BALEEN IN MUSEUM COLLECTIONS: ITS SOURCES, USES, AND IDENTIFICATIONJULIE A. LAUFFENBURGER

ABSTRACT—An investigation of baleen was initiated in order to identify an unknown material used to wrap Japanese sword hilts in the collection of the Walters Art Gallery, Baltimore. This paper focuses on the sources, structure, identification, and working properties of baleen and compares it to horn and other similar materials. Primary uses of baleen are described as they pertain to Inuit, early European and American, and Japanese cultures. Methods used to identify the unknown material are described, and the difficulty of distinguishing between horn and baleen is illustrated. The condition of baleen artifacts and factors that contribute to their state of preservation are discussed. The paper concludes with various conservation techniques used to repair baleen artifacts in addition to those that make use of its strength and flexibility as a repair material. 1 INTRODUCTIONThis investigation of baleen was initiated during the examination and treatment of two 19th-century Japanese swords in the collection of the Walters Art Gallery, Baltimore, Maryland, during the spring of 1991. A number of sword hilts displayed in Hackerman House, the Walters Art Gallery Museum of Asian Art, were wrapped with a thin, black plastic-like material of unknown origin (fig. 1). In several cases the wrappings were in very bad condition with extensive losses, and they required conservation treatment. First, it was important to identify all materials involved so that subsequent treatment, storage, and exhibit would be compatible. One likely material was whale baleen.

The use of baleen to wrap sword hilts was brought to our attention by a local Japanese sword enthusiast. This information prompted the ensuing research into the production and use of baleen on Japanese swords, which are world renowned for their superior quality and craftsmanship. The art of the Japanese sword includes not only the blades themselves but the scabbards, hilts, tsuba (swordguards), and other associated ornamental metalwork. The materials and techniques of the craft have been written about at length; hilt wrappings, although not the focus of much written information, are mentioned in several texts on Japanese swords. The investigation soon expanded to include Inuit, European, and early American uses of baleen. Not surprisingly, very little information on baleen was available in the conservation literature, yet it soon became apparent that baleen was commonly found on many museum artifacts. 2 BALEEN AND ITS SOURCES2.1 THE WHALE AND BALEENMammals of the Cetacea order, which includes whales, dolphins, and porpoises, can be divided into two suborders: Mysticeti and Odontoceti. The primary difference between Mysticeti and Odontoceti whales is their feeding mechanism. The Odontoceti are equipped with teeth to tear their food, and the Mysticeti have a special filtration system created by baleen. Baleen is a flexible horn-like material that grows in plates from the upper jaw of the Mysticeti (fig. 2). There are many species within this suborder, such as the humpback, finback, minke, sei, blue, and right whales. The more familiar sperm whale, immortalized by the writings of Herman Melville, is of the Odontoceti suborder.

Baleen plates grow in parallel triangular sheets approximately 1 cm apart and can reach lengths of up to 13–14 ft (fig. 3). The plates grow continuously from the epidermal tissue of the gum and, like hair of other mammals, grow to maximum size sometime during adulthood. Seasonal variations in development result in visible growth ridges perpendicular to the length of each plate (fig. 4). When viewed from the exterior of the whale's mouth, the plates resemble rows of teeth on a comb. The lateral surfaces of baleen are flat, smooth, and resemble worked horn; the inner surfaces have hairlike fibrils. These fibrils are exposed only on the interior of the whale's mouth.

