AN EXAMINATION OF THE PATINA AND CORROSION MORPHOLOGY OF SOME ROMAN BRONZESDAVID A. SCOTT

ABSTRACT—The Roman bronze statues of Togati, Roma, and Venus (Demeter) and in the collection of the J. Paul Getty Museum were subject to a detailed technical study. Of particular interest are their unusual, matte, and finely preserved patinas, which closely parallel another bronze, the Nike, in the Cleveland Museum of Art. The bronzes, which date to A.D. 40–68, are described and analyzed and an account of their corrosion is given, drawing on the early work of W. von Geilmann, who examined the corrosion of bronzes from sandy soils in Germany. The patinas of these objects contain substantial amounts of tin oxide and also display warty corrosion. It was postulated, and confirmed by analysis, that patinas of this kind should contain no chloride ions; thus, there are at least two types of warty corrosion of ancient bronzes. The first type, as here, is chemically stable and does not necessarily require strictly regulated humidity conditions. The second type of warty corrosion is related to the presence of chlorides, usually with an accumulation of cuprous chloride. The three bronzes studied here are closely related and are almost certainly from the same burial deposit, as evidenced by their associated soil and minerals. These materials were not completely cleaned from the surfaces of the bronzes, so essential information regarding their origin was preserved. Cleaning during conservation to a uniform “original surface” or “marker layer” would have removed this important evidence. 1 INTRODUCTIONThe aim of this paper is to examine, in detail, the corrosion and patina of some Roman bronzes in the collection of the J. Paul Getty Museum. Strictly speaking, “patina” and “corrosion” are different words for the same surface alteration, but here “patina” will be used to describe a smooth, continuous layer that preserves detail and shape, while “corrosion” is used to describe mineral deposits and surface accretions that do not form a continuous and smooth layer. Patina formation and the corrosion of ancient bronze objects have been the subject of many previous studies, yet there are few detailed descriptions of the corrosion products of ancient bronzes that comprehensively document identity, mode of appearance, and corrosion micromorphology. Corrosion structures encountered in ancient bronze objects have many similarities to morphological processes that occur during the weathering of soils and rocks, yet the descriptive terms available, taken from metallic corrosion, are not adequate to describe the thick, complex mineral layers that are often observed on ancient bronzes. The information that can be derived from mineralogical study of ancient bronzes has a direct impact on the degree to which surface cleaning of such objects can be carried out during conservation. One of the most currently favored and best-informed approaches to their surface cleaning is to examine the object carefully under a binocular low-power microscope and clean the artifact to reveal, if possible, an “original surface.” Such surfaces often retain surface detail derived from the object itself, such as spinning marks, inscriptions, and mold lines from casting. It is possible to find this interface preserved in corrosion products because copper alloys frequently exhibit a layered structure in their corrosion, and one of these layers often preserves surface detail, either in the cuprite, malachite, tin oxide, or other “marker All of the artifacts examined in this paper could have been cleaned skillfully during conservation to a uniform and aesthetic patina layer. Surface cleaning was carried out, but many areas were left uncleaned, and, as a result, much evidence has been preserved that would otherwise have been lost completely. In some cases—the cleaning of coins and inlaid artifacts, for example—uniform mechanical cleaning to reveal detail is highly desirable, but in other cases, mechanical cleaning can directly remove evidence of archaeological association and of the complete history of the events that have occurred to the object since burial. The archaeological conservator has a tendency to clean all bronzes mechanically, especially if they have a good patina layer, without appreciating the destruction of evidence that this process necessarily entails. In accord with the advice of Jedrzejewska, echoed recently by Chase (1993) and Bassett and Chase (1993), the Antiquities Conservation Department of the J. Paul Getty Museum has developed a cautious approach to the conservation of archaeological bronzes. As a result, much associated material is now being left uncleaned in areas of less visual importance to an overall appreciation of the object itself. 2 THE OBJECTS AND THEIR CORROSION2.1 STRUCTUREThe J. Paul Getty Museum houses a small but important collection of classical bronzes, mostly Greek and Roman. Within this collection are three bronzes of Roman origin but otherwise of unknown provenance: Togati, Roma, and Venus (Demeter)(figs. 1–6). These bronzes were reputed to have traveled through the art market from the same source. A fourth bronze, a winged Nike or Victory (Cleveland Museum of Art), was also reputed to have been obtained through the art market from the same source.

