FILLS FOR BRIDGING STRUCTURAL GAPS IN WOODEN OBJECTSPAUL S. STORCH

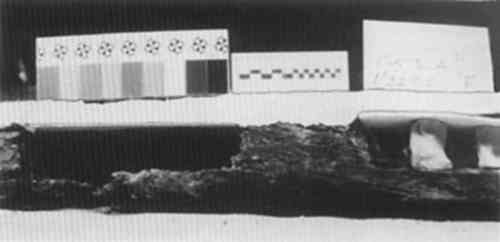

ABSTRACT—The use of room temperature vulcanizing (RTV) silicone resin as a flexible gap filler for restoring structural integrity to the components of a wooden architectural object is explained. The advantages of using an RTV for this type of fill are its compatibility with a flexible structure consisting of wood that responds to changing environmental conditions. The method of consolidation prior to the structural fill insertion is also described. 1 INTRODUCTIONCracks and surface gaps in wooden objects have been filled with various materials to restore surface integrity. Waxes are the traditional choice, since they are inert, easily reversed, and can be color matched to the surrounding surface. The main drawback with wax fills is that they do not expand or contract with the hygroscopic movements of the wood and can become dislodged. Epoxies have also been utilized as fillers, as well as being used as consolidants for rotted structural members in buildings (Phillips and Selwin 1978) and more recently as a fill material in weak wood with a low modulus of compressibility (Barclay and Mathias 1989). Since they cure by chemical reaction and soak into the wood fibers themselves, epoxies should be considered irreversible. It is granted that, in some cases, their strength is required and the principle of irreversibility is modified by the necessities of the treatment, as was thoroughly discussed by Barclay and Mathias (1989). The use of soda lime borosilicate glass microspheres mixed with Acryloid B-72 as an easily reversible void-filling compound in moisture-sensitive wooden objects has been presented by Hatchfield (1986). For architectural members that may be exposed to moderate stresses during exhibition or use, conservators have utilized the type of silicon-based polymers referred to as room temperature vulcanizing (RTV) silicones as a fill material when infilling cracks in surfaces (Fogle 1987; Barclay and Grattan 1987; Grattan and Barclay 1988). The RTVs, which are available in proprietary formulations, are chemically known as dimethyl siloxanes and cure by the emission of either methyl alcohol (alkoxy curing, noncorrosive) or acetic acid (acetoxy curing, corrosive). RTV silicones are available at most hardware stores and stores specializing in lacquer and adhesive products. The RTVs chosen for this treatment project were Dow Corning single-component RTVs 734 and 738 due to their availability, ease of application, and the author's previous experience with them as mold-making materials for large metal objects. RTV 738 may be obtained in a clear, white, or black coloration. The RTV used here was the clear type. RTVs have a compression modulus less than that of most wood, are stable for at least 10 years when used outdoors, do not penetrate into the wood fibers, and are easily reversed by mechanically pulling them out of the gap. They are available in both gel and self-leveling (flowing) viscosities, and the viscosity may be adjusted by adding glass microballoons or The acetoxy curing 734 is used as a surface coating only. In this application, 734 does not present a problem since there is no contact with metal. During work, the ventilation in the lab was adequate to remove vapors as they were produced. The 738 is applied from a tube using a caulking gun. The 734 comes in a can and can be applied with a spatula. This material is thinner and fills in the irregularities in the surface of the thicker, more puttylike 738. Similar products such as General Electric 1200, the Silastic series of RTV rubbers made by Dow Corning, and the RTV-M series made by Wacker-Chemie of Germany were not examined in this project. The GE product, which is acetoxy curing, was not appropriate in this application. The latter two silicones are two-component systems developed for mold making (West 1985). They are used in applications thinner than that needed in this situation. A systematic comparison of different caulking silicone RTV products with various fillers was beyond the scope of this project. Such a study was undertaken by Grattan and Barclay (1988), who described the details of the different products. Their conclusions support the choice of fillers described above. The filling methods described above have been used for gaps and cracks in a surface where the fill did not have to support its own weight. The problem to be solved here was how to adapt a reversible, lightweight fill material such as RTV silicone to bridge a structural gap. 2 TREATMENT METHODfigure 1 shows the object that required the structural fills. It is one of a pair of doors that constitute a large gate structure. Attributed to Spanish Colonial period manufacture in south central Texas during the late 18th or early 19th century, the doors were recovered from a historic farmstead south of San Antonio in 1986.

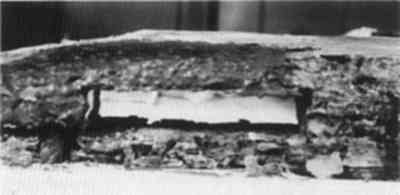

The door designated gate A (fig. 1) sustained advanced decay, especially on the right side, as it had been stored outdoors with the right side resting on the soil surface. The construction method is tongue and groove, with the side and crossbeam tongues held together with wooden pegs. Several of the edges of the grooves had broken off, exposing 2–3 in of the tongue of the spacer block. Since the goal of the conservation treatment of the doors was to stabilize them for display in a vertical frame, restoring structural integrity to the grooves was necessary to prevent the spacer blocks from pushing out when the doors were set upright. Bridging the gaps required several steps. Since the wood in the gap margins was decayed and friable, consolidation was carried out with a 5% g/l solution of Butvar B-98, a polyvinyl butyral resin, in denatured ethanol and butanol (Barclay 1981; Wang and Schniewind 1985; Sakuno and Schniewind 1990). Two to three coats were applied until the areas were satisfactorily consolidated. Next, a flat support surface consisting of a piece of four-ply mat board covered with silicone release paper was positioned in the gap areas supported by adjustable plasticene pylons (fig. 2). RTV 738 was then applied onto the support, keying the silicone into the wood. The top surfaces of the beam adjacent to the gap were protected from any overlap of the silicone with masking tape.