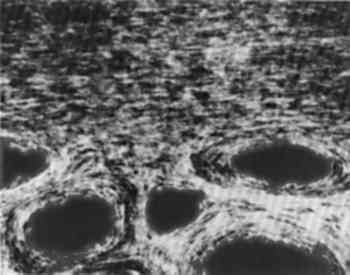

Sheets of baleen can vary in quantity and size depending on the age and species of the whale; bowhead whales are especially known for long baleen plates, which can exceed 700 in number. These plates also vary in quality, color, and relative fineness depending on the location of the plate in the whale's mouth and on the species. Baleen is generally cream, brown, gray, black, or white. Variation among plates can best be illustrated by comparing right whale baleen, which is extremely fine and gray in color, On the interior of the whale's mouth, the baleen fibrils act as a filter during feeding by forming a porous mat. Mysticeti whales feed primarily on small shrimp-like crustaceans called krill, which measure approximately 2 in long. The whale strains water filled with krill, other small crustaceans, squid, and fish by using its tongue to press against the “sieve” created by the frayed baleen fibers. Excess water and unwanted debris are expelled from the whale's mouth, while small krill and other edibles are trapped in the baleen mat. 2.2 STRUCTURE AND COMPOSITIONBaleen is a protein. Animal proteins are of two major categories: collagen and keratin. Collagen is an insoluble fibrous protein that is the chief constituent of connective tissues and bone. It is the primary component of leather and other skins. Keratin is a sulfur-containing fibrous protein Keratin is the major component of baleen. The complex keratin structure is held together by hydrogen bonds, polar linkages, and characteristically disulfide linkages of cystine (O'Connor 1987). Keratinaceous materials are divided into two groups: “soft” and “hard” keratins. Hard keratins have fibrils oriented along a major axis, giving them structure and strength, whereas soft keratins are randomly oriented proteins. Soft keratins exist in the continuously renewed outer layers of the epidermis of mammals, birds, and reptiles. Baleen and horn are both hard keratins and therefore have many of the same physical properties. Like horn, baleen can be softened in hot or boiling water. This process breaks down some of the disulfide bonds and allows the baleen to be pressed into a new conformation. When it is cooled under pressure, new bonds form, and the baleen retains its new shape. A plate of baleen is composed of a sandwich-like, three-part structure: a central section of tubules in a cementing keratin matrix, flanked by a horny covering. Figure 5 is a cross section taken from a plate of bowhead baleen. Inside the whale's mouth, the horny covering and cementing matrix are worn away by the abrasive action of the tongue, revealing the central tubules or hairlike structures that form the mat or sieve during filtration. These tubes are highly calcified, containing crystals of hydroxyapatite (a basic calcium phosphate) (O'Connor 1987), and they have central hollow cavities of varying sizes depending on the species. Calcification occurs in alternating rings around the outer edge of the tubes, an arrangement that strengthens the tubes without loss of flexibility (O'Connor 1987). Baleen is the most highly calcified of the keratin materials and as a result is slightly more brittle (Halstead 1974).

Artifacts made from complete plates of baleen can be easily identified because of the unique tripartite structure, but if only the

3 HISTORIC USES OF BALEEN3.1 ALASKA NATIVESBaleen emerged as a useful by-product of the whaling industry in many cultures and societies. Its thermoplastic nature and enormous strength allowed it to fulfill many functional and decorative roles. In the Arctic communities of northwest Alaska, whaling was central to the way of life as early as 1000 A.D. (O'Connor 1987). The Inuit of Alaska hunted whales in the spring amid great ritual and ceremony. They concentrated primarily on the bowhead whale, a baleen whale that spent its entire life cycle in polar waters. The Inuit made use of all their resources, and baleen was not overlooked. Prior to European and American influences, baleen traditionally was worked by the men of these communities, whose job it was to work the so-called “hard materials.” This tradition continued until this century. Baleen was easily removed from the gum of a dying whale while the plates were still elastic and flexible. As it dried it became hard and inflexible. In order to be worked, baleen was cut into sizes appropriate for use. Baleen basketry of a particular type developed in the regions of Barrow, Point Hope, and Wainwright, Alaska, sometime after the decline of Yankee whaling around 1914 (fig. 8). The first documented example of this basketry, based on a willow-root prototype, was made for Yankee whaler and Barrow resident Charles D. Brower (Lee 1983). Early in the development of the craft, few people were making baskets; each had a distinctive style and working method. Baskets were often signed on the bottom with the name of the artist and the town where they were made. Sometimes a combination of vertical, diagonal, and horizontal lines used for property marks was added.

In order to make baskets of this type, strips of baleen were laboriously trimmed and polished into a flat or rounded contour by applying pressure to the strip with a sharp implement. Throughout the weaving process, the baleen strips were soaked in water so that they remained moist and flexible. Perfectly symmetrical wefts were also produced by drawing strips of baleen through a steel draw plate (Lee 1983). The baleen strips were then woven through a perforated starter disc at the base of the basket; the disc was often made of bone or walrus ivory. Such a basket could take from days to months to complete, depending on the quality of the woven wefts and rods. The completed baskets were sold directly to visitors or itinerant traders or at locally owned stores (Lee 1983). Contemporary basket makers in the region have shortened the time-consuming polishing process and have instead applied mineral oil or an aerosol varnish to the finished wefts and rods. Today, objects such as letter openers, small decoratively inscribed plates, model boats, and toys are still made of baleen for the tourist market. Baleen had other functional uses. Because it did not collect frost, it was especially useful for objects such as fishing line and snares, which required strength and flexibility and were necessary for subsistence fishing and trapping. Baleen hairs were used as bow