The Togati, also known as Relief with Two Togate Magistrates(figs. 1, 2), shows two figures dressed for a patrician ceremony. These bronzes may originally have belonged to a frieze; there is a break along the older man's left side which suggests that the figures could possibly have been continued. Details of dress and clothing suggest many comparisons, as does the hair on the older figure, brushed forward on the neck, as in contemporary portraits of Caligula, Nero, and their contemporaries (Herrmann 1988). The two figures were cast in one piece, with heads downward, as evidenced by being more porous toward the feet (Podany 1988). There is evidence of a riser or vent on the right hand of the proper left figure. The right arm and toga sleeve of the left figure have been cast on, and this area has corroded somewhat differently and is separated in places from the main body by as much as 3 or 4 mm. The pupils of the eyes are drilled and the backs of the figures are left open. The thickness of the bronze varies from 17 mm in the body of the older man to 5 mm in the head of the younger. There are four diamond-shaped marks on the back surface, almost in the center—marks made in the wax, perhaps for registration (Podany 1988). The Roma(figs. 3, 4), which may originally have been a chariot attachment, is shown The Venus(figs. 5, 6) is clad in a long tunic unbuttoned down the left. Over this tunic is wrapped a palla. Venus wears a diadem, and in her left hand she offers a libation from a patera. The details suggest imitation of the high classical Attic style of 430–410 B.C. (Herrmann 1988). Although the dress of the Venus was popular in coinage of the period from A.D. 120–150, the Venus is probably earlier. Herrmann (1988) states that it probably was found with the bronze relief of the Togati, which can be dated confidently to the middle of the first century A.D. Although larger in scale and in higher relief than the Togati, the Venus statuette could have come from a separate composition, but the detail of the drapery is so similar that it appears likely that they were produced in the same workshop. The Venus is hollow, and was direct cast with the head and body integral. Numerous chaplet repairs can be seen, and part of the surface shows the same hexagonal network structure in the patina as the Roma reveals. Voluminous corrosion on the back suggests that the burial environment allowed sufficient space for localized corrosion to develop and for the copper carbonates to be retained on the surface in botryoidal or mammilar form. The Nike, or Victory, in the collection of the Cleveland Museum of Art (fig. 7) is thought to have come from the same locality as the three Getty pieces. Christman (1988) notes that the left arm, right leg, and wings were cast separately from the body, which is hollow, a very similar mode of manufacture to the Venus and Roma. In an ancient restoration the wings were repositioned, further apart from each other and lower.

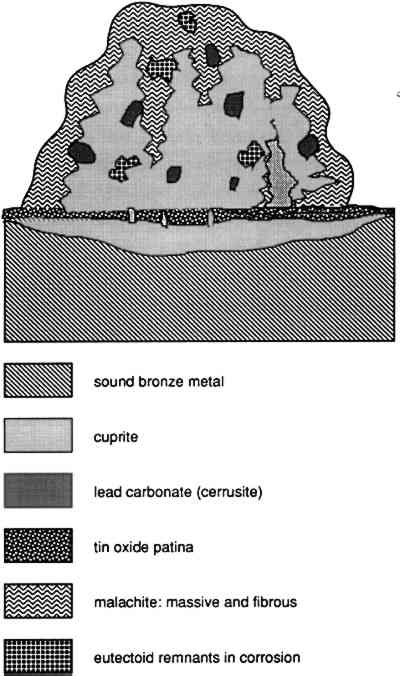

All four objects are assigned a date between A.D. 40 and 68, and all are made in leaded tin bronze by the lost-wax process with cast-on additions. Further details of their x-radiography and casting were reported by Scott and Podany (1991). 2.2 CORROSION AND PATINATIONLow-power binocular microscopy (10–50x) was used to examine the bronzes, which preserve a number of different corrosion products. These products were characterized by Debye-Scherrer powder x-ray diffraction (XRD) and have been previously reported (Scott and Podany 1991). On the Venus, for example, blue crystals were identified as azurite; off-white as a mixture of quartz, calcite, and cuprite; black as romarchite and cassiterite; green as cassiterite; and gray as cuprite and quartz. Analysis of samples from the Togati identified pale blue as azurite; light green as malachite; and a second sample of light green as cassiterite and malachite. The corrosion products on both bronzes are tin oxides and basic copper carbonates. There is nothing unusual about the identity of these corrosion products: what is remarkable is the variety of corrosion morphology observed on each of these objects. Some of the features discussed here are illustrated in figures 8–13.