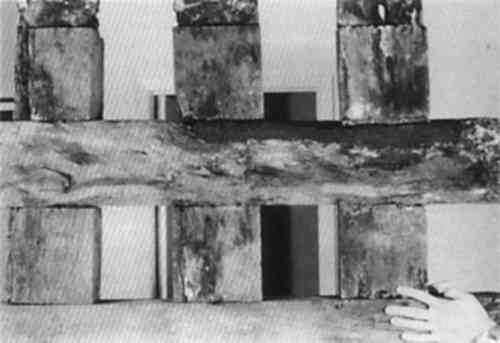

When the fill had dried enough to support its own weight, the board support was removed to allow the fill to cure on all sides. The progress of curing was monitored by inserting a thin metal rod into the center of the fill to test for the presence of uncured resin. When the rod can be removed without resin sticking to it, then the cure is complete. The RTV cures best at a relative humidity of 50% and will form a surface skin after 2–3 hours at this RH, according to the Dow Corning product data. For the thickest fill, which was approximately 1.5 in thick, the cure time was about one week under the conditions in the lab. figure 3 shows the bridge fill prior to final finishing. One coating of self-leveling RTV 734 colored with dry earth pigments has been added. The surface was built up another ⅛ in to a texture that blended with the surrounding wood.

Dry pigments were then rubbed into the surface to give a matte appearance. figure 4 shows a completed bridge fill on one of the crossbeams. It now supports the weight of two spacer blocks when held in the upright position. The reverse surface of the beam was also treated in this manner.

3 CONCLUSIONSThe adaptation of an infilling method to bridge structural gaps where flexibility is required has been described and explained. The fill may be easily removed by carefully pulling it back from the wood. A test was performed on a didactic piece of wood prior to treatment. If the wood in the gap margins is extremely weak, this method may not be appropriate. Stronger consolidation with an epoxy may then be needed prior to the filling procedure. The fills are flexible and will allow the wood around them to move in response to ambient environmental conditions without creating additional stresses. SOURCES OF MATERIALSButvar B-98 (Monsanto Corporation)Conservation Materials, Ltd., Box 2448, Sparks, Nev. 89431 REFERENCESBarclay, R.1981. Wood consolidation on an eighteenth century English fire engine. Studies in Conservation26:133–39. Barclay, R. L., and D. W.Grattan.1987. A silicone rubber/microballoon mixture for gap filling in wooden objects. In ICOM Committee for Conservation 8th Triennial Meeting, Sydney. 1:183–87. Barclay, R., and C.Mathias.1989. An epoxy/microballoon mixture for gap filling in wooden objects. Journal of the America Institute for Conservation28:31–42. Fogle, S.1987. Personal communication. Bethesda, Md. Grattan, D. W., and R. L.Barclay.1988. A study of gap-fillers for wooden objects. Studies in Conservation33:71–86. Hatchfield, P.1986. Note on a fill material for water sensitive objects. Journal of the American Institute for Conservation25:93–96. Phillips, M., and J. E.Selwin.1978. Epoxies for wood repairs in historic buildings.Washington, D.C.: U.S. Department of the Interior. Sakuno, T., and A. P.Schniewind. 1990. Adhesive qualities of consolidants for deteriorated wood. Journal of the American Institute for Conservation29:33–44. Storch, P. S.1987. The analysis and conservation of an historic wooden gate. In Recent advances in the conservation and analysis of artifacts, comp. J. Black. London: Summer Schools Press. 257–62. Wang, Y., and A. P.Schniewind. 1985. Consolidation of deteriorated wood with soluble resins. Journal of the American Institute for Conservation24:77–91. West, S.1985. Iridescent pigments, silicone rubbers. AIC Newsletter10(6):18. AUTHOR INFORMATIONPAUL S. STORCH is objects conservator at the Minnesota Historical Society. He received his B.A. in 1978 in anthropology and archaeology at Case Western Reserve University, Cleveland, Ohio, and an M.A. in anthropology and museum studies with a concentration in ethnographic and archaeological conservation from the George Washington University, Washington, D.C. He completed internships at the Anthropology Conservation Laboratory of the Smithsonian's National Museum of Natural History, the National Park Service at Harpers Ferry, West Virginia, and the Texas Memorial Museum, University of Texas at Austin. After graduate training, Storch became assistant conservator of objects at the Materials Conservation Lab, Texas Memorial Museum, where he undertook archaeological field conservation projects, taught undergraduate courses in archaeological conservation, and treated archaeological, ethnographic, and historic objects. He then went to the new South Carolina State Museum to develop that institution's conservation program and serve as the first chief conservator. He is the ditor and publisher of the Leather Conservation News. Address: Objects Conservation Laboratory, Minnesota History Center, 345 Kellogg Blvd. W., St. Paul, Minn. 55102–1906.

Section Index Section Index |