3.2 EUROPEAN AND AMERICAN USESWhaling in Europe and the Americas was driven by current market demands. The primary products of the whaling industry were whale oil and whale meat, which was commonly processed into meal, feed, or fertilizer. Early on, baleen comprised only a small portion of the useful by-products. According to written records, baleen plates were first imported into England quite by accident in 1594 when a Biscayan ship wrecked off the coast and the cargo drifted to shore (Stevenson 1907). Bone spades, made of steel, were used to harvest baleen plates from the whale's mouth. After the plates were removed from the gum, they were scraped clean, sorted, and stacked according to color, size, and quality before awaiting their final destination. In the American industry, baleen was delivered to factories in Boston and New York bundled into groups of 15 to 25 individual plates. Because the plates are not uniform, areas on an individual plate were selected for specific purposes. The intended function of each section depended on the flexibility of the baleen in each area and the probability of splitting it along straight lines. According to Stevenson (1907), in order to make the baleen workable, the plates were soaked in tepid water for one to two weeks and then placed in a steam box for 40 to 60 minutes. In the 1590s, the introduction of the farthingale, a hooped petticoat stiffened by strips of baleen, was the primary reason for the increased market for baleen in Europe (Stevenson 1907). In the 18th and 19th centuries baleen continued to play a role in women's fashions. The staybusk, a wide flat strip inserted into the front of a corset to prevent a woman from leaning forward and having bad posture, and strips of dress bone or corset bone made of baleen were advertised in catalogs of the period. Gray whale baleen was most commonly used for dress bone because of its light cream color. The staybusk usually was produced by seamen as a form of folk art for their wives and girlfriends at home. Several fine, elaborately incised examples of staybusks are found in the collection of the Kendall Whaling Museum in Sharon, Massachussetts (fig. 10). Sailors also used baleen to make sewing

The harvesting of baleen became the focus of the whaling industry after 1875, when the use of mineral oil lessened the need for whale oils. In about 1848, during the peak consumption years of baleen, Yankee whaling moved to the Arctic and focused on the bowhead whale. The bowhead was especially prized for its large jaw, which holds up to 700 12-ft baleen plates weighing in the neighborhood of 3,500 lbs (Lee 1983). At the peak of the market for baleen, the amount harvested from just one whale could pay for the expenses of an entire voyage (Matthews 1968, 236). Prices of baleen varied dramatically, from $5.00 per pound in 1907 to $0.075 in 1912 (Lee 1983). In the 19th century baleen was an important raw material comparable to present-day plastics. Second only to its popularity in the fashion industry was its common use by the brush industry for bristles. In the 19th century the British obtained a patent for the manufacture of baleen brushes, and until the introduction of synthetic fibers the brush industry remained one of the major consumers of baleen (MacGregor 1985). In the 20th century baleen was eventually replaced with spring steel and plastics, but not before it had been used for a multitude of functions (table 1). Even the fibrous waste was preferred over horsehair for sofa or chair stuffing. TABLE 1. HISTORIC USES OF BALEEN One particularly interesting object made of baleen in the collection of the Kendall Whaling Museum is a bas-relief panel made from pressed and carved baleen (fig. 11). The panel, entitled The Bacchanalian Frolic, was made by a Dutch artisan, Jan Lutma the Elder, and Jan Osborn, an Englishman working in Amsterdam. The panel is dated to ca. 1618–41, Amsterdam. In 1618 the Dutch North Sea Company granted the two men a patent to produce decorative baleen panels. Their endeavor was short lived and did not enjoy much success, but some of their work survived. The panel in the Kendall Whaling Museum simulates the ebony panels inserted into Dutch furniture of the time and was made as follows:

