AN ECONOMICAL DESIGN FOR A MICROCLIMATE VITRINE FOR PAINTINGS USING THE PICTURE FRAME AS THE PRIMARY HOUSINGLAURENT S. G. SOZZANI

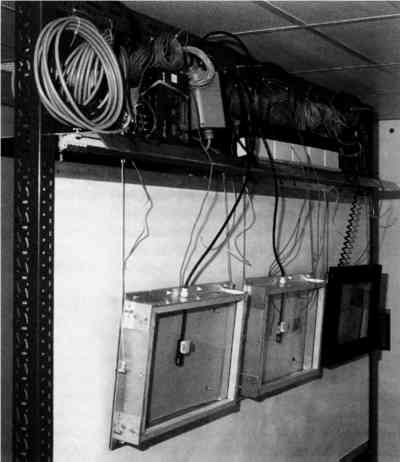

5 TESTING THE DESIGNFrom 1992 to 1994 testing was carried out in Amsterdam at the Central Research Laboratory for Objects of Art and Science (CRL)3 in collaboration with the Rijksmuseum, Amsterdam, and the Mauritshuis, The Hague. The goal was to evaluate the mechanics and viability of microclimate vitrines as protection for panel paintings. The research was also designed to compare the effectiveness of the wooden picture-frame vitrine with the more commonly used Bosshard inert, insertable box design. A poster presented at the International Institute for Conservation 15th International Congress held in Ottawa, Canada, in 1994 gave details of the experimental setup and was published in the poster preprints (Wadum et al. 1994). A synopsis of the testing, results, and conclusions follows. 5.1 EXPERIMENT SETUPTwo microclimate vitrine designs were tested. The first was the wooden frame design, the type used in the Rijksmuseum and presented in this article. The second type, constructed following the Bosshard design, used an aluminum box as the housing for the painting. This vitrine design was in use at the time at the Mauritshuis (Wadum 1992). An array of the two microclimate vitrine types was created, each assembled with different internal configurations that accounted for specific variables—empty or with a wooden panel and/or with silica gel.4Figure 2 depicts a partial view of the climate room at the CRL. Three of the six microclimate vitrines as assembled for testing are visible. The internal volume of each

Six vitrines at a time were hung in a climate room (specially constructed at the Central Research Laboratory for this type of testing) and subjected to 18 week-long sessions of controlled cycles of varying temperature and/or relative humidity.5 RH and temperature sensors attached to data loggers were positioned at locations inside and around the vitrines. 5.2 SUMMARY OF RESULTSWith constant temperature and fluctuating relative humidity (30–70%) in the ambient environment, there was no effect on RH or temperature within the microclimate vitrines. Conversely, with cycles of fluctuating temperature (10–30�C) and constant RH, both the temperature and the RH fluctuated inside all boxes, regardless of the contents. (In vitrines containing silica gel, however, the RH fluctuation was minimal in the vicinity of the silica gel.) Temperature changes inside the boxes quickly followed outside temperature changes. In the wooden frame vitrines that were empty or contained only a wooden panel, and in the aluminum vitrines that held only a wooden panel, RH values rose and fell in correspondence with increases and decreases in temperature. In an empty aluminum vitrine, however, the opposite occurred: as the outside temperature rose, the inside RH dropped and vice versa. In both types of vitrines, when a panel and silica gel were inside, RH remained stable behind the panel where the silica gel was located, whereas fluctuations were recorded in front 5.3 DISCUSSIONNormally, as recorded in the empty aluminum vitrine, a rise in temperature in a closed, inert environment leads to a lowering of RH. The rise and fall in RH with a corresponding rise and fall in temperature in the vitrines either made of wood or containing wooden panels (and no silica gel) indicates that the wood gives off some of its moisture with a rise in temperature (drying) and absorbs moisture when the temperature is lowered. In the presence of silica gel, the moisture given off by the wood with a rise in temperature will be absorbed by the silica gel as the silica gel reacts to the change in RH thereby maintaining its preconditioned RH. Due to the response of silica gel, in a period of sustained, elevated temperature, the wood can continue to give off moisture that in turn, is absorbed by the silica gel. The consequence is a greater potential for dimensional change in the panel, precisely what one seeks to minimize by employing a vitrine.6 In contrast, under the same conditions of elevated temperature within a vitrine, in the absence of silica gel (or other RH-activated buffering material), the wood itself will quickly reach an equilibrium with the surrounding internal atmosphere after having exchanged only an inconsequential amount of moisture. The following data support this result:7

With a rise in temperature from 10�C to 30�C, the air will reach a moisture content equilibrium with the addition of 0.063 g of water (0.090–0.027 = 0.063). This change in moisture content results from moisture being released from the wood; it is recorded as a rise in RH in vitrines containing a panel. This additional moisture, if released entirely by the panel, is equal to only 0.18% of the 36 g of water contained in the wood panel at 20�C. More realistically, with a less dramatic rise in temperature, from 20�C to 30�C, the panel would release 0.041 g of water, a mere 0.11% of the 36 g of water in the panel at 20�C. Further, with a fall in temperature from 20�C to 10�C, the air will lose 0.022 g of water (0.049–0.027 = 0.022). This amount is equal to only 0.07% of the 36 g of water in the wood panel at 20�C. These exchanges in moisture between the wood and the air may be recorded as large changes when measuring RH within the closed space of a vitrine, but the amounts of water involved are actually quite small and will result in little or no substantial dimensional change in the panel painting. Minimizing the air space within the microclimate box will reduce the capacity for moisture exchange and hasten an equilibrium between wood and air.8 It is also probable that additional temperature-regulating hygroscopic material, such as the exposed wood at the inside of the frame or the addition of wood or other cellulosic materials (such as museum board placed behind the painting), will reduce the overall burden of moisture loss and uptake by the wood panel. This observation appears to be confirmed in current research at the Central Research Laboratory on the mechanics and materials of backing boards on canvas paintings.9 Preliminary testing of various backing board materials indicates that the more hygroscopic the backing board the greater the overall buffering effect. 5.4 SUMMARY OF CONCLUSIONS OF THE MICROCLIMATE RESEARCH PROGRAM

|