PHYSICAL AND MECHANICAL PROPERTIES OF ALBUMEN PHOTOGRAPHSTIMOTHY VITALE, & PAUL MESSIER

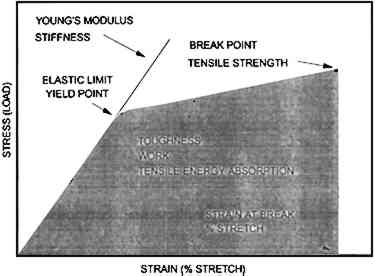

2 EXPERIMENTAL DESIGN2.1 SAMPLE PREPARATION2.1.1 19th-Century PrintsThe three 19th-century albumen prints used in this study are typical examples of the mature albumen printing process used between the mid-1860s and the 1890s. They have a moderate to high sheen and appear to have been coated with albumen by large-scale, commercial manufacturers. Mounted prints samples were removed from mounts through aqueous immersion. They were thoroughly dried prior to testing. 2.1.2 Unsized Cotton Paper (Paper Base)The paper was an unsized sheet composed of 91% cotton fiber and 9% kraft and bleached wood pulp. It was a machine-made, wove paper. Six samples were used. 2.1.3 Experimental Albumen PrintsThe three prints for this study were made to simulate the 19th-century process. A cotton paper base was used unsized for the base of the experimental albumen prints and the albumen/paper composite. Although contrary to 19th-century practice, the unsized paper was used to focus the experiment more precisely on the interaction 2.1.4 Albumen/Paper CompositeThe three composites of paper and albumen were created by soaking the washed cotton paper for 30 minutes in a tray of the albumen. The saturated sheet was hung from a corner and allowed to air-dry for 2 days. 2.1.5 Unsupported Nonsensitized AlbumenTwo types of unsupported albumen “bars” were fabricated: five with internal microfissures and cracks using the Blanquart-Evrard method (Reilly 1980) and five crack-free using the Towler plate method (Towler 1864). These bars were approximately 0.2 in. wide and 0.05–0.1 in. thick. Casting albumen into a film or bars proved to be very difficult. As albumen dries, it shrinks massively and cracks in most situations. The drying process for the Blanquart-Evrard method albumen with 1.86 M NaCl (Reilly 1980) on a smooth polyester base shows the growth of salt crystals, which force crazing in the coating. Following crazing, large cracks formed in the sample. The Towler plate method with 0.06 M KI (Towler 1864) and multiple frothings, shows similar salt crystallization behavior. Drying the equivalent salt solutions (no proteins) produced crystal patterns related to the 0.06 M and 1.86 M salted albumen solutions. Albumen coatings on glass and unsupported bars made using the Towler plate method (1) with 0.06 M KI (Towler 1864) and (2) with no salt of any type show no crystal growth patterns and few cracks. The Towler plate method involves prolonged frothing (one cycle only) of the salted or unsalted albumen, placing all froth and liquid in a clear glass bowl and covering the surface of the foam with an unsized, thin paper cap cut to the circumference of the foam surface (paper touching edge of bowl). When the foam has shrunk from the liquid surface and the paper is crusty (approximately 2 days at 50% RH), the liquid can be carefully drained from the bowl. The coatings made on glass microscope slides can be made to crack massively if temperature and humidity are cycled or held at low relative humidity for prolonged periods. The crack-free albumen bars made using the Towler plate method remain stable under these same conditions. High shear frothing (3 minutes on low speed in a kitchen blender) using the Blanquart-Evrard method with 1.86 M NaCl salted albumen, with approximately 2 weeks of room temperature fermentation (inoculation by leaving outdoors), produced bars with microfissures The crack-free bars used for mechanical testing were made using the Towler plate method with 0.06 M KI (Towler 1864). The development of a casting method required considerable experimentation and persistence. During the drying process, if the shrinking albumen was in any way impeded, the sample would shatter. Casting was attempted using a Teflon mold. Results were very poor: all casts dried with severe cracking and were unusable. A bed of mercury was added to the Teflon mold: the albumen would not form into bars but formed misshapen islands on the mercury with the edges defined by the Teflon walls. Finally, molds were made by cutting troughs in silicone grease. This method allowed the albumen to shrink virtually unimpeded and the drying bar to deform its surroundings rather than meeting the resistance of rigid walls. The method also had the advantage that the dried samples could be carefully excavated from the molds by removing the surrounding grease. Residual grease was removed with petroleum benzine. It was impossible to sensitize the albumen bars without them breaking into chips. Upon wetting, the bars broke apart into chips of approximately the same size, 1–1.5 mm in diameter. 2.1.6 Unsupported, Sensitized AlbumenChips of sensitized Blanquart-Evrard method bars were used in the humidity and water swelling experiments. Aside from sensitization, the chips were toned, fixed, and washed as described above for the experimental albumen print. 2.2 MECHANICAL ANALYSIS2.2.1 Equilibrium Stress-Strain ProtocolTests were performed using a tensile strength test bed designed and built by Mecklenburg (1988). The paper-based samples were strained at a rate of 0.0025 in./minute. Unsupported albumen was strained at 0.00025 in./minute. The stepwise, slow rate of strain allows the load to be evenly distributed throughout all parts of the sample before measurements are taken and a new strain applied. Strain is applied, and the resulting stress is measured until the sample fails. This mechanical analysis protocol has been designated equilibrium stress-straining (Mecklenburg 1988). Measurements were taken at 20.5 � 0.5�C) and 50% (� 2%) relative humidity. Paper-based samples were measured in both the machine direction (MD) and cross-machine direction (CD). Generally three repetitions of each sample were made, with the exception of the paper base, which was repeated six times. Essential information generated by stress-strain data include: Young's modulus, tensile strength, yield point, percent stretch, and work. Figure 2 indicates the various mechanical properties on a typical stress-strain curve for an unsized cotton paper. The slope of the initial linear portion of the stress-strain curve is known as Young's modulus. This is a region of elastic behavior, where strain-induced changes are recoverable. When in this region, the material will return to its original size and shape when the load is removed. Young's modulus is a measure of a material's stiffness. The yield point is the point at which load begins to cause irreversible deformation and marks the transition between recoverable and permanent deformation. Strain builds until failure occurs. Percent stretch is the strain at failure, times 100. The stress at failure is the tensile strength. The total area under the stress-strain curve is an indication of a material's toughness. This area

