ULTRASONIC MISTING. PART 2, TREATMENT APPLICATIONSCAROLE DIGNARD, ROBYN DOUGLAS, SHERRY GUILD, ANNE MAHEUX, & WANDA McWILLIAMS

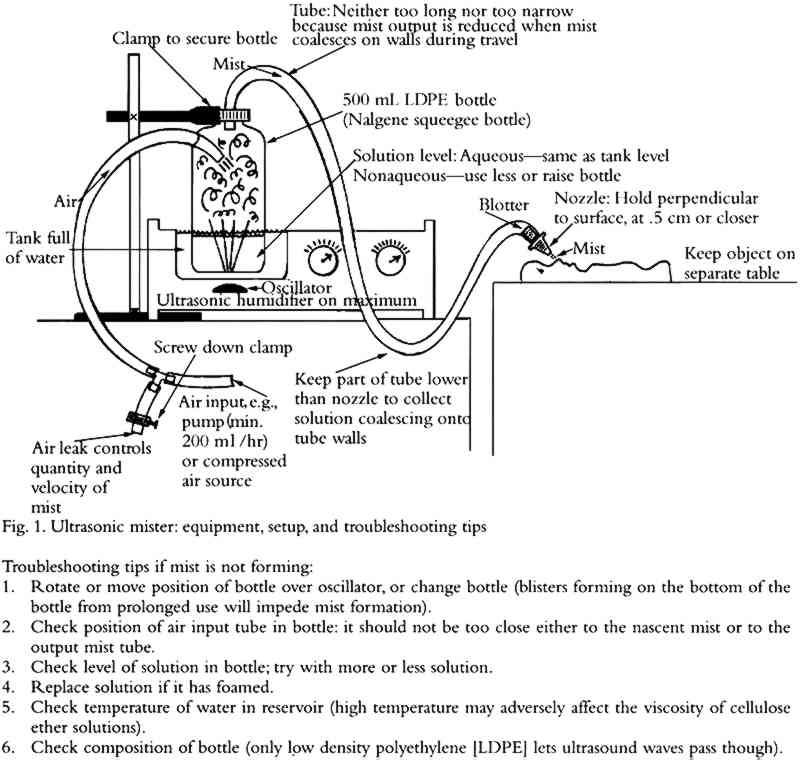

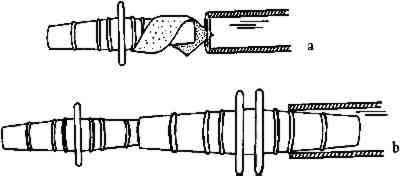

2 EQUIPMENT, SETUP, METHOD, AND MISTING SOLUTIONSThe setup of the ultrasonic mister equipment is uncomplicated (see fig. 1, which also contains troubleshooting tips). Modifications to this basic setup, such as the addition of a small solution input hole in the shoulder of the bottle or an air input assemblage to improve the mist via air circulation, have been found to be effective (Michalski et al., forthcoming). The original mister incorporated a local extraction system over the handpiece to draw away overspray mist that might deposit on areas adjacent to the treated area (Michalski et al. forthcoming); however, the compact reducer-connector nozzle handpiece is in practice more manageable and popular (fig. 2). For the treatment of paper objects, the suction table is often used in conjunction with the mister because it aids in the containment and drying of the misting solution and reduces the risk of surface deformation during treatment.

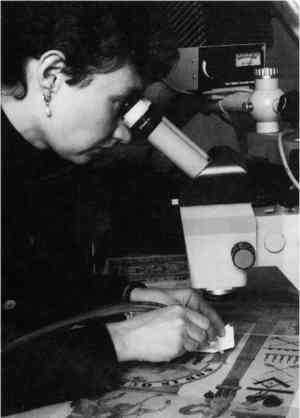

The method of applying the ultrasonic mist differs from spraying in that the nozzle is kept stationary over the object as the solution wets and penetrates the powdery layer. Only when the area is fully saturated with consolidant solution, but just before it starts to flood, is the nozzle moved to the next area to be treated. In practice, this means that the nozzle is moved very slowly across the area being treated. During wetting of the paint layer, darkening will usually occur because of the optical changes due to the presence of solvent. This darkening usually disappears after drying, but a spot test prior to the treatment is recommended. Full wetting and saturation are important because the consolidant must penetrate the paint layer down to the substrate; otherwise, only partial consolidation may occur. Treatment strategy using the ultrasonic mister usually involves successive applications of a solution of dilute concentration. The consolidant is allowed to dry, and color change, gloss, and adhesion are monitored between each application. Only nonviscous solutions can be misted. Solutions that are known to mist are listed in table 1. TABLE 1 SOLUTIONS KNOWN TO MIST One drawback to the delivery of consolidant with the mister is that mist may deposit on the walls of the tubing or the nozzle and form a drop, which can inadvertently land on the object and cause a stain or disturb the position of

When using misting solutions containing organic solvents, it may be safer to use tubing that resists solvent extraction, such as platinum-cured silicone tubing (Williams 1995). While there is no possibility of the mist becoming contaminated with extractables from the tubing, the droplets that deposit on the tubing walls may become contaminated. |