3.3 JAPANESE USESSimilar to the Inuit whaling industry, Japanese whaling was founded on great tradition and ceremony. In the early 17th century, whaling became an organized industry in Japan. Before then the Japanese caught stray whales that had run aground or mistakenly wandered into bays. A scroll dated 1760 from the Kendall Whaling Museum, titled “Fourteen Varieties of Whales,” indicates that the Japanese had extensive knowledge about whale species and identifies with illustrations 14 different whales. In the early years of the whaling industry, the Japanese focused on the right whale, which resided in coastal waters. The scroll specifically identifies the portions of the whale that the Japanese used, and in several cases plates of baleen are clearly illustrated. One may assume that because of its strong, flexible nature, baleen undoubtedly served many of the same functional purposes in Japan as it did in the West, though because of cultural differences in clothing, the demand for baleen may not have been as driven by the fashion industry. Little is written in English regarding the Japanese use of baleen, but it is commonly known that baleen was used to make novelties such as shoehorns and tea trays (Matthews 1968). Stevenson notes that around the turn of the century in the United States, “very thin baleen strips, about a millimeter in diameter, were employed to a small extent for winding on ornamental sword hilts; this use however is more popular in Japan than in this country” (Stevenson 1907). Even today, baleen is preferred over modern plastics or spring steel as springs in the heads of the puppets of the National Bunraku Puppet Theater of Japan. 4 BALEEN IN THE COLLECTION OF THE WALTERS ART GALLERY4.1 JAPANESE ARMORThe Walters Art Gallery has a sizeable collection of Japanese swords, mainly collected in the late 19th century. Traditionally, a limited variety of materials have been used to wrap the hilts, including braided silk thread, paper, leather, metal wire, baleen, and even horsehair. At least 22 of the approximately 152 Japanese swords in the collection are likely wrapped in baleen. The wrapping improves the grip on the sword; bound hilts were frequently used in battle, while bare lacquer hilts were more commonly used for ceremonial purposes. The wrapping also played a decorative role in the finished product, and a variety of different wrapping techniques were used. The use of baleen, or “whalebone,” as it was often referred to in older texts, is specifically described in a book on Japanese swords by B. W. Robinson (1961). Robinson outlines a method of wrapping from the center out with lozenge-shaped spaces finished off in a neat flat-knot. This type of wrapping is the most common found on the swords in the Walters collection (fig. 1). The strips of baleen are often wrapped around a layer of same, or ray skin, that has been covered by layers of Japanese paper (Joly and Hogitaro 1979). In order to wrap the baleen strips evenly around the hardened calcified bumps of the ray skin, dampened layers of Japanese paper are inserted between the skin and the baleen to make the surface level (fig. 12).

The strips of baleen found on the Walters's swords (nos. 51.1256 and 51.1218) are semicircular in cross section and have distinct vertical striations along the outside edges. The existence of these vertical, The strips of baleen on the Walters swords range in color from brown or blue-black to tortoise shell to deep cherry red. Upon close examination it appears that some of the wrappings were intentionally dyed. In some cases the color has faded on the side of the hilt exposed to light. Several sword hilts in the collection of the George Walter Vincent Smith Art Museum, Springfield, Massachusetts, were examined to compare color, width, and wrapping techniques. Of 35 swords, 10 were thought to have baleen. The wrappings ranged from deep cherry red to warm black. Generally the cherry red had faded most noticeably. In an effort to understand the Japanese use of baleen, other Japanese arms, armor, and decorative arts were examined for the presence of the material. During the examination and treatment of a Japanese helmet from the Edo period (1615–1865) (fig. 13), visiting conservator Ann Boulton made several observations regarding the materials and techniques; the materials included a horn-like substance of unknown origin. The helmet consists of four main elements: the helmet bowl, the neck guard, two inverted, detachable lacquered axes on either side of the bowl, and a detachable gilded bird. The substrate of the lacquered battle axe handles and bird tailfeathers appears to have been made of the same unidentifiable material. Prior to restoration, a sample was taken of the unknown substrate and mounted for future analysis.