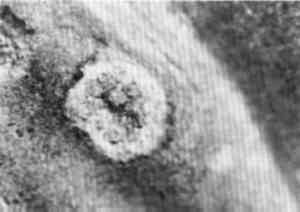

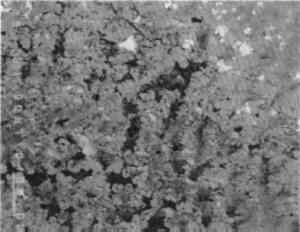

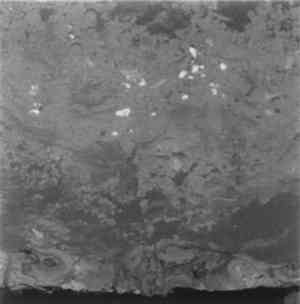

Figure 8 shows a surface view at low magnification of fibrous malachite growing on the In areas where the surface has been cleaned, the Togati has a smooth, sometimes mottled patina (fig. 10). Not only does this patina preserve pseudomorphic remnants of dendritic structure, but it also has a mottled color ranging from pale brown to umber and a smooth, matte appearance. Overlying this layer are disseminated fragments of a copper-rich phase whose globular shapes are oriented in a pattern suggesting interdendritic regions (fig. 11). These globular particles can easily be cleaved from the patina using a gentle scalpel movement parallel to the patinated surface. Figure 12 illustrates the occasional interruption to this smooth patina on the front surface by warty corrosion. These pustules have an apparently layered structure, judging from the stepwise appearance of the contours visible in figure 12. Beneath each pustule, at the base, the smooth patina is interrupted by a zone of cuprite, evident in figure 13. A detail of the reverse surface of the Roma near a large opening in the back (fig. 14) reveals an unusual hexagonal network. Each hexagon is about 1 mm across and can clearly be seen in many areas of this surface. This hexagonal network structure is rarely seen in corrosion layers, and it is difficult to explain its mode of occurrence.

The patina of the Roma is enriched in tin (as tin oxides), compared with the composition of the metal, and has a similar matte lustre with surface mottling in the patina as seen in the Togati. Tin-enriched patinas have been discussed frequently: a good general account is given by Gettens (1969). Dendritic pseudomorphosis on the surface of the Venus is clearly seen in figure 15, and a complex association of crystalline corrosion products, including fibrous malachite and small cuprite octahedra, is illustrated in figure 16. In other areas of the surface, the malachite is curved and banded in the same fibrous growth formation but has assumed a botryoidal appearance (fig. 17).

The Cleveland Nike also has areas on the reverse preserving fibrous malachite crystals, azurite, and the same patina as that shown by the Togati. A photomicrograph of a dispersion of malachite fibers from the Nike(fig. 18) displays exactly the same features seen on the Togati(fig. 9).

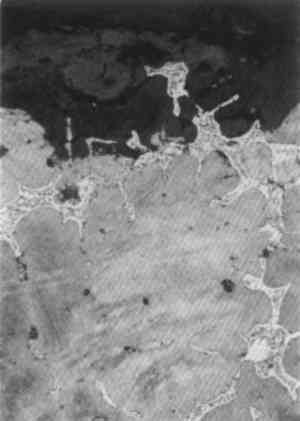

One other very significant remnant of associated material links these four bronzes: small fragments of red brick or tile are preserved on the back surfaces of the Roma, Venus, and Togati, and the Cleveland Nike had such fragments, too, before they were mechanically 3 ANALYTICAL STUDIES3.1 MICROSTRUCTURE OF THE METALNo metallographic samples could be taken from the bronzes without noticeable damage. Nevertheless a decision was made to remove a sample from the back of the Roma in the vicinity of the casting core hole, specifically to study the unusual hexagonal network structure. The sample was taken with a diamond-tipped core drill, 1.5 mm in internal diameter, with periodic cooling and lubrication with a metal-cutting fluid. The core drill sample was removed from the surface by dislodging with a scalpel and mounted and polished in the usual way. Toward the top of the metallographic section (fig. 19), an area of eutectoid is seen isolated within the corrosion layer, showing that the copper-rich alpha phase of the bronze is preferentially corroded with preservation of eutectoid relicts. The micro-structural study clearly shows that the tin-enriched surface has not been formed by the corrosion of a deliberately tinned surface layer, and as a result of work to be discussed below it is apparent that tin-enriched patinas can form by natural burial processes. The alpha grains are equiaxial and bordered by eutectoid fringes. This part of the structure is not obviously dendritic, and it has an appearance of an annealed casting, which could well be caused by the casting-on of the legs and feet.

