CONSOLIDANT DISTRIBUTION IN DETERIORATED WOOD TREATED WITH SOLUBLE RESINSARNO P. SCHNIEWIND, & PETER Y. EASTMAN

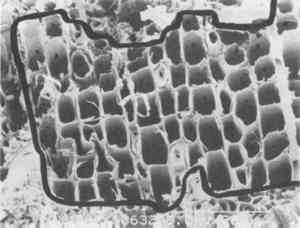

ABSTRACT—Scanning electron microscopy was used to study the distribution of synthetic resin consolidants after treatment of deteriorated wood samples by vacuum impregnation. These resins included Butvar B98, Acryloid B72, and Butvar B90. After the samples had been completely saturated with consolidant, evidence of resin could be found throughout cross sections taken from them, although examination of the samples showed that the resin was not uniformly distributed. Most strikingly, some tracheids could be observed to have heavy deposits of resin, which in some cases completely filled the cell lumen, while adjacent tracheids contained little or no resin. The percentage of earlywood tracheids with visible resin deposits in a given sample area was then used as an indicator of resin content. Results showed that there was greater concentration of resin in the surface layers of radial or tangential faces than in the specimen core, as well as a tendency toward increasing concentration toward the end surfaces. 1 INTRODUCTIONOne of the factors that can be expected to significantly influence the performance of consolidants used for treating detcriorated wood is their distribution within the wood structure following treatment and removal of the solvents. In porous stone, for example, reverse migration of soluble synthetic resin consolidants can take place during the drying phase following impregnation (Domaslowski 1988). In this process, consolidant solution flows in bulk toward the surface, and the solvent evaporates there, leaving behind a high concentration of consolidant in the surface layers. Such uneven distribution of consolidant may be undesirable. In wood, fluids can move either by bulk flow or by diffusion. Diffusion can take place by movement of vapor through the void structure or by transport of adsorbed fluid within the cell walls (Siau 1989). In drying wood from the wet state, as it is in the living tree, the major part of moisture movement takes place in the form of diffusion (Arganbright 1989). Bacterially degraded wood typically has increased permeability due to degradation of pit membranes (Blanchette et al. 1990), which would lead to increased amounts of bulk flow. Even in normal wood, bulk flow can have significant consequences, as, for instance, in the development of seasoning stain in redwood (Anderson et al. 1960). In this case water-soluble extractives are carried to the surface where the water evaporates, leaving the extractives behind, causing objectionable patterns of discoloration on the surface. It was therefore desired to determine, by making a microscopic study of consolidant distribution, whether similar phenomena take place during solvent removal following treatment of deteriorated wood with thermoplastic synthetic resins in solution. 2 MATERIALS AND METHODSThe material for the present study was taken from matchstick-size specimens that had previously been treated with consolidants by vacuum impregnation and then subjected to static bending tests in a study of consolidant effectiveness (Wang and Schniewind 1985). The material was taken from the outer layers of Douglas fir foundation piles that had been in the ground for approximately 70 years and had In addition, three specimens treated with 20 wt% solution of Butvar B90, two in a 40/60 mixture of ethanol and toluene (90.ET.H) and one in ethanol (90E.H), were examined. Finally, one specimen treated with a 5 wt% solution of Butvar B98 in a 40/60 mixture of ethanol and toluene (98ET.L) was included in the study. The specimens were examined in a Hitachi S-2300 scanning electron microscope (SEM). Initially both cross sections and split radial sections were to be examined, but it was found much more difficult to locate consolidant resin in the radial sections. Accordingly, the examination was confined to cross sections. It was found that the brash fractures that occurred during the previous static bending tests made excellent surfaces for examination. These fractures had taken place at approximately midlength of the 3 � 3 � 50 mm bending specimens. Since wood is known to be more permeable along than across the grain, it wassuspected that a substantial amount of drying would take place from the end surfaces, possibly leading to differences in the longitudinal distribution of consolidant. To study this possibility, closely spaced serial sections were desired. It was found that by using specially constructed clamping devices that held all four sides of the 3 � 3 mm sticks, one half-length of bending specimen could reliably be broken into six pieces, each approximately 3.5 mm in length. Brash fractures were encouraged by drying the specimens in a desiccator and scoring the tension and the two side surfaces with a razor blade to a depth of 1 to 5 cell diameters at the desired fracture section. The 3.5 mm lengths were smoothed at one end to obtain a level contact surface. They were mounted on an SEM specimen stub with colloidal carbon. The samples were then dried and sputter coated with gold. They were viewed in the SEM with an accelerating voltage of 8 to 15 kV at various magnifications. Systematic measurements were made on prints taken at a magnification of 200� of an area of earlywood as close as possible to the center of the cross section (core position) and another area close to the surface (edge position) and within the same growth ring. Occasionally the area near the surface had to be selected from an adjacent growth ring. The examination was confined to earlywood, because the latewood tracheids were too seriously degraded and distorted for analysis. On each of the prints used for analysis, a sample area of earlywood was marked out. Depending on ring width, cell size, and image clarity, this area contained from 30 to 139 tracheids, the average being 85. The number of tracheids containing solid plugs of resin in the lumen and those that had a thick lining or sleeve or resin in the lumen were counted and expressed as a percentage of the total number of tracheids in the sample area. An example of such a marked sample area is shown in figure 1.