5 IDENTIFICATION OF BALEEN5.1 MICROSCOPIC EXAMINATIONSeveral samples from the Walters objects were examined and compared to the known sample of baleen discussed in section 2. Samples of leather and horn were also prepared for comparison. All samples were mounted in Cargille Meltmount (n = 1.662) and viewed with transmitted light under crossed and uncrossed polars using a Leitz analytical microscope. The samples prepared included: (1) a lateral section of the sword hilt wrappings; (2) a lateral section from the helmet battle axe handle; (3) a known sample of worked cattle horn; and (4) a known sample of calf leather. Samples 1 and 2 were examined. Both samples looked similar to the known baleen sample and showed little structure at 250x. In transmitted light, the sections were pale tan colored and translucent; dark spots were visible in areas, and there was some indication of direction. When viewed under crossed polars both samples exhibited a full range of polarization colors; thinner areas were restricted to white, black, and gray. In both cases a faint “herringbone” or braided pattern was visible at points of extinction. In sample 1, a slightly thicker sample, a faint linear pattern was visible under crossed polars parallel to the length of the sample. Under the same conditions the known baleen sample exhibited a vivid rainbow of polarization colors and a faint “herringbone” pattern at extinction. The horn sample (sample 3), also showed little structure and under crossed polars exhibited a range of blue, pink, black, and white colors. Under crossed polars at points of extinction, banding parallel to the length of the sample was visible; the banding in this case was far more clearly delineated than that seen in sample 1. A “herringbone” pattern was also visible every 90� at points of extinction. The leather sample (sample 4) contained large fiber bundles and open pores; it exhibited orange, white, and tan polarization colors and looked completely different from both the baleen and the horn. It appears that if the Walters sword hilt wrappings are baleen, they were not made from a complete cross section but rather from the horny outer covering of the baleen plate; thus, the positive identification of these sections is very difficult. To help confirm the identification, a sample from one of the sword hilt wrappings was sent to David Stoney of the University of Illinois, who is conducting research on the identification of baleen versus rhinoceros horn. His work thus far is based on optical microscopy but may later include scanning electron microscopy. Given the lack of structure in the sample, Stoney was unable to confirm or rule out the identification of baleen. It was evident from the lack of tubular structure that the wrappings definitely were not made from the fibrils or hairlike structure of a baleen plate. During his examination Stoney observed only muted black, white, and blue polarization colors. According to Barbara Stephan, who had been working in conjunction with Stoney and is now affiliated with the McCrone Laboratories, Chicago, polarization colors are always present in baleen, but the particular colors depend on the species of whale, the thickness of the sample, and the pigmentation of the baleen itself. In very thin samples only first-order polarization colors—black, gray, and white—are visible. As the sample thickens, second-, third-, and fourth-order colors are visible to include a full range of the spectrum. According to In order to see whether boiling and shaping baleen affects its optical properties, two samples of finback whale baleen were cut from the outer and inner edges of a modern plate, two areas in which the texture and thickness of the baleen are quite different. Cattle horn was also sectioned for comparison. The tests conducted in the lab were not meant to mimic traditional techniques but were only quick exercises to get a feel for how long it would take to soften baleen. Each sample was placed in a beaker of distilled water and boiled for 45 minutes. The samples were then removed from their water baths and tested for flexibility. Sample 1 (thin outer portion of plate) and sample 3 (horn) were very flexible and felt like a soft fingernail. Sample 2 (thick inner portion of plate) was still somewhat stiff, and some of the individual fibrils had begun to delaminate. The samples were then allowed to soak overnight in room-temperature water. In the morning the samples were removed again; samples 2 and 3 had become quite stiff, but sample 1 remained quite flexible. The samples were then boiled again for 45 minutes and pressed between bent metal mending plates and allowed to dry. The samples were removed after 3 days; each retained the shape of the mending plates and took on a slick plastic look from the surface of the metal. Longitudinal sections from the interior curvature of each molded sample were mounted and viewed under polarized light. The appearance of these samples differed very little from the samples taken before “boiling and shaping.” This finding implies that working in this manner has little effect on the optical properties of the baleen when it is viewed under polarized light. 5.2 OTHER ANALYTICAL TESTSOther basic tests were performed in the laboratory to help identify the baleen. Several known samples of baleen were viewed with long-wave ultraviolet light side by side with the unknown sample from the sword hilt and a sample of horn. The baleen samples fluoresced to differing degrees depending on their degree of pigmentation. The horn sample was very translucent, sparsely pigmented, and fluoresced bright yellowish-white. The unknown sample from the sword hilt was dark black-brown in visible light and did not fluoresce. The boiled and molded samples of finback baleen were then viewed with UV light and compared with the original baleen plate from which they were taken. The baleen plate itself fluoresced pale yellowish-white. The thick sample taken from the inner margin of the plate looked the same in UV light after treatment, but the thin sample taken from the outer margin of the plate no longer fluoresced in the