The original dendritic and cored microstructure could have been altered by heating during casting on to produce a microstructure more typical for annealed bronzes. Evidence for changes in structure of this type have been seen in other examples where casting-on has been employed, as, for example, in a dagger handle from Luristan, Iran (Scott 1991, app. F, 94). Since casting-on was also used in the Togati and probably the Venus, and since all the bronzes have a similar composition, there is no reason to suppose that their structures are very different from each other. 3.2 COMPOSITIONAL DATADetailed analytical results for the composition of the metal are given in tables 1, 2, and 3. These results were obtained by atomic absorption spectrophotometry and by inductively coupled plasma-mass spectrometry. As shown in table 1, the tin content of these objects varies between 6.6–9.5%, lead 1.8–2.7%, and copper 85.7–89.8%. In both the Togati and Nike(tables 2, 3), trace amounts of antimony, arsenic, barium, bismuth, cobalt, gold, iron, nickel, palladium, rhodium, silver, and zinc were detected. Both major and minor components are quite representative of the composition of Roman bronzes of this period (Craddock 1983), and the extraordinarily interesting nature of their surfaces is due entirely to the effects of the burial environment rather than to compositional uniqueness. TABLE 1 COMPOSITION OF ROMAN BRONZES, DATED A.D. 40–68 TABLE 2 COMPOSITION OF THE BRONZE GOGATI, J. PAUL GETTY MUSEUM TABLE 3 COMPOSITION OF THE THE BRONZE NIKE, CLEVELAND MUSEUM OF ART 3.3 WARTY CORROSIONA pustule of corrosion from the Togati was removed intact, mounted, and polished so that a cross-sectional view of its structure could be studied and analyzed by electron probe microanalysis (EPMA). In addition, nondestructive x-ray fluorescence (XRF) analyses were carried out on the objects themselves with the Kevex 0750A spectrometer utilizing a barium-strontium secondary target and energy dispersive analysis. The XRF and XRD analyses of the surfaces of the Togati indicated that a very high proportion of tin remained in the patina, which was about 60–70% tin oxide, a proportion of tin much higher than the tin content of the metal itself. Darker, mottled areas in this patina fig. 9) were found to have a higher iron content than lighter, contiguous areas. Examination of the clean patina of the Roma showed the same TABLE 6 COMPOSITION OF METAL AND CORROSION OF TWO BRONZES FROM THE EUROPEAN BRONZE AGE: GERMANY The pustule from the Togati, which shows a complex microstructure, was examined by EPMA; analytical data are given in table 4 and back-scattered electron images taken by a scanning electron microscope are shown in figures 20–27. Figure 20 shows the pustule at low magnification. Part of the structure on the right side contains a vacuole, surrounded by malachite crystals, which appear very dark. The lower part of the figure represents the surface adjacent to the tin-rich patina, and the top of the figure represents the outer surface of the pustule. One surprising observation was the existence of metallic remnants of alpha + delta phase eutectoid at the outer extremity of the pustule, a considerable distance from the metallic core of the Togati, and 1 mm above the tin oxide patina. The apparent layering of the pustule, seen under low-power binocular microscopy, does not correspond to any stratification in the corrosion products of the pustule, as is evident from the figures shown here. The spread of lighter particles seen in figure 20 are lead carbonates, while the gray mid-tones are mostly cuprite interspersed with malachite. TABLE 4 COMPOSITION OF CORROSION PUSTULE FROM THE BRONZE TOGATI