Although plugs and sleeves of resin were counted separately, the combined percentage of all tracheids containing obvious amounts of resin was used for analysis. Statistical analysis was carried out using Statgraphics software and a personal computer. 3 RESULTS AND DISCUSSIONAll of the specimens examined showed that the earlywood appeared to be substantially intact, while the latewood showed severe cell

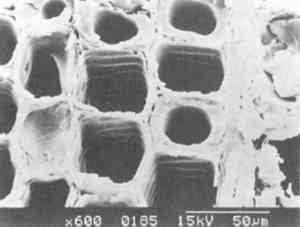

The most striking finding of the SEM examination of specimens treated with consolidant was that many tracheids contained little if any resin, while others showed either solid plugs or thick inner sleeves of consolidant (fig. 3). Note that in the empty tracheids the spiral thickenings are clearly visible, while no such markings are shown on the inner surfaces of the resin sleeves. Some plugs had smooth, concave surfaces, suggesting that there were bubbles in the resin. Since most of the samples had been treated with a 20 wt% solution of resin, and since there had been evidence that complete saturation with consolidant solution had been achieved during vacuum impregnation (Wang and Schniewind 1985), it would have been expected that on average about 12–14% of the void space in the wood be filled with consolidant. (These values are less than 20% because the resins have higher density than the solvents.) That most tracheids were empty shows that considerable bulk flow of solution must have taken place during drying, resulting not so much in a uniform flow toward the specimen surfaces but rather a migration toward and deposition in certain tracheids. These tracheids could then serve as loci for further resin deposition and solvent vapor diffusion.

There did not appear to be any qualitative differences in the observed pattern of resin distribution that could be attributed to either type of resin or type of solvent, or even concentration of consolidant solution. However, it was noted that in Acryloid B72 the plugs or sleeves of consolidant almost always failed in the same fracture plane as the wood, while in Butvar B90 or B98 tubes of consolidant, identifiable by the spiral thickenings molded on their outer surfaces, could sometimes be seen protruding from the fracture plane. An extreme example of such protrusions is shown in figure 4. These protrusions may be due to higher tensile strength of the polyvinyl butyral, which would allow the sleeves or plugs to be broken at a weak point distant from the overall fracture plane. Since Butvar B98 has been shown to have adhesive qualities comparable to Acryloid B72 in acetone and much superior to B72 in toluene (Sakuno and Schniewind 1990), lack of adhesion of the Butvar resins is not a likely explanation for this phenomenon.

