AN ECONOMICAL DESIGN FOR A MICROCLIMATE VITRINE FOR PAINTINGS USING THE PICTURE FRAME AS THE PRIMARY HOUSINGLAURENT S. G. SOZZANI

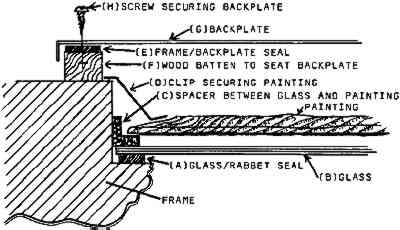

7 DESIGN PLAN AND MATERIALSThe basic materials mentioned here are available in most countries. If a particular component is unavailable, another similar material can be substituted. Often, sealants, gasket material, and framing attachments can vary from vitrine to vitrine due to the structure of the particular frame or painting. Nevertheless, the basic design (fig. 3)—adding glass and a backplate to a frame, sealed to create an airtight package that encloses a painting within its frame—remains constant. The success of the design depends on properly sealing the system, eliminating the possibility of air exchange with the outside.10

7.1 FRAME RABBETThe frame rabbet should be carefully examined and evaluated for possible leakage. A solid, flat, rabbet poses no problem for sealing the glass. Open corner joins, splits, and insect holes, however, should be filled and sealed with a good proprietary wood filler or silicon seal material. If a frame is badly insect-damaged or otherwise porous, the entire rabbet can be covered to seal it. This procedure can be done easily and quickly using a proprietary aluminum or polyester self-sticking tape. As an alternative, an aluminum or polyester film prepared with a heat-set adhesive can also be used. Marvelseal 360A, an aluminum polyethylene laminate prepared with BEVA 371 as the adhesive, is a good combination for this purpose. 7.2 SEAL BETWEEN GLASS AND FRAME (A)Closed-cell neoprene, felt fabric lightly impregnated with microcrystalline wax, or any of a variety of proprietary self-sticking gasket materials that are relatively dense, impermeable, and neutral in color are suitable for use. If the frame rabbet is uneven or out of plane, a thickened silicone-rubber mold material can be carefully applied to the rabbet and pressed flat by the glass during curing. The silicone-rubber will conform to the space between the glass and rabbet, forming a custom seal. After curing, any excess can be easily trimmed from the front along the edge of the sight opening and from the back along the edge of the glass. 7.3 GLASS (B)The Rijksmuseum uses Schott Mirogard Protect Magic Glass, type 22.1, a nonreflective, glass-acrylic-glass laminate for both aesthetics and safety. (Noviflex: GE Coated Safety Glass, first quality, has also been used.) 7.4 SPACER BETWEEN GLASS AND PAINTING (C)As in normal glazing practice; L-shaped wood or cork can function both as a spacer and to hold the painting in the proper sight position. Felt added to the spacer will protect the picture from abrasion. 7.5 CLIPS HOLDING THE PAINTING (D)Spring clips, bent brass plates, or wood, cork, or foam blocks in different variations have been used. (Note: With the exception of the air-tight sealing of the glass, after the clips are inserted, the painting is framed as with normal glazing.) 7.6 BACKPLATE SEAL (E) WITH OR WITHOUT WOODEN BATTENS (F)This step both seals and seats the backplate to the frame. As with the glass-to-frame seal (section 7.2), it is important to create an airtight fit. A variety of options are available. As illustrated in figure 3, thin wooden battens are generally used to seat the turned-over lip of a metal backplate (G). The battens can be as thin as necessary to seat the backplate or adjusted in thickness to increase the depth of the frame rabbet to accommodate a thick or cradled panel. The battens must be sealed overall to the frame back and to each other at their corners. Silicone or acrylic seal materials are suitable for this purpose. Custom-shaping the undersurface of the wooden battens can level any slight unevenness of the frame back. As an alternative or for a very uneven or rough frame back, silicone rubber mold material can be used between the battens and frame to create a good seal, following a procedure similar to that in section 7.2. If available, a dense, impermeable gasket material of the proper thickness can be substituted for the wooden battens to both seat and seal the backplate. 7.7 BACKPLATE (G)At the Rijksmuseum, 1-mm-thick sheet metal with the four edges bent over 3 mm to a 90� angle for added rigidity is being used most often. Stainless steel, galvanized steel, or aluminum are all suitable. These are made to order at a local sheet metal shop. Other options for the metal plate include wood, acrylic sheet, polypropylene channel plate, and Fome-Cor covered on one side with Marvelseal 360. Backplate material should in any case be impermeable to long-term moisture. If the edge of the material is not sufficiently rigid, it is advisable to use L-shaped metal trim over the edges to increase the rigidity, thereby reducing the possibility of warping and subsequent air leaks. Figure 4 illustrates four of the many possible options for attaching different backplates. The backplates are attached to the wooden batten or frame back with wood screws (H). As a rule of thumb the screws are never more than 10 cm apart. |