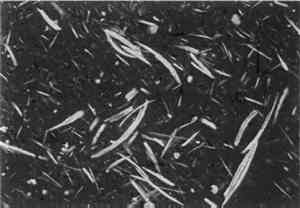

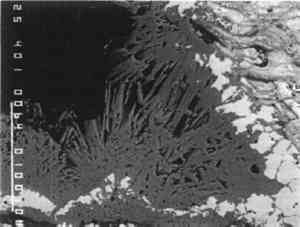

Acicular malachite crystals surround the vacuole, shown in figure 20, while the fibrous malachite in the back-scattered electron image in figure 21, toward the edge of the pustule, accounts for some of the apparent layering as each curved set of fibers undulates in and out of the mass. A cluster of acicular malachite crystals in another region of the pustule can be seen in figure 22. The central part of the pustule is shown in figure 23. It consists of interconnected ribbons of massive and euhedral cuprite passing upward away from the patinated surface. Interspersed in this cuprite are isolated patches of cerussite, islands of alpha + delta eutectoid and malachite, the latter becoming more prevalent toward the outer surfaces of the pustule. The well-crystallized nature of this cuprite can be seen in figure 24. Figure 25 shows an interfacial region between the tin-rich patina and the pustule as it grows from the patinated surface. Views of one of the edge areas of the pustule (fig. 26) and The microstructure of the brick or tile fragments that are embedded in corrosion in all four objects is essentially the same as the sample microstructure taken from the Venus(fig. 28). The fabric of the brick is relatively homogeneous and consists essentially of silica and iron oxides with relatively low amounts of aluminum, sodium, magnesium, potassium, and calcium; these analyses were obtained on brick samples from the Roma and the Venus, and the results are given in table 5. TABLE 5 COMPOSITION OF BRICK SAMPLES FROM THE ROMA AND THE VENUS

4 PROCESSES OF CORROSIONGeilmann's paper (1956) was the first full account of the corrosion of bronze artifacts in which the principal remaining component is stannic oxide. Geilmann employed wet chemical analysis to investigate the elemental or element oxide concentrations of 12 bronzes, examining in turn the analysis of completely corroded objects, samples in an advanced state of deterioration, samples of patina, dissolution of copper from the patina, fixation of metallic constituents that had been dissolved from the patina or bronze, and the process of corrosion of bronzes in the absence of chloride ions. In his examination of objects in an advanced state of corrosion, Geilmann analyzed an urn from a grave site dating to the second or third century A.D. and a sword blade of the Middle Bronze Age dating to about 1000 B.C. from Germany. The sword blade retained a marker layer, or original surface, even when only hydrated tin oxide remained. The urn, on the other hand, had a thin, dark green patina and an almost white tin oxide layer underneath this green surface, which retained the shape of the object. A representative set of these analyses is given in table 6. Geilmann deduced that the absolute tin content of these bronzes was unchanged during corrosion and that no arsenic or antimony were lost either. As a result of interactions with soil minerals, iron and aluminum levels were increased in the patina layer. Geilmann's data, while showing that some objects retain a copper-rich patina, also revealed that others have copper leached from the surface zone until only hydrated tin oxide remains; this hydrated tin oxide layer is then stable to further attack by soil groundwaters. Geilmann states:

Experimental dissolution studies by Geilmann showed that copper would be lost from a synthetic laboratory mixture of copper carbonate

These corrosion processes, Geilmann convincingly argues, occur in the absence of chloride ions, and his analytical results support this interpretation. In discussing the corrosion of Chinese bronzes, which may also have tin oxide–enriched patinas, Chase (1993) draws attention to the work of Robbiola (1990). Robbiola proposed that the dissolution of copper depends kinetically on the mass transport of copper from the alloy by events that are either under cationic control or anionic control. This model results in a precipitation-dissolution mechanism, after which various other reactions become possible. Anionic control, for example, in the presence of chloride ions produces greater volume change and less coherent corrosion layers. Cationic processes result in the diffusion of metallic components becoming the rate-determining step. This latter process generally results in compact corrosion layers that may show pseudomorphosis. Several papers have proposed schemes for the explanation of corrosion structures and possible mechanisms (Fink and Polushkin 1936; Cushing 1965; Graedel 1987). Structures may be classified on the basis of their morphological or descriptive characteristics or on the basis of their presumed mode of origin. Both of these approaches involve some compromise. Descriptive classifications such as those used by Fink and Polushkin provide little information about the genesis of structures. On the other hand, genetic classifications may be misleading; some structures could easily form by more than one process or by a mixture of processes that would be genetically distinct. With an awareness of these difficulties, a general conclusion can be