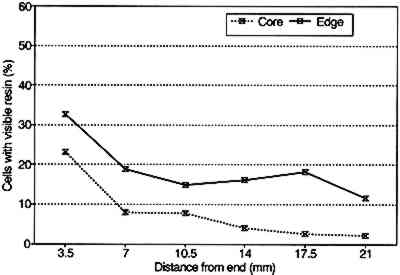

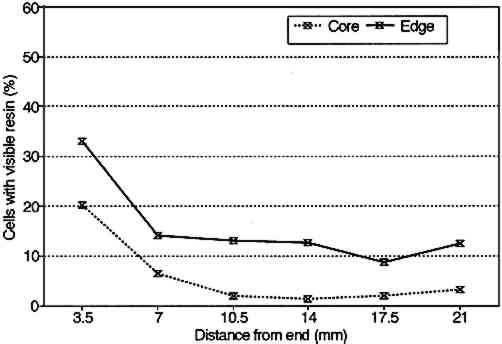

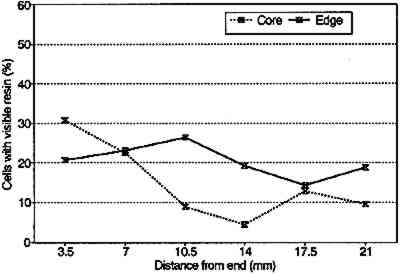

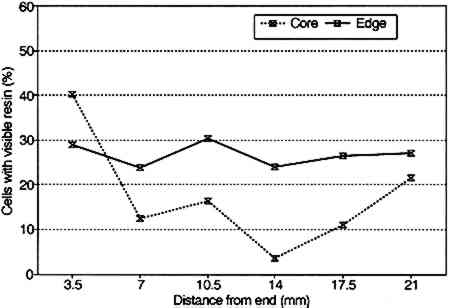

The tracheids containing plugs or sleeves of resin appear to be scattered irregularly throughout the wood structure, and visual examination of cross sections did not reveal any obvious distribution patterns. Plots were made showing the percentage of plugs and sleeves in sample areas near the surface and at the core as a function of distance from the end. Average plots for Acryloid B72 and Butvar B98, each for two different solvents, are shown in figures 5–8. It must be emphasized that the percentages given refer to the relative number of tracheids containing significant amounts of resin and are not measures of actual resin content.

The general trend seen in figures 5–8 is for more tracheids near the edge of the cross Average values of the data that form the basis for figures 5–8 (i.e., the data for B72 and B98 excluding B90 and the one specimen treated with a 5 wt% solution of B98) are shown in table 1. Averaged over all treatments and positions, 15.9% of the earlywood tracheids contained visible consolidant. Average loading (i.e., gravimetrically determined resin content) was 29.4% for B72 in acetone, 32.2% for B72 in toluene, 28.2% for B98 in ethanol, and 31.8% for B98 in ethanol-toluene mixture. (Resin loading is a function not only of solution concentration but also of the porosity of the material being treated, so that solution concentration alone is not indicative of the resin loading that can be achieved.) The loading was therefore substantially the same for both resin types, but specimens treated with B72 had much lower percentages of earlywood tracheids containing visible resin as compared to those treated with B98. Solutions of B72 probably tend to migrate to selected tracheids more effectively owing to their much lower viscosity as compared to solutions of B98. The concept of more resin in fewer tracheids in the case of B72 is supported by the observation that the ratio of plugs to sleeves was much greater for B72—1.01 and 0.72 in acetone and toluene, respectively—as compared to B98—0.17 and 0.07 in ethanol and ethanol-toluene, respectively. The type of solvent appeared to have less of an effect. TABLE 1 PERCENTAGE OF EARLYWOOD TRACHEIDS WITH RESIN ACCORDING TO TREATMENT AND LONGITUDINAL AND LATERAL POSITION For longitudinal position, table 1 shows that the location closest to the end of the specimens had by far the greatest percentage, 28.6%, of tracheids with consolidant. All of the interior positions had much smaller percentages, ranging from 10.6% to 16.1% but not in steadily decreasing order from the end to the most interior position. Lateral position within a given cross section indicates a substantially greater percentage of tracheids with visible resin near the cross section edge as compared to the core. The data were subjected to an analysis of variance and associated statistical tests. The results of the basic three-way analysis of variance are shown in table 2. All of the main effects—treatment (resin-solvent combination), longitudinal position, and lateral position—were found to be statistically significant at better than the 1% level. Tukey multiple range tests showed that effect of treatment was due to resin type alone, solvent type showing no statistically significant effect. However, while B72 in toluene was significantly different from B98 in either of its solvents, B72 in acetone differed significantly only from B98 in the ethanol-toluene mixture. The significance of longitudinal position was entirely due to the high percentage of tracheids with resin at the end position. All other longitudinal positions were not significantly different from each other. All the findings are reflected in the 95% confidence limits in table 1. Where the intervals overlap, the differences are not statistically significant, whereas significant effects are characterized by intervals that do not overlap. TABLE 2 ANALYSIS OF VARIANCE FOR TREATMENT AND POSITION EFFECTS No statistical analyses were made for the specimens treated with B90, but the results for the few specimens examined were similar to those for specimens treated with B98. The one specimen treated with 5 wt% B98 in ethanol-toluene also showed a similar pattern of migration, but since the loading was only 7.5%, there were far fewer tracheids with visible resin. The results have shown that there is consolidant migration during solvent evaporation by bulk flow from the interior toward specimen surfaces. Since there had been conclusive evidence of complete saturation of the material with consolidant solution, incomplete penetration during treatment is clearly ruled out as a factor. There is also internal migration to selected tracheids, so that in earlywood the consolidant appears to be concentrated on average in only 16% of the total number of tracheids. Since in the case of B72 the polar acetone that is adsorbed by wood and causes substantial swelling gives nearly the same results as non-polar toluene that does not swell wood, the diffusion of solvent vapor appears to take place through the porous structure rather than by diffusion through the cell walls in the form of solvent vapor bound to internal sorption sites. One can only speculate as to why the consolidants become concentrated in selected tracheids. One possible explanation might be that the resins form chemical complexes with tannins or decomposition products within the wood that initiate precipitation of resin in particular locations. It is not clear whether plugs and sleeves extend over the entire length of tracheids. In some cases plugs could be seen in association with bubbles, so that plugs and sleeves may alternate in the same tracheid. Some protruding sleeves and plugs were quite long, up to 1.3 mm, suggesting that if resin is present it extends over the entire length of the tracheid. Completely uniform consolidation treatments may not be possible, either because complete penetration by consolidant solution cannot be achieved or because of a certain amount of reverse migration, as observed in the present study. In either case there will be more consolidant near the surface than in the interior, and this type of nonuniform distribution can be quite desirable in some instances. A greater concentration of consolidant in the surface layers will, for instance, improve surface hardness and abrasion resistance and will also result in greater improvement of bending strength as compared to a uniform distribution. The latter comes about because the surface layers contribute disproportionately to the resistance against flexural loads. Some degree of reverse migration can therefore be beneficial and a valuable attribute of the treatment in particular circumstances. ACKNOWLEDGEMENTSAppreciation and thanks are due Julie Trosper, who assisted with this project as a volunteer. Discussions with S. L. Quarles and T. G. Rials of W. W. Wilcox were very helpful and are gratefully acknowledged. REFERENCESAnderson, A. B., E. L.Ellwood, E.Zavarin, and R. W.Erickson. 1960. Seasoning stain of redwood lumber. Forest Products Journal10(4):212–18. Arganbright, D. G.1989. Drying processes. In Concise encyclopedia of wood and wood-based materials, ed.A. P.Schniewind. Cambridge, Mass.: MIT Press. 92–97. Blanchette, R. A., T.Nilsson, G.Daniel, and A.Abad. 1990. Biological degradation of wood. In Archaeological wood, properties, chemistry, and preservation, ed.R. M.Rowell and R. J.Barbour, Advances in Chemistry series 225. Washington, D.C.: American Chemical Society. 141–74. Domaslowski, W.1988. The mechanism of polymer migration in porous stones. Wiener Berichte �ber Naturwissenschaft in der Kunst4/5:402–25.