same way but now appeared dull brownish-orange. When the water baths were reexamined after soaking, some residue remained in the bottom of each beaker. The loss of this solubilized material may have been responsible for the change in appearance of the thin baleen sample under ultraviolet light. A sample from each beaker was saved for future analysis. When heated with a flame, baleen smells like burning hair. Other keratin-based materials such as wool and horn also exhibit this characteristic, so it alone cannot be used as a definitive test for baleen. Both unknown Toward the end of the project, Mary Baker of the Smithsonian Institution Conservation Analytical Laboratory carried out Fourier-transform infrared analysis on two samples: one from a plate of baleen and one from the Japanese sword hilt wrappings. The baleen produced a clear spectrum for keratin. The unknown sample produced a very similar spectrum with some peak shifts, probably due to subsequent working of the baleen. In light of this investigation, there appears to be little in the way of simple laboratory tests to clearly distinguish horn from baleen. The identification of baleen as the material used for the sword hilts and the substrate of the battle axe handles on the Japanese helmet was based upon the similarities of their physical and optical properties to those of known baleen samples and the knowledge that baleen was used in Japanese arms and armor. Because horn is much shorter than a baleen plate, the size of the object or part thereof may also help in identifying the material. The sword hilt wrappings consist of strips several feet long, which rules out the possibility of horn. The battle axe handles from the Japanese helmet are also over a foot long, and each is approximately 6 in wide. Their wide, flat shape is reminiscent of a baleen plate. Because baleen and horn are both hard keratins and exhibit so many similar characteristics, continued research is necessary to help distinguish the two. In this study only cattle horn was compared. Until further research is carried out, form, function, and the availability of the material to a particular culture may be most helpful in distinguishing between horn and baleen. 6 CONSERVATION OF BALEEN6.1 HISTORY OF CONSERVATION TREATMENTArchaeological baleen has been found in northern Europe, northeastern Canada, and Alaska, and it is likely that other examples exist in regions where baleen was frequently used. A relatively robust material prior to burial, baleen rarely survives burial intact due to its susceptibility to bacterial and fungal growth. Furthermore, several burial conditions, including alkaline and reducing environments, will break down the disulfide linkages as well as the hydrogen bonds. Baleen has nevertheless survived very well in permafrost conditions along coastal Alaska where it is often found saturated with salts and minerals from its burial environment. It is only after the baleen is allowed to thaw and begins to dry that delamination and cracking occur. Historical baleen, on the other hand, is strong and durable but prone to splitting and delamination as a result of dimensional changes caused by fluctuations in relative humidity. Baleen is also subject to attack by insects due to its proteinaceous nature. The fact that changes in relative humidity can cause dimensional changes in baleen seems inconsistent with Inuit accounts of baleen as a strong, flexible material that is not swelled by water. This inconsistency probably can be explained by the fact that the Inuit and others used it in a fresh, well-soaked state. In arctic climates the constant high relative humidity along the coast would keep the baleen flexible year-round. Such an artifact transferred to an overheated, poorly controlled museum environment The condition of baleen artifacts in museum collections is rarely cited in the conservation literature, although there are some historical precedents for its treatment. In the late 1920s the treatment of baleen aimed at creating a water-resistant coating to help minimize the effects of relative humidity. Two techniques outlined in the Annual Report for the National Museum of Canada in 1929 include (1) soaking baleen in a thin solution of gelatin, allowing it to dry, and then immersing it in formaldehyde and (2) removing a fatty substance found on archaeological baleen and replacing it with a thin immersion coating of a celluloid solution (Leechman 1929). The source does not make clear whether the greasy substance seemed to have been intentionally applied or was just a consequence of burial near fatty substances such as whale blubber. Between 1978 and 1982, during several field seasons in Labrador, Canada, Mary Peever, formerly of the ethnology lab of the Canadian Conservation Institute, developed a treatment for wet archaeological baleen. Badly delaminated artifacts were immersed in warm water to relax the delaminated sections and consolidated with Rhoplex AC-33, an acrylic emulsion. The pieces were then weighted in place and allowed to dry slowly. Ten years later the artifacts appeared to be in good condition, but Peever now questions the use of Rhoplex AC-33 with a naturally acidic protein because of its alkalinity when wet. Acrysol WS-24, an acrylic colloidal dispersion, has been suggested because of its neutral pH, finer particle size, and higher glass transition temperature (Peever 1989). In the early 1980s Christine Del Re, of the Field Museum of Natural History, worked on a Native American headdress; the cylindrical frame that fits around the head was made of strips of baleen lashed together with lengths of sinew. The baleen frame was badly distorted, and Del Re describes attempts at humidifying and reshaping the baleen collar as unsuccessful (Del Re 1988). The baleen was placed in a humidity chamber to restore flexibility, a common conservation technique, but water vapor alone was insufficient for such thick plates. In this case, it would have been necessary to soak the baleen in hot water for an extended period to restore flexibility. Because this technique physically and chemically alters the baleen structure, it should not be carried out on original material. 