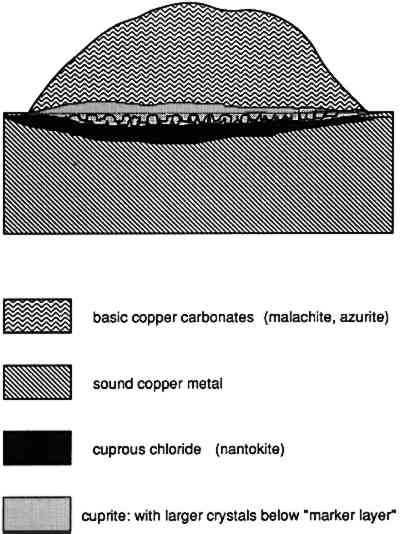

A model of pitting corrosion applicable to the former case was developed by Lucey (1972). The original study was initiated to investigate the corrosion failure of copper boilers in England. Lucey proposed that the cuprite that develops at the surface functions as a bipolar electrode, allowing chloride ions to diffuse through the cuprite layer where a film of cuprous chloride develops close to the metal surface. On the outer surface of the cuprite, diffusing copper reacts with carbonate species to build up a mound of corrosion products. The cuprous chloride that forms in this case is metastable and can react further to produce paratacamite or atacamite with disruption of the patina or of the corrosion pustule, especially if the surface is cleaned and the cuprous chloride is exposed to the atmosphere. In many archaeological examples, cuprous chloride may also be present in the pustule itself along with cuprite, often covered with a cap of malachite, azurite, or one of the copper trihydroxy-chlorides (fig. 29).

In the case of the bronzes examined here, the corrosion pustule appears to originate in the formation of cuprite septa, which pass across the tin oxide patina, allowing the diffusion of copper to occur at particular locations. The tin oxide layer that develops is probably hydrated, and at varying times may be liable to dehydrate to some extent during burial. As a result of the cracking of this layer that would accompany partial dehydration, further loss of copper could occur as septa of cuprite move through the tin oxide patina and relay copper ions to the exterior. These cracks can be seen in figure 25, passing through the tin oxide layer at the bottom of the photomicrograph. The expansion of the corroded matrix of the original bronze is shown by the existence of the lead carbonates and particularly by the relict fragments of alpha + delta eutectoid phase toward the outer surface of the pustule. This localization of extruded corrosion products argues for the continued corrosion of the bronze surface as part of the enrichment in tin as copper is preferentially lost. The preferential loss of copper and the corresponding precipitation contiguous to the tin oxide patina can be seen in figure 11, where isolated and sometimes coalescing dark green corrosion preserves an interdendritic pseudomorphosis. To account for this formation, exterior to the metal itself, the continued corrosion of the substrate would be necessary, with loss of copper through the dendritic pseudomorph of the tin oxide patina and the corresponding precipitation of copper exactly in the location where it passed through the patina layer. In contrast to many of the corrosion processes that occur in iron, copper corrosion products may exemplify epitaxy. In epitaxial processes, there is often a direct morphological correspondence between the substrate on which the corrosion or phase develops and the structure or orientation of the corrosion itself. The same linear extension of copper ions may be responsible for the formation of the fibrous malachite crystals seen in many areas on the surfaces of these objects, although part of the corrosion present on the surface and on the edge of the pustules is also fibrous, and local growth conditions in this case The microstructure of the pustule is not simple, and it is difficult to reconstruct every aspect of the growth of this kind of corrosion, as can be gauged from figures 20–27. The presence of euhedral crystals of cuprite (fig. 24) suggests a slow growth process during the transformation of metallic ions into corrosion products, allowing these crystals to form in a background of malachite. The lead that is present in the alloy as discrete, small lead globules has been carried outward into the pustule. There it, too, has become carbonated and converted to cerussite, with considerable expansion in volume, which accounts for the relatively large size (10–35 μm across) of these lead-rich zones in the corrosion. The tin-rich region of the eutectoid is preferentially preserved, while the copper-rich region becomes converted to corrosion products, principally cuprite. A simplified diagrammatic view of the pustule is shown in figure 30, and a summary of the analytical data that were obtained by EPMA for the pustule is given in table 4.