Sakuno, T., and A. P.Schniewind. 1990. Adhesive qualities of consolidants for deteriorated wood. Journal of the American Institute for Conservation29:33–44. Siau, J. F.1989. Fluid transport. In Concise encyclopedia of wood and wood-based materials, ed.A. P.Schniewind. Cambridge, Mass.: MIT Press. 112–17. Wang, Y., and A. P.Schniewind. 1985. Consolidation of wood with soluble resins. Journal of the American Institute for Conservation24:77–91. AUTHOR INFORMATIONARNO P. SCHNIEWIND is professor of forestry, emeritus, at the University of California, Berkeley. He holds a Ph.D. in wood technology from the University of Michigan and has been associated with the University of California Forest Products Laboratory since 1956. His research and teaching have dealt with the mechanical behavior of wood and wood-based materials, and since 1982 he has been active in the application of wood science to the conservation of wood artifacts. He was recently editor of the quarterly journal Wood and Fiber Science. Address: University of California, Forest Products Laboratory, 1301 S. 46th St., Richmond, Calif. 94804. PETER Y. EASTMAN is assistant furniture conservator at the Philadelphia Museum of Art. After receiving a B.A. in political science from Swarthmore College, he worked as a furniture restorer and conservator in Berkeley, California, for over a decade. In the fall of 1990 he entered the M.S. program in wood science and technology at the University of California, Berkeley, and was employed at the Forest Products Laboratory as a graduate student researcher, working with Arno P. Schniewind, until 1992. He has completed his course work and is writing his M.S. thesis. Address: Philadelphia Museum of Art, P.O. Box 7646, Philadelphia, Pa. 19101.

Section Index Section Index |