6.2 TREATMENT OF THE SWORD HILT WRAPPINGSThe Japanese swords in the collection of the Walters Art Gallery were treated by two different conservators who approached the problem of replacing the missing and broken baleen with different materials. The brittle baleen strips generally had broken across their widths, and there were many losses. Their poor condition may have been a result of the manufacturing processes or of their subsequent use and storage conditions. In one case, split monofilament nylon fishing line, tinted with Lefranc and Bourgeois restoration colors and adhered with Acryloid B-72 in acetone, was prepared to replace the missing baleen wrappings. Although the monofilament thread made a convincing match for the baleen losses, it was very difficult to work with in small lengths, and it 6.3 BALEEN AS A CONSERVATION MATERIALBaleen incorporates many desirable properties, such as strength, flexibility, and durability. Consequently, conservators and artisans alike have used baleen for a variety of purposes. Mary Peever reports on a baleen repair on a Northwest Coast mask. Although recently treated and documented by a conservator, the repair looked as if it could have been made during the useful lifetime of the mask (Peever 1986). In this case the conservator had mimicked an existing ethnographic mend that used strips of baleen and sinew lashed together. Because of its appearance and the lack of documentation, the more recent repair could be misinterpreted as an original ethnographic repair. A treatment that avoided this confusion and still used baleen as a repair or replacement material is outlined below. Conservators at the American Museum of Natural History recently treated a Tsatsalkwatal mask from the Northwest Coast that originally had a fringe of baleen fibers inserted into a series of holes around its perimeter. Remnants in the holes were identified as baleen, and an artist's rendering from 1909 showed the mask with strips of split baleen emanating from its outer edge like hair or fringe. In order to minimize intervention with the original object and make sure that the new baleen strips were not presumed to be the originals, a special mount was designed. Baleen strips were soaked in ammonia to break down the disulfide bonds, a process that enabled large sheets to be peeled into thin strips. The strips were then placed into a Pliacre epoxyputty mount, specially designed to accommodate the baleen strips while not having to be directly attached to the original object. With this technique, the conservators were able to avoid confusion as to the context of the repair. The baleen used for the repair was obtained through the mammology department of the American Museum of Natural History, New York. Under the Marine Mammal Act, all trade of marine mammal products is strictly forbidden. There are a few exceptions for Native Americans who hunt whales for subsistence purposes. In those instances, articles made from baleen must be significantly modified before they are sold. Baleen has also been used by conservators as a support to strengthen weaker materials. An example is provided by Katherine Munro of the Canadian Museum of Civilization, who used some baleen strips to support broken feather shafts on a North American Indian headdress. Of a total of 22 splints applied to weakened or broken golden eagle feather shafts, 15 were made of split feather shafts and 7 were made of baleen. Baleen splints were used when the split feather shafts were too weak to support the weight of the broken feathers. The splints were adhered with a 30% solution of Acryloid B-72 in ethanol (Munro 1988). 7 CONCLUSIONSOur knowledge of baleen and its use in artifacts is fairly limited, yet its occurrence in ACKNOWLEDGEMENTSThe author would like to thank the staff at the Kendall Whaling Museum for their assistance and cooperation; Emile Schnorr of the George Walter Vincent Smith Art Museum for letting me examine the museum's Japanese sword collection; Charlie Potter of the National Museum of Natural History for his assistance in obtaining samples for research; Mary Peever of the Cayman Islands National Museum for sharing her knowledge on the subject; Linda Nieuwenhuizen and Judy Levinson of the American Museum of Natural History for providing treatment information; David Stoney and Barbara Stephan for examining the unknown sample using polarized light microscopy; Mary Baker of the Smithsonian Institution Conservation Analytical Laboratory for carrying out the FTIR analysis; the objects conservation staff at the Walters Art Gallery for allowing me the time to complete this project and providing continued support and consultation; and especially the Andrew W. Mellon Foundation for its support during this research project. Thanks also go to Jonathon Fuqua and Ann Boulton for their critical review of the manuscript. REFERENCESDel Re, C.1988. Technology ande conservation of five Northwest Coast head-dresses. Symposium 86, Proceedings: The care and preservation of ethnological materials. Ottawa, Canada: Canadian Conservation Institute. 53–61. Florian, M. E., D. P.Kronkright, and R. E.Norton. 1990. The conservation of artifacts made from plant materials. Malibu, Calif.: J. Paul Getty Trust. 53. Halstead, L. B.1974. Vertebrate hard tissues. London: Wykeham Publications. 100. Hill, B. T.1986. Baleen bacchanal. KWM Newsletter4(1):10–11. Joly, H. L., and I.Hogitaro. 1979. The sword and same. London: Holland Press. 22. Lee, M.1983. Baleen basketry of the North Alaskan Eskimo. Barrow, Alaska: North Slope Borough Planning Department. 8, 14, 36. Leechman, D.1929. Technical methods in the preservation of anthropological museum specimens. National Museum of Canada Bulletin67:127–58. MacGregor, A.1985. Bone, antler, ivory and horn: The technology of skeletal materials since the Roman period. Totowa, N.J.: Barnes and Noble. 183. Matthews, L. H.1968. The whale. New York: Crescent Books. 236. Munro, K.1988. The treatment of a feather head-dress. In Proceedings IIC-CG, 14th Annual Conference, IIC, Canadian Group, Toronto, Canada. 172–79.