Some of the salient features are the low levels of chlorine detected and the presence of some phosphorus—and, by inference, phosphates—in the tin oxide analyses shown in points 16, 17, and 18 of table 4. Point 11 gives an analytical result for the relict eutectoid phase and shows that this material is uncorroded, with a tin concentration found by analysis very close to the theoretical amount of tin in this component of the original alloy, as derived from the equilibrium diagram (Cu31Sn8 contains about 32.6% 5 DISCUSSIONOn the basis of tin oxide enrichment in the patina, the presence of mottled areas containing enhanced levels of iron, and the pseudomorphosis of structural details, a hypothesis can be formulated, based on the research by Geilmann. This hypothesis would state that one possible environment for the corrosion observed on these bronzes would have been burial in a porous soil, with both oxygen and carbon dioxide readily available but with no chloride ion corrosion. The corrosion products and pustules should show no evidence of chloride corrosion, nor should the pustules be associated with cuprous chloride. This hypothesis is confirmed by the analytical and microstructural studies carried out here. That the corrosion environment was not deficient in carbon dioxide can be seen from the extensive malachite deposits on the surface, the conversion of the lead globules to lead carbonates, and the presence on the Nike and Venus of azurite crystals. In the case of the Venus, these crystals can be seen growing on individual malachite fibers as tiny deep blue compact crystals. The outer surfaces of the corrosion pustule on the Togati are also malachite rather than basic copper chlorides. The associated fragments of red brick or tile embedded in the corrosion products of all four bronzes not only link them together but indicate that the environmental conditions were favorable to the permeation of groundwaters and to oxygenated soil conditions and also allowed enough space adjacent to some of the object surfaces for the fibrous malachite crystals to grow. Unlike warty corrosion associated with chloride ions, the kind of warts seen on the surface of these bronzes are chemically stable formations under proper storage or exhibition conditions and do not require especially strict humidity control in display or storage. They had, for example, been kept in a special case with regulation of the humidity to below 40% RH, but since there is no chloride instability, such measures are unnecessary. Similarly, during conservation treatment there is no need to remove the warty corrosion, unless there are good aesthetic arguments for doing so. These four bronzes show an interesting variety of corrosion phenomena, ranging from fibrous malachite to tin oxide patina, and their surfaces preserve details of the “original surface” very well in a matte tin oxide patina. The bronzes were mechanically cleaned during conservation, revealing this fine detail, but they were also treated with a respect for the preservation of corrosion and associated material overlying the fine patina. It is easy, with hindsight, to criticize earlier methods for the conservation of archaeological bronzes, such as electrolytic cleaning, glass-bead air-abrasion techniques, use of chemical stripping reagents or removal of outer layers of the patina, sometimes to reveal a cuprite surface. An analogy is frequently made to medicine, where earlier treatment techniques have been discarded. The only difficulty is in gauging the health of the patient. We know that we overtreated the patient in the past, but there is still a danger that by cleaning and removal of corrosion, we are losing precious ACKNOWLEDGEMENTSThanks are due to Bruce Christman, head, Conservation Department, Cleveland Museum of Art, for allowing Lisbet Thoresen, associate conservator, Department of Antiquities Conservation, J. Paul Getty Museum, and me to study and sample the Cleveland Nike; to Eric Doehne for carrying out the many microprobe analyses; to WestCoast Analytical Services for performing the ICP-MS analyses; to Jerry Podany, head, Department of Antiquities Conservation, J. Paul Getty Museum, for commenting on the manuscript; and to Karen Manchester, Antiquities Curatorial Department, J. Paul Getty Museum. Special thanks are due to Eva Sander, conservator, who assisted in preparing an English translation of the paper by Geilmann in 1986. REFERENCESBassett, J., and T. W.Chase.1993. Considerations in the cleaning of ancient Chinese bronze vessels. In Ancient and historic metals: Conservation and technology,ed.D. A.Scott, J.Podany, and B.Considine. Los Angeles: Getty Conservation Institute. In press Chase, T. W.1993. Chinese bronzes: Casting, finishing, patination, and corrosion. In Ancient and historic metals: Conservation and technology, ed.D. A.Scott, J.Podany, and B.Considine. Los Angeles: Getty Conservation Institute. In press. Christman, B. 1988. Condition report for the Nike. In The Gods delight: The human figure in classical bronze,ed.A. P.Kozloff and D. G.Mitten. Cleveland: Cleveland Museum of Art. Christman, B.1992. Private communication. Conservation Department, Cleveland Museum of Art. Craddock, P. T.1983. Three thousand years of copper alloys: From the Bronze Age to the Industrial Revolution. In Application of science in examination of works of art, ed.P. A.England and L.van Zelst. Boston: Museum of Fine Arts. 59–67. Cushing, D.1965. Principles of corrosion applicable to ancient metals and methods of identifying corrosion products. In Application of science in examination of works of art. Boston: Museum of Fine Arts. 53–65. Fabrizi, M., and D. A.Scott. 1987. Unusual copper corrosion products and problems of identity. In Recent advances in the conservation and analysis of artifacts, comp. J.Black. London: Summer Schools Press. 131–33. Fink, C. G., and E. P.Polushkin.1936. Microscopic study of ancient bronze and copper. Transactions of the American Institute of Mining and Metallurgy122:90–120. Geilmann, W. von1956. Verwitterung von bronzen im Sandboden. Angewandte Chemie68: 201–12. Gettens, R. J.1969. The Freer Chinese bronzes 2. Technical Studies. Washington: Freer Gallery of Art, Smithsonian Institution. Gettens, R. J., and E. W.FitzHugh.1974. Malachite and green verditer. Studies in Conservation19: 2–23. Graedel, T. E.1987. Copper patinas formed in the atmosphere. Part 2. A qualitative assessment of mechanisms. Corrosion Science7:685–94 Herrmann, J. J., Jr.1988. Catalog entries 63, 64, 65. In The gods delight: The human figure in classical bronze, ed.A. P.Kozloff and D. G.Mitten. Cleveland: Cleveland Museum of Art. Jedrzejewska, H.1976. A corroded Egyptian bronze: Cleaning and discoveries. Studies in Conservation21: 101–14.

