistant alloy including bronze and stainless. Larger hooks work well with larger grids, but may be difficult to engage in a 1-in. � 1-in. grid. Try them before you buy and ask about bulk quantity pricing. The storage racks that I have seem very stable with regards to the materials. They have been in place for 23 years and show no signs of corrosion. The black iron pipe comes with an unknown coating on it. I have not seen it react with anything. The fencing, stainless hose clamps and Al-Mg fittings are left natural. The fencing can be found with a galvanized surface or with a green PVC coating for nicer gardens. The PVC should be avoided. Artifacts or the fence can be padded if there is a need to protect or pad objects. It is up to you to choose the protective materials that are compatible with your artifacts. You can attach materials to the fence with nylon cable ties. Buy these in bulk from a home center or commercial electrical supply house. You may find lots of other uses for them. (They may become a strong competitor for “duct tape” as the craftsman's friend.) The Al-Mg fittings come from two major sources listed below. They encompass a variety of common plumbing pipe sizes from � in. to 1� in. pipe and are intended for construction of hand rails. Hollaender's latest catalog shows special fittings that can be used for erecting shelving units. It also includes some engineering information about pipe spans and strength of materials. I spaced my uprights 6–8 ft. apart when I made the first racks. I could climb on the finished rack when it was new, as an informal test of strength. (If I tried that now, I'd probably hurt myself.) If the engineering tables and/or the concept is too daunting, a carpenter or someone with building skills should be able to put some of these racks together for you. The systems is inexpensive enough that it can be over-built a bit. The work will require two people for the pipe cutting, fence handling and erection of the components. Black iron pipe comes in 21-ft. lengths from the supplier. A full piece of 1� pipe will weight about 44 pounds. It can be cut to length by the supplier for a cutting charge. I have a Ridgid pipe cutter that cost about $100. It has paid for itself and given several people some good exercise. A small pair of double action chain cutters is useful for cutting the fencing. I go back later with a large pair of diagonal cutters (side nipping wire cutters) and trim the cut wire ends. A file can be used to round off any sharp edges that are created. A “T” handled Allen drive tool is useful tightening the set screws in the Al-Mg fittings. The extra few dollars for one with a wire or “T” plastic handle will be appreciated and speed the operation. Also, a nut driver will be useful for tightening the stainless hose clamps. This means that you should make sure that the clamps have a hex drive nut or a hex/slotted drive nut. Good tools make the job go faster. The resulting rack is not beautiful, but it is inexpensive and strong if you use welded heavy wire fencing and follow the engineering data. If you have little money and some good labor, you can create a lot of hanging storage surface area with this off-the-shelf system that uses common components. You'll get some exercise, too. SOURCES OF MATERIALSAl-Mg fittingsHollaender Manufacturing Company, 10285 Wayne Ave., P. O. Box 156399, Cincinnati, Ohio 45215–6399, (513) 772–8800 or (800) 772–8800. Kee Industrial Products, Inc., P. O. Box 207, Buffalo, N. Y. 14225–0207, (716) 896–4949 or (800) 851–5181 AUTHOR INFORMATIONDAVID LEE COLGLAZIER apprenticed in Washington, D. C. for 10 years before becoming the only conservator at Old Sturbridge Village in 1972. In addition to being the conservator for a small town he has worked actively in the New England Conservation Association and the New England Museum Association. Address: Old Sturbridge Village, 1 Old Sturbridge Village Rd., Sturbridge, Mass. 01566.

Section Index Section Index |