Nieuwenhuizen, L.1991. Personal communication. American Museum of Natural History, New York, N.Y. O'Connor, S.1987. The identification of osseous and keratinaceous materials at York, archaeological bone, antler and ivory. Occasional Papers 5. London: United Kingdom Institute for Conservation. 9–21. Peever, M.1986. Characterization of alterations to artifacts. Symposium 86, Proceedings: The care and preservation of ethnological materials. Ottawa, Canada: Canadian Conservation Institute. 142–46. Peever, M.1989. A treatment for bison hornsheaths. Collection Forum5(1):32–37. Robinson, B. W.1961. The arts of the Japanese sword. London: Faber and Faber. Stambolov, T.1969. Manufacture, deterioration and preservation of leather: A literary survey of theoretical aspects and ancient techniques. ICOM Committee for Conservation Preprints, 2d Plenary Meeting, Amsterdam, 69/36. 3, 5. Stevenson, C. H.1907. Whalebone: Its production and utilization. U.S. Department of Commerce and Labor, Bureau of Fisheries document no. 626. Washington, D.C.: U.S. Government Printing Office. Reprinted in Bulletin from Johnny Cake Hill (Old Dartmouth Historical Society) 1965–66 (Winter): 4–11. Tuck, J. A., and R.Grenier. 1989. Red Bay, Labrador: World whaling capital A.D. 1550–1600. St. John's,Canada: Atlantic Archaeology. 48. FURTHER READINGKidwell, A.1983. Whales and seals: A guide to coastal and offshore mammals. Freeport, Maine: Delorme Publishing Co.–Maine Geographic. Kistemaker, R., and R.Van Gelder. 1982. Amsterdam: The Golden Age 1275–1795. New York: Abbeville Press. Lytle, T. G.1984. Harpoons and other whalecraft. New Bedford, Mass.: Old Dartmouth Historical Society. Matthews, L. H.1958. A note on whaling. In A history of technology and the Industrial Revolution: The Industrial Revolution c. 1750–1850, vol 4., ed.C.Singer et al. London: Oxford University Press. 53–63. Meldsaard, J.1960. Origin and evolution of Eskimo cultures in the eastern Arctic. Canadian Geographical Journal64–75. Nelson, R. K.1969. Hunters of the northern ice. Chicago: University of Chicago Press. Numata, K.1959. String wrapping on sword hilts. Tokyo: Tokyo Museum. 32–33. Peever, M.1982. Treatment of baleen. In Abstracts: IIC-CG, 8th Annual Conference, IIC-Canadian Group, Universit� Laval, Quebec. 21–22. Robinson, H. R.1969. Japanese arms and armor. New York: Crown Publishers. Sato, K.1983. The Japanese sword. Tokyo: Kodansha International and Shibundo. Tuck, J. A.1984. 1984 Excavations at Red Bay, Labrador. In Archaeology in Newfoundland and Labrador 1984 annual report no. 5, 227. Von Endt, D. W., and W. C.Jessup. 1986. The deterioration of protein materials in museums. In Biodeterioration 6: Proceedings of the 6th International Biodeterioration Symposium. Slough, U.K.: CAB Mycological Institute, Biodeterioration Society. 332–37. Weaver, M.1987. The polar home. In Canadian heritage. Ottawa, Canada: Heritage Canada Foundation. 28–31. AUTHOR INFORMATIONJULIE A. LAUFFENBURGER received a B.A. in art history from Cornell University in 1985 and an M.A. and certificate of advanced study in art conservation from the State University College at Buffalo, New York, in 1989. She is assistant objects conservator at the Walters Art Gallery, Baltimore. Address: Walters Art Gallery, 600 N. Charles St., Baltimore, Md. 21201.

Section Index Section Index |