WAX COATINGS ON ETHNOGRAPHIC METAL OBJECTS: JUSTIFICATIONS FOR ALLOWING A TRADITION TO WANEDANAL L. MOFFETT

3 PRESENT TREATMENTIncralac is the trade name of a lacquer manufactured using Acryloid B-44 (methyl methacrylate copolymer), which can be solubilized readily in acetone, toluene, xylene, and dichloromethane, as well as in a number of solvents less commonly used in the conservation field (Horie 1987). Removal of the microcrystalline-polyethylene wax blend coating would not be as straightforward. Although the natural waxes were used early on in conservation treatments, the synthetic waxes are now more favored by the field; they are generally more neutral and stable and are unfettered with free fatty acids. Of the synthetic variety, microcrystalline and polyethylene waxes are most commonly employed. Semisynthetic by-products of petroleum, microcrystalline waxes are derived from the same source as paraffin but, as the name suggests, have a structure that allows for a considerable increase in plasticity; they are highly branched and irregular molecules. Moreover, these materials can hold other waxes in suspension, a characteristic that aids in the manufacture of smooth polishing pastes. Polyethylene waxes are made from the polymerization of ethylene gas derived from petroleum. Structurally, they vary little from paraffin and are usually white, translucent, hard, and tough. In the last two decades, attempts have been made to reverse wax coatings with varying success. Treatments have focused on the application of solvents or heat or, in some cases, a combination of the two. Boiling water was suggested by Organ and Shorer (1962), but Johnson (1984) tested this approach and found it to be ineffective. The application of cold solvents is not always successful; hot solvents used in quantity pose health and safety risks, and consequently this approach may be unrealistic for large objects or for mass treatment of numerous artifacts. Johnson (1984) proposed the use of commercial solvent cleaning systems that employ a hot liquid wash, a hot vapor wash, or a combination of the two. These methods have yielded good results in industry but require commercial equipment that may be impractical for the treatment of individual objects.

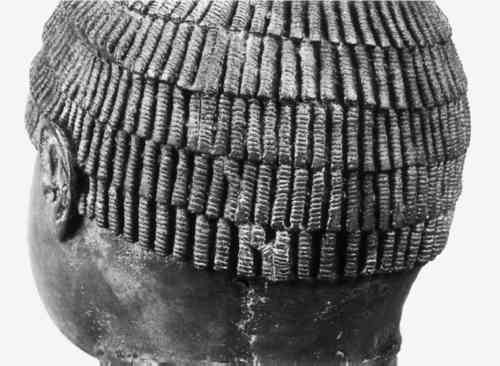

Organ (1970) advocated the use of a Soxhlet extractor for wax removal on small pieces and a Fuller's Earth–toluene poultice for treatment of larger objects. The latter technique has been modified more recently by Dove (1989), who suggested poulticing a waxed surface with a polyvinyl acetate emulsion and diatomacious earth pack; heat is added by placing the poulticed object in an oven with the temperature set just above the melting point of the wax. The molten coating is successfully absorbed In the case of the Benin head, the above treatments were discounted for various reasons. Poulticing techniques, reported to be the most successful, were rejected due to concern that the pack material would remain in the deep and intricate sculpting of the hair and face. Moreover, total poulticing of the metal surface under gently elevated temperatures posed the problem of control during cleaning; it would be impossible to keep an eye on the condition of the surface—important, as noted above, for aesthetic reasons—beneath the poultice. Heating large quantities of solvents without specialized equipment was felt to be unsafe, and industrial solvent cleaning systems were deemed financially impractical for one object. Consequently, an attempt was made to try to reverse the coatings with cold solvents. As noted above, Renaissance wax is a mixture of microcrystalline and polyethylene waxes (Plenderleith and Werner 1971; Horie 1987), both of which are slightly soluble at room temperature in naphtha, xylene, and toluene (Warth 1956). It seemed possible and practical that one could remove both the lacquer and the wax with the same solvent, at one time, and toluene was tested in a small area using cotton ball applicators. Visual assessment, a slight discoloration of the cotton, and a change in the appearance of the surface suggested that at least some wax was removed with this method, and as a further test a portion of the head was immersed in a toluene bath for several hours. The unexpected result of this trial treatment, on evaporation of the solvent from the “cleaned” surface, was a brittle, translucent white residue tenaciously adhered to the treated area. This material was totally insoluble in toluene at room temperature (fig. 3).

Regarding the exact nature of this residue, it seemed probable that the white waxy material would be one of the two components of the Renaissance wax. This assumption was substantiated by FTIR analysis; the spectrum closely matched that for polyethylene wax, and there were no signs of remaining Incralac or microcrystalline wax (Hopwood 1992). The differing results obtained in the two trial cleanings may be explained by molecular weights—that of microcrystalline wax is lower than that of polyethylene wax. Although they are both reportedly soluble in toluene at room temperature, only the microcrystalline wax, because of its lower molecular weight, was completely reversible with extended immersion; the polyethylene wax was not. In the first trial, the added mechanical action of swabbing may have aided in the apparent removal of both waxes. After conversations with various industrial chemists, a literature search, and trials with a number of solvents, it was found that hot (82�C) xylene (Warth 1956) would successfully remove the white flakes of polyethylene wax. As a safety precaution, only small quantities (150 ml) of xylene were heated within a fume hood to the desired temperature, and then the heated solvent was applied with cotton swabs to the affected surface. This procedure worked well to remove the white flakes. An unanticipated benefit of the treatment was the removal of a vivid yellow substance, which was identified as carboxylic acid by FTIR (Hopwood 1992); this organic acid is likely to be residual from the coating removed during the 1984 treatment. After the polyethylene flakes were eliminated, the problem of removing the wax and lacquer from the rest of the object remained. For several reasons, the same hot solvent application was believed to be the best method for completing treatment of the object. First, heated xylene seemed to clean the surface more deeply than cold solvent, as evidenced by extraction of the residual carboxylic acid. Moreover, in a comparison of areas cleaned by the two methods, the surface treated with hot xylene appeared to be cleaner. With repeated applications of solvent, swabbing could proceed until no yellow discoloration was detected; this standard could serve as a gauge for completion |