2.2.2 Ultrasonic ImpediometryTo determine the mechanical properties of unsupported albumen, ultrasonic impediometry was used, with the assistance of Donald Hunston, Polymers Division, National Institute of Standards and Technology. The first reflection from a 5 MHz quartz rod transducer was used to determine shear modulus. The face of the transducer was oriented so samples could dry flat on the face and the shock wave would travel through the thickness of the sample. The albumen was applied in solution and dried on the horizontal transducer face. Measurements were made continuously during drying. Only one run is reported because it was the only sample to reach completion intact. Three other runs were similar and confirmed the accuracy of the measurement. Initial runs showed that the shear modulus increases up to approximately 3,500,000 psi, and then the layer cracked. As the sample continued to dry past this halfway point, it peeled away from the surface and acoustic contact was lost, causing loss of signal. After some experimentation, a small piece of Kimwipe was dropped on the top surface of the drying albumen. This reinforcement did not affect the shear modulus of the albumen oriented normal to the transducer face. The fact that the intermediate shear modulus peak was 1,131,000 psi (Young's modulus = 2,640,000 psi) and well within the range of initial samples proved that adding reinforcement out of plane to the shock wave had no effect on the signal. The reinforcement did, however, prevent cracking and the loss of signal. The sample took approximately 30 minutes to dry. After peaking at approximately 15 minutes, the modulus decreased to a steady state in equilibrium with the room humidity, which was approximately 40% RH at approximately 21�C. Shear modulus is calculated using the equation E = 2G(1v), where E = Young's modulus, G = shear modulus, and v = Poisson's ratio and assuming a Poisson's ratio for albumen of 0.33 (based on similar figures for plastics and related protein polymers). Density of the native egg white (unsalted) was calculated to be 1.663 g/cc. 2.3 MEASUREMENT OF EXPANSION WHEN WETAll samples were immersed in water and had their in-plane elongation measured. The three examples of each modern sample were measured three times each. Five historical albumen prints were measured three times. Once thoroughly wetted, the paper-based samples were removed from the deionized water and quickly measured. Nine individual unsupported albumen fragments were measured three times each. They had a tendency to dissolve when fully immersed in water. Therefore, they were wet and measured in situ under a Leitz component measuring microscope. Measurements were taken within 30 seconds of exposure to water; thereafter the samples swelled into a shape that could not be measured accurately. 2.4 MOISTURE SORPTION-DESORPTION BEHAVIOR OF ALBUMEN PRINTS AND COMPONENTSPaper-based samples were placed in a sealed humidity chamber. Three samples of each material were measured three times at each stage; the entire experiment (1 month) was not repeated due to time constraints. The relative humidity was precisely controlled through the use of a General Eastern dew point hygrometer and a custom-made apparatus designed by Timothy Padfield, formerly of the Conservation Analytical Laboratory, Smithsonian Institution. The hygrometer controlled the amount of moisture added or withheld until the desired relative humidity was achieved. Conditions were maintained through continuous monitoring. Conditioning time at each relative humidity measurement point was 24 hours. Temperature was controlled externally and remained at 20�C � 0.5�. The samples were measured to the nearest 0.01 in. 2.5 SORPTION-DESORPTION BEHAVIOR OF UNSUPPORTED SENSITIZED ALBUMENTen unsupported, sensitized, randomly oriented albumen chips were placed on a rigid support. The chips were measured in length and width five times each. A clear glass Petri dish was inverted over the samples. Silicone grease was used to create an airtight seal between the base and the inverted Petri dish. Small dishes of saturated salt solutions were placed in the chamber. The various salts had the effect of conditioning the air within the sealed chamber to specific relative humidities. Since the Petri dish was transparent, measurements could be made with the chamber sealed. The albumen fragments were measured with the Leitz component-measuring microscope. The fragments were measured first at 50% RH, because those were the conditions in which they were dried. Temperature remained at 20�C � 0.5�. Twenty albumen fragments were used for this experiment. Conditioning time at each relative humidity was 24 hours. The average dimensional change for these twenty fragments was calculated for each measurement point in the relative humidity cycle. Swelling and shrinkage were highly variable. A few samples showed a maximum change of 30%, while others showed a change of approximately 10%. The experiment was repeated three times to confirm the dramatic results and the variability of the change. |