Lucey, V. F.1972. Developments leading to the present understanding of the mechanism of pitting corrosion of copper. British Corrosion Journal7:36–41 Organ, R. M.1963. The examination and treatment of bronze antiquities. In Recent advances in conservation, ed.GarryThomson. London: Butterworths. 107–8. Organ, R. M.1977. The current status of the treatment of corroded metal artifacts. In Corrosion and metal artifacts, ed.B. FloydBrown et al. NBS Special Publication no. 479. Washington, D.C.: U.S. Department of Commerce. 107–42. Palache, C., H.Berman, and C.Frondel, eds. 1951. Dana's system of mineralogy, vol. 2. New York: JohnWiley. 252–53. Podany, J.1988. Condition reports for the Roma, Togati, and Demeter. In The gods delight: The human figure in classical bronze,ed.A. P.Kozloff and D. G.Mitten. Cleveland: Cleveland Museum of Art. Robbiola, L.1990. Caract�risation de l'alteration des bronzes arch�ologiques enfous � partir d'un corpus d'objets de l'age du bronze. M�canismes de la corrosion. Doctoral thesis, University of Paris. Scott, D. A.1990. Bronze disease: A review of some chemical problems and the role of relative humidity. Journal of the American Institute for Conservation29:193–206. Scott, D. A.1991. Metallography and microstructure of ancient and historic metals. Malibu, Calif.: J. Paul Getty Conservation Institute and J. Paul Getty Museum. Scott, D. A., and J.Podany.1991. Ancient copper alloys: Some metallurgical and technological studies of Greek and Roman bronzes. In Symposium on ancient bronzes, ed.M.True. Malibu, Calif.: J. Paul Getty Museum. 31–60. Tennent, N. H., and K. M.Antonio.1981. Bronze disease: Synthesis and characterization of botallackite, paratacamite, and atacamite by infra-red spectroscopy. ICOM Committee for Conservation Preprints, 6th Triennial Meeting, Ottawa81/23/3-1-81/23/3–11 AUTHOR INFORMATIONDAVID A. SCOTT studied chemistry at the University of Reading and later took degrees in conservation and a Ph.D. in the study of ancient metallurgy of the New World from University College, Institute of Archaeology, London. In 1981 he began lecturing in the conservation training course at the Institute of Archaeology in the Department of Conservation and Materials Science. He was appointed as an editor of Studies in Conservation in 1984 and became a Fellow of IIC in 1991. He was made a Fellow of the Royal Society of Chemistry in 1993, having been a member since 1984. In 1987 he was named head of museum services for the Getty Conservation Institute. His principal interests are the archaeometallurgy of ancient Colombia, Ecuador, and Costa Rica, the study of metals and their corrosion products, the examination of pigments, and Chumash Indian rock art. Address: Getty Conservation Institute, 4503 Glencoe Ave., Marina del Rey, CA 90292-6537.

